Front wheel cover outer plate reinforcing plate flexible positioning device

A technology of positioning device and plate flexibility, applied in the field of tooling and fixtures, can solve the problems of difficult tooling switching, unfavorable process layout, and use in one vehicle, etc., and achieve the effect of facilitating process layout and simple tooling switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

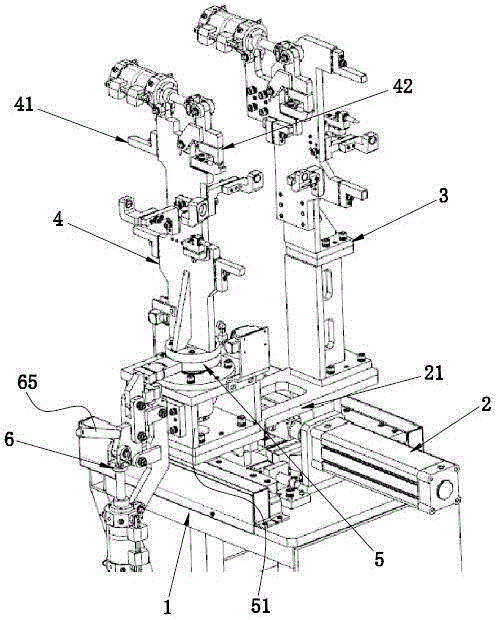

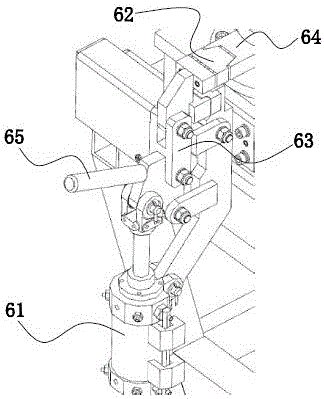

[0017] Such as figure 1 , figure 2 As shown, the present invention discloses a flexible positioning device for the front wheel house outer panel reinforcement plate, comprising a bracket 1, a translation mechanism 2 and a positioning mechanism, the translation mechanism 2 is installed on the bracket 1, and the positioning mechanism is located on On the translation mechanism 2, the position in the horizontal direction of the positioning mechanism can be adjusted by the translation mechanism 2, and the positioning mechanism includes a first positioning mechanism 3 and a second positioning mechanism 4, and the first positioning mechanism 3 and the second positioning mechanism The upper ends of the two positioning mechanisms 4 are provided with a positioning unit, and the lower end of the second positioning mechanism 4 is also provided with a rotating mechanism 5 and a locking mechanism 6. The second positioning unit 42 is set in the opposite direction of the unit 41, so that it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com