Mixed combustion device and combustion equipment utilizing same

A technology of mixed combustion and combustion equipment, which is applied in the direction of combustion equipment, the combustion of block fuel and liquid fuel, and the combustion of block fuel and gaseous fuel, which can solve the problems of large energy loss and prolong the service life , easy maintenance and replacement, and optimize the effect of excess air coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

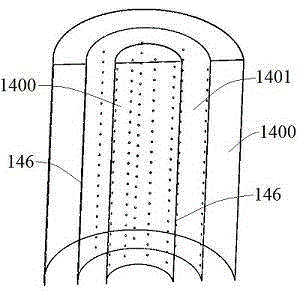

[0088] see figure 1 , a mixed combustion device of the present embodiment, the mixed combustion channel 1401 is an interlayer cavity between two medium channels 1400 to be sprayed, the mixed combustion channel 1401 is neither an air channel 142 nor a fuel channel 141, and the medium channel 1400 to be sprayed The medium to be sprayed is air and fuel, and each medium to be sprayed channel 1400 can only flow through air or fuel. The medium passage 1400 to be sprayed as the air passage 142 injects air to the mixed combustion passage 1401 through the air nozzle 1411 offered on the reaction partition wall 146; Injection port 1412 injects fuel into mixed combustion passage 1401 .

Embodiment 2

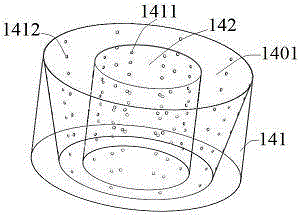

[0090] see figure 2 , a kind of mixed combustion device of the present embodiment, its center is cylindrical air passage 142, and the periphery of air passage 142 wraps truncated conical mixed combustion passage 1401, and fuel passage 141 then wraps the periphery of mixed combustion passage 1401, and fuel passage A fuel nozzle 1412 is opened on the reaction partition wall 146 between the 141 and the mixed combustion channel 1401 , and an air nozzle 1411 is opened on the reaction partition wall 146 between the air channel 142 and the mixed combustion channel 1401 .

Embodiment 3

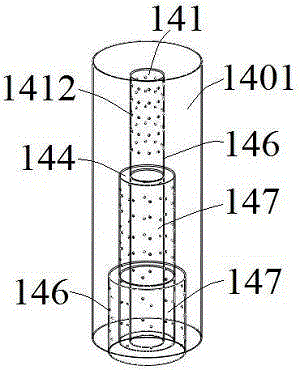

[0092] see image 3 , a mixed combustion device of the present embodiment, the center of which is a truncated conical fuel channel 141, the mixed combustion channel 1401 is an interlayer cavity between the fuel channel 141 and the air channel 142, and the reaction room between the fuel channel 141 and the mixed combustion channel 1401 A fuel nozzle 1412 is opened on the partition wall 146 , and an air nozzle 1411 is provided on the reaction partition wall 146 between the air channel 142 and the mixed combustion channel 1401 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com