Manufacturing method for potato rice noodles made of fresh potatoes and having low breakage rate

A production method and potato technology, which are applied in the fields of application, food science, food preservation, etc., can solve the problems of low addition of potatoes, improve the rate of rice noodle breakage, etc., so as to reduce processing procedures and pollution, ensure the quality of rice noodle, and increase toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for making potato rice flour with a low sliver breakage rate made from fresh potatoes, the components of the potato rice flour in percentage by weight are: 50 kg of freshly washed and peeled potatoes, 40 kg of soaked and drained rice, and 10 kg of cornstarch . The rice is harvested for more than 8 months.

[0029] The method that adopts above-mentioned component to make potato rice flour comprises the steps:

[0030] (1) Wash the rice and soak it in tap water for 6 hours, drain the water and weigh it, then grind it into powdered rice noodles for later use.

[0031] (2) One hour before the end of rice soaking, wash and peel the fresh potatoes and divide them into two parts, one part is 40kg and the other part is 10kg. The 40 kg portion of potatoes was ground into a potato slurry which was held in narrow mouth buckets and sealed with lids. The 10kg portion was steamed in a steamer and mashed into mashed potatoes.

[0032] (3) Mix all the starch with the rice ...

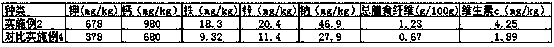

Embodiment 2

[0045] The invention discloses a method for making potato rice flour with a low sliver breaking rate made from fresh potatoes. The components of the potato rice flour are as follows in percentage by weight: 60 kg of freshly washed and peeled potatoes, 35 kg of soaked and drained rice, and 5 kg of sweet potato starch. The rice is harvested for 1-2 years.

[0046] The method that adopts above-mentioned component to make potato rice flour comprises the steps:

[0047] (1) Wash the rice and soak it in tap water for 5 hours, drain the water, weigh it, and grind it into rice flour for later use.

[0048] (2) One hour before the end of rice soaking, wash and peel the fresh potatoes and divide them into two parts, one part is 48kg and the other part is 12kg. A 48 kg portion of potatoes was crushed and ground into a potato slurry which was held in narrow mouth buckets and sealed with lids. The 12kg portion was steamed in a steamer and mashed into mashed potatoes.

[0049] (3) Mix al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com