Method for polishing glass and polishing machine

A glass edging and edging machine technology, which is applied to machine tools, grinders, grinding/polishing equipment and other directions suitable for grinding the edge of workpieces, can solve the problem that the detection accuracy of glass finished products is difficult to guarantee, positioning efficiency and positioning accuracy are low, and Problems such as low production efficiency, to achieve the effect of eliminating mechanical positioning procedures, high production efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the drawings.

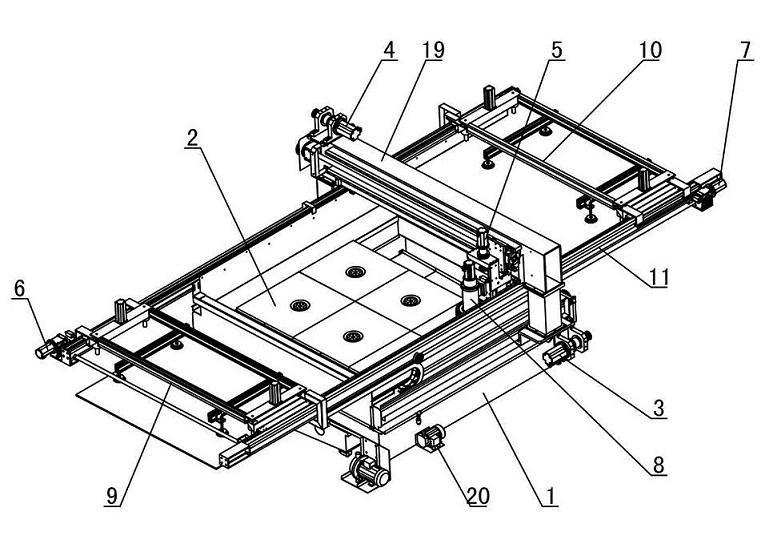

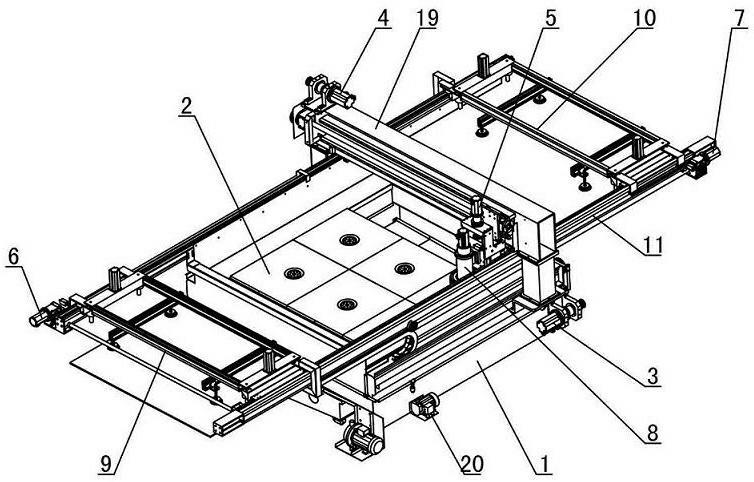

[0036] The glass edging method of the present invention is suitable for figure 1 The shown glass edging machine controlled by a numerical control system is used for edging processing of glass, which includes the following steps:

[0037] a. First, place the glass blank to be processed on the edging table 2 and fix it. Of course, before starting the edging procedure, the glass blank can be initially cut by cutting according to the shape of the final product to make It becomes a polygon formed by mutually perpendicular straight edges and connected hypotenuses, in order to minimize the machining allowance of the edging, and at the same time facilitate the determination of the reference point in step b. In addition, the glass blank can be sent to the edging worktable by a loading manipulator 9 for fixing. The loading manipulator can be equipped with a vacuum suction cup to facilitate the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com