Pneumatic torsion beam stamping die holder assembly

A stamping die, pneumatic technology, applied in the field of pneumatic torsion beam stamping die base assembly, can solve the problems of difficulty in distinguishing left and right directions, reducing welding efficiency, time-consuming and laborious parts positioning, etc., to achieve easy identification of left and right directions and improve processing efficiency. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

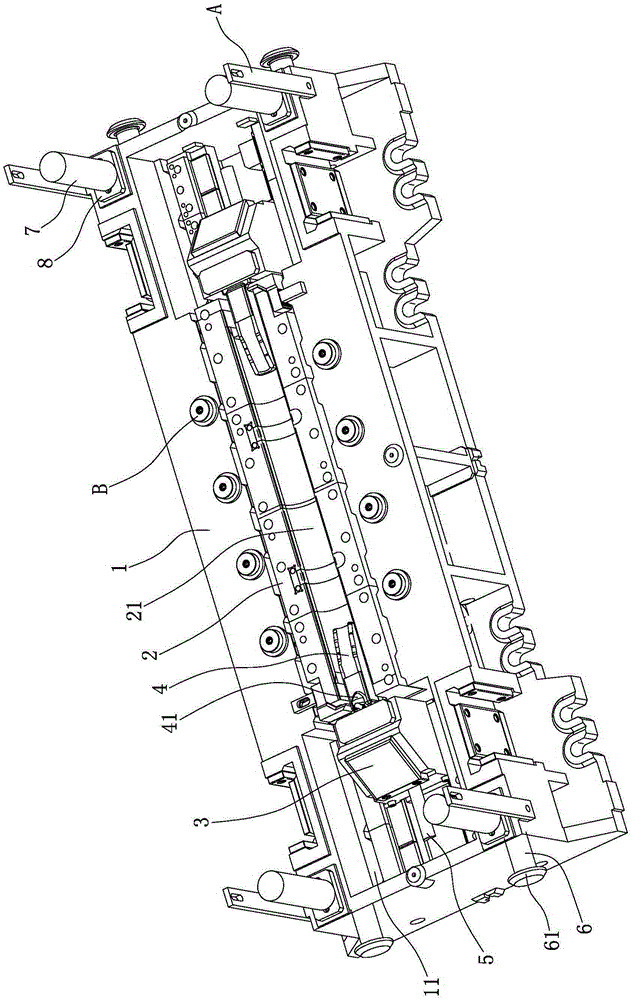

[0017] Such as figure 1 As shown, the mold base 1 is formed by casting. A group of lifting lugs 6 are respectively arranged on the left end surface and the right end surface of the mold base 1, and each group of lifting lugs 6 is divided into front and rear two, and four lifting lugs 6 are distributed in a rectangle on the same horizontal plane. The lifting lug 6 is a cylinder, one end of the lifting lug 6 is fixed to the mold base 1 , and the other end of the lifting lug 6 is integrally formed with an annular boss 61 .

[0018] Such as figure 1 As shown, the four corners of the top surface of the mold base 1 are provided with columns 7, the columns 7 are cylinders, and the four columns are distributed in a rectangle. Die base 1 is fixedly connected. A group of connection plates A are respectively arranged at the left and right ends of the mold base 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com