Pneumatic vehicle V-shaped torsion beam molding device

A pneumatic and vehicle-used technology, which is applied to molding tools, vehicle parts, transportation and packaging, etc., can solve the problems of time-consuming and laborious positioning of parts, difficulty in distinguishing left and right directions, and increased labor intensity of workers, so as to achieve low labor intensity and mold clamping Fast, easy-to-shape effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

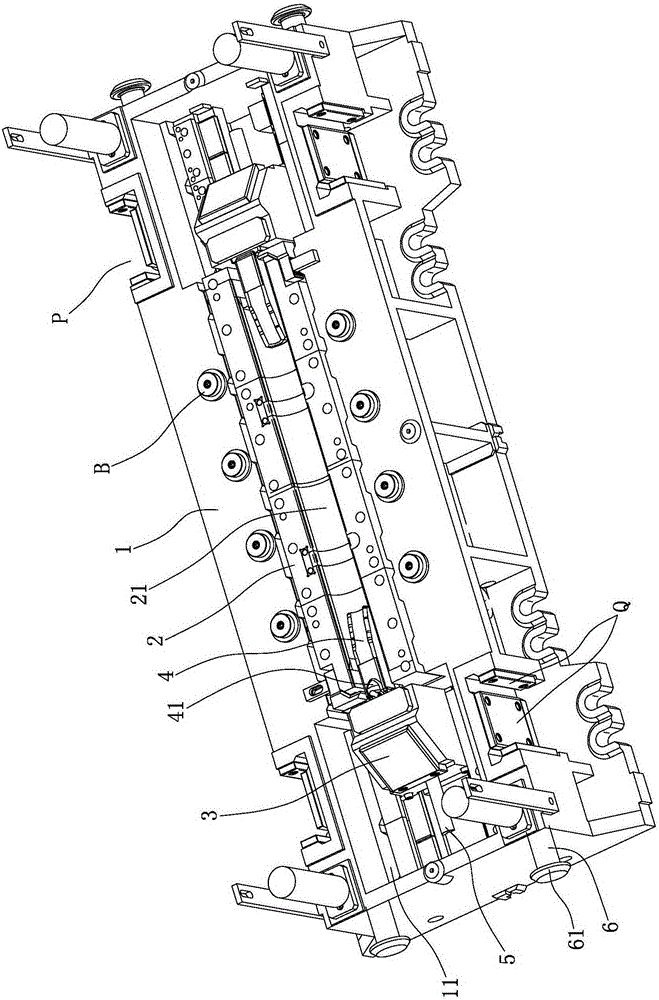

[0015] Such as figure 1 As shown, the mold base 1 is formed by casting. A group of lifting lugs 6 are respectively arranged on the left end surface and the right end surface of the mold base 1, and each group of lifting lugs 6 is divided into front and rear two, and four lifting lugs 6 are distributed in a rectangle on the same horizontal plane. The lifting lug 6 is a cylinder, one end of the lifting lug 6 is fixed to the mold base 1 , and the other end of the lifting lug 6 is integrally formed with an annular boss 61 . There are two rows of limit blocks B in the middle of the top surface of the mold base 1. The two rows of limit blocks B are separated on both sides of the forming groove. The two rows of limit blocks B are parallel and symmetrical. Two adjacent limit blocks B in the same row The distance between bit blocks B is equal. The limit block B is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com