IGBT variable-frequency power source for energy-saving intermediate-frequency smelting furnace

A variable frequency power supply and smelting furnace technology, which is used in electrical components, structural components of conversion equipment, and the conversion of AC power input to AC power output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

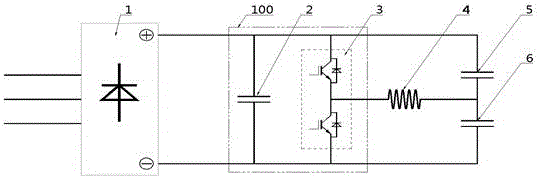

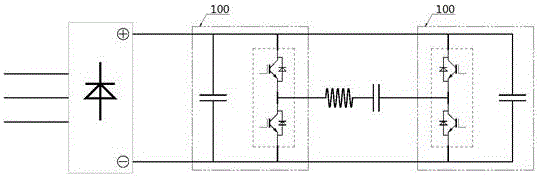

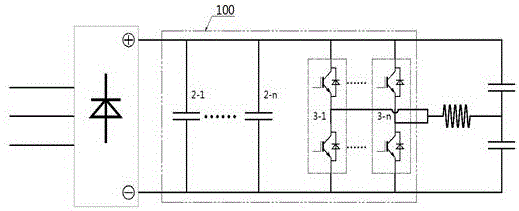

[0027] Referring to the above attached drawings: at figure 1 Among them, a half-bridge series resonant inverter circuit is composed of an equivalent structural unit 100, an induction coil 4, an upper resonant capacitor 5, and a lower resonant capacitor 6; figure 2 Among them, a full-bridge series resonant inverter circuit is composed of two equivalent structural units 100, an induction coil, and a resonant capacitor.

[0028] An energy-saving IGBT frequency conversion power supply for an intermediate frequency melting furnace, comprising a frequency conversion power supply cabinet, a diode rectifier bridge 1, a filter capacitor 2, an IGBT module 3, an induction coil 4, an upper resonant capacitor 5 and a lower resonant capacitor 6, characterized in that:

[0029] The variable frequency power supply cabinet is provided with one or more structural units 100 composed of filter capacitor 2, water cooling box 15, IGBT module 3, connecting copper bars and current transformers 13, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com