Main factory building structure system for large-scale thermal power plant

A technology for factory owners and workshops, which is applied in building structures, industrial buildings, buildings, etc., and can solve problems such as severe torsion resistance, heavy equipment loads, and staggered floors in high-intensity areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

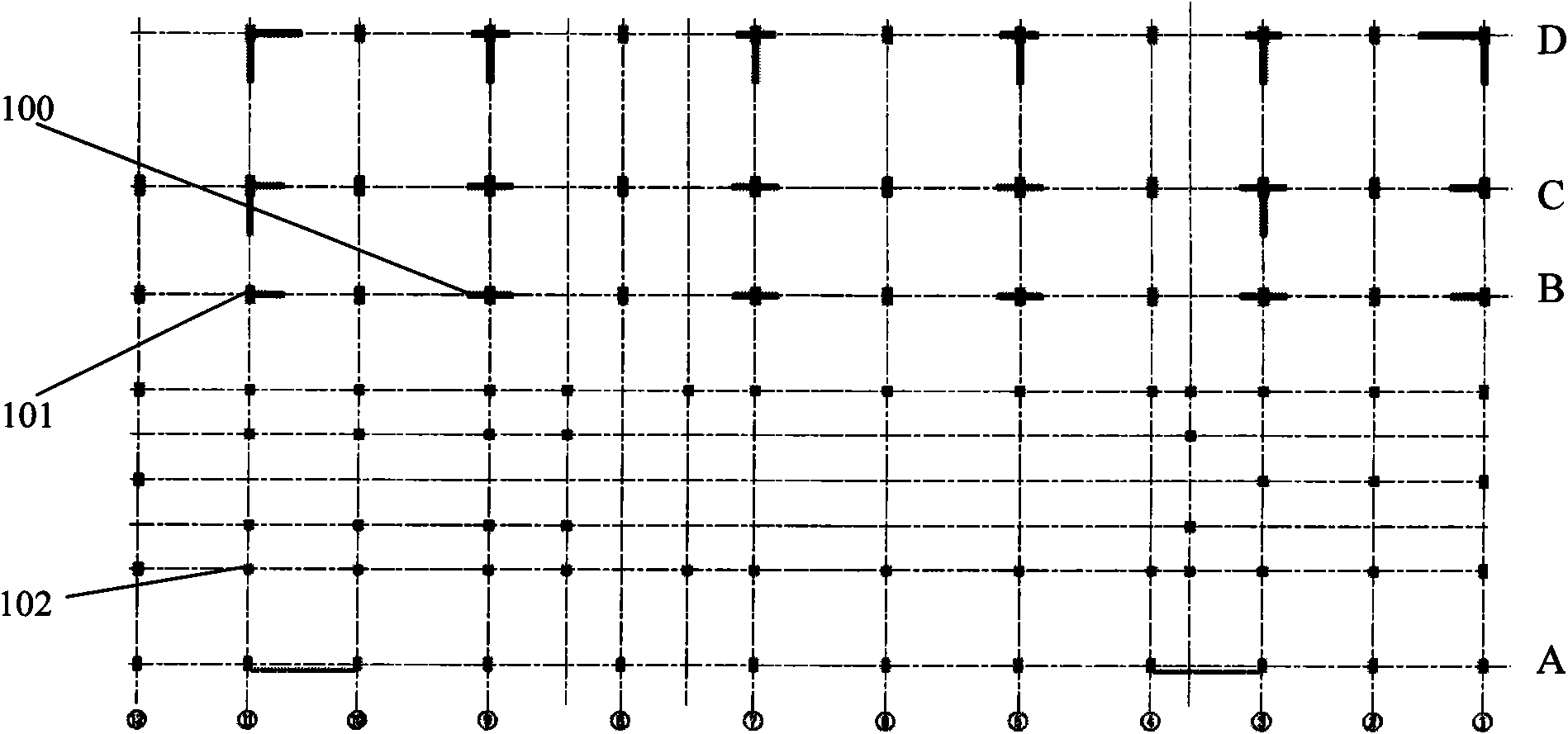

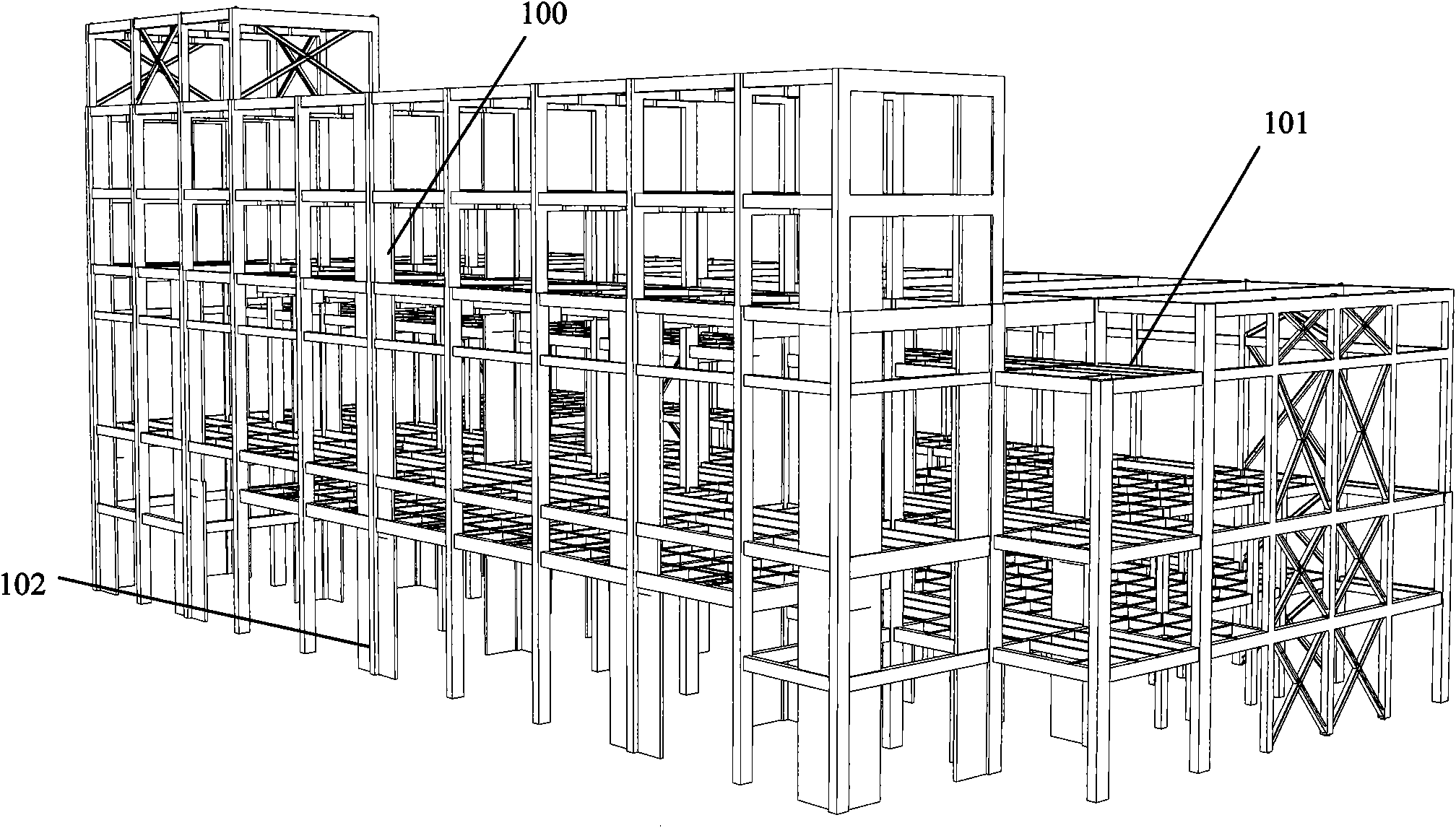

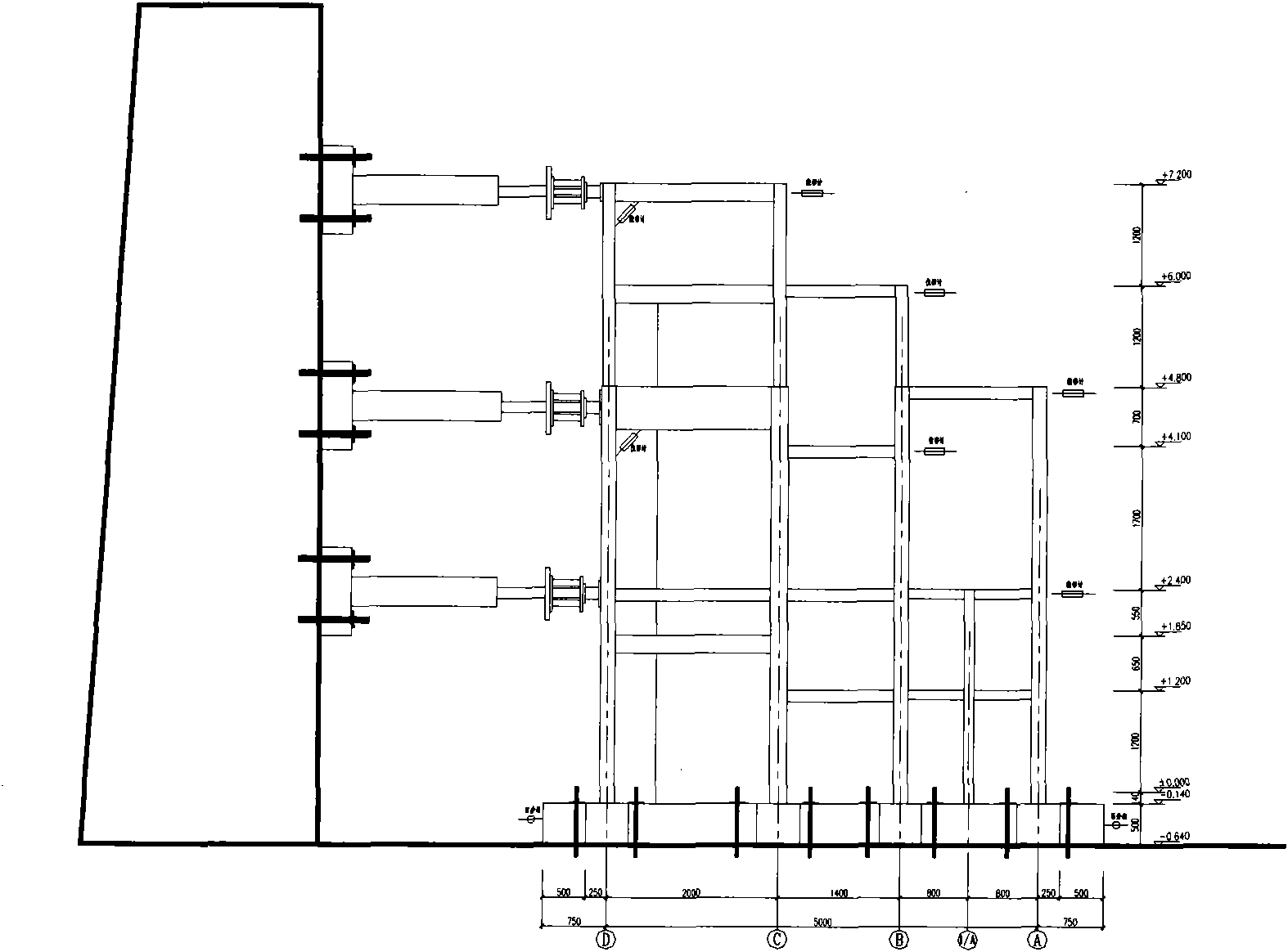

[0030] The structural system of the main factory building of the present invention adopts a steel concrete frame-reinforced concrete shear wall hybrid structure, such as figure 1 , figure 2 As shown, the planar column network in this embodiment has 12 longitudinal axes in total, and the distance between the main axes is between 10 and 12 m. For the convenience of description, the length direction of the structural system is defined as the horizontal direction, and the width direction of the structural system is defined as the vertical direction. There are 7 horizontal axes in the planar column network. Columns A to B are listed as the frame of the turbine room, and the distance between the four horizontal axes on one side is 8.3m. Columns up to D are listed as frames between coal bunkers with a span of 14m. Among them, the coal bunker room and the oxygen removal room are integrated multi-layer frame structures, while the turbine room adopts the form of bent frames.

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com