Composite cable clamp stamping tool and stamping method thereof

A cable clamp and composite technology, which is applied in the field of composite cable clamp stamping tooling and stamping, can solve the problems of poor clamp uniformity, time-consuming and labor-intensive, high production costs, etc., to achieve rapid stamping and forming, ensure the quality of the forming, and prolong the service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

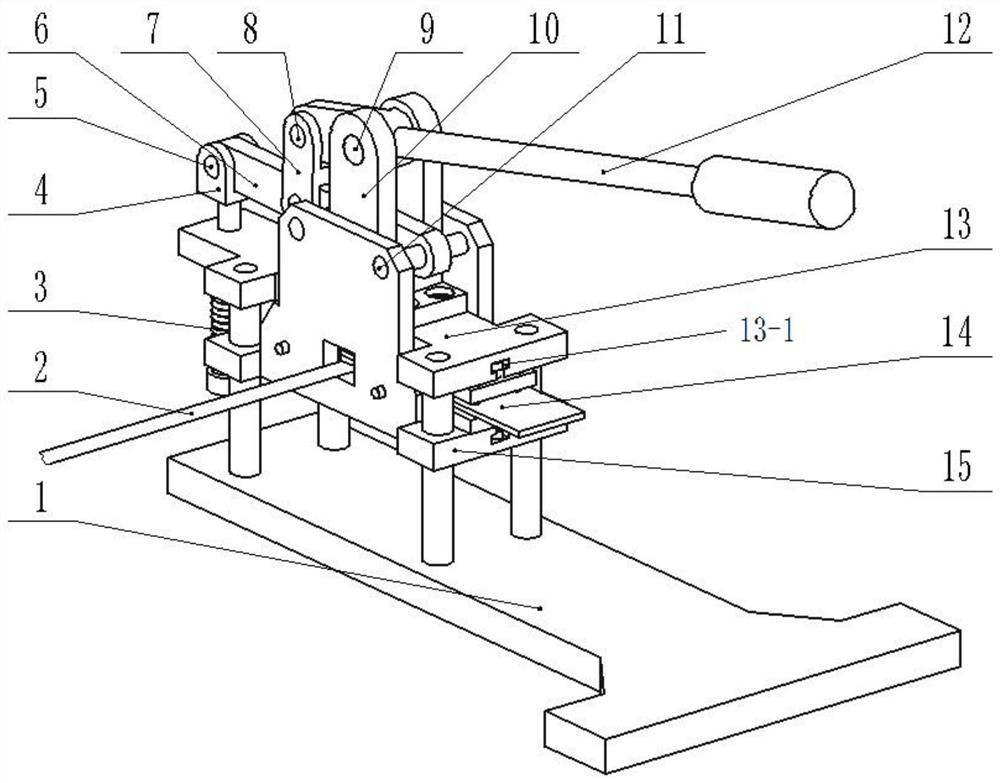

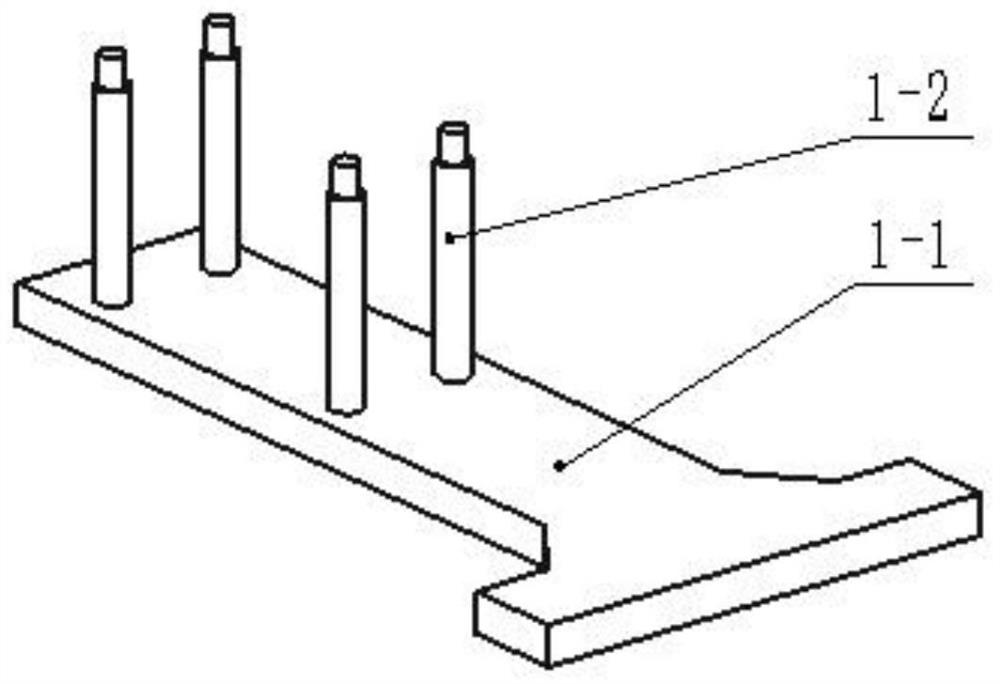

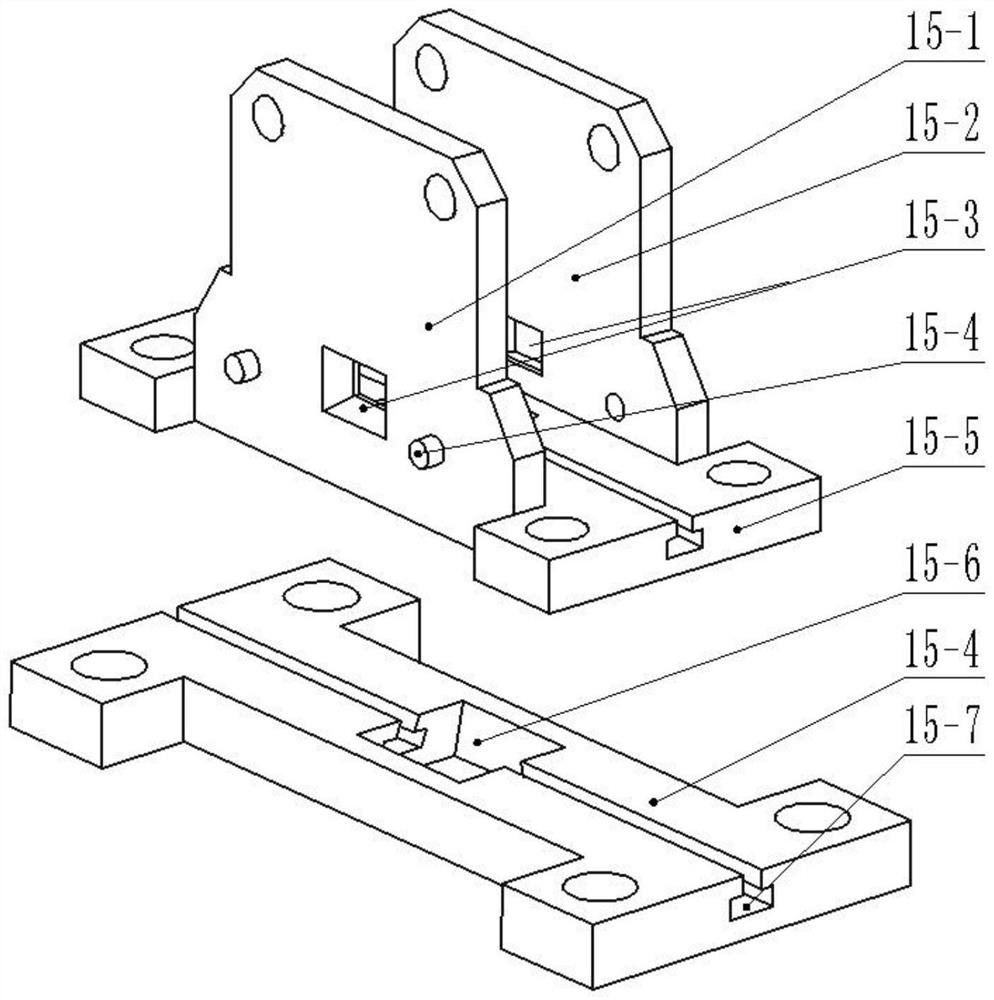

[0044] A specific embodiment of the present invention discloses a composite cable clamp stamping tool, such as Figure 1-8 As shown, it includes: a base 1, a connecting rod mechanism, a reset mechanism, a fixed plate 13, a composite stamping die 14 and a bracket 15;

[0045] Wherein, the composite stamping die 14 includes: a first die 14-1 and a second die 14-5. Outer arc punches 14-1-1, outer arc punching grooves 14-1-5, and round hole punches that are respectively arranged on the corresponding positions of the first mold 14-1 and the second mold 14-5 14-1-4, round hole punching groove 14-1-6, its shape and size specifications are consistent with the specifications of the outer arc edge 2-1 of the cable clamp, and the specifications of the nail hole 2-2; that is to say, the stamping process of the composite stamping die 14 Among them, the outer arc punch 14-1-1 and the outer arc punching groove 14-1-5 cooperate to punch out the outer arc edge 2-1 on one side of the cable cla...

Embodiment 2

[0083] This embodiment provides a stamping method of the composite cable clamp stamping tool of the present invention, using the composite cable clamp stamping tool of Embodiment 1 to stamp and form the cable clamp, which specifically includes the following steps:

[0084] S1: Install the composite stamping die 14 on the stamping tool; send the material 2 into the stamping tool through the inlet and outlet 15-3;

[0085] S2: Press down the pressure rod 12 to close the first mold 14-1 and the second mold 14-5 to stamp the material 2; loosen the pressure rod 12 to reset the stamping tool; the first stamping is completed, and the cable clamp is obtained unilateral outer arc edge 2-1 and nail hole 2-2;

[0086] S3: Push the material 2 forward to move the length of the distance cable clamp; press down the pressure rod 12, and the composite stamping die 14 punches out the outer arc edge 2-1 and the nail hole 2-2 on the other side of the clamp and the lower One-side outer arc edge 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com