Organosilicone waste acid contained tributylamine, siloxane and aluminum chloride recycling technology

A technology of tri-n-butylamine and aluminum chloride, applied in aluminum chloride, organic chemistry, silicon organic compounds, etc., can solve the difficult to achieve the purpose and requirements of enterprise recycling, limit the utilization value of waste acid, a large amount of solid waste salt Material and other issues, to achieve the effect of reducing investment and equipment space layout, reducing emissions, and low cost processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

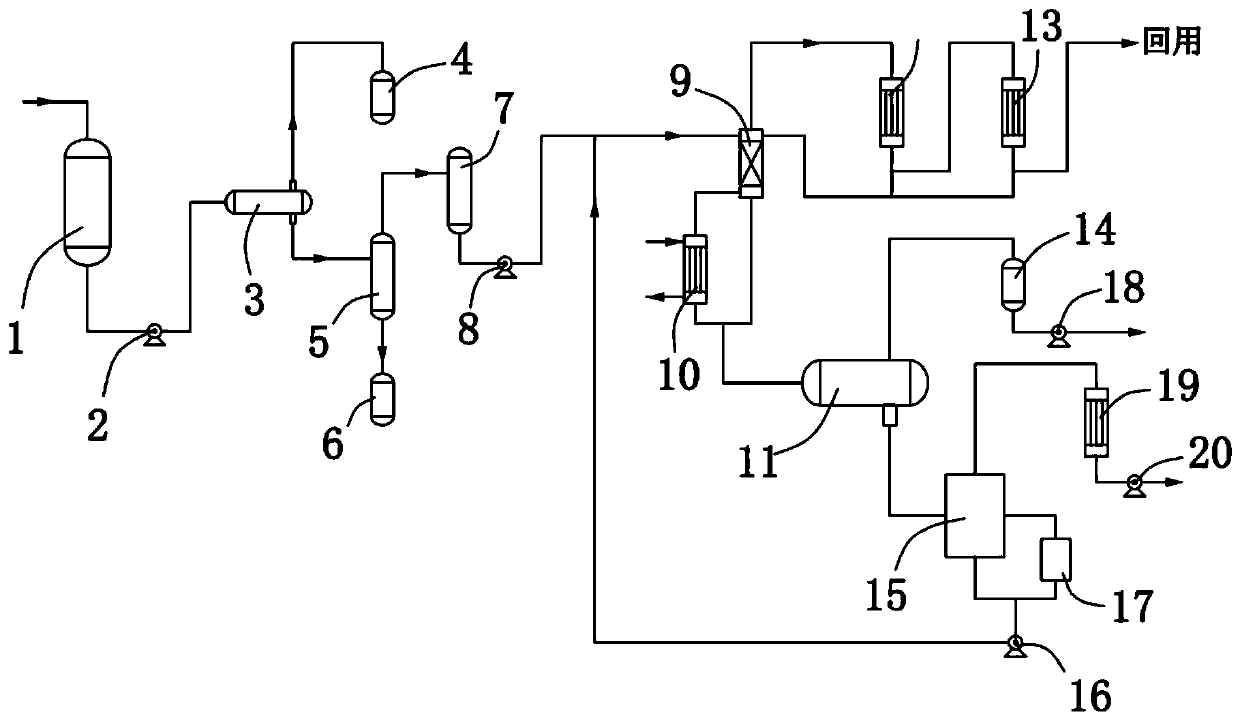

[0033] Such as figure 1 As shown, a kind of organosilicon waste acid of the present invention contains tri-n-butylamine, siloxane, and aluminum chloride recovery process, including acid oil separation, aluminum chloride membrane separation, hydrochloric acid and salt analysis, tri-n-butylamine and The process of salt separation and salt evaporation and concentration mainly includes the following steps: (1) Metering and pumping the waste hydrochloric acid containing catalyst to the oleic acid phase separator for acid oil separation; (2) The waste hydrochloric acid separated by the acid oil separator 3 The acid is separated by membrane filtration to remove some impurity aluminum chloride particles; (3) the siloxane separated by the acid oil separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com