Quasi-orthogonal optical wedge adjustment mechanism

An adjustment mechanism, quasi-orthogonal technology, applied in optics, optical components, installation and other directions, can solve the problems of complex structure, high assembly accuracy requirements, intolerant of shock and vibration, etc., to achieve easy use, small size, and improved adjustment accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

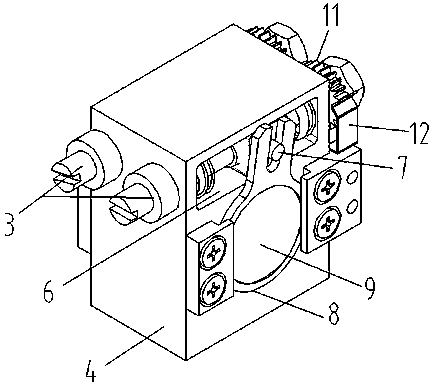

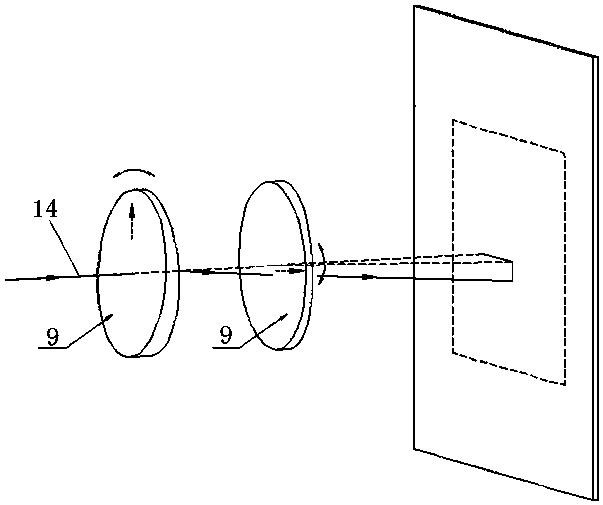

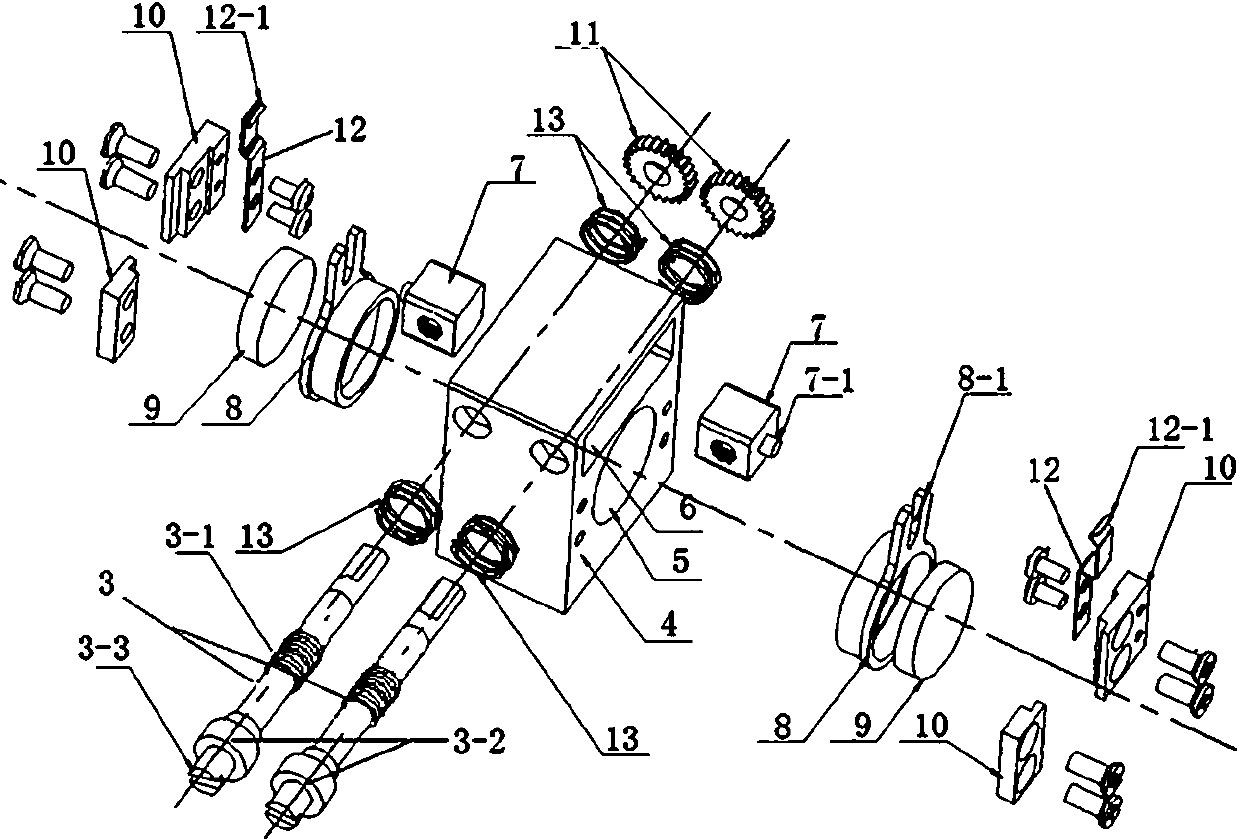

[0040] When the quasi-orthogonal optical wedge adjustment mechanism is in use, it has a hollow equipment box 1, a laser transmitter 2 is fixedly installed at the rear end of the equipment box 1, and a quasi-orthogonal optical wedge adjustment mechanism is fixedly installed in front of the laser transmitter 2; On the equipment box 1, there is a light channel through hole at the position directly in front of the quasi-orthogonal optical wedge adjustment mechanism, and the optical axis 14 used for the laser transmitter 2 to emit laser light is emitted after the position is adjusted by the quasi-orthogonal optical wedge adjustment mechanism. ; One side of the equipment box 1 is provided with two through holes of equal size, which are used for the top of the adjustment screw 3 on the quasi-orthogonal optical wedge adjustment mechanism to protrude for easy adjustment.

[0041] On the outer wall of the equipment box 1, a scale is provided on the edge of the adjusting screw 3 for conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com