Method for designing stamping die universal for steel and aluminum parts

A technology of stamping die and design method, which is applied in the field of parts manufacturing, can solve the problems that cannot be applied to manufacturing at the same time, does not solve the problems of steel plate and aluminum plate stamping die itself, and the bending performance of aluminum plate is poor, so as to be easy to master and realize, and save development The effect of cost and development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A stamping die design method of a steel and aluminum part common to the present invention will be further described below with reference to the accompanying drawings and examples.

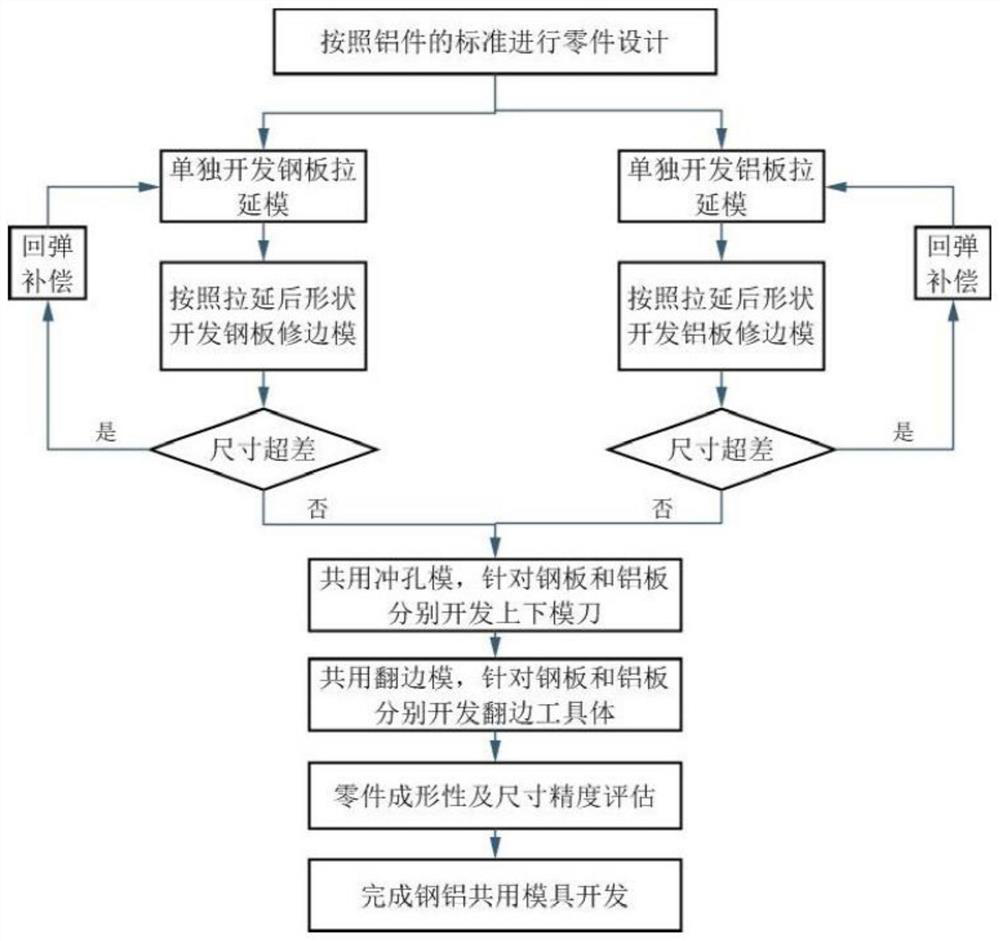

[0051] Example - Design and development of engine cover outer panel steel shared stamping die, such as Figure 1 ~ 3 As shown, it is as follows:

[0052] 1. Part design:

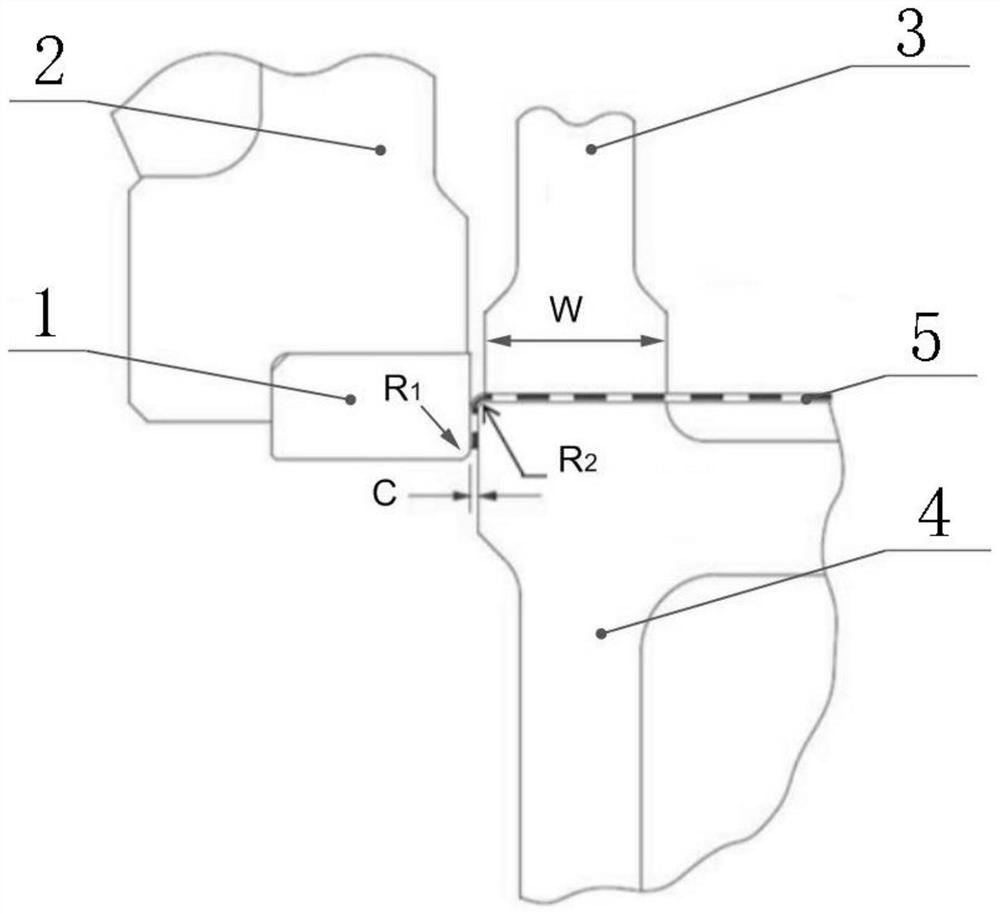

[0053] According to the standards of aluminum parts, the shape is designed, the profile has no sharp change, and the characteristic rounded angle radius is 5mm or more, and the stretch depth of the product is 100mm;

[0054] 2. Leading mode design:

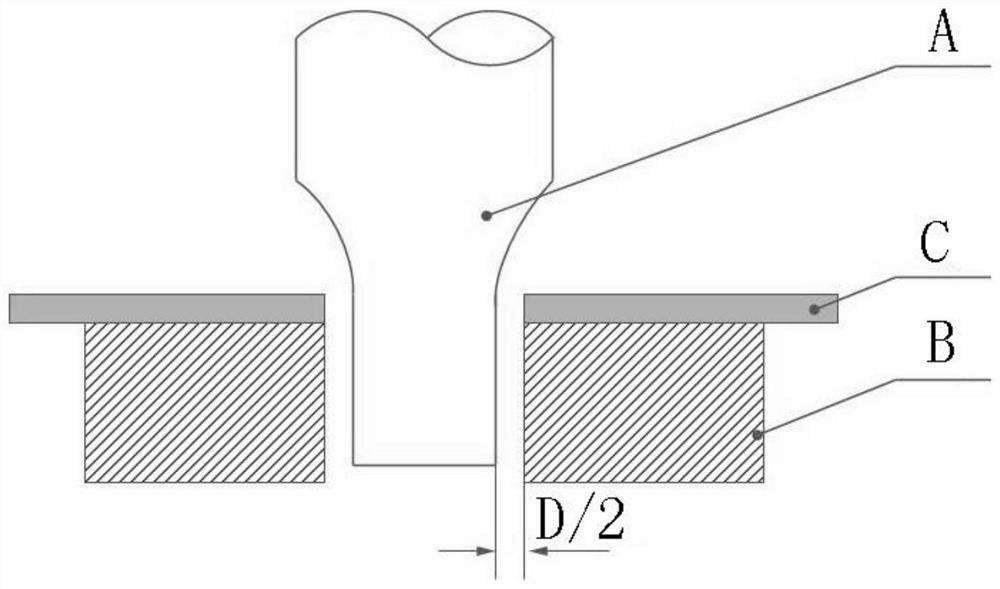

[0055] The first step of pulling the part is aimed at the difference in steel aluminum plasticity and the rebound characteristics, and the steel sheet pulling mode and the aluminum plate pull-extended mold die, the steel sheet pull-up mode supplement surface end wall is 10 ° 10 ° ~ 15 °, the convex concave-filled angle radius is 5 ~ 25mm; the process supplemental surface wall of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com