Preparation method of bone tissue engineering porous ceramics scaffold

A technology of bone tissue engineering and porous ceramics, applied in tissue regeneration, pharmaceutical formulations, coatings, etc., can solve the problems of limitations, inability to embed and release drugs, and inability to ensure the distribution of microspheres, and achieve the effect of promoting tissue growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

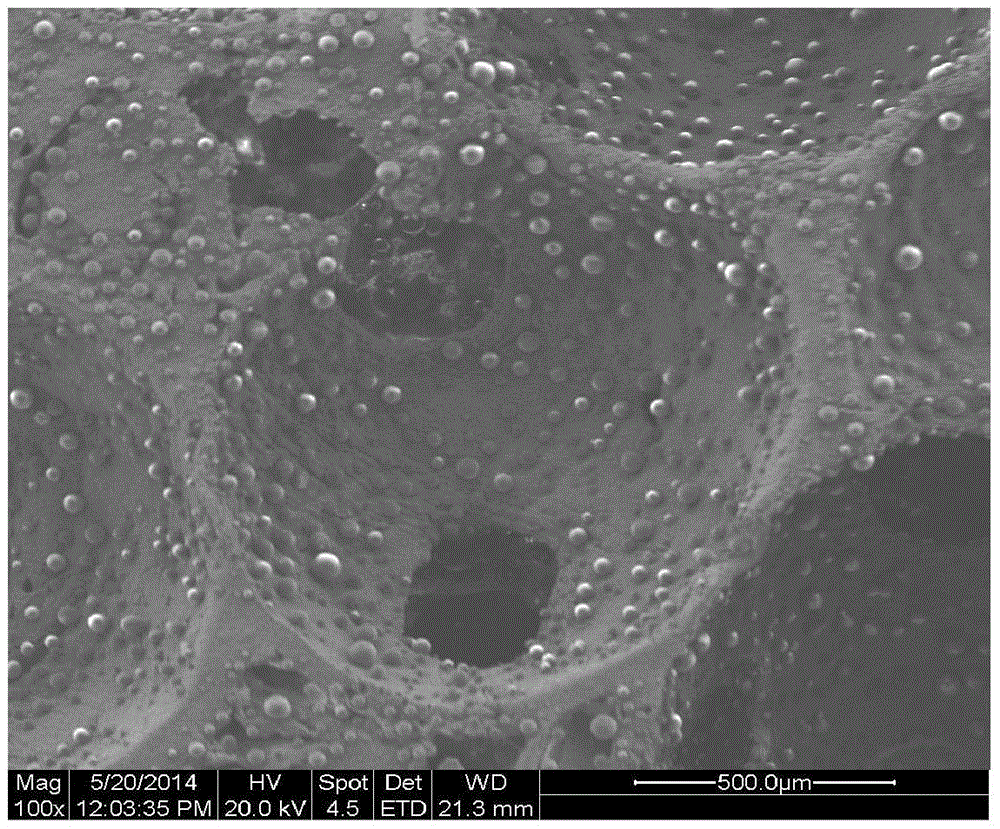

[0023] A, the preparation of drug-loaded microspheres: the chitosan of 0.25g is dissolved in the glacial acetic acid solution of 10ml2%, then add 0.125g salvianolic acid B and mix evenly, then 10ml salvianolic acid B / chitosan mixed solution Slowly add dropwise to the kerosene system in 100ml oil phase containing 2ml Span 80 and stir for 2h, then add 1ml6% glutaraldehyde and stir for 2h, then centrifuge to collect the prepared drug-loaded chitosan microspheres, respectively wash with isopropanol , after washing with ethanol and deionized water, the drug-loaded microspheres were prepared by freeze-drying after being frozen at minus -10°C.

[0024] B. Preparation of ceramic support: add 0.75g of chitin into dimethylacetamide solvent containing 5% lithium chloride, and then add 25g of inorganic powder to prepare inorganic powder / chitin slurry. Then the sugar ball particles are deposited in the bracket mold, and then heat treatment is carried out at a temperature of 60°C for 10 min...

example 2

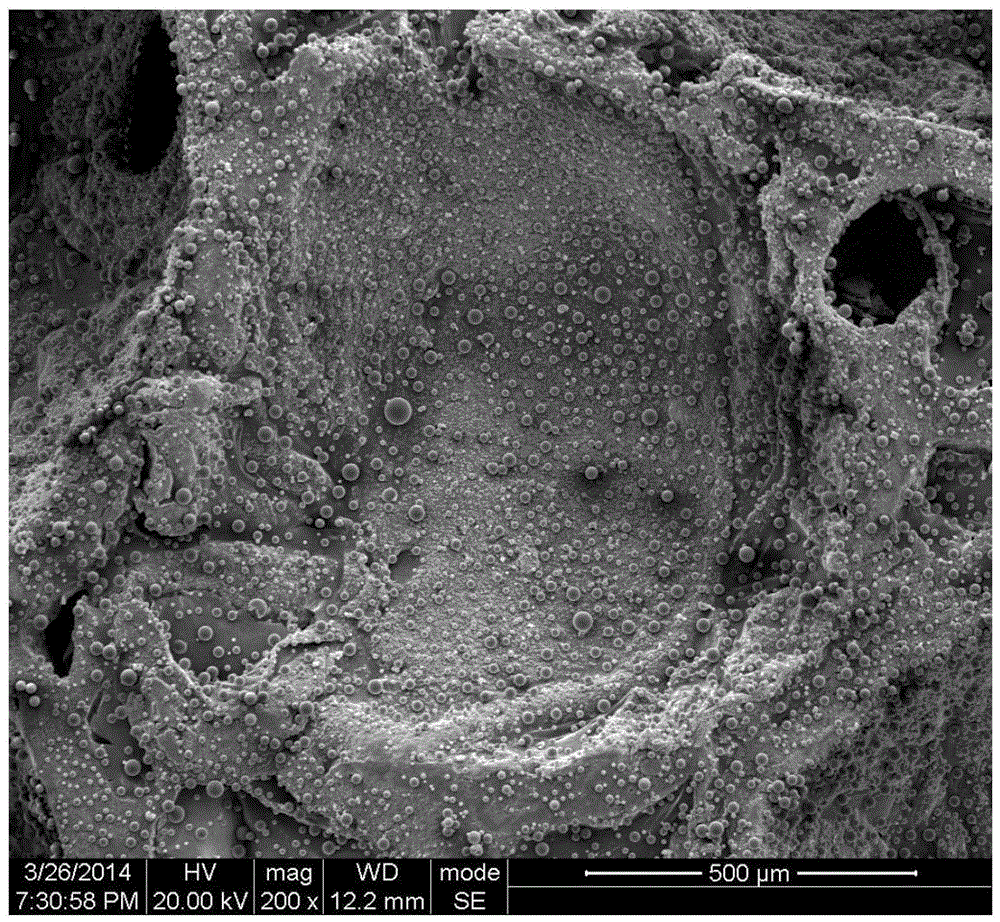

[0028] A, the preparation of drug-loaded microspheres: the chitosan of 0.25g is dissolved in the glacial acetic acid solution of 10ml2%, then adds 0.031g salvianolic acid B and mixes evenly, then 10ml salvianolic acid B / chitosan mixed solution Slowly add dropwise to the kerosene system in 100ml oil phase containing 2ml Span 80 and stir for 2h, then add 1ml25% glutaraldehyde and stir for 2h, then centrifuge to collect the prepared drug-loaded chitosan microspheres, respectively wash with isopropanol , after washing with ethanol and deionized water, the drug-loaded microspheres were prepared by freeze-drying after being frozen at minus -10°C.

[0029] C. Preparation of coated alginic acid stent: Dissolve 0.5g of alginic acid in 100ml of deionized water to prepare the alginic acid solution, immerse the porous stent in step B in the above-mentioned alginic acid solution for 10min and take it out at a speed of 2000r / min under centrifugation. Repeat 4 times, take out after immersin...

example 3

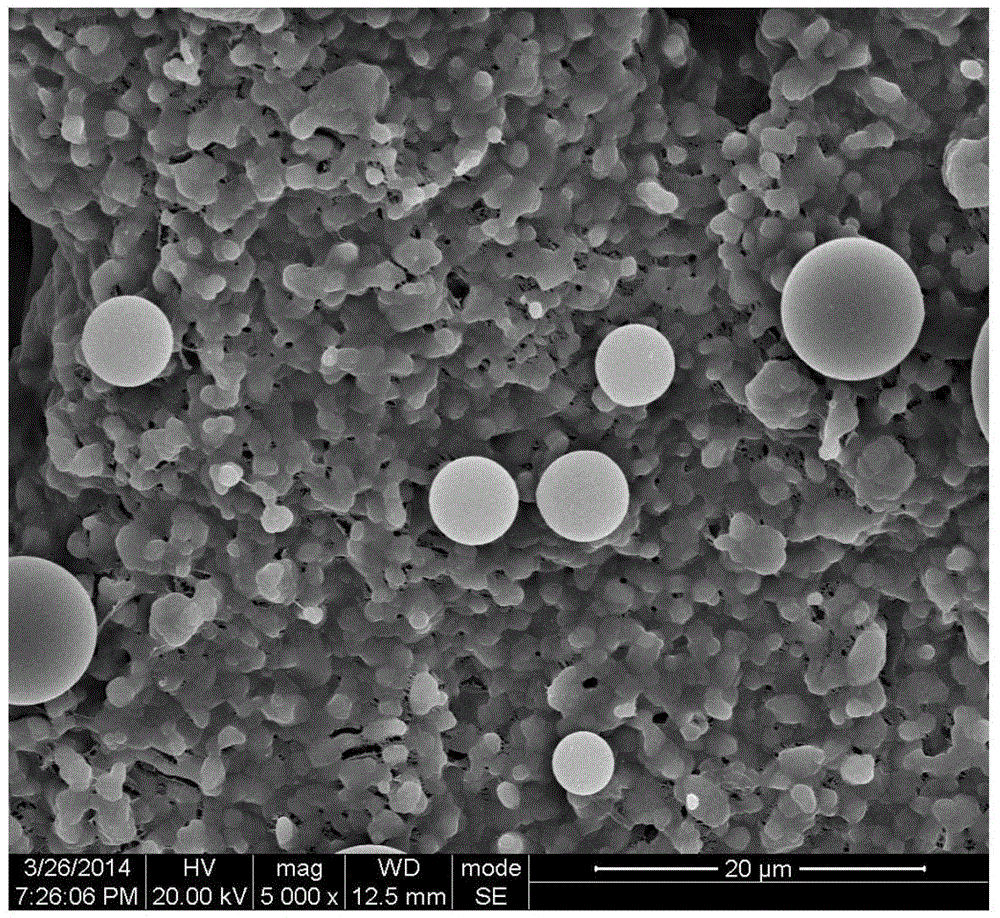

[0033] A. Preparation of drug-loaded microspheres: Dissolve 0.5g of chitosan in 10ml of 2% glacial acetic acid solution, then add 0.063g of bone morphogenetic protein and mix evenly, then mix 10ml of bone morphogenetic protein / chitosan mixture Slowly added dropwise to the 100ml liquid paraffin system containing 2ml Span 80 and stirred for 2h, then added 25ml5% sodium tripolyphosphate and stirred for 3h, then centrifuged to collect the prepared drug-loaded chitosan microspheres, respectively with petroleum ether, iso After washing with propanol and deionized water, the drug-loaded microspheres were prepared by freeze-drying after freezing at minus -10°C.

[0034] C. Preparation of coated alginic acid stent: Dissolve 1.3g of alginic acid in 100ml of deionized water to prepare an alginic acid solution, immerse the porous stent in step B in the above-mentioned alginic acid solution for 10 minutes and take it out at a speed of 2000r / min under centrifugation. Repeat 4 times, take o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com