Rotatable hanging device and technique for vehicle painting production line

A coating production line and re-hanging technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of not being able to adapt to the requirements of large-scale production lines, restricting production efficiency, wasting time, etc., and achieving low cost and easy. Operational realization, reliable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

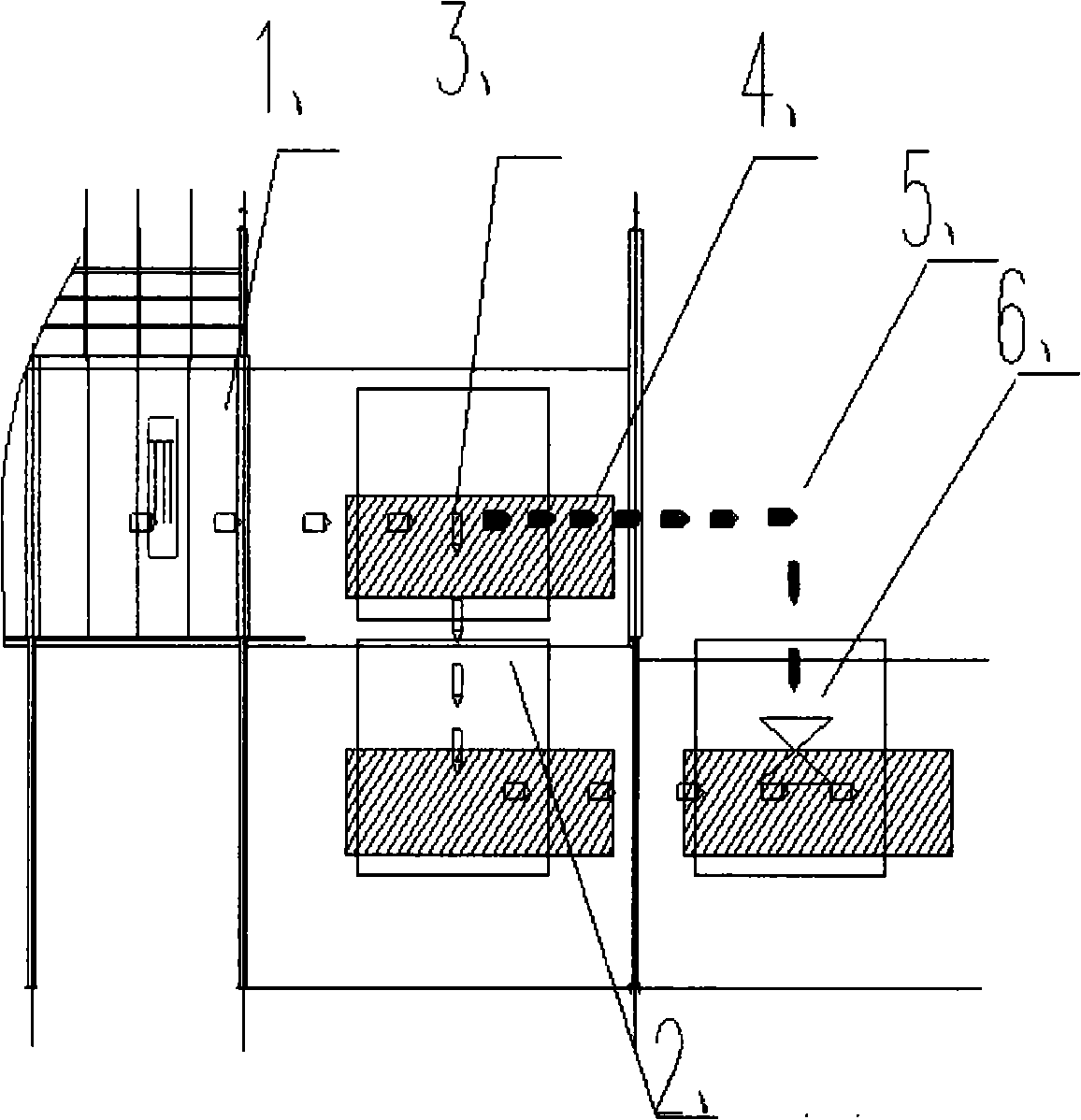

[0013] Such as figure 1 As shown, what the present invention relates to is a kind of process improvement that promotes automobile painting production capacity. The technical solution to be provided by the present invention is a hanging device used in an automobile painting production line, which includes a bottom plate where the lower parts are hung up, and a lifting section and a lowering section of the hanger for hanging the lower pieces. Between the descending segments, a pre-descending segment is added at the lateral position. The pre-descending section is located at the opening of the bottom plate of the hanging part of the lower part, and the opening is located at the front end of the descending section. A transfer and hanging process used in an automobile painting production line, including a lower part transfer and hanging process, an ascending process and a lowering process, and a pre-lowering station 2 is added to the lower part transferring and hanging process. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com