Floating core-pulling mechanism for pipe fitting forming

A core-pulling mechanism and pipe fitting technology, applied in forming tools, metal processing equipment, peeling devices, etc., can solve the problems of long core-pulling stroke, high manufacturing cost, low production efficiency, etc., and achieve the effect of stamping and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

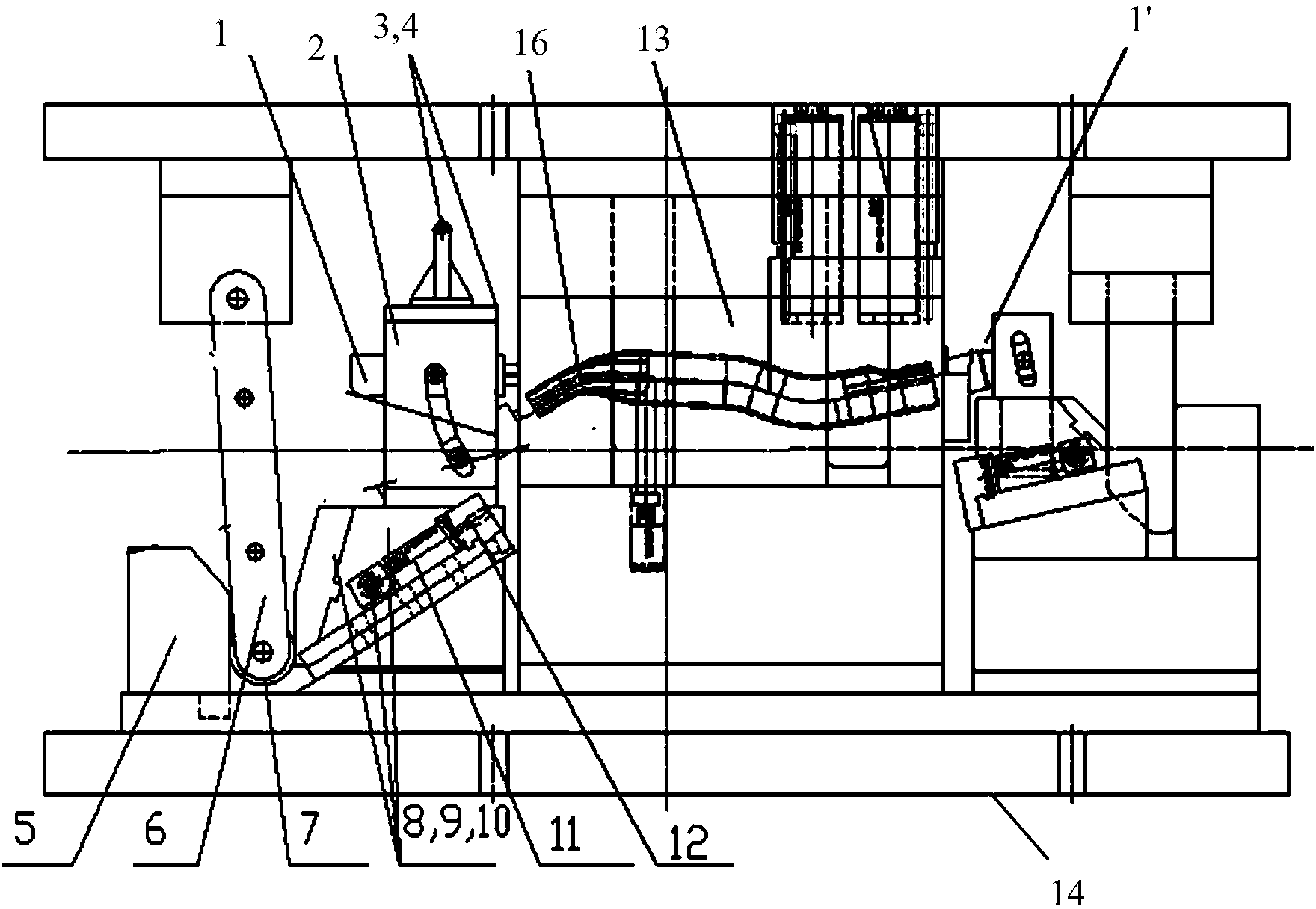

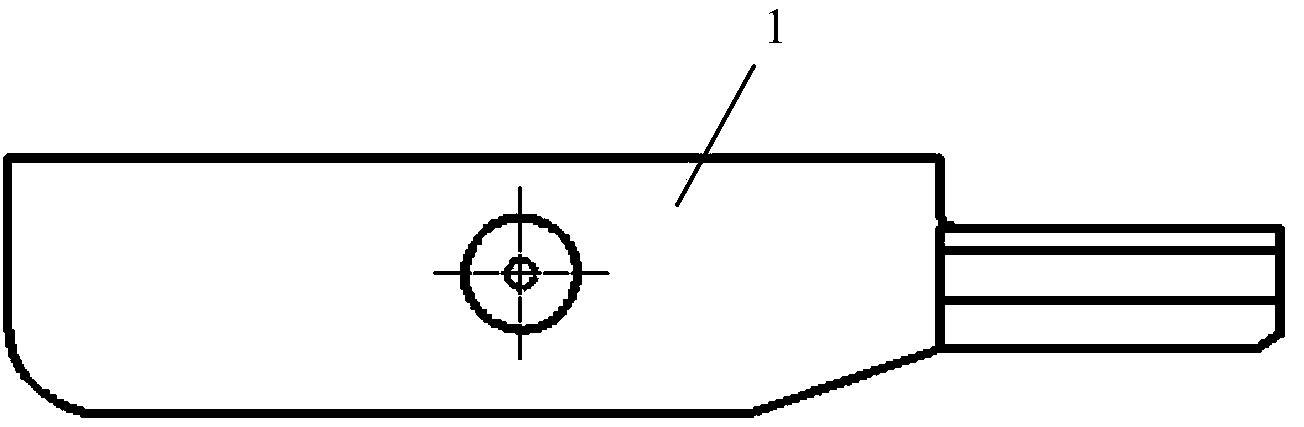

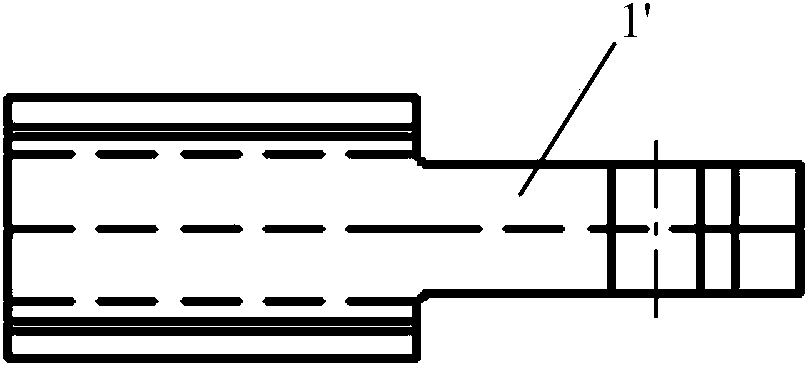

[0027] exist figure 1 The combined multi-position pipe fitting forming mold uses two sets of pipe forming floating core-pulling mechanisms to control the entry and exit of the floating core-pulling for the two sections of the formed pipe respectively. In the following description, the main description figure 1 The structure and working principle of the pipe forming floating core-pulling mechanism on the left side in the middle are basically suitable for the pipe forming floating core-pulling mechanism on the right. The difference between the two is mainly that the core-pulling action is reversed and the installation position is different. In addition if figure 2 As shown, the floating core-pulling 1 on the left is a flat rod, such as image 3 As shown, the floating core pulling 1' on the right is a round mandrel.

[0028] Such as figure 1 As shown, the pipe forming floating core-pulling mechanism can be divided into upper, middle and lower parts, namely the upper die wedg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com