Iron cylinder stamping forming equipment

A stamping forming, cylinder technology, applied in the direction of metal processing equipment, feeding devices, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

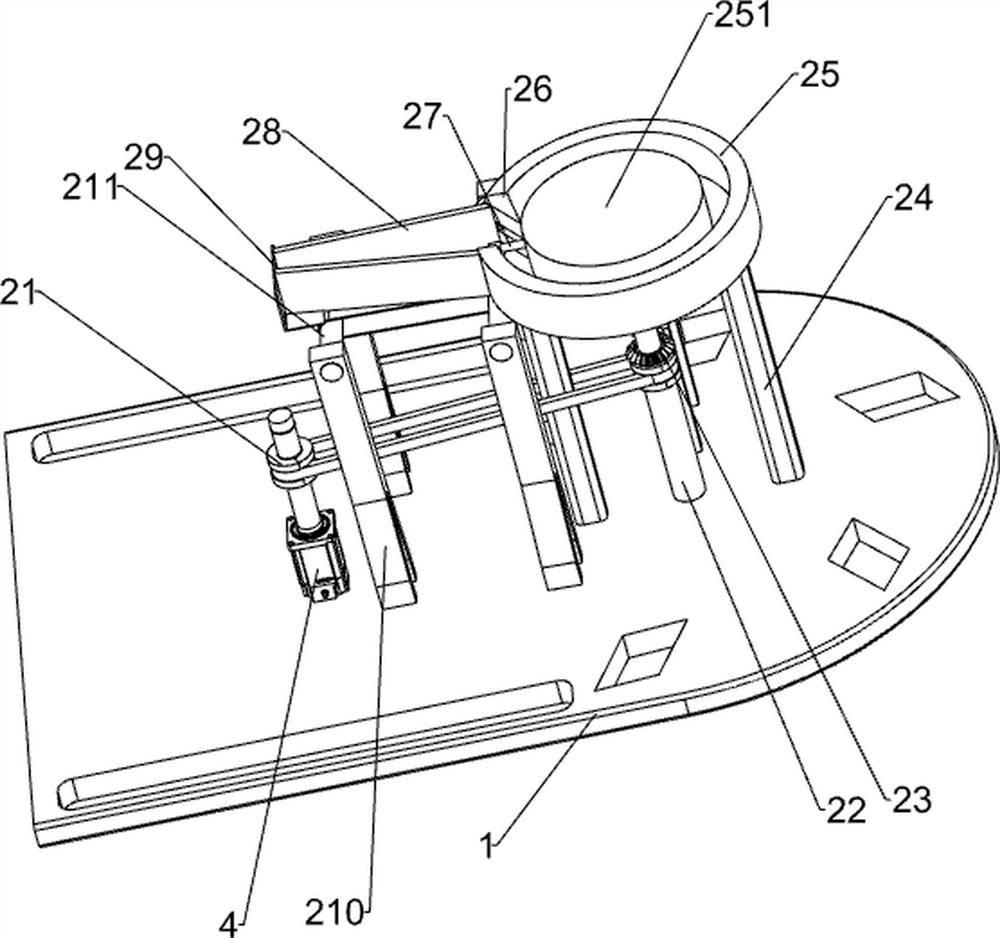

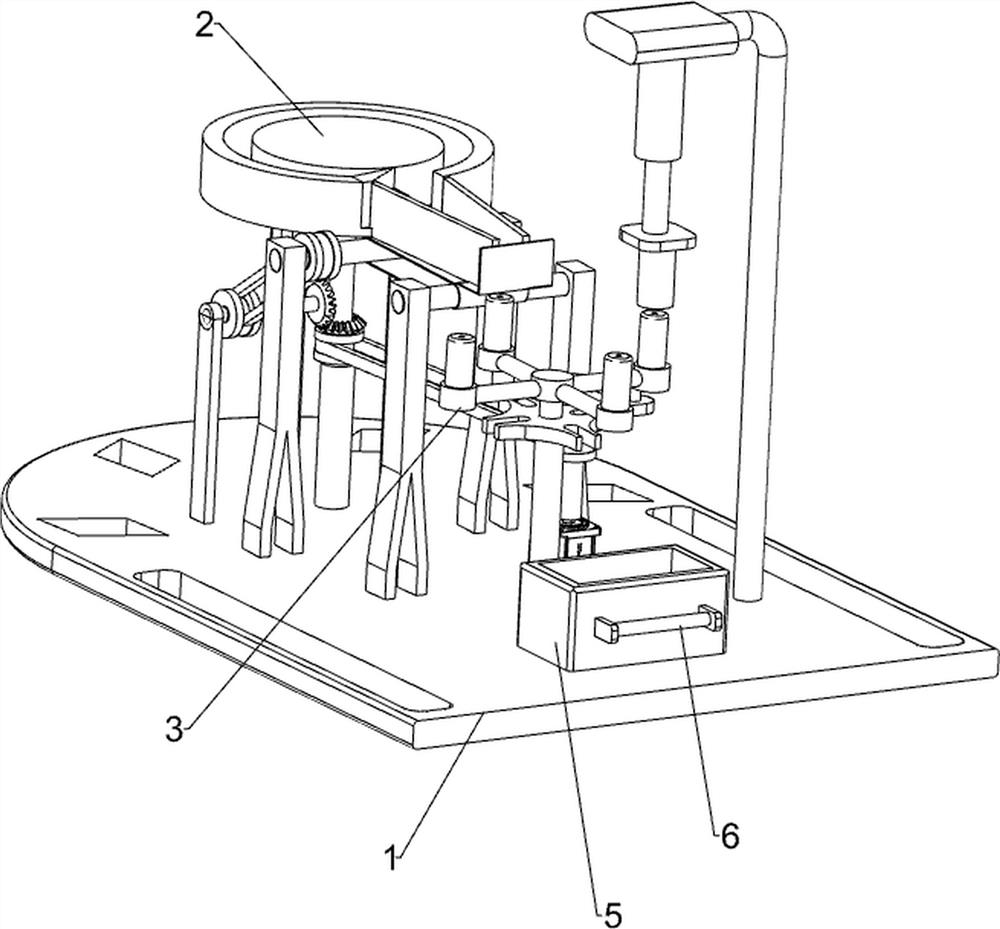

[0020] One kind of cylindrical iron press-molding apparatus, such as figure 1 Shown, it comprises a bottom plate 1, the transfer mechanism 2, pressing mechanism 3, 4, 5 and lever 6 collecting box, a rear top plate conveying means 2 is provided with a servo motor, the base plate 1 is provided with a top front side of the press means 3, punching means transfer mechanism member 3 is connected to the member 2, the base plate 4 is provided with a top in the middle, is connected to an output shaft of the servo motor member 4 and the transport mechanism 2, the intermediate side plate is placed on top a front frame 5 collected, the collection box servomotor 5 the front portion 6 is provided with pull rod.

[0021] When people need a cylindrical iron press-molding, it is first placed on a cylindrical iron member conveying mechanism 2, the collection box 5 is placed in the front side of the top plate 1, and then it starts the servo motor and the press mechanism 4 member 3, the output shaft ...

Embodiment 2

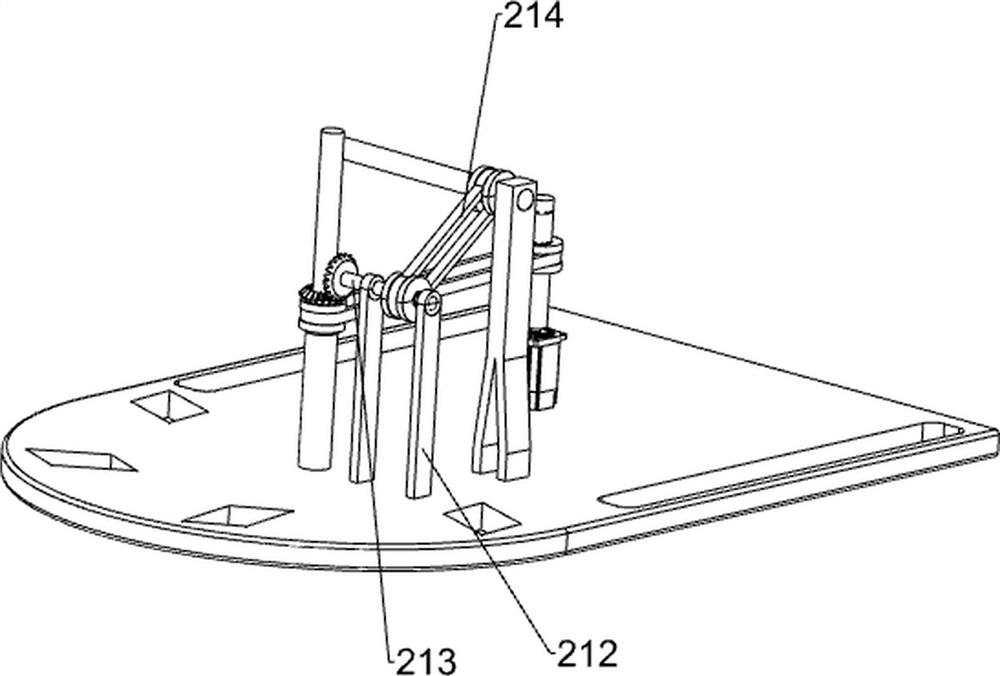

[0023] On the basis of Example 1 above, such as Figure 2-4 , The transfer mechanism 2 includes a first transport assembly 21, shaft 22, bevel gear set 23, a first support column 24, a support table 25, the turntable 251, the wedge block 26, the push rod 27, the guide plate 28, L-shaped stopper plate 29, bearing housing 210, the second transfer assembly 211, holder 212, the pawl 213 and the third transport assembly 214, a rear side of the top plate intermediate rotary shaft 22 is connected between the shaft 22 and the output shaft of the servo motor 4 connected with a first transport assembly 21, the base plate 1 is provided with a uniform top left rear bracket 212, the bracket 212 is the number 2, between the rotary bracket 212 is connected to the pawl 213, the shaft 213 and the right side of the pawl 22 between the bevel gear set 23 is connected to the base plate 1 is provided with a first intermediate top rear support column 24, support post 24 is located at the rear side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com