Automatic welding device for automobile rear axle housing

An automatic welding and rear axle housing technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high equipment investment, large floor space, affecting welding efficiency, etc., to reduce equipment floor space and save energy. Equipment cost and the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

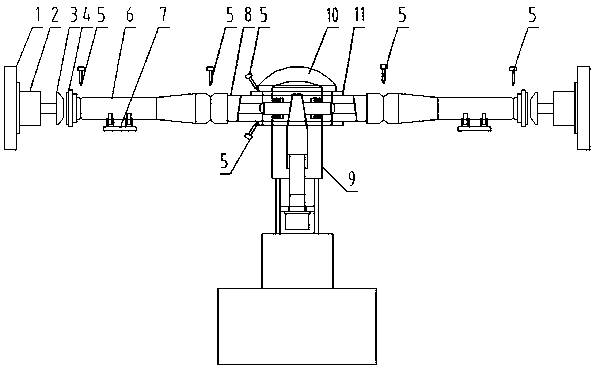

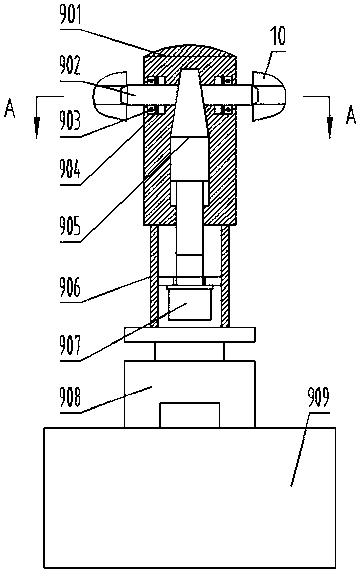

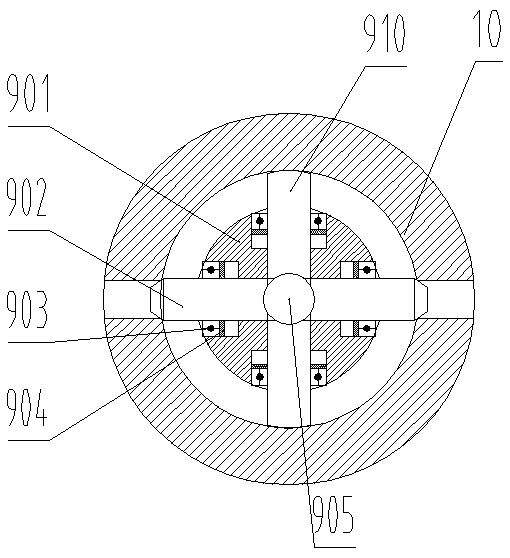

[0023] see Figure 1 to Figure 4 , an automatic welding device for the rear axle housing of an automobile, comprising a clamping plate 3 and a rotary clamping mechanism 9, characterized in that: the rotary clamping mechanism 9 is vertically arranged, and the rotary clamping mechanism 9 includes a wedge 905, The oblique wedge seat 901, the first ejector rod 902, and the second ejector rod 910, the oblique wedge 905 is a tapered structure, the cross section of the first end of the first ejector rod 902 is a wedge-shaped structure, and the cross section of the second end is tapered structure, the first push rod 902 is arranged symmetrically 180° in the first chute of the wedge seat 901, the cross section of the first end of the second push rod 910 is a wedge structure, the cross section of the second end is an arc structure, and the second The ejector rod 910 is arranged symmetrically at 180° in the second chute of the wedge seat 901, the first chute and the second chute form an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com