Frame type swinging cutting machine

A cutting machine and swing mechanism technology, applied in ceramic molding machines, manufacturing tools, etc., can solve problems such as low motion accuracy, wire rope breakage, and many intermediate connectors, optimize process layout, improve reliability, and simplify the structure of the cutting machine. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

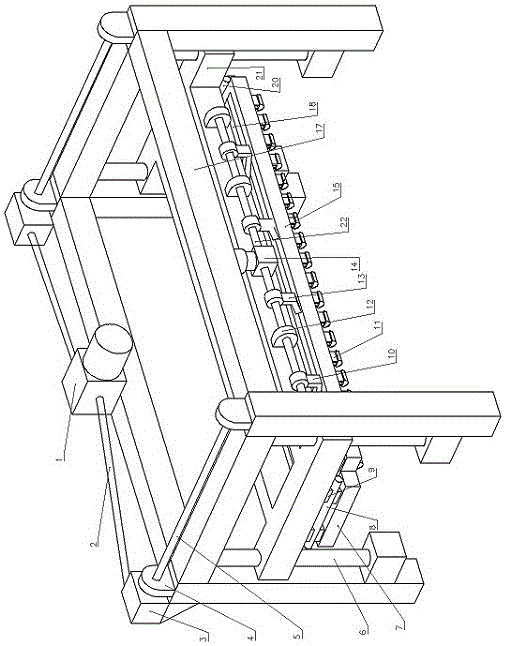

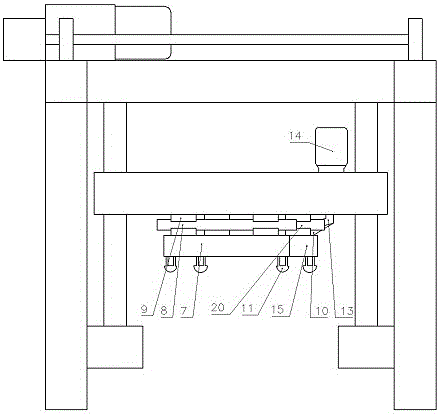

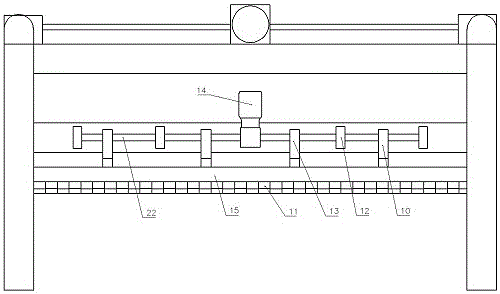

[0015] Such as Figure 1 to Figure 4 As shown, the present invention provides a cutting machine frame-type swing mechanism, which includes a body 17 with beams on both sides, a swing frame inside the body, and a lifting reducer 1 in the middle of the beam on one side of the body. There are respectively a reducer 3 connected to the lifting reducer, a vertical guide column 6 is provided on the legs of the frame, and a sprocket mechanism 4 connected by four synchronous shafts is provided at the top corner of the frame. The sprocket mechanism drives the inner swing frame to move up and down.

[0016] The swing frame includes an inner swing frame 15 and an outer swing frame 7. The two ends of the swing frame are respectively connected to linear guide rails 8 arranged horizontally. A small square frame-shaped fixed mount 21 and a swing motor 14 are arranged above the swing frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com