Production technology of winch support

A technology of winch support and production process, which is applied in the field of production process of winch support, can solve the problems such as difficult to guarantee the strength of winch support, poor precision, weak strength of winch support, etc. The effect of stress uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

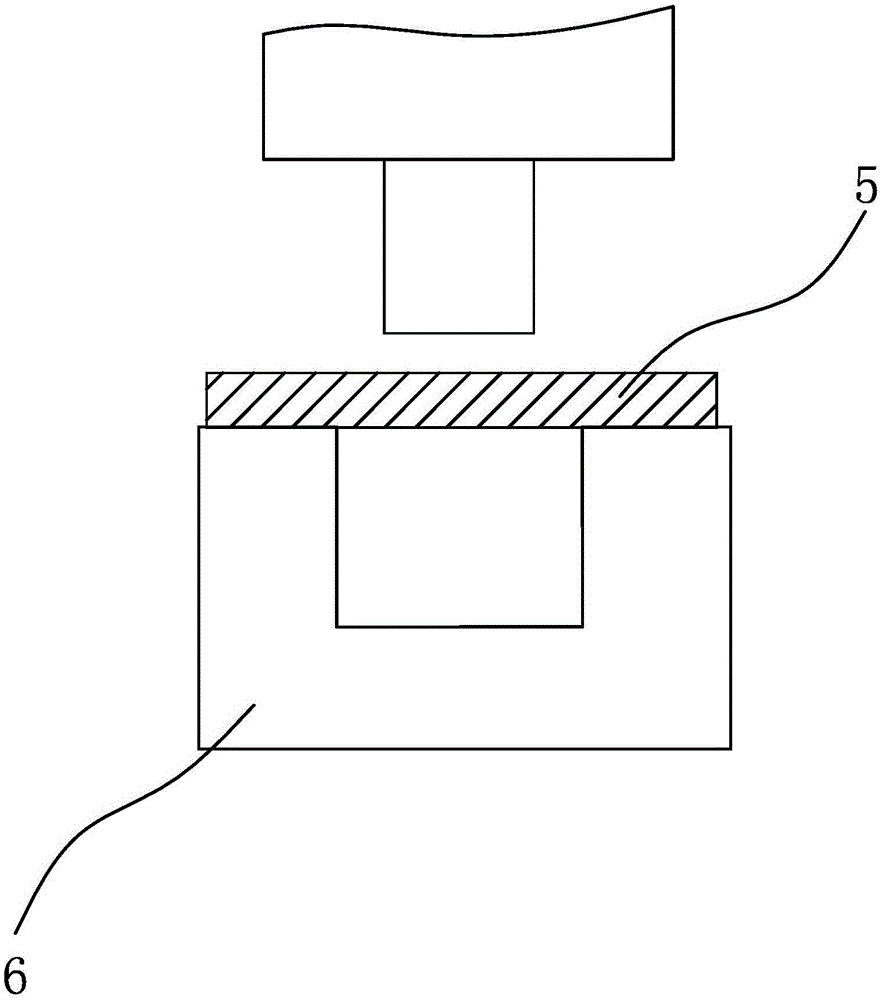

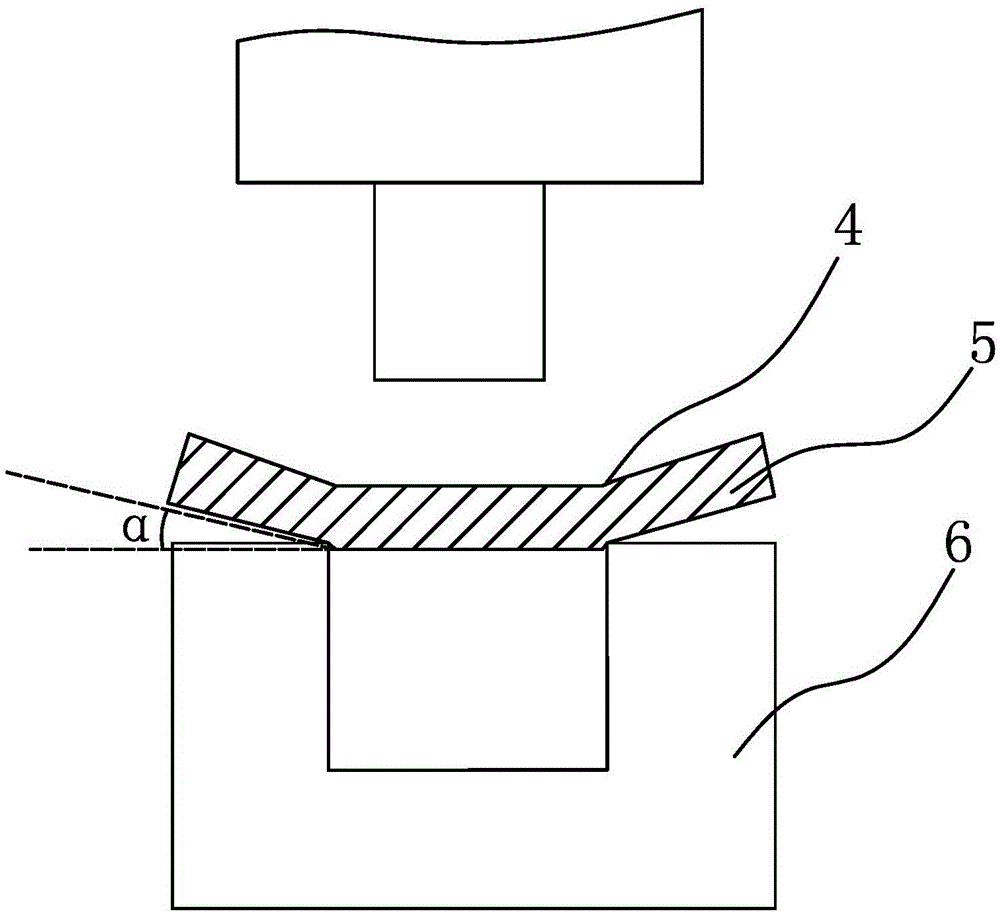

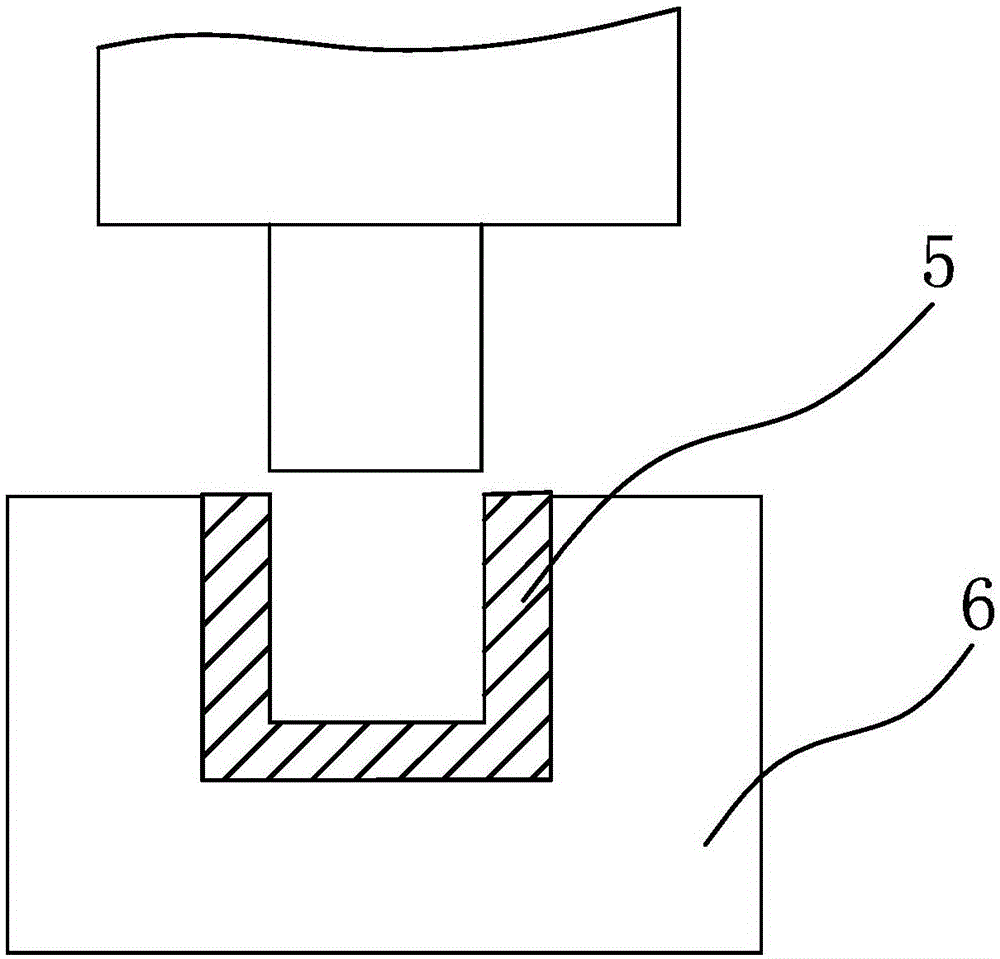

[0032] Such as Figure 1 to Figure 5 As shown, the production process of the winch support in the present embodiment comprises the following steps:

[0033] a, sheet material 5 preparation: the original sheet material that takes material is medium carbon steel is cut into the sheet material 5 that manufactures winch support 1, and is placed on stamping table 6;

[0034] Preferably, the sheet material 5 is in the shape of a strip;

[0035] Grind the sheet material 5, and punch hole one 2 and hole two 3 respectively at the positions near the two ends of the sheet material 5, then chamfer the holes one 2, hole two 3 and the periphery of the sheet material 5, and the polished sheet material 5 Smooth and flat, easy to use, ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com