Feeding device for cores of multi-level flywheels

A technology of feeding device and core, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high labor intensity and high operational danger of manual feeding, and achieve the effect of releasing labor and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

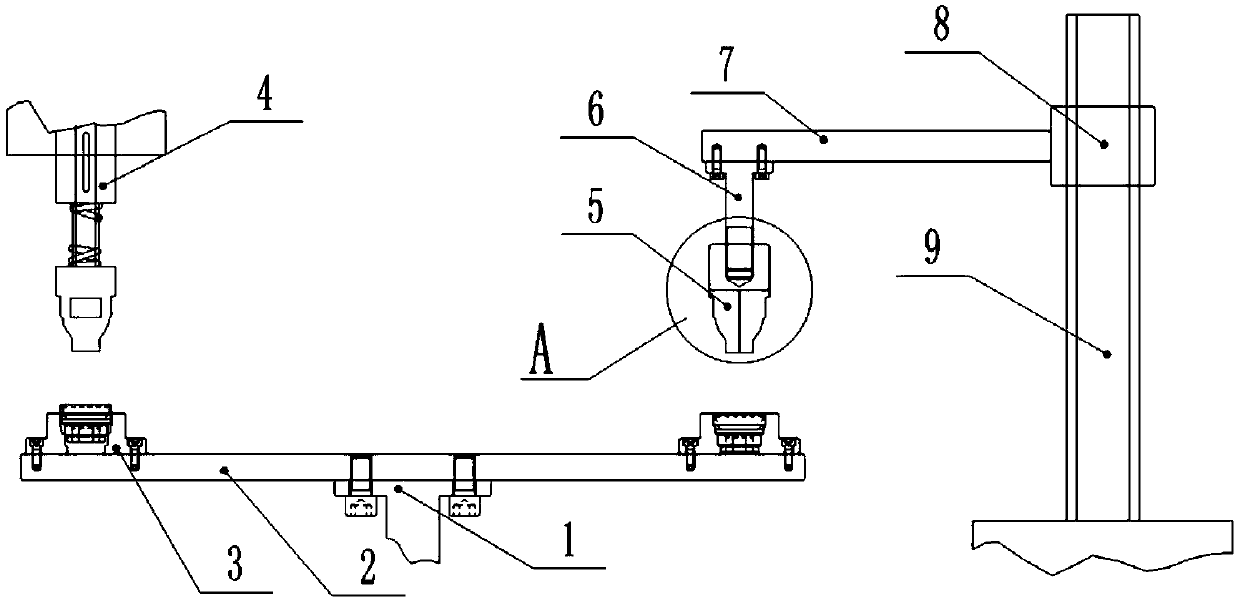

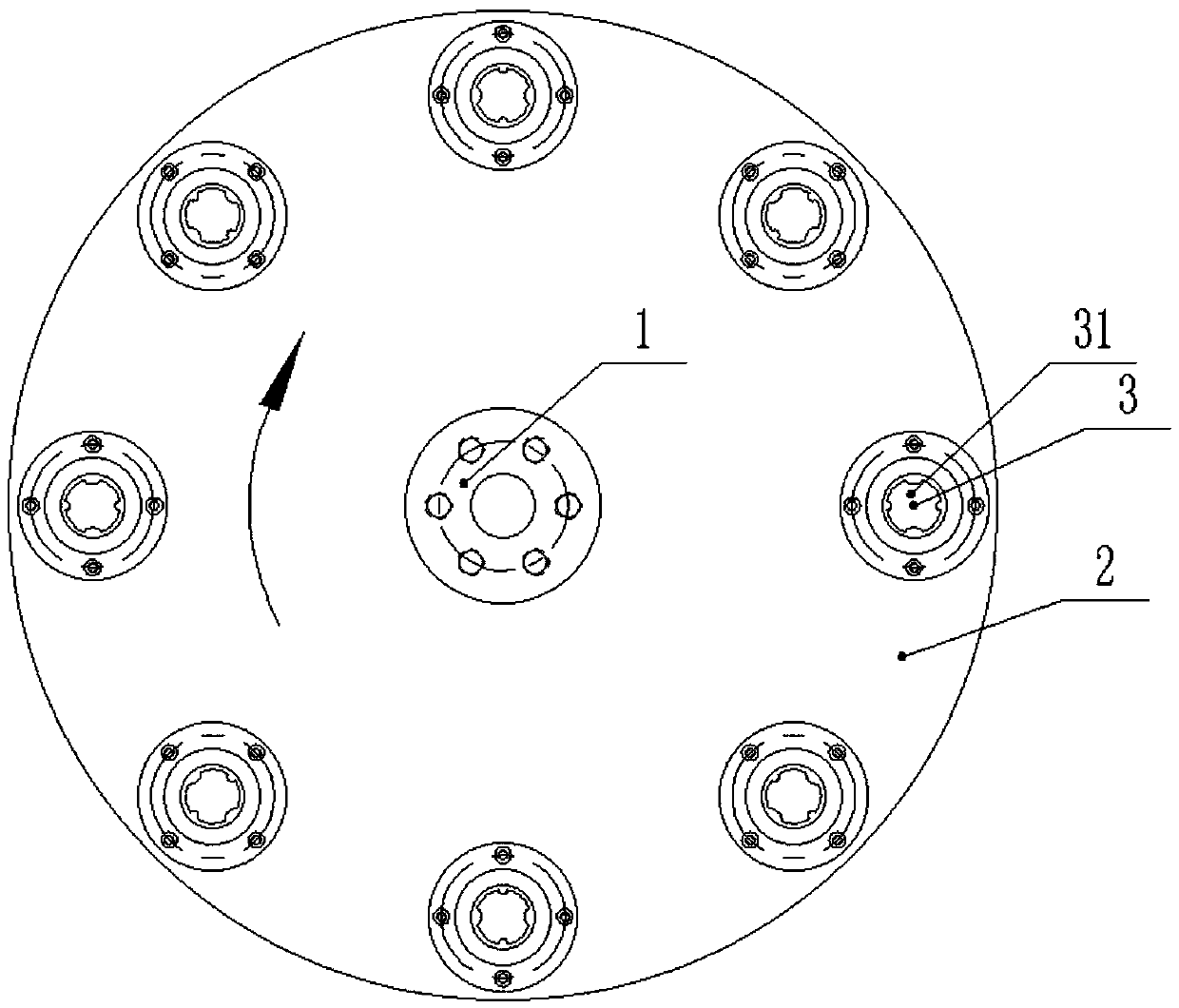

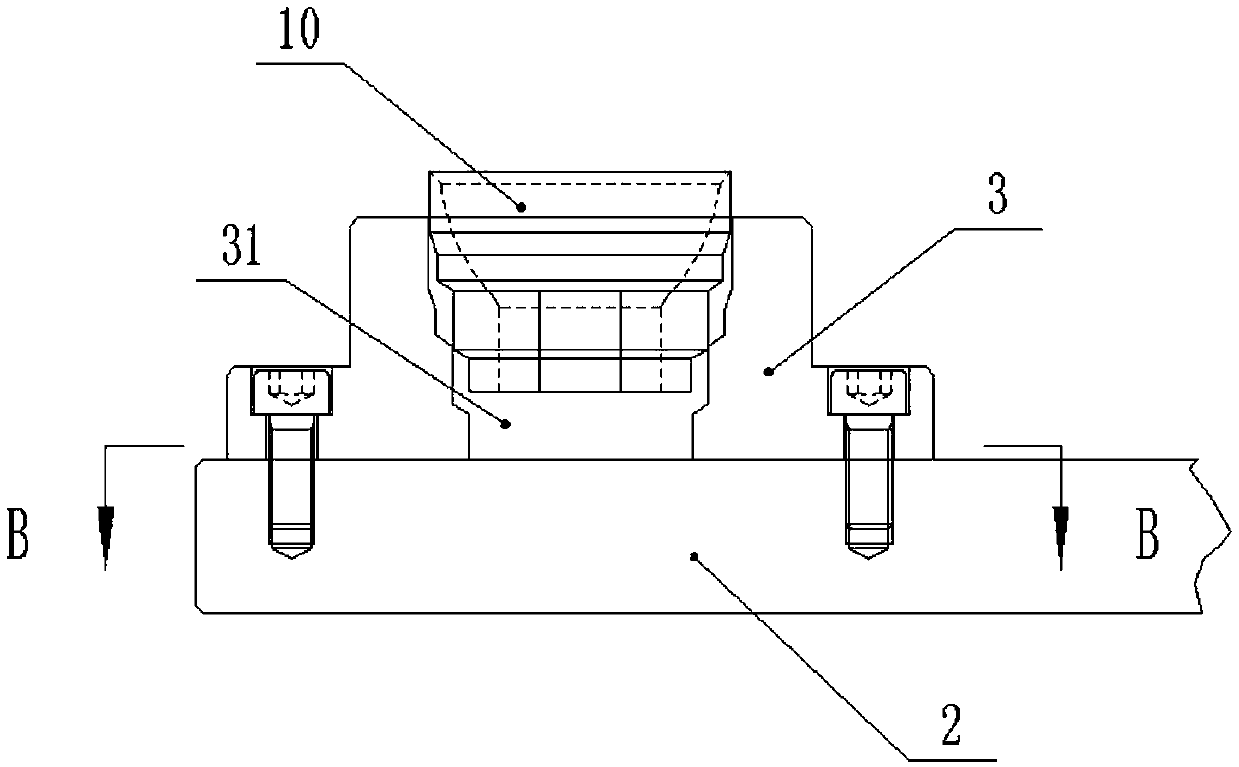

[0028] Such as figure 1 , figure 2 As shown, a feeding device for a core of a multi-stage flywheel according to an embodiment of the present invention includes a turntable 2, the lower end of which is connected to a cam divider through a flange 1, and is driven by the cam divider to rotate clockwise, and the turntable 2 is evenly distributed with positioning molds 3 on the disk surface, and the middle part of the positioning mold 3 is processed with a positioning cavity 31 for placing the core 10 (see image 3 , Figure 4 ); the deviation correction mechanism 4 is positioned at the upper left side of the turntable 2, and the deviation correction mechanism 4 includes a lifting platform 41 moving on a vertical line, a central axis 42 that can be lifted and rotated relative to the lifting platform 41 inside the lifting platform 41, and fixed The positioning head 44 at the lower end of the central axis 42, the electromagnet 45 built into the positioning head 44, the lifting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com