Thin-wall sheet metal part stamping molding method

A technology of stamping and sheet metal parts, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing manufacturing costs, affecting the reliability of parts, and shortening the manufacturing process of parts, so as to reduce the manufacturing cost of parts, The effect of eliminating potential safety hazards, huge economic value and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

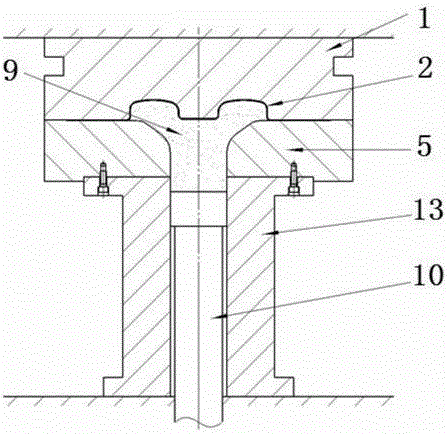

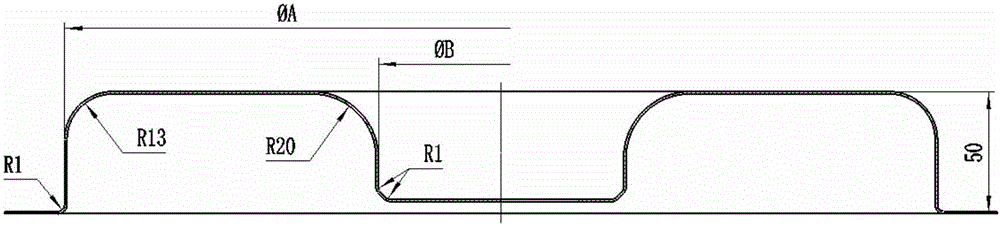

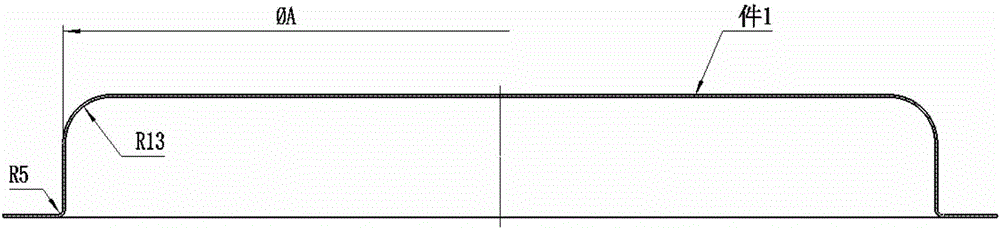

[0036] A thin-walled sheet metal part stamping forming method, the material of the thin-walled sheet metal part 2 as the workpiece is 0Cr17Ni4Cu4Nb stainless steel plate; the minimum forming transfer radius of the thin-walled sheet metal part 2 is R1mm; The rough outline of the overall blank of the wall sheet metal part is pre-processed, and the size of the pre-processed semi-finished product is not yet available, especially the small curvature bending deformation still needs to be dealt with; 0Cr17Ni4Cu4Nb stainless steel plate, the material room temperature stamping performance is poor, and the room temperature elongation is not 20%, according to the test, the maximum drawing ratio of 0Cr17Ni4Cu4Nb stainless steel plate with a thickness of 1mm is 1.25-1.3 for ordinary stamping and deep drawing. The forming deformation of this part is relatively large, and its drawing ratio exceeds 1.5 through calculation, and the minimum forming transfer radius of the part is only R1; See f...

Embodiment 2

[0050] The content of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0051] A thin-walled sheet metal part stamping forming method, the material of the thin-walled sheet metal part 2 as the workpiece is 0Cr17Ni4Cu4Nb stainless steel plate; the minimum forming transfer radius of the thin-walled sheet metal part 2 is R1mm; The rough outline of the overall blank of the wall sheet metal part is pre-processed, and the size of the pre-processed semi-finished product is not yet available, especially the small curvature bending deformation still needs to be dealt with; 0Cr17Ni4Cu4Nb stainless steel plate, the material room temperature stamping performance is poor, and the room temperature elongation is not 20%, according to the test, the maximum drawing ratio of 0Cr17Ni4Cu4Nb stainless steel plate with a thickness of 1mm is 1.25-1.3 for ordinary stamping and deep drawing. The forming deformation of this part is relatively large, and its drawin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com