Bending die of multi-angle V-shaped workpiece

A multi-angle, bending die technology, applied in the field of cold stamping dies, can solve the problems of low production efficiency and troublesome operation, and achieve the effects of high production efficiency, convenient operation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

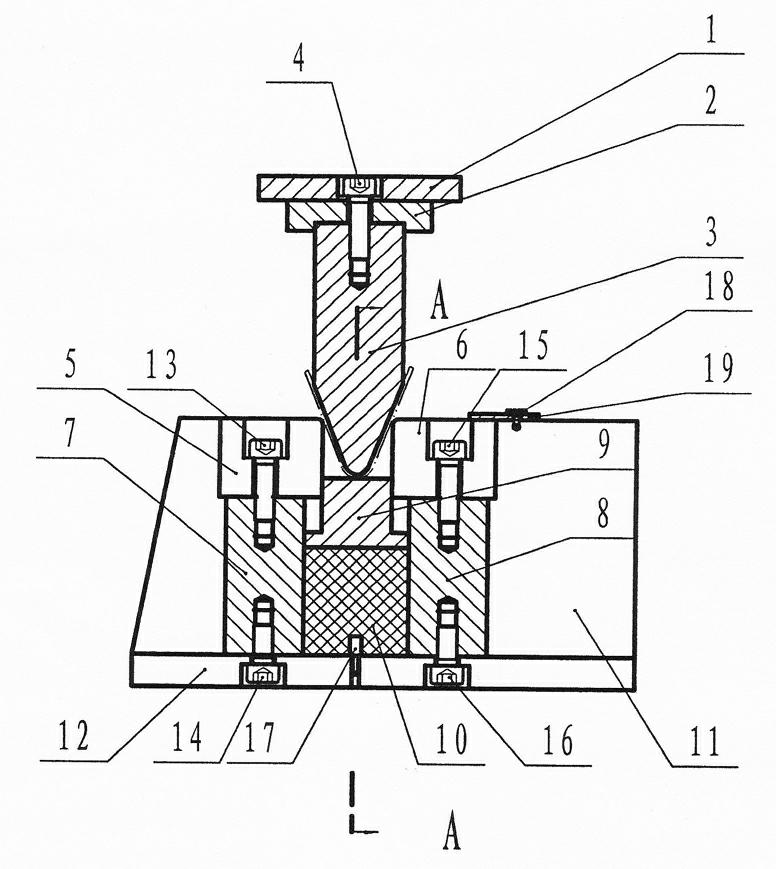

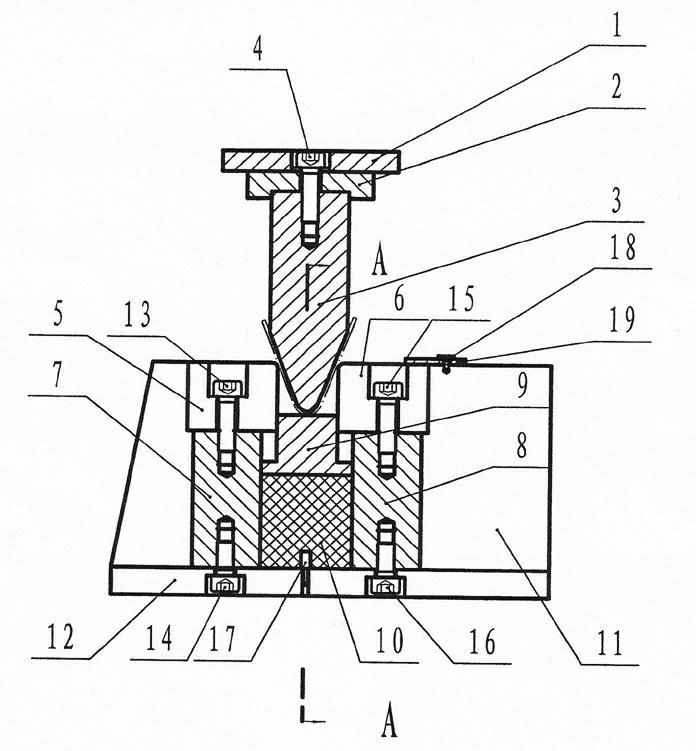

[0008] Now, the present invention will be described in detail in conjunction with the embodiments shown in the accompanying drawings.

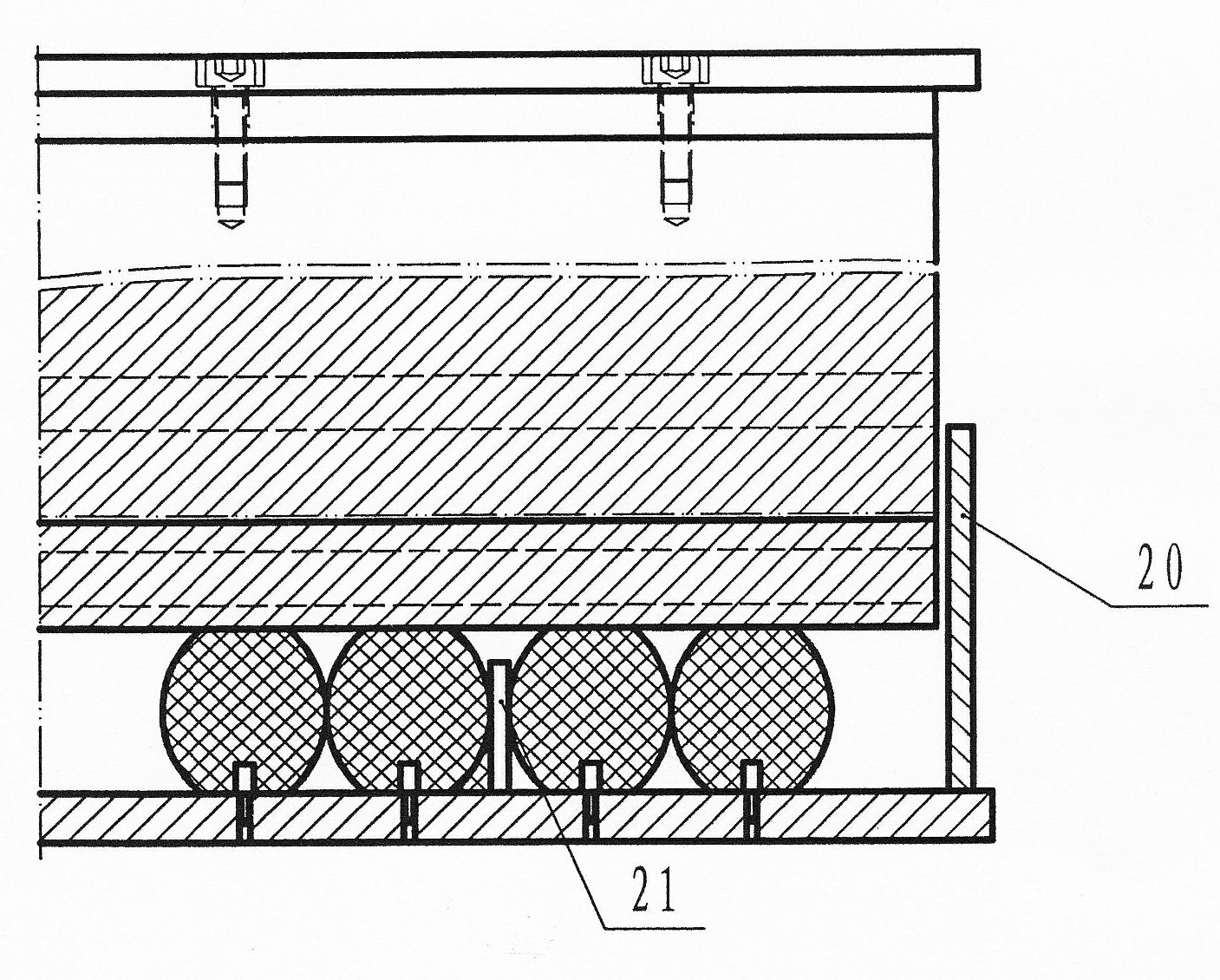

[0009] As shown in the figure, a multi-angle V-shaped piece bending die includes an upper die consisting of an upper die base 1, a punch pad 2, and a punch 3, and the three are connected by screws 4. The lower die is composed of two die upper blocks 5, 6, two die lower blocks 7, 8, top plate 9, elastic rubber pad 10, die holder 11, lower die base 12, die upper block 5 , 6 and the lower blocks 7, 8 of the die are respectively connected by screws 13, 14, 15, 16 and snapped into the inner cavity of the die holder 11, and the upper blocks 5, 6 of the die protrude from the lower block 7, 8, the inner surface forms a step, the port on the inner surface has a circular arc-shaped transition edge, and the end surface is an inverted T-shaped top piece plate 9. The outer surface of the upper part is snapped into between the inner sides of the upper block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com