Cam-type continuous punching mold

A stamping die, cam type technology, applied in the field of stamping die, can solve the problems of prolonged time, unfavorable required time, unfavorable stamping efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

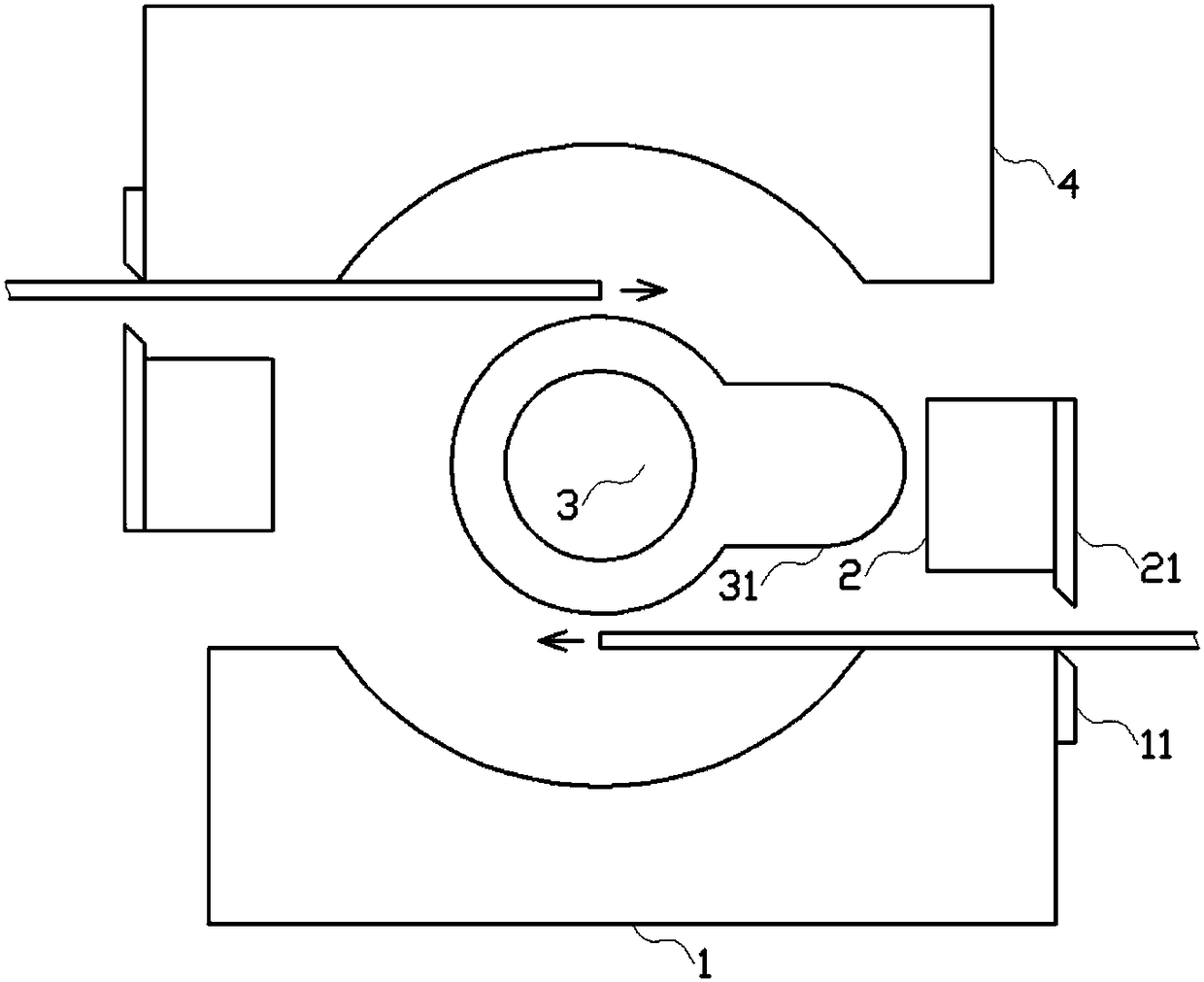

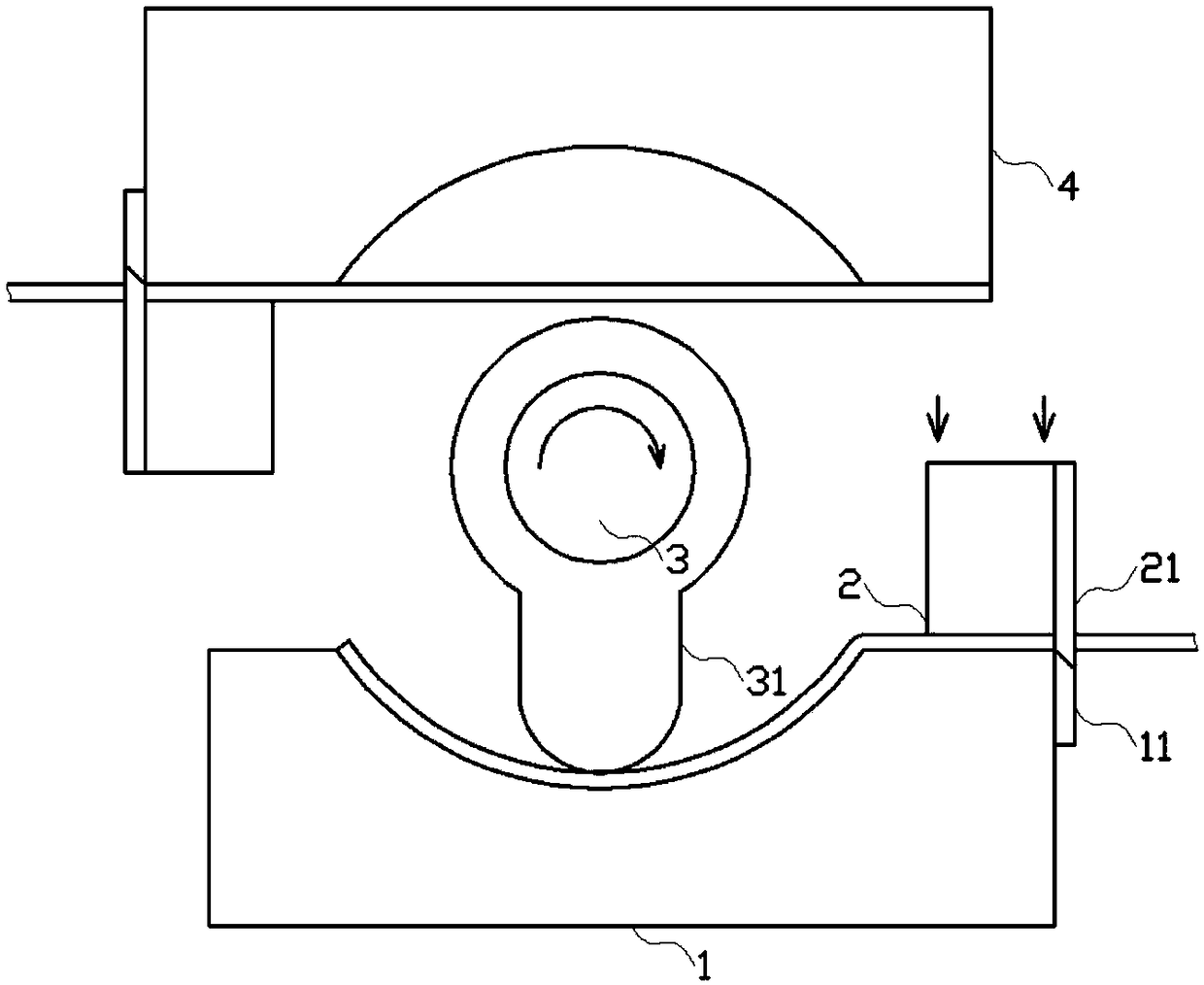

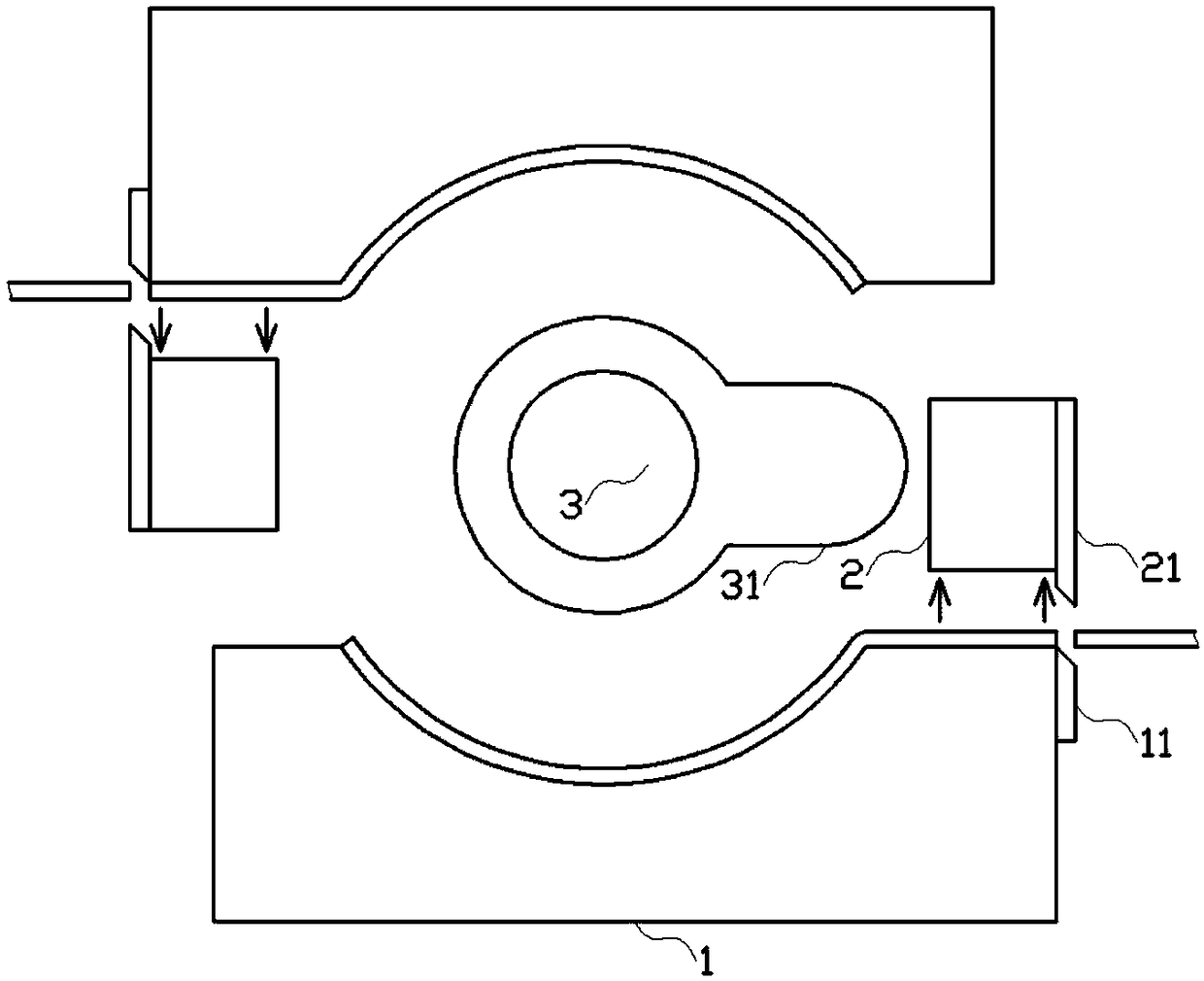

[0014] Such as figure 1 , figure 2 , image 3 As shown in the embodiment, the cam-type continuous stamping die is a process in which the sheet workpiece to be processed can be stamped after the rotating stamping rod rotates, and can realize continuous feeding, cutting, stamping and blanking operations. The stamping efficiency is high, and no manual operation is required, which greatly reduces the time required for stamping. It includes a forming module 1, a cutting module 2 and a rotating shaft module 3; the forming module 1 is a group of front and rear symmetrical dies, and the The opposite surface of the mold is provided with a molding surface with the same shape; the feeding direction of the symmetrical molding module 1 is opposite, and the side of the feeding end of the molding module 1 is provided with a fixed cutter 11, and the blade of the fixed cutter 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com