Automatically-controlled hydraulic material dividing device

A material distribution device and hydraulic device technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problem of increasing operation time, increasing system energy consumption, and material flow that cannot accurately meet the needs of workshops or boiler materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

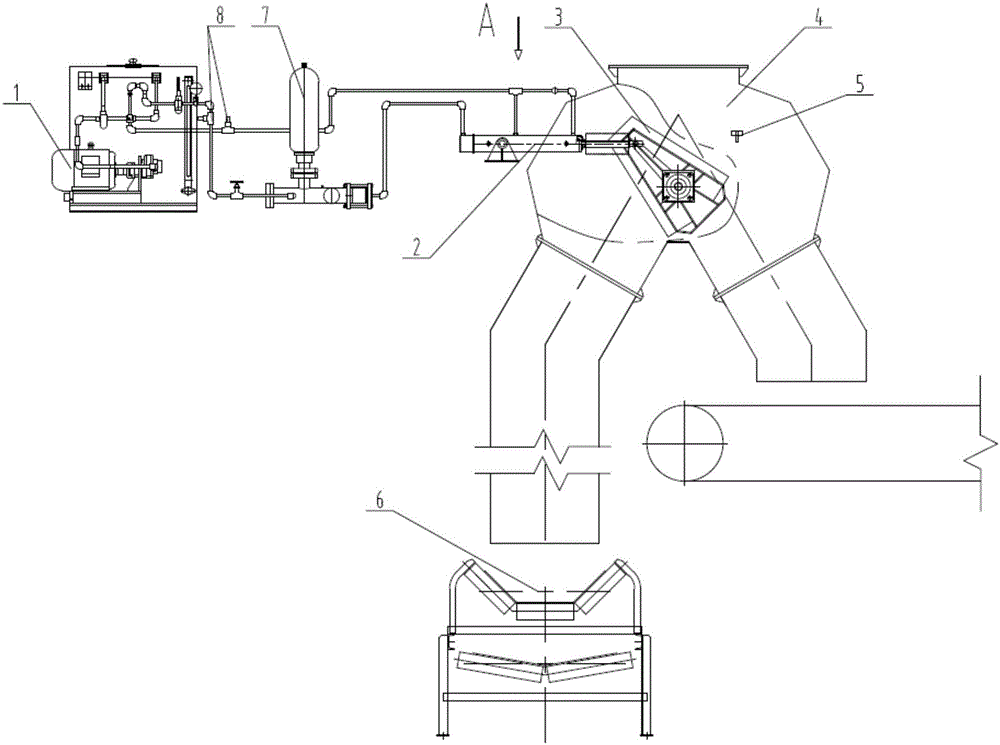

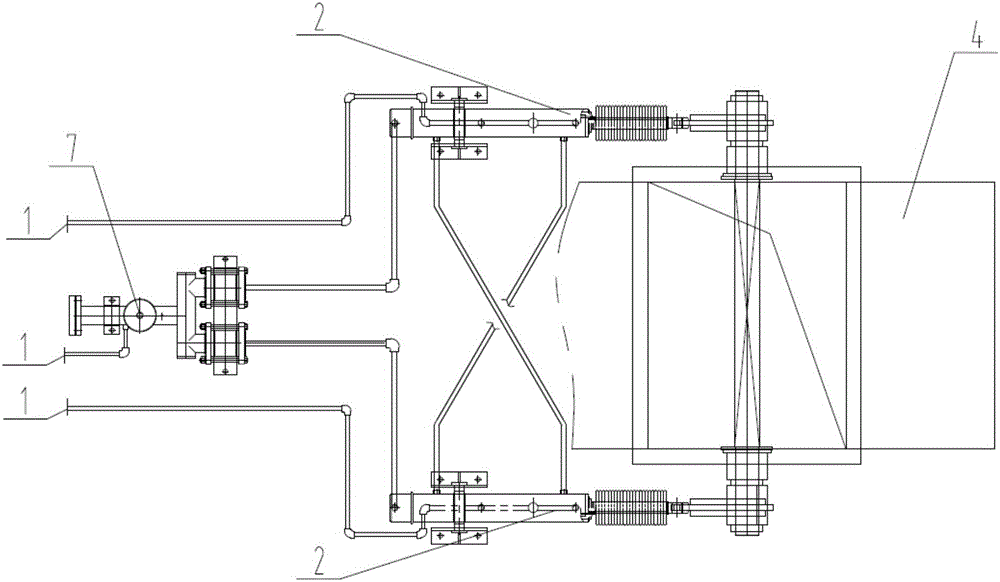

[0012] Referring to the accompanying drawings, an automatic control hydraulic material distribution device includes a hydraulic device 1, a transmission device 2, a material flow divider 3, a three-way body 4, a limit switch 5, a weighing tape machine 6, an impact stabilizer 7, and a locking adjustment The valve 8 and the material flow divider 3 are trapezoidal box structures, which are connected with the transmission device 2 through the rotating shaft. The main structure of the transmission device 2 is a hydraulic cylinder located on both sides of the three-way body 4. The hydraulic device 1 is closed with the transmission device 2 through the oil pipe. circuit, the position can be adjusted according to the actual working conditions on site, the impact stabilizer 7 and the lock regulating valve 8 are set on the oil circuit between the hydraulic device 1 and the transmission device 2, the weighing belt machine 6 is located at the bottom of the whole device, and the limit switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com