Multi-vehicle-type white body collinear flexible welding device

A welding device and body-in-white technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of device assembly, debugging and maintenance troubles, affect the accessibility of welding stations, and complex device structure design, etc., to achieve optimization Welding process and workshop process layout, saving labor costs, accurate and reliable conveying positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

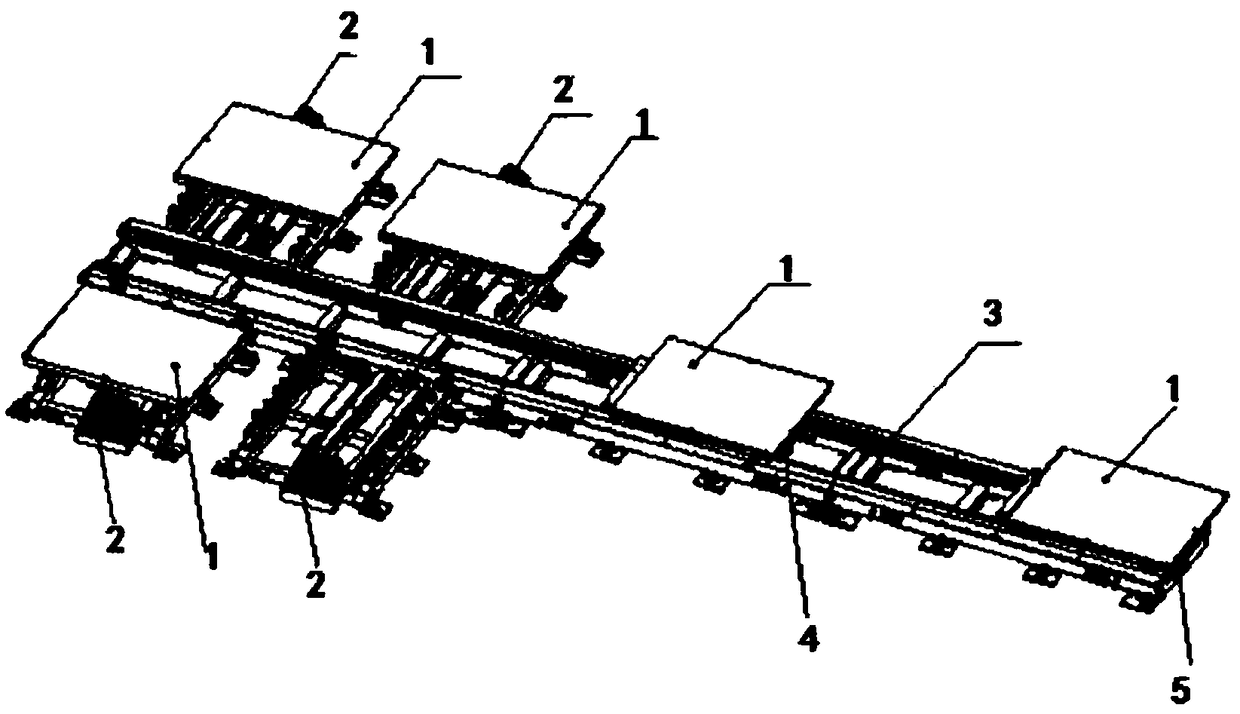

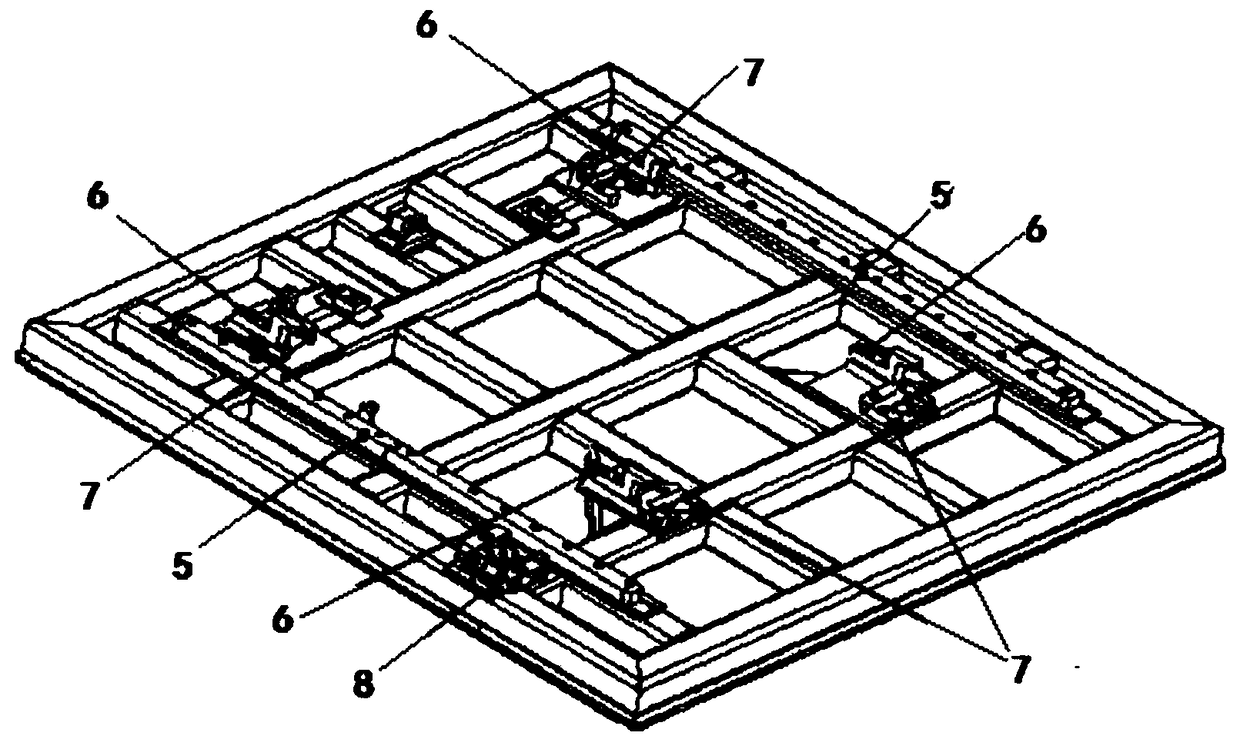

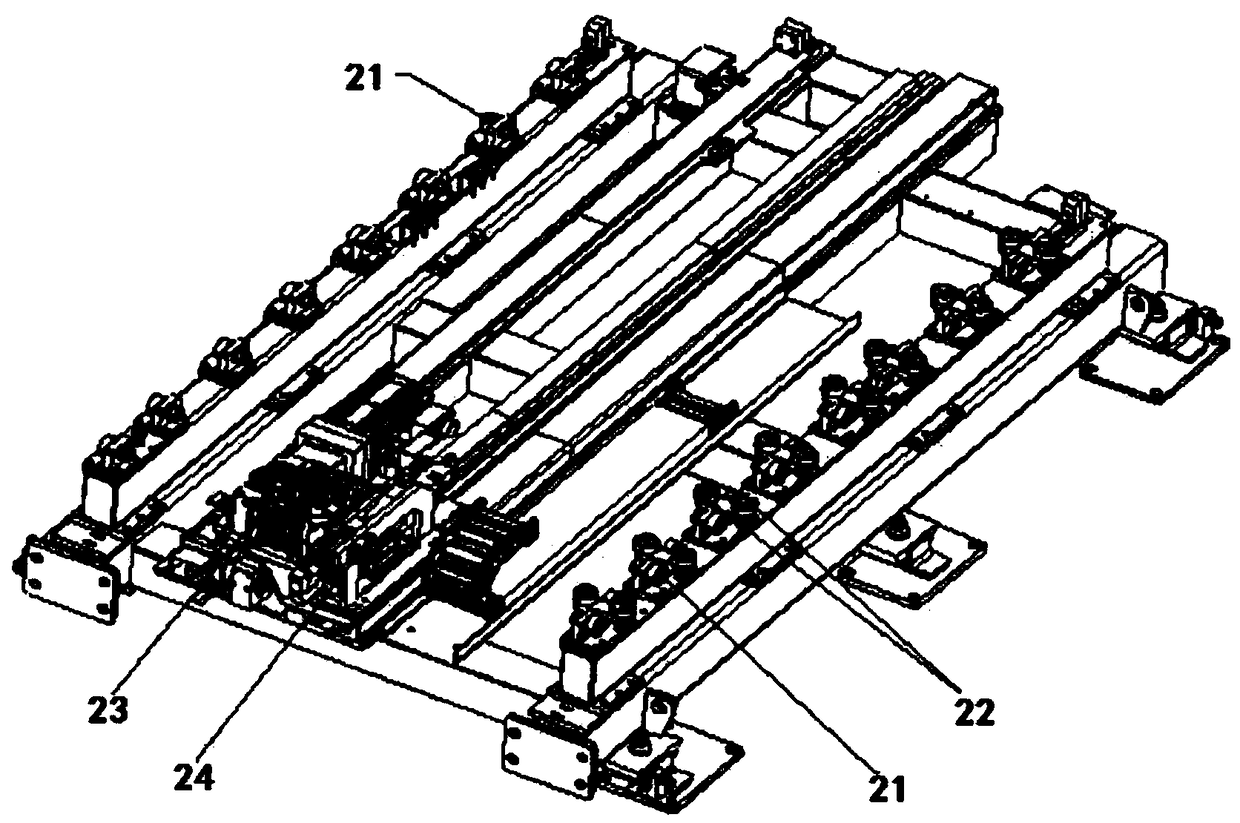

[0025] A collinear flexible welding device for multi-vehicle body-in-white, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it includes a positioning fixture platform 1, a storage mechanism 2, a sliding support mechanism 3 and a sliding positioning platform 4, wherein the sliding positioning platform 4 is slidably installed on the sliding supporting mechanism 3, the storage mechanism 2 is connected with the sliding supporting mechanism 3, and Distributed on both sides of the sliding support mechanism, a positioning fixture platform is provided on the sliding positioning platform, and the positioning fixture platform slides between the sliding positioning platform and the storage mechanism;

[0026] When the positioning fixture platform 1 is ready for production and use, the driving device of the sliding positioning platform 4 drives the sliding platform to the corresponding position of the storage unit, the sliding positioning platform and the guide wheels o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com