Hub polishing machine and using method thereof

A technology for polishing machines and hubs, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., which can solve the problems of inconsistent polishing stripes, low pass rate, and uneven finish of products, and reduce intermediate handling Process and safety hazards, increase production and qualification rate, and the effect of simple operation of machinery and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

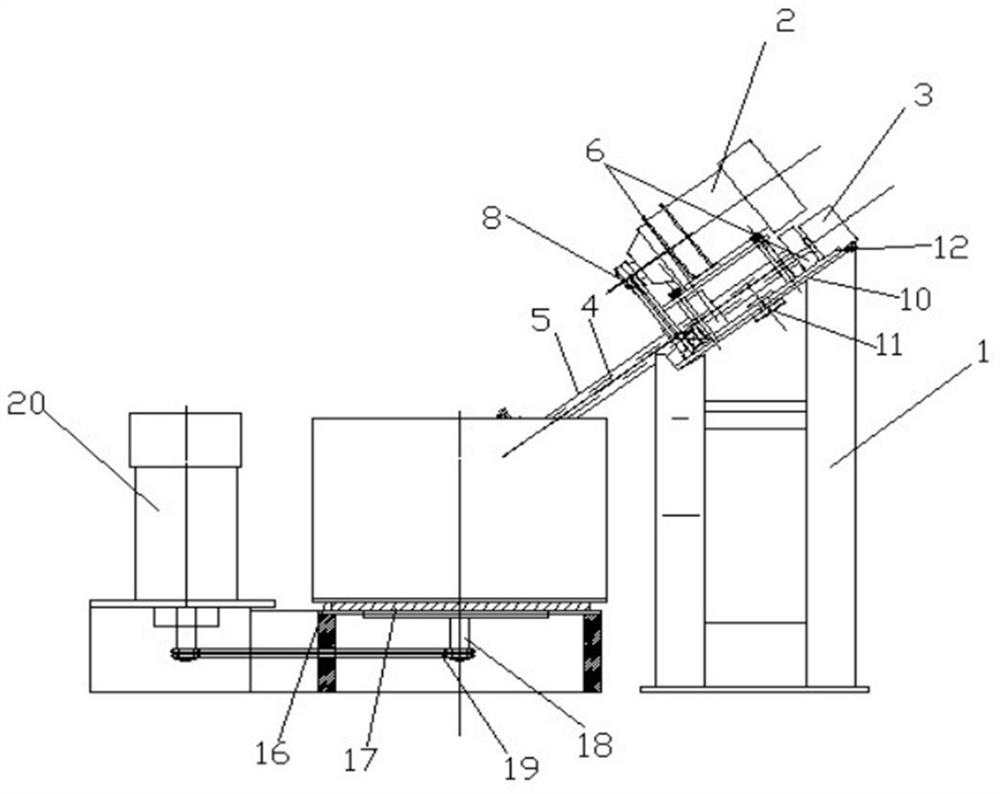

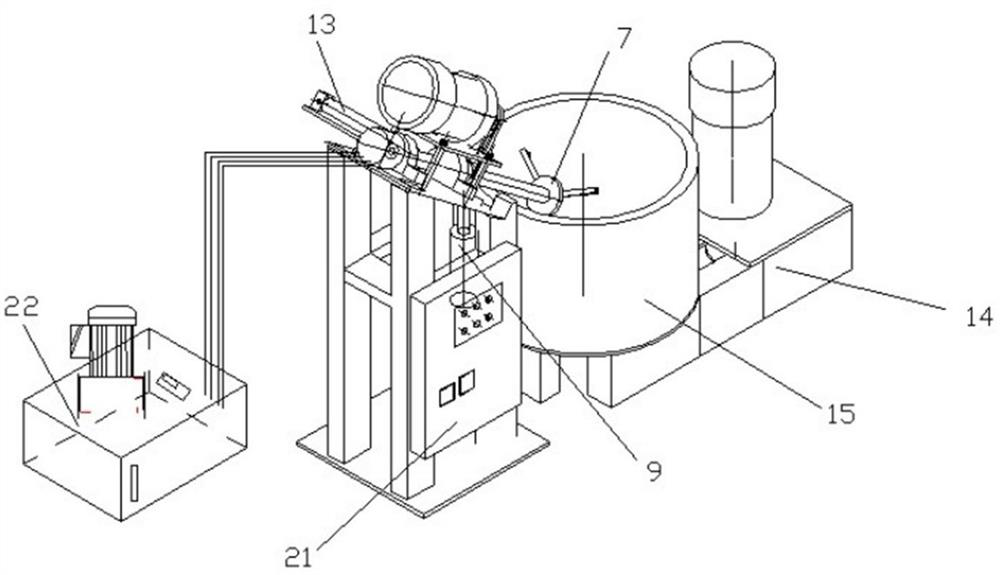

[0050] A wheel hub polishing machine, including a frame 1, a horizontal straight-side motor 2, a hollow rotary cylinder 3, a cylinder connecting rod 4, a rotating main shaft 5, a vertical bearing 6, a three-jaw chuck 7, a sprocket combination A 8, and a lift Oil cylinder 9, lifting plate 10, positioning pin 11, rotating plate 12, cylinder 13, seat frame 14, vertical drum 15, drum supporting plate 16, flange bearing plate 17, drum bottom shaft 18, sprocket combination B 19 , vertical motor 20, control cabinet 21, hydraulic station 22,

[0051] Frame 1 is an integrated structure made of square tube welding with length*width*height 900MM*700MM*2100MM.

[0052] The horizontal direct-connected motor 2 is composed of a forward and reverse motor and a gearbox group, and is fixed on the rotating plate 12 after being tensioned by a chain.

[0053] The hollow rotary oil cylinder 3 is an existing technology, and the hydraulic station 22 provides a driving force, and the internal piston ...

Embodiment 2

[0077] A wheel hub polishing machine, including a frame 1, a horizontal straight-side motor 2, a hollow rotary cylinder 3, a cylinder connecting rod 4, a rotating main shaft 5, a vertical bearing 6, a three-jaw chuck 7, a sprocket combination A 8, and a lift Oil cylinder 9, lifting plate 10, positioning pin 11, rotating plate 12, cylinder 13, seat frame 14, vertical drum 15, drum supporting plate 16, flange bearing plate 17, drum bottom shaft 18, sprocket combination B 19 , vertical motor 20, control cabinet 21, hydraulic station 22,

[0078] Frame 1 is an integrated structure made of square tube welding with length*width*height 900MM*700MM*2100MM.

[0079] The horizontal direct-connected motor 2 is composed of a forward and reverse motor and a gearbox group, and is fixed on the rotating plate 12 after being tensioned by a chain.

[0080] The hollow rotary oil cylinder 3 is an existing technology, and the hydraulic station 22 provides a driving force, and the internal piston ...

Embodiment 3

[0104] The present invention also relates to a method for using a hub polishing machine, comprising the following steps:

[0105] A: Turn on the power supply of the control cabinet 21 and compress the air;

[0106] B: The control cabinet 21 panel starts the hydraulic station 22 to raise the lifting cylinder 9 to the highest point, and at the same time ejects the cylinder 13 so that the three-jaw chuck 7 is outside the vertical drum 15, then lowers the lifting cylinder 9 to the bottom point, and passes The hollow rotary cylinder 3 opens the three-jaw chuck 7 to clamp and fix the hub;

[0107] C: Lift the lifting cylinder 9 to the highest point, return the cylinder 13, and lower the lifting cylinder 9 into the vertical drum;

[0108] D: Start the horizontal direct-connected motor 2 and the vertical motor 20;

[0109] E: According to the original set speed and time, stop running after reaching the set value;

[0110] F: Reverse operation to take out the wheel hub, the control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com