Vehicle cable automatic detection device and method

An automatic detection and automatic testing technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of large man-hours, low work efficiency, missing data, etc., to avoid mistakes, realize fast and accurate positioning, and solve problems Effects that are not easy to test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

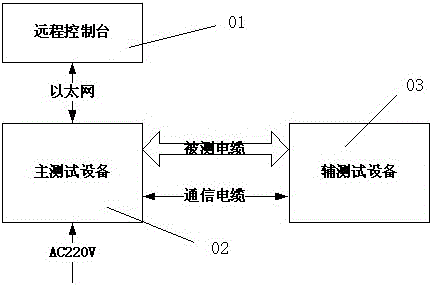

[0039] see figure 1 , the vehicle cable automatic detection equipment provided by the present invention comprises: remote console 01, main test equipment 02 and auxiliary test 03; Local control is carried out to main test equipment and auxiliary test equipment, or is installed with test equipment software through Ethernet Connect to the remote console 01 and accept the control of the remote console 01. When performing the cable test, the main testing device 02 and the auxiliary testing device 03 are connected through a communication cable, and the tested cable is connected to the test ports of the main testing device 02 and the auxiliary testing device 03 for testing.

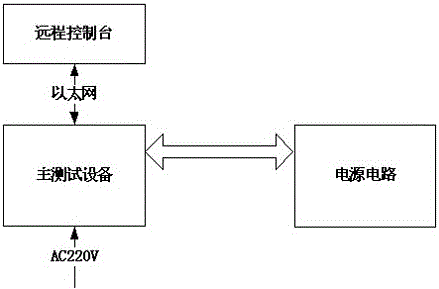

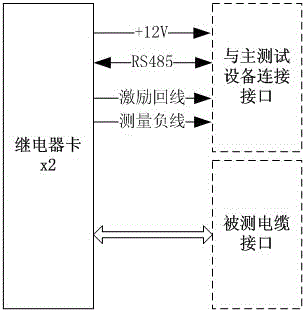

[0040] see figure 2 , the vehicle cable automatic detection equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com