Compound fertilizer particle cooling and screening equipment

A kind of screening equipment and compound fertilizer technology, which is applied in the direction of filtration, solid separation, and separation of solids from solids by air flow, etc. It can solve the problems of increasing the rework rate of fertilizer granulation, poor turning effect, troublesome turning, etc. problem, to achieve good cooling and screening effect, reduce crushing rate, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

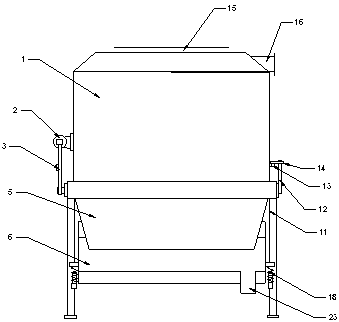

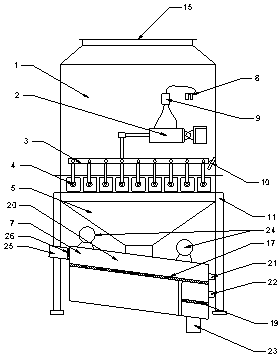

[0017] see Figure 1-2 , a compound fertilizer granule cooling and screening equipment, comprising a cooler 1, a buffer bucket 5, a screening device 6 and a frame 11, the cooler 1 is located at the upper end of the frame 11, the lower end of the cooler 1 is provided with a buffer bucket 5, and the buffer The outlet of the bucket 5 is connected to the inlet of the screening device 6, and both sides of the screening device 6 are fixedly connected to the frame 11 through springs 18. The top of the cooler 1 is provided with a cooler feed port 15, and the upper part of the side of the cooler 1 is provided with Cooler air outlet 16, the lower part of the cooler is provided with a flap 4, and the upper side of the flap 4 is provided with a cylinder 2 and a swing arm 3, and the cylinder 2 is connected to the flap 4 through the swing arm 3, and the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com