Vertical spinning machine

A spinning machine and vertical technology, applied in the field of vertical spinning machines, can solve problems such as low centering accuracy of the spindle tail top, inability to perform staggered spinning, and circumferential slipping of parts, etc., to achieve high-efficiency one-time compounding Convenient forming and staggered spinning, controllable plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

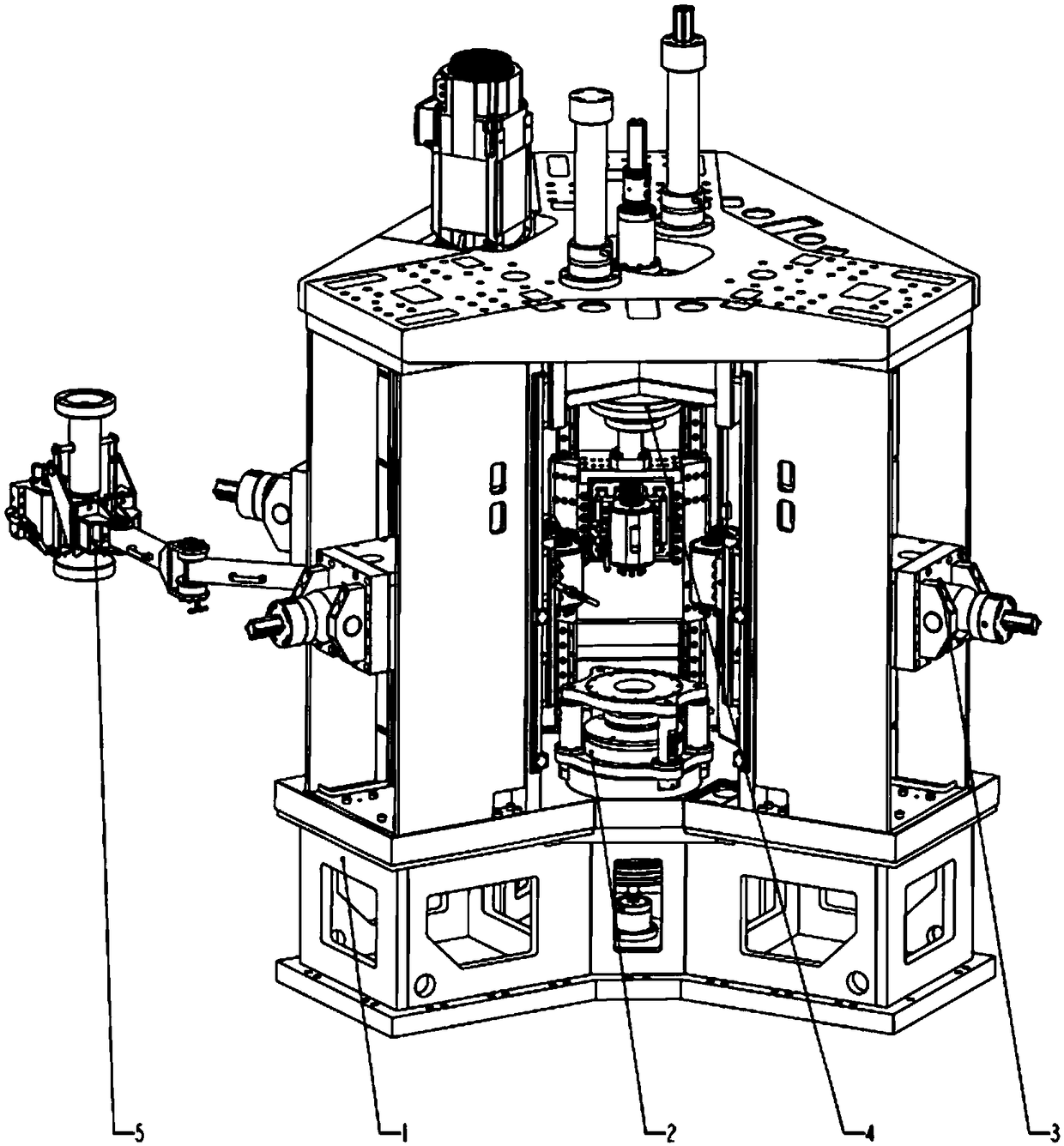

[0019] Such as figure 1 As shown, the main body of the spinning machine of the present invention adopts a vertical structure layout, which mainly includes a bed part 1, a main shaft part 2, a rotating wheel part 3, a tail top part 4 and a mechanical arm part 5, as well as electronic control, hydraulic pressure, lubrication, Cooling, protection and other systems.

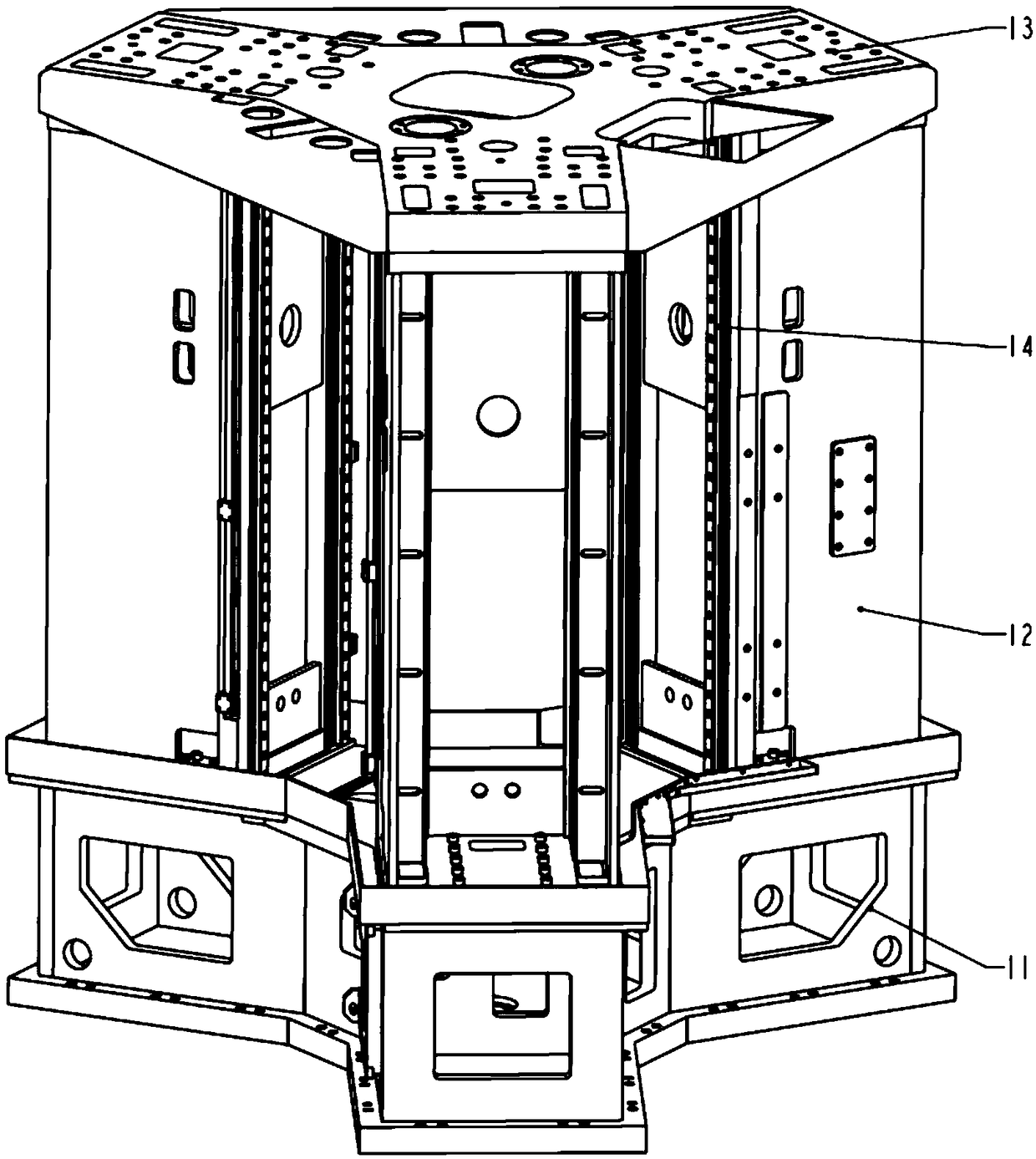

[0020] Such as figure 2 As shown, the bed adopts a vertical fully enclosed split structure, consisting of a base 11, a column 12, and a top cover 13;

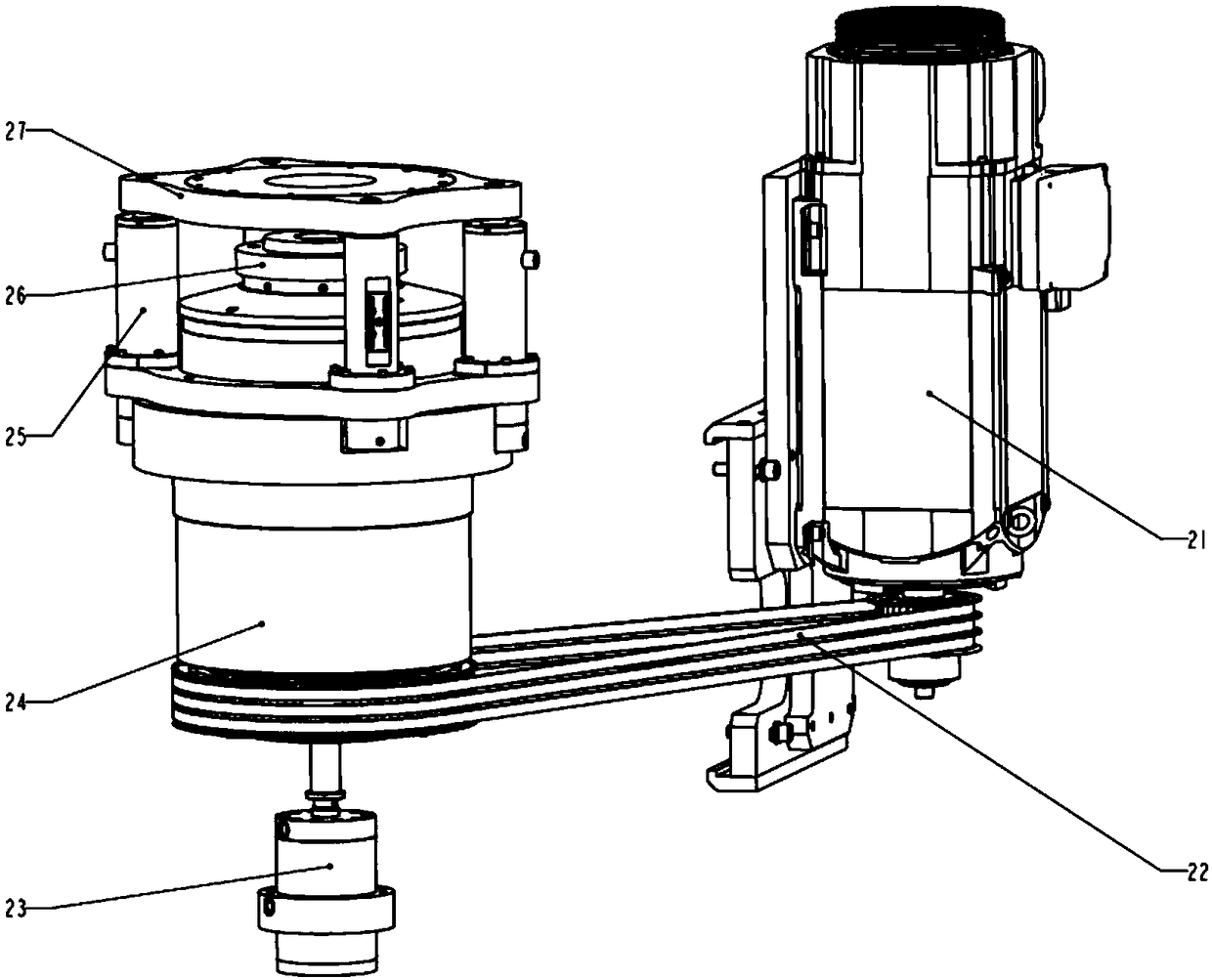

[0021] Such as image 3 As shown, the main shaft components are fixed on the bed ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com