Siphon-type degreasing device and degreasing method thereof

A degreasing device and a siphon-type technology, applied in the field of degreasing, can solve the problems of unreasonable furnace structure, slow degreasing speed, inconvenience in taking out finished products, etc., and achieve the effects of saving energy consumption, improving degreasing speed, and reducing intermediate handling processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

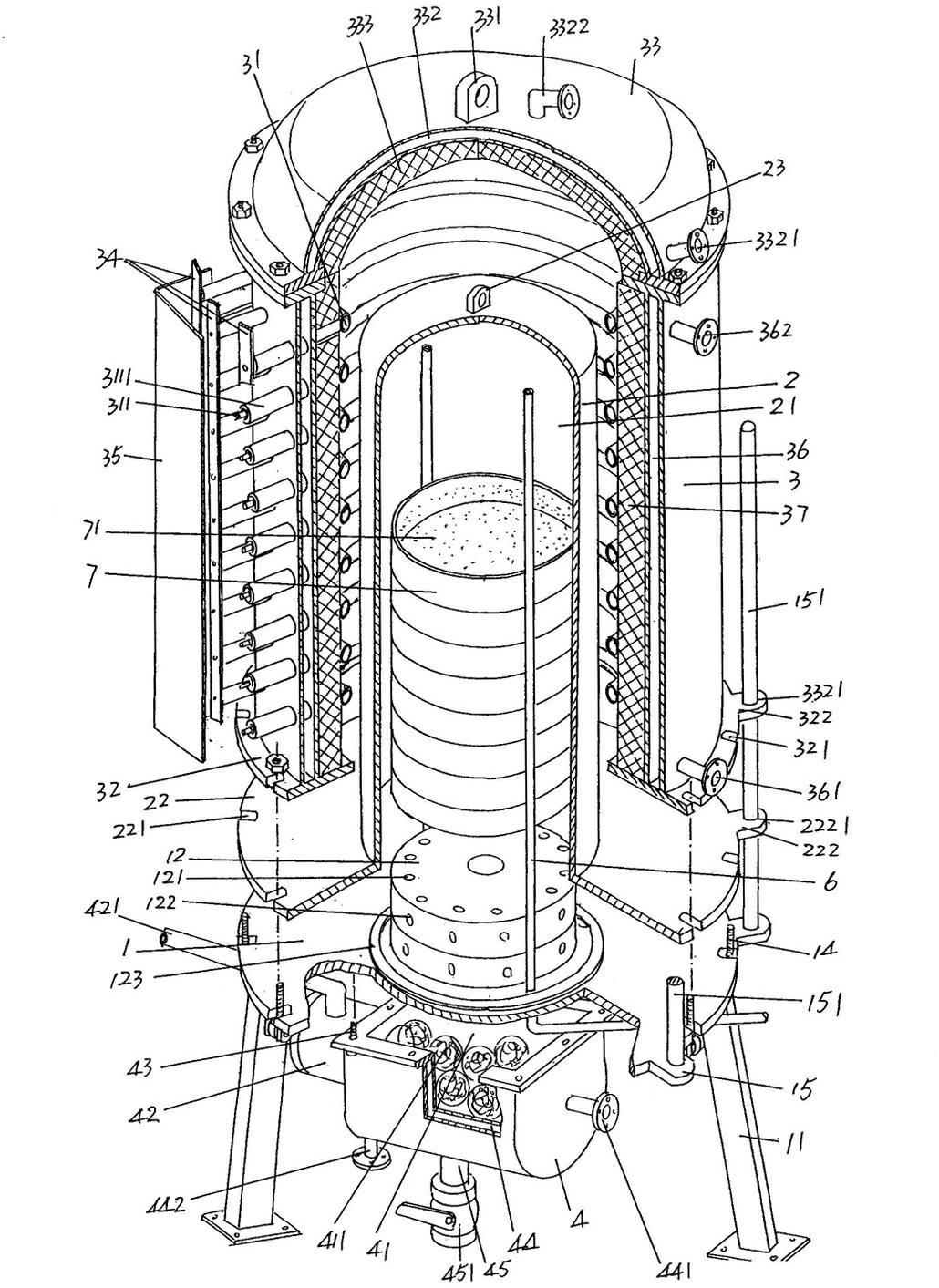

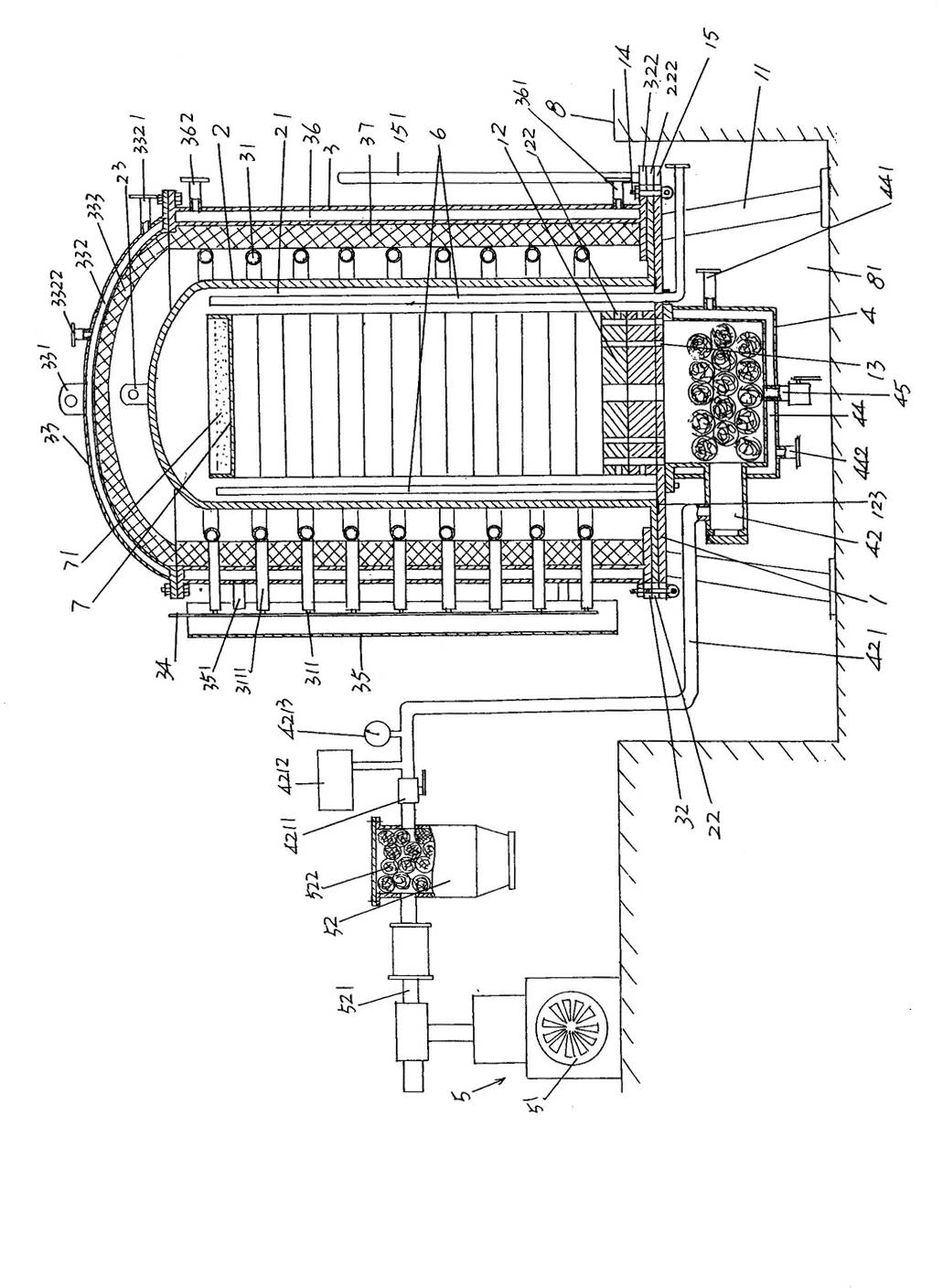

[0027] please see figure 1 and figure 2 , a furnace platform 1 is given, and the furnace platform 1 has a group of vacating feet 11 for vacating the furnace platform 1 on the floor of the place of use, that is to say, the furnace platform 1 and the floor are kept At a certain distance, a group of furnace platform through holes 13 ( figure 2 shown), a pair of bases 12 are stacked at the position corresponding to the through hole 13 of the furnace platform. Of course, the number of bases 12 is not limited by the number shown in the figure, for example, it can be as few as one or as many as three or more. Its function is mainly used to adjust the height. On the base 12, a group of longitudinal through-holes 121 are spaced apart from one side of the base 12 to the other side. A group of transverse through-holes 122 are spaced apart in the circumferential direction of the base 12, and each transverse through-hole 122 communicates with the aforementioned longitudinal throu...

Embodiment 2

[0042] Only change the material of the blank in step A) to iron powder, and the diameter is 10mm, and the thickness is 1.5mm; the vacuum degree in step B) is changed to 50Pa; the temperature of the furnace cavity 21 in step C) is changed to Raise to 70°C, change the holding time to 120min, change the protective gas to nitrogen, change the flow rate to 0.75L / min, change the temperature to continue heating to 550°C, change the holding time to 180min, change the heating temperature to pre-sintering Be 700 ℃, heat preservation time is changed into 30min, and all the other are the same as the description to embodiment 1.

Embodiment 3

[0044] Only change the material of the blank in step A) to cemented carbide powder, change the diameter to 20mm, and change the thickness to 3mm; change the vacuum degree of step B) to 30Pa; change the temperature of the furnace cavity 21 in step C) Change it to 80°C, change the holding time to 180min, change the protective gas to nitrogen, change the flow rate of the protective gas to 1L / min, change the temperature to continue heating to 500°C, change the holding time to 200min, and pre-sinter the heating The heating-up temperature is changed into 850 ℃, and the soaking time is changed into 120min, and all the other are the same as the description to embodiment 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com