Carcass layer tread rubber of aviation radial tire

A radial tire and carcass layer technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of high retreading times of aviation radial tires, affecting service life and safety, and deformation of sidewall parts, etc., to achieve Improves anti-reversion performance, improves fatigue resistance, inhibits oxidation and thermal aging effects

Active Publication Date: 2017-07-25

中国化工集团曙光橡胶工业研究设计院有限公司

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

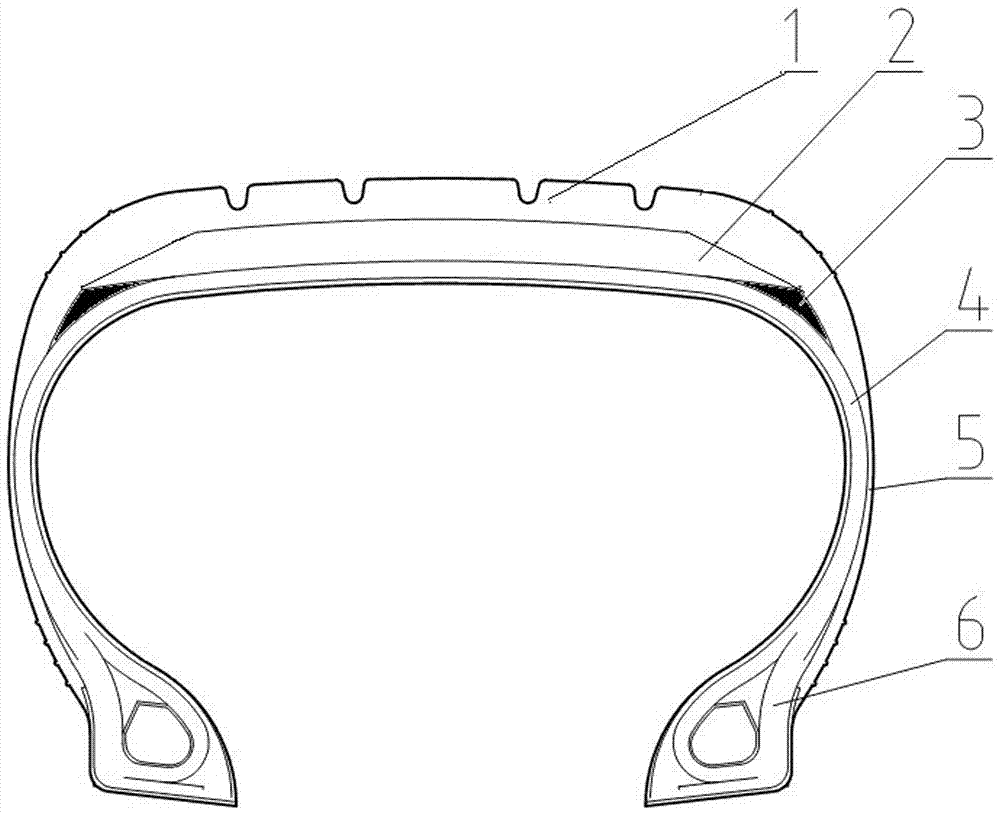

[0002] The carcass layer of aviation radial tire is the skeleton of the tire. In addition to bearing the air pressure of the tire, it also bears the load of the tire and buffers the external impact force. The cords of the radial tire carcass layer are arranged radially, and the radial deformation ratio of the sidewall Bias tires are 10% to 30% larger. In addition, the number of retreading of aviation radial tires is high. The existing aviation radial tires are caused by many reasons such as high speed and heavy load, large deformation of the sidewall, and the use of rubber materials and material compatibility. Carcass layer delamination, bulging, sidewall burst, etc. are prone to occur when the tire is rolling at high speed, which affects the service life and safety

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the examples, but the present invention is not limited thereto.

[0016] Raw material name Example 1 Example 2 1 # Smoked sheet glue

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

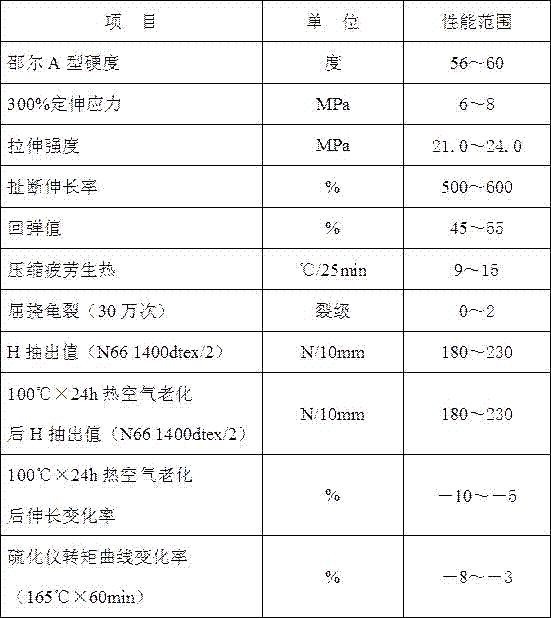

The invention discloses a carcass layer tread rubber of an aviation radial tire. A crude rubber system of the carcass layer tread rubber jointly adopts natural rubber and butadiene rubber; a reinforcement system adopts STERLIN V (SV) carbon black and adopts parts of white carbon black; accessory ingredients, including silane coupling agent KH-560, binding agent SL-3090, adhesion promoter AIR-201, adhesion promoter AIR-1 and the like, are added into a formula. The carcass layer tread rubber disclosed by the invention has the advantages of low hardness and stress at definite elongation, soft rubber material and small possibility of generating gaps during repeated deformation; the carcass layer tread rubber can be suitable for the performance requirements of high speed, high load and high refurbishment frequency of a novel tire in the future; before and after ageing, the carcass layer tread rubber has the advantages of high bonding strength of the rubber material and a nylon cord, good fatigue durability, low heat generation, high rebound value and small hysteresis loss; a carcass layer of the tire can be protected from delamination, swelling and tire side puncturing, and the service life and the safe performance of the aviation radial tire are improved.

Description

technical field [0001] The invention relates to the technical field of high polymer materials, in particular to rubber coating for carcass layers of aviation radial tires. Background technique [0002] The carcass layer of aviation radial tire is the skeleton of the tire. In addition to bearing the air pressure of the tire, it also bears the load of the tire and buffers the external impact force. The cords of the radial tire carcass layer are arranged radially, and the radial deformation ratio of the sidewall Bias tires are 10% to 30% larger. In addition, the number of retreading of aviation radial tires is high. The existing aviation radial tires are caused by many reasons such as high speed and heavy load, large deformation of the sidewall, and the use of rubber materials and material compatibility. Carcass layer delamination, bulging, sidewall bursting, etc. are prone to occur when the tire rolls at high speed, which affects the service life and safety. Contents of the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L7/00C08L9/00C08K13/02C08K3/04C08K3/36C08K5/5435C08K3/22C08K5/09C08K5/18B60C1/00

CPCB60C1/0041C08L7/00C08L2201/08C08L2205/03C08L9/00C08K13/02C08K3/04C08K3/36C08K5/5435C08K2003/2296C08K5/09C08K5/18

Inventor 吴春齐俞华英刘蓉

Owner 中国化工集团曙光橡胶工业研究设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com