Material taking and stamping device for hot-forging processing

A stamping device and material reclaiming device technology, applied in forging/pressing/hammer devices, operating devices, metal processing equipment, etc., can solve the problems of a large amount of labor cost input, affecting bolt processing efficiency, high labor intensity, etc., and achieve production and manufacturing costs Low, high degree of automation, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

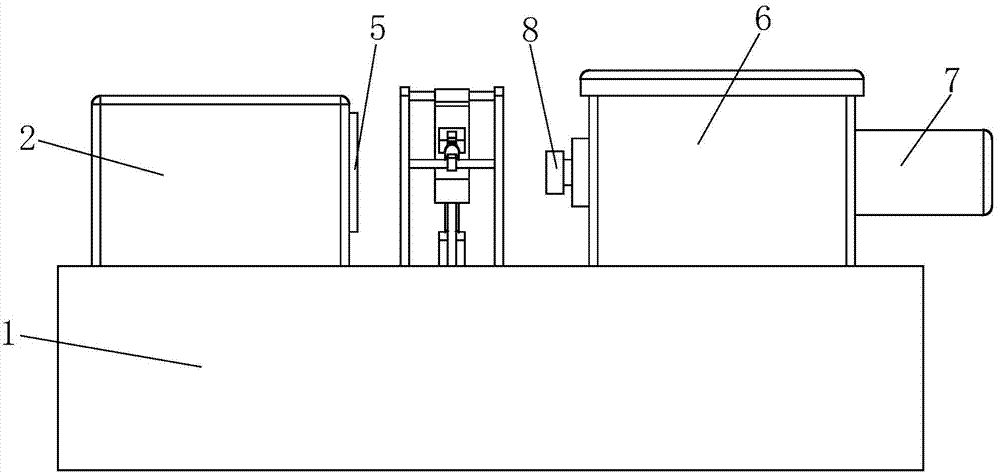

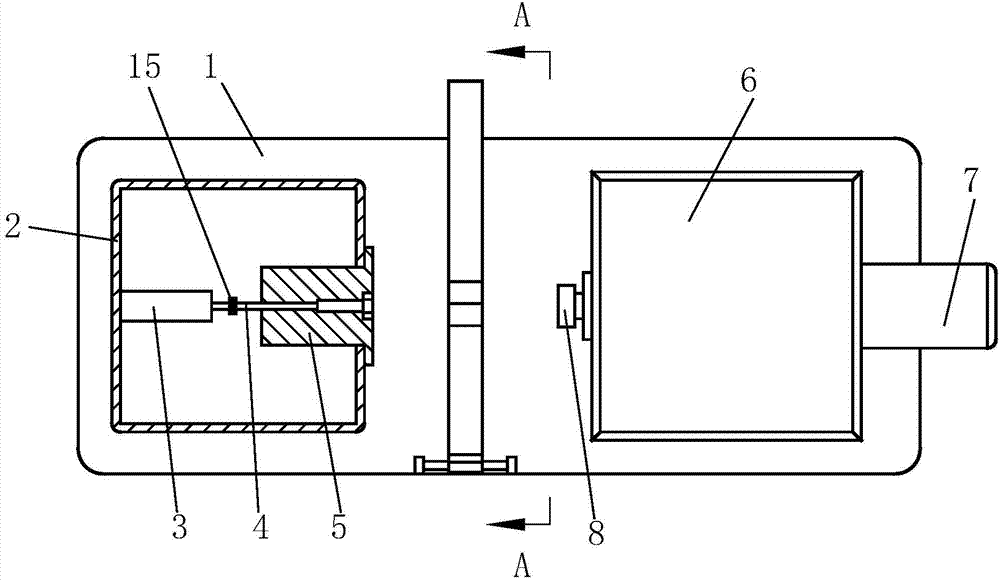

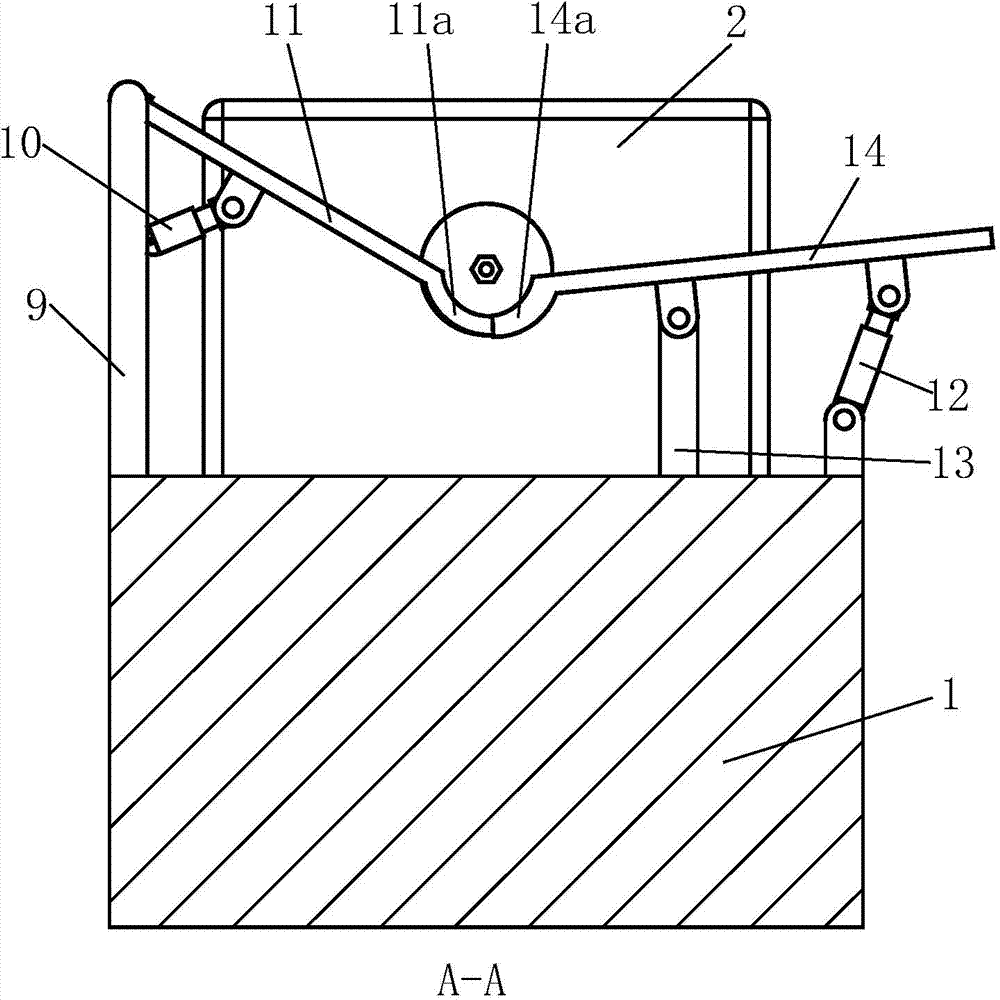

[0017] Such as Figure 1 to Figure 4 As shown, a retrieving and stamping device for red beating processing includes a retrieving device and a punching device, and the retrieving device is installed in the middle of the upper end of the punching device. The take-off device can automatically remove the bar after the external heating equipment completes the heat treatment of the bar, and guide the bar to a determined position, then start the stamping device, and use two stampings to finish The bolt is stamped from the bar stock to complete the bolt forming process.

[0018] The stamping device includes a stamping table 1, a mold holder 2, a discharge cylinder 3, a coupling 15, a discharge push rod 4, a bolt die 5, a cylinder holder 6, a stamping cylinder 7 and a punch 8. The mold fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com