Automatic trolley transferring line used for casting heat treatment furnace group workshop and transferring method

A heat treatment furnace and trolley technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of not being able to meet large-scale, multi-variety logistics operations, etc., to achieve intelligent logistics transportation, optimize process layout, and improve transfer efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

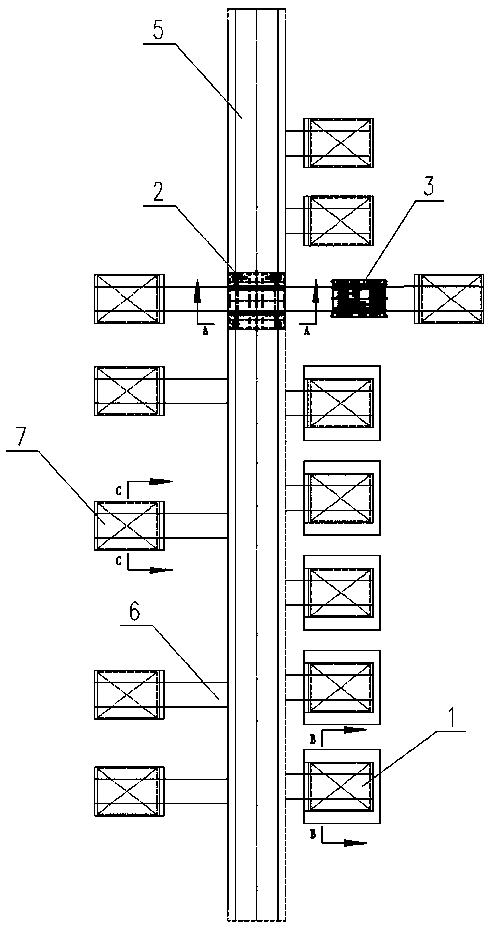

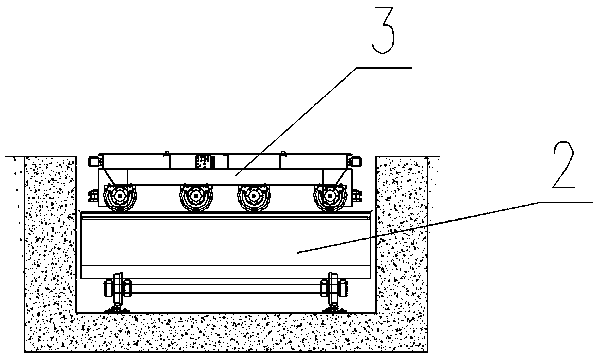

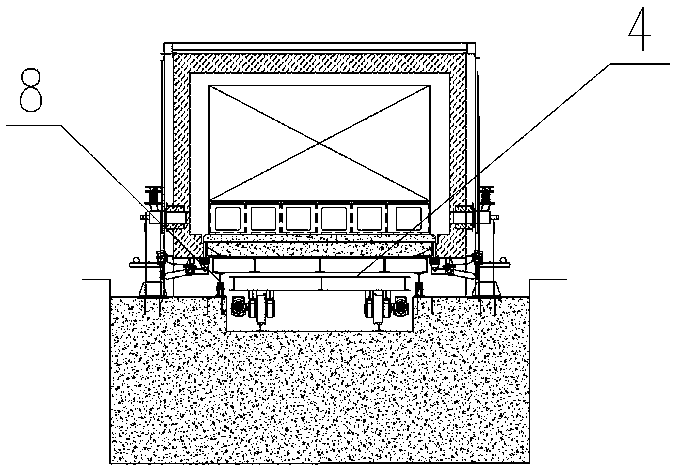

[0015] Such as Figure 1-4 As shown, the automatic trolley operation line for the foundry heat treatment furnace group workshop according to the present invention includes multiple heat treatment furnaces 1 and trolleys, each trolley includes a mother car 2 and a sub-car 3 driven by external force, and the sub-car 3 is used to load the pallet 4. The top of the sub-cart 3 is provided with a jacking mechanism and a positioning mechanism for matching with the pallet 4. Specifically, the jacking mechanism is designed to be driven by a hydraulic cylinder, and the top of the sub-cart 3 is designed according to the position of the supporting point of the pallet. 4 jacking hydraulic cylinders, the jacking height is 50mm; the positioning mechanism is a hole and shaft matching structure, and 4 positioning shafts are designed on the diagonal direction of the upper plane of the sub-cart 3. Four positioning holes are designed. After the jacking mechanism is lowered, the positioning shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com