Separated vacuum chuck grasp device on duct piece assembling machine

A technology of segment assembly machine and vacuum suction cup, which is applied in shaft equipment, wellbore lining, tunnel lining, etc., can solve the problems that the grasping device cannot be used universally, is not safe, and is not easy to operate, so as to increase the pure excavation time and reduce the manufacturing cost , The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

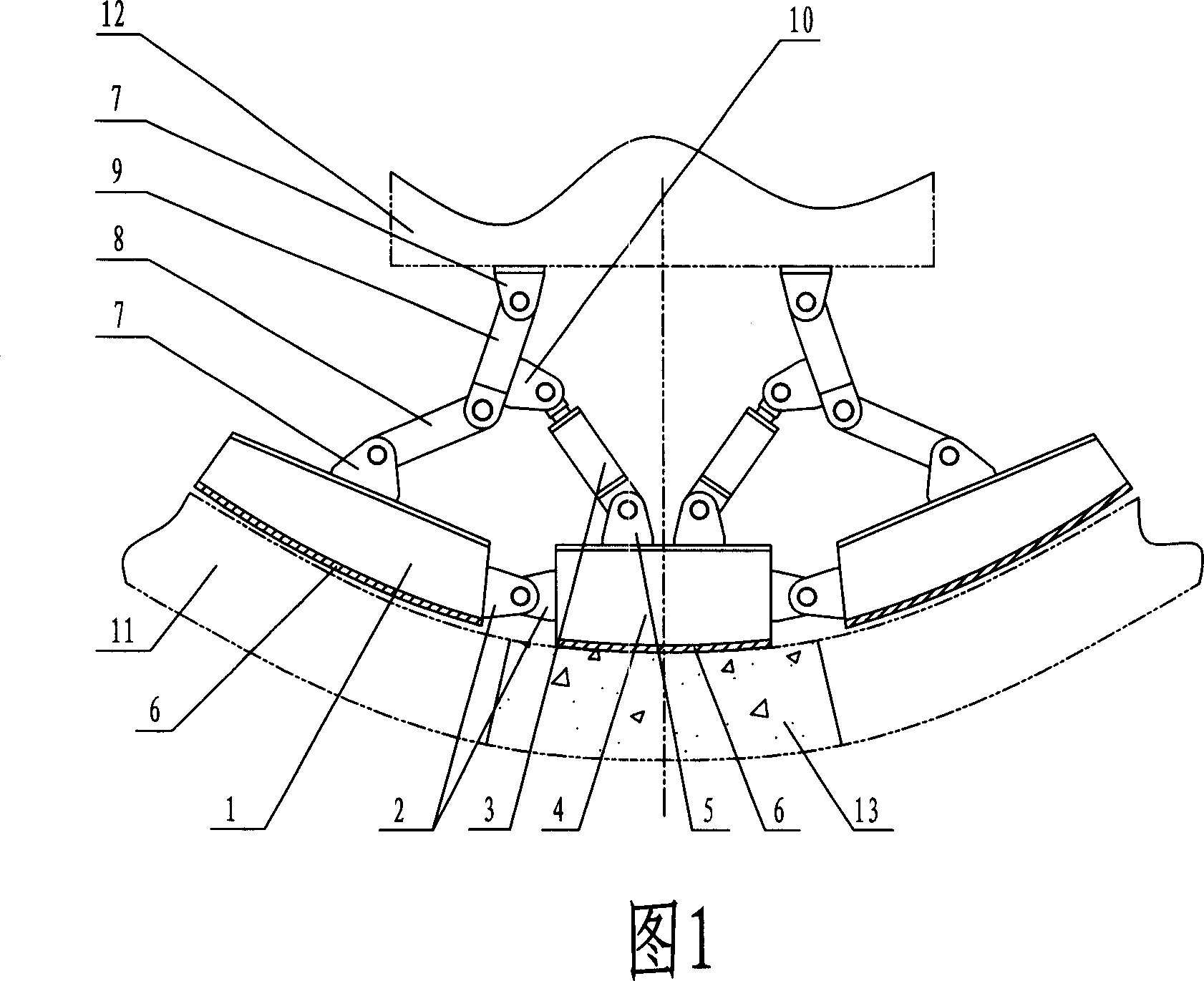

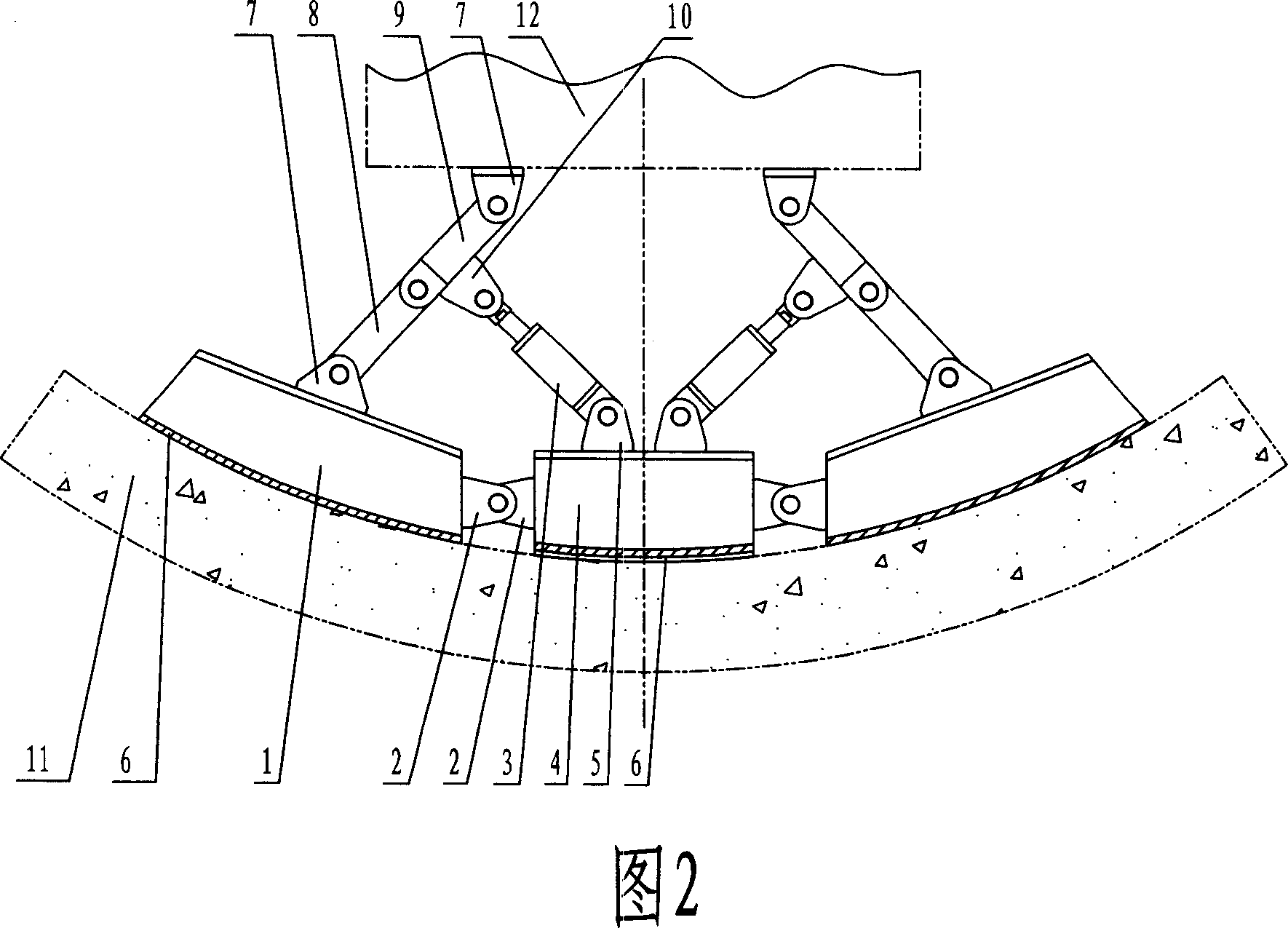

[0015] Fig. 1 is a specific embodiment of the present invention, which is a split-type vacuum suction cup gripping device installed on a segment assembly machine of a shield machine. Fig. 1 shows the working state after the piston rod of its hydraulic cylinder 3 is retracted, that is, The medium vacuum suction cup 4 is tightly pressed on the surface of the short tube piece 13, and its structure includes a machine base 12, which is characterized in that: a side vacuum suction cup 1, a medium vacuum suction cup 4, a suction cup connecting seat 2, a hydraulic cylinder 3, a cylinder support 5, Rubber liner 6, long pipe piece 11, short pipe piece 13 are formed, the whole vacuum sucker in the prior art is divided into a medium vacuum sucker 4, left and right side vacuum sucker 1, in the concrete short pipe piece 13 In the middle position, close to the inner arc surface of the short pipe piece 13 and install the medium vacuum suction cup 4 made of steel plate, and the left and right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com