Weather-resistant water-based sand-textured paint and preparation method thereof

A weather-resistant, water-based technology, applied in the field of coatings, can solve the problems of general weather resistance of coatings, not meeting the standard requirements, affecting the mechanical properties of the paint film, etc., achieving excellent weather resistance, reducing maintenance costs, and improving surface cleanability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

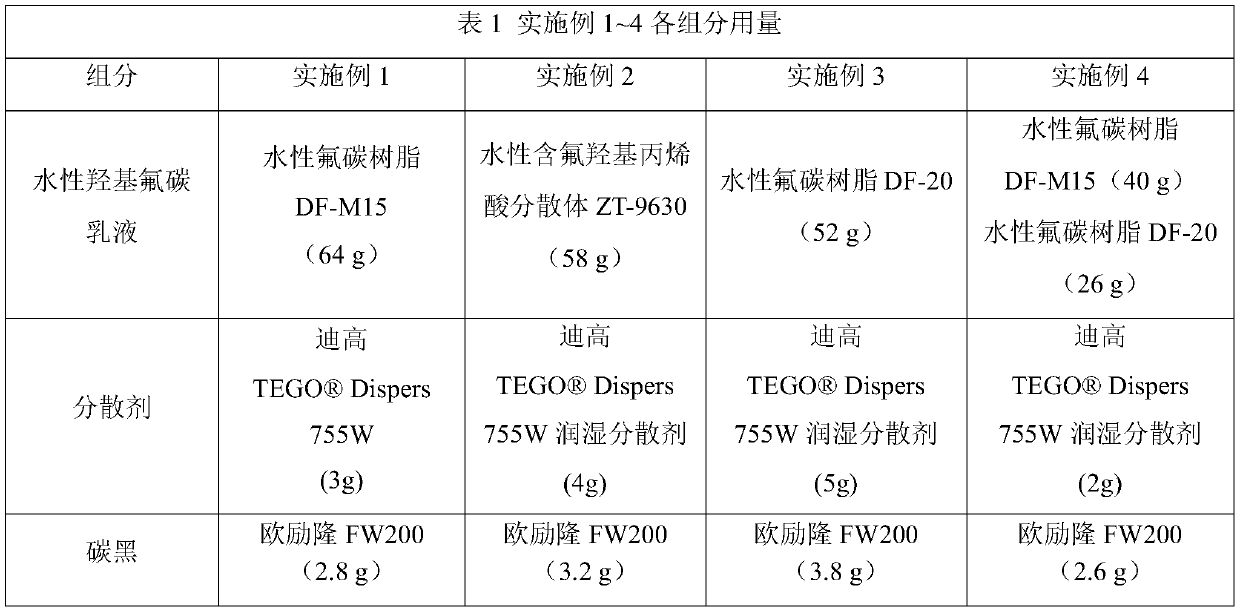

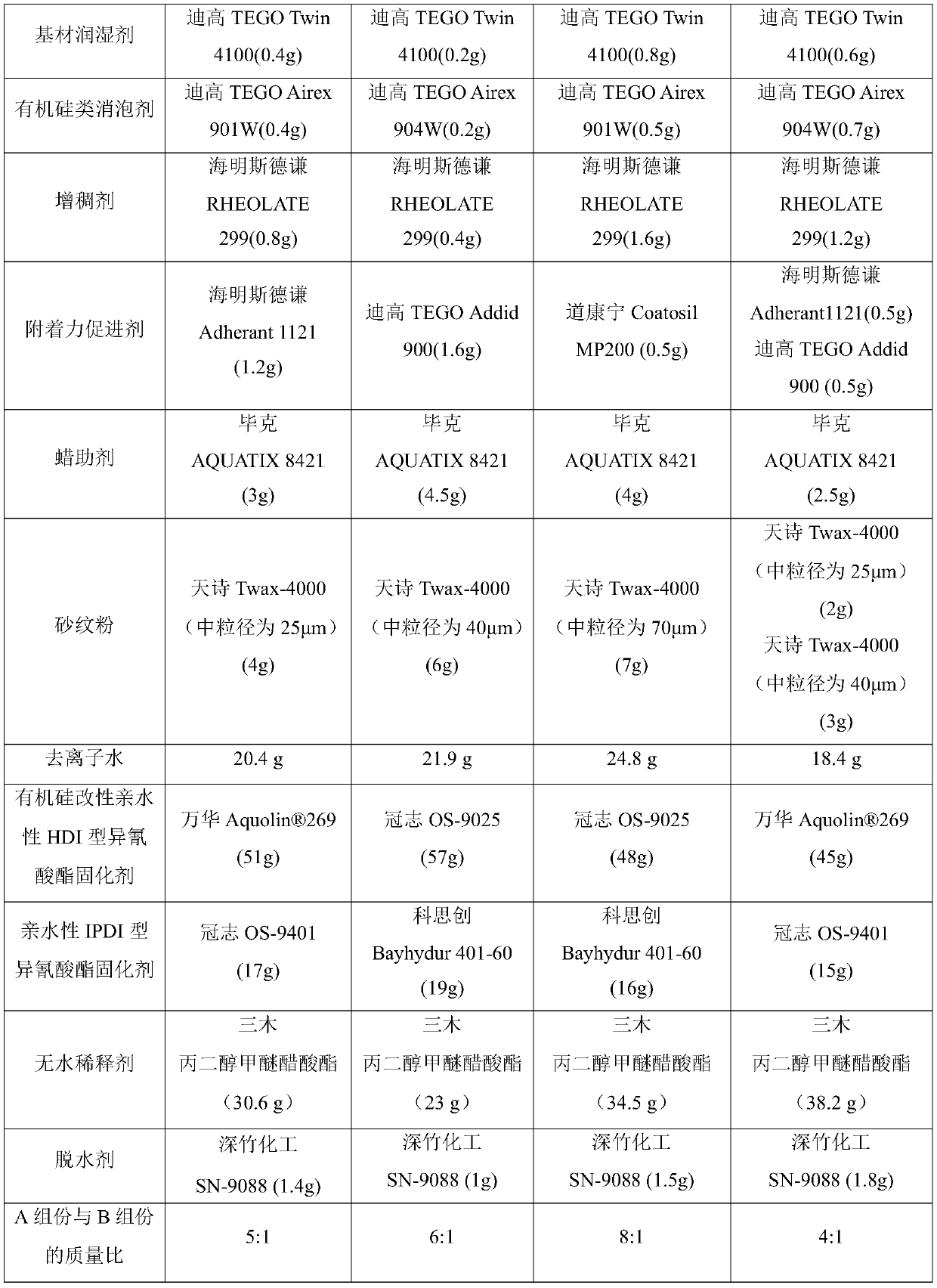

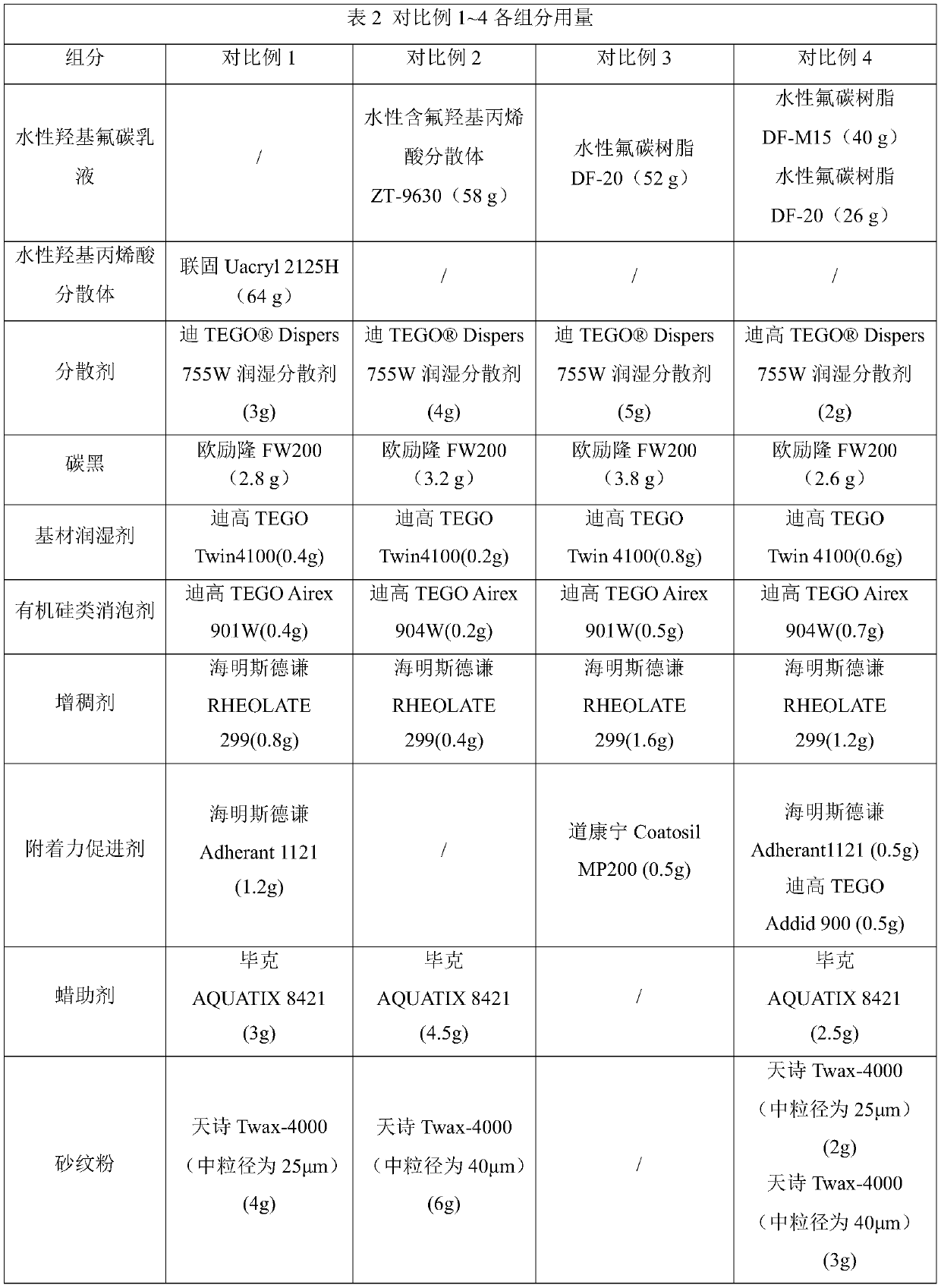

Embodiment 1~4

[0036] The preparation method of embodiment 1~4

[0037] (1) The preparation of component A includes the following steps:

[0038] Step a: Add deionized water, 50% dispersant, defoamer, and carbon black, mix and stir evenly, and transfer to sand mill equipment to grind to a fineness of ≤20 μm, and prepare a water-based resin-free black slurry mixture;

[0039] Step b: add deionized water, 50% dispersant, and sand grain powder, mix and stir evenly, disperse at 2800 rpm / min for 20 minutes at high speed, and prepare a water-based sand grain slurry mixture;

[0040] Step c: Mix water-based hydroxyfluorocarbon emulsion, water-based resin-free black slurry mixture, and water-based sand grain slurry mixture in proportion, then stir evenly, and add substrate wetting agent, thickener, wax additive, and adhesion promoter one by one Mix and stir the agent evenly, and disperse at a high speed of 700rpm / min for 35min to obtain component A of water-based sand texture paint;

[0041] (2) The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com