Lithium silicate interior and exterior wall coating and preparation method thereof

A lithium silicate, interior and exterior wall technology, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve the problems of poor storage stability, poor construction performance, easy cracking, etc., to improve weather resistance and stability, Excellent self-cleaning effect, effect of improving aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

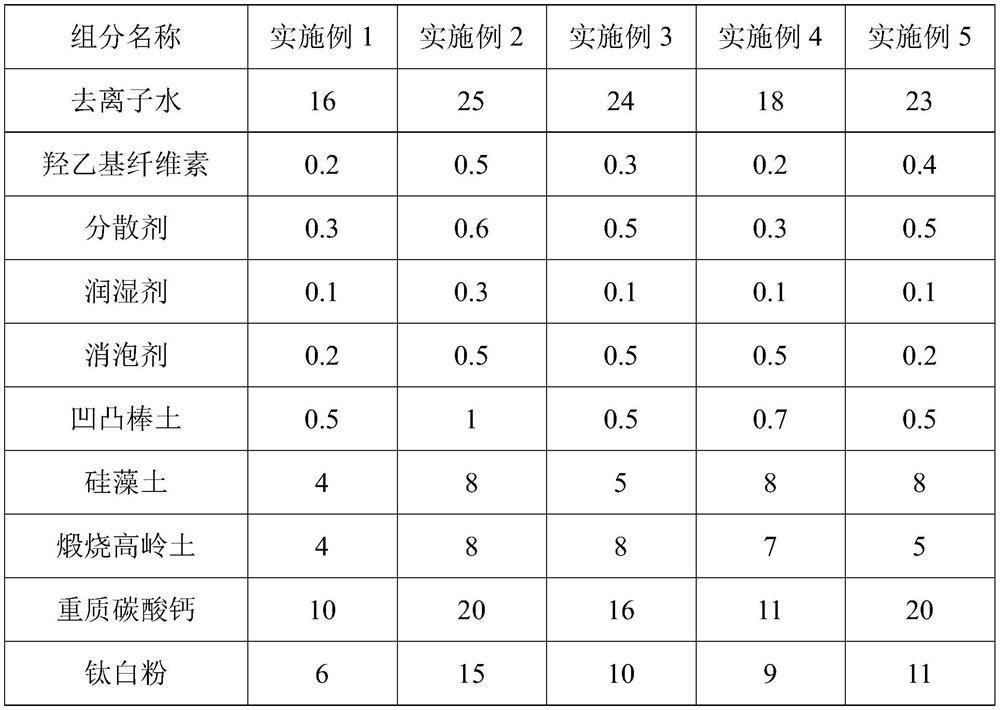

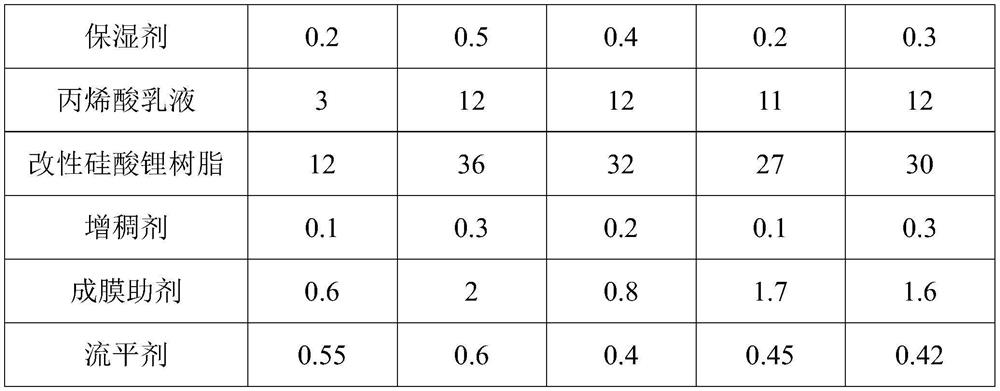

Examples

preparation example Construction

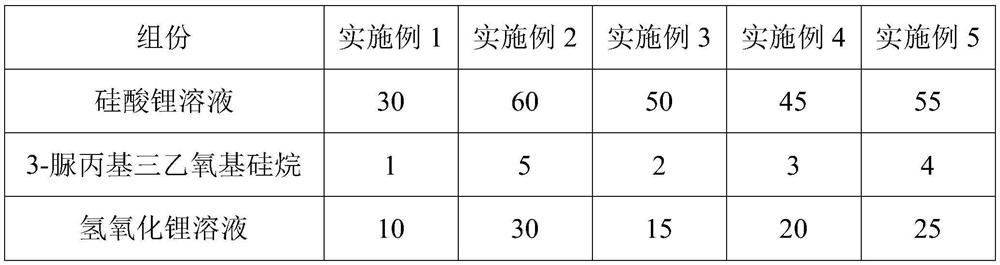

[0043] The synthetic method of the modified lithium silicate resin of embodiments 1-2 comprises the following steps:

[0044] 1) Add lithium silicate solution into the constant temperature device, control the temperature at 50~60°C, and stir;

[0045] 2) Add 3-ureidopropyl triethoxysilane, and then add lithium hydroxide solution to adjust the pH to 11-12.5;

[0046] 3) Continue to add γ-aminopropyltriethoxysilane, and then add methyltriethoxysilane, and stir and react for 2 hours to obtain a modified lithium silicate resin, which is cooled and used for later use.

[0047] The synthetic method of the modified lithium silicate resin of embodiments 3-4 comprises the following steps:

[0048] 1) Add lithium silicate solution into the constant temperature device, control the temperature at 50~60°C, and stir;

[0049] 2) Add 3-ureidopropyl triethoxysilane, and then add lithium hydroxide solution to adjust the pH to 11-12.5;

[0050] 3) Continue to add γ-aminopropyltriethoxysilane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com