Patents

Literature

162results about How to "Low cost processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

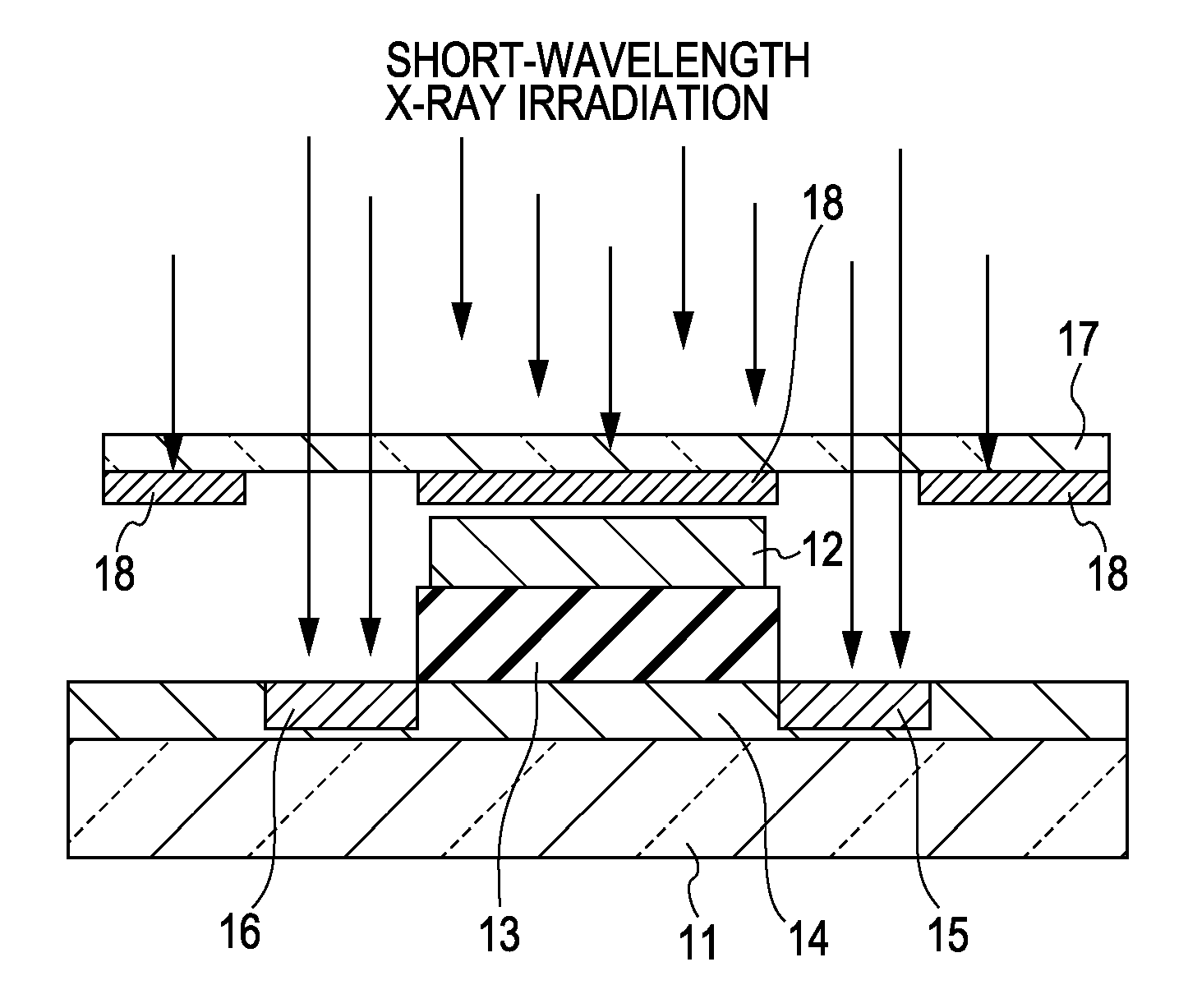

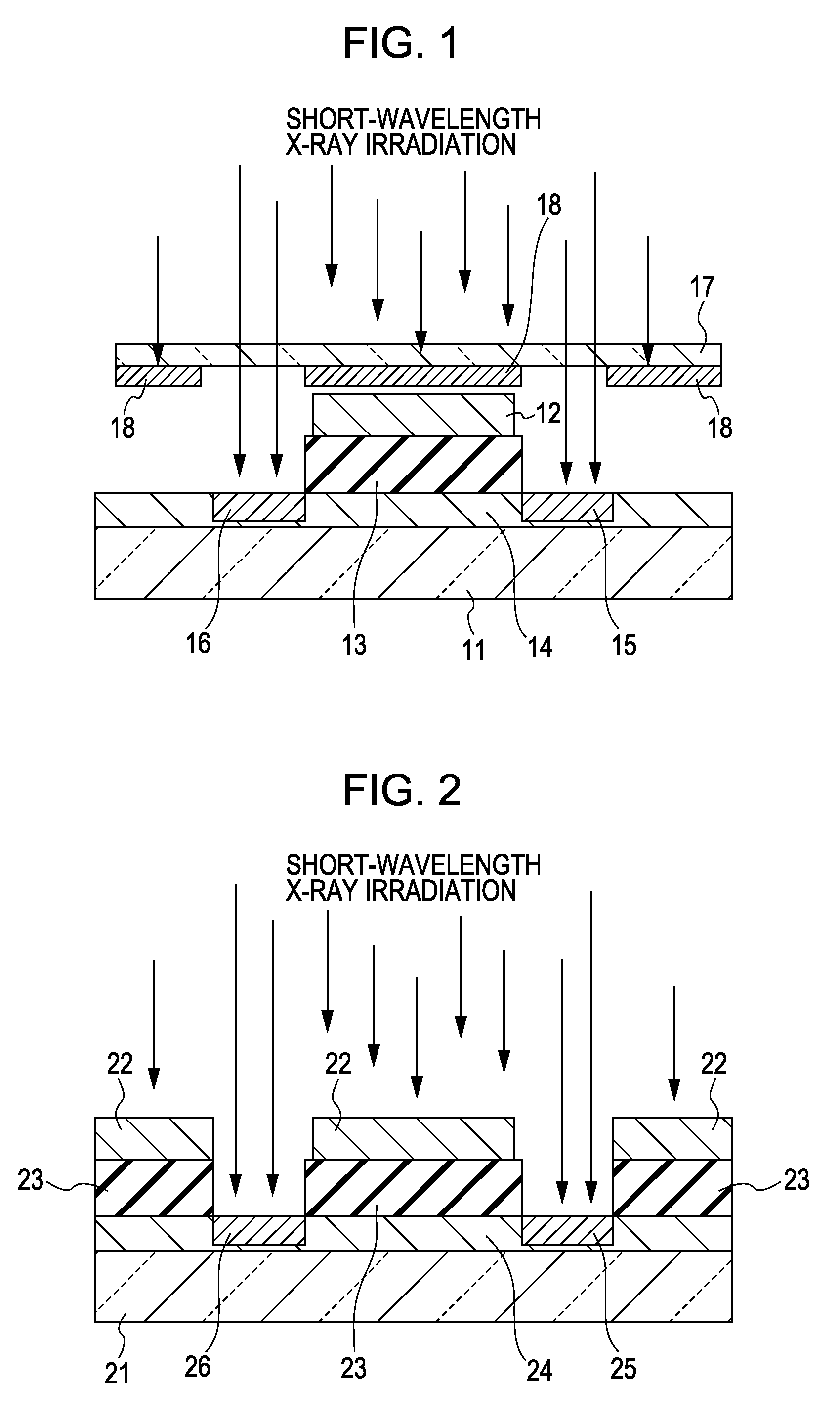

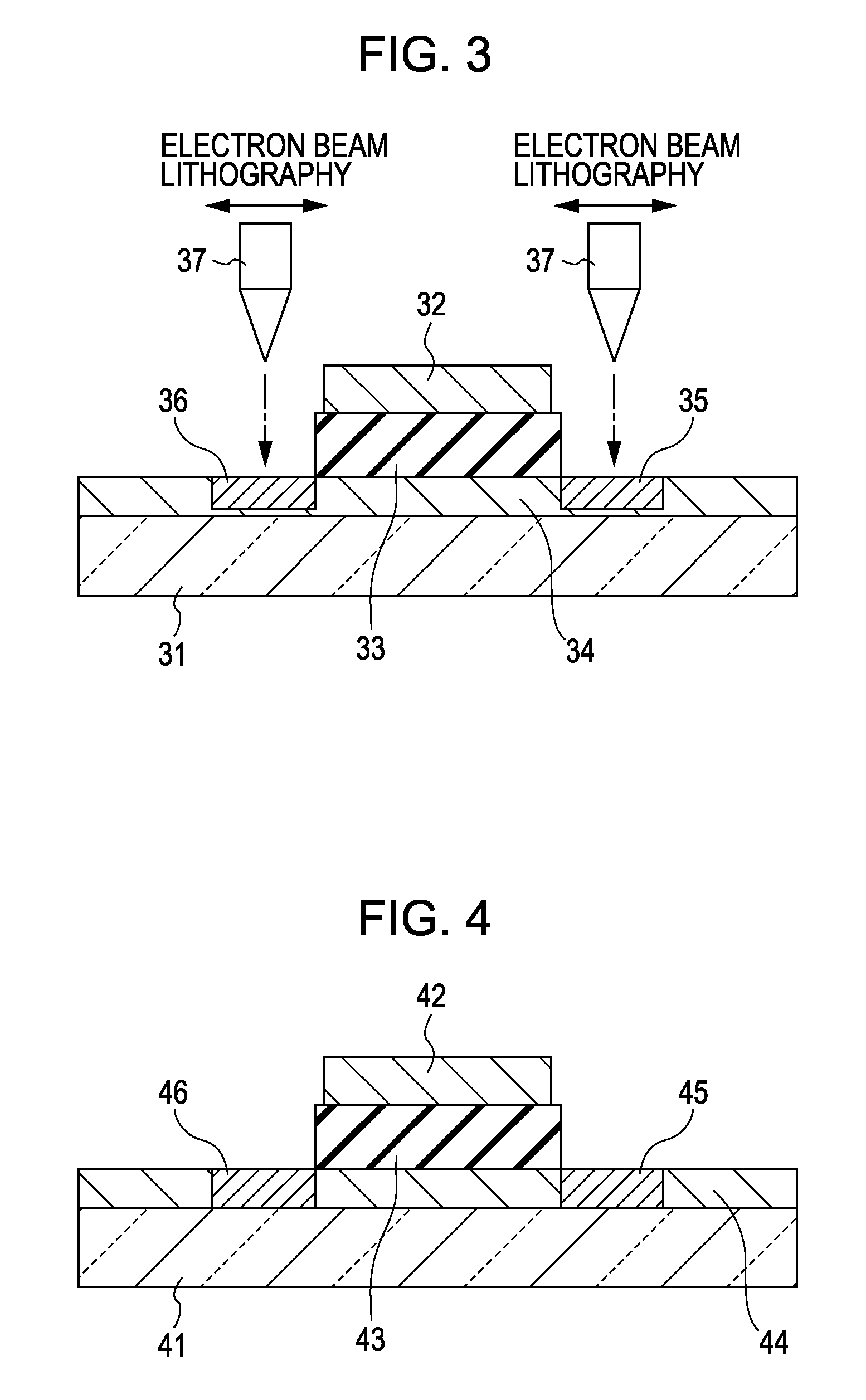

Method of fabricating oxide semiconductor device

InactiveUS20070054507A1Efficient solutionReduce conductivitySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorMaterials science

A method for fabricating a device using an oxide semiconductor, including a process of forming the oxide semiconductor on a substrate and a process of changing the conductivity of the oxide semiconductor by irradiating a predetermined region thereof with an energy ray.

Owner:CANON KK

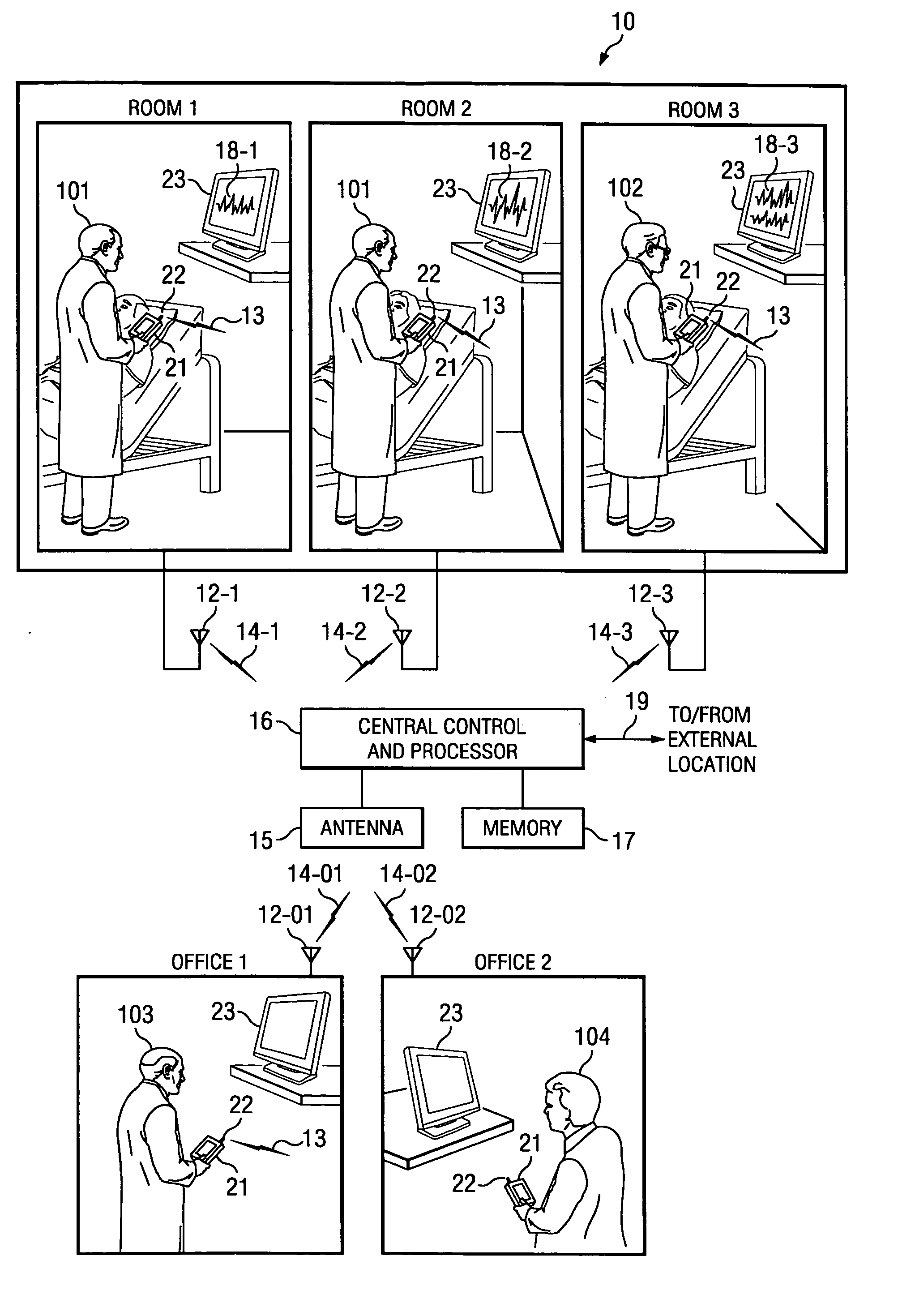

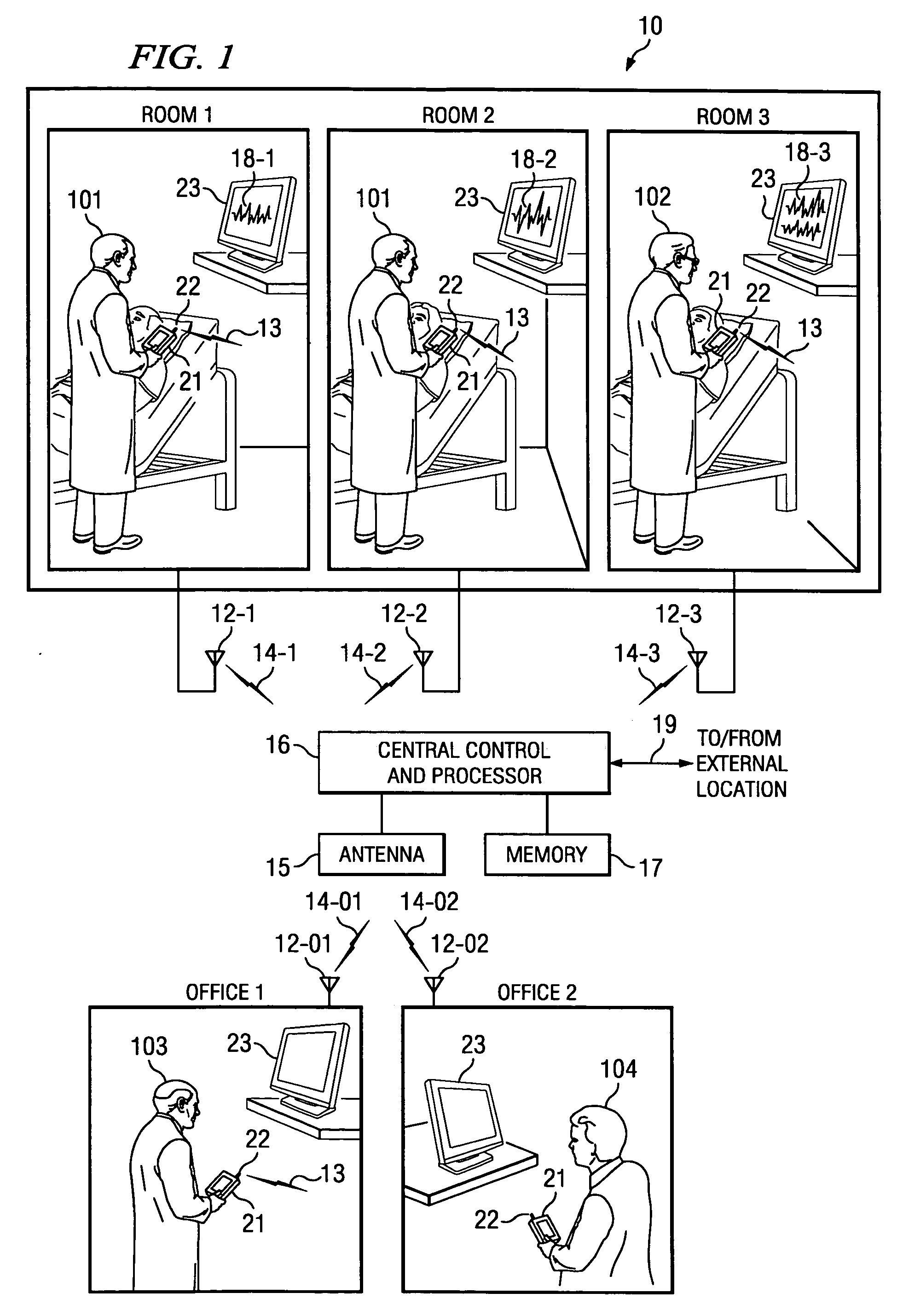

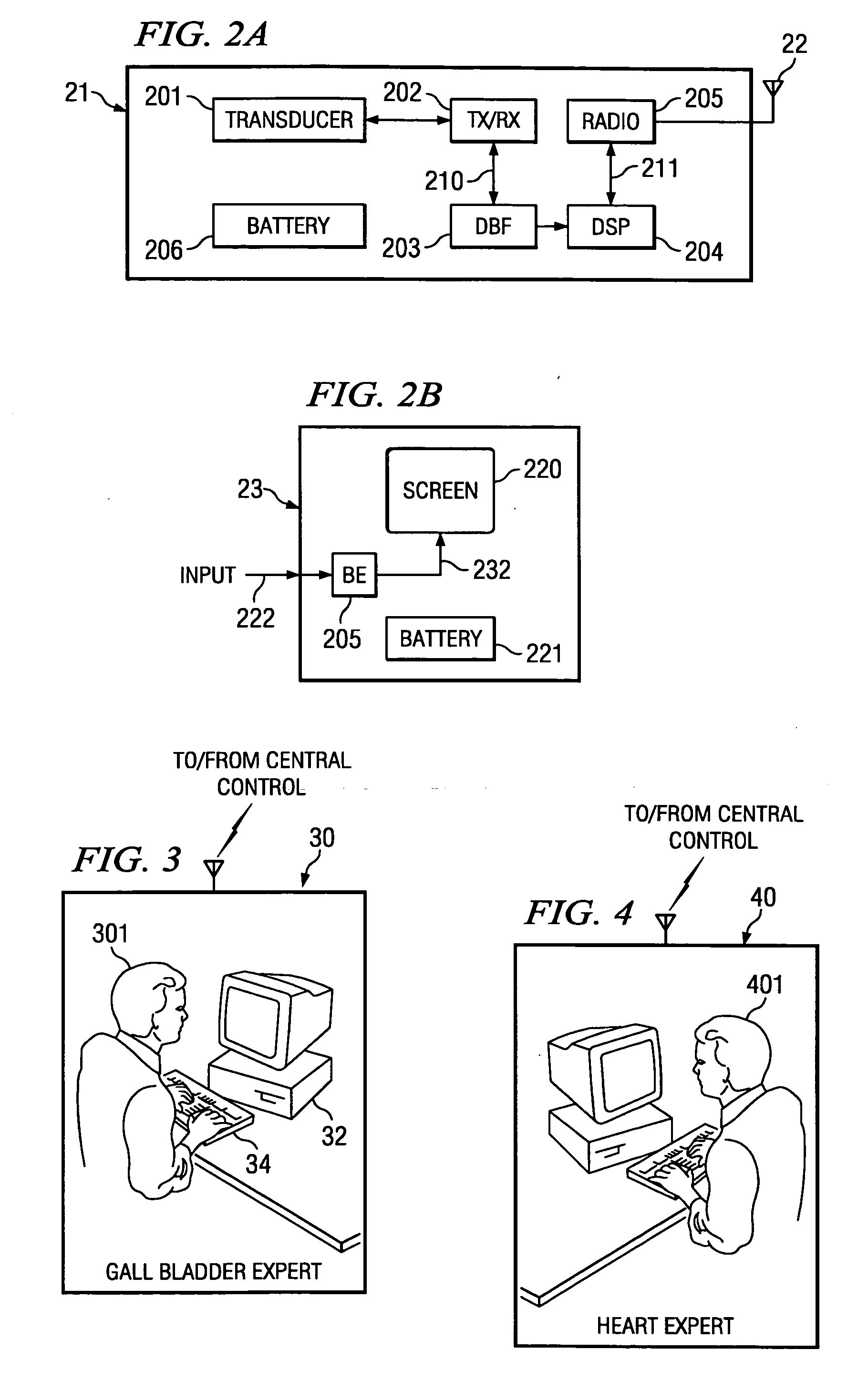

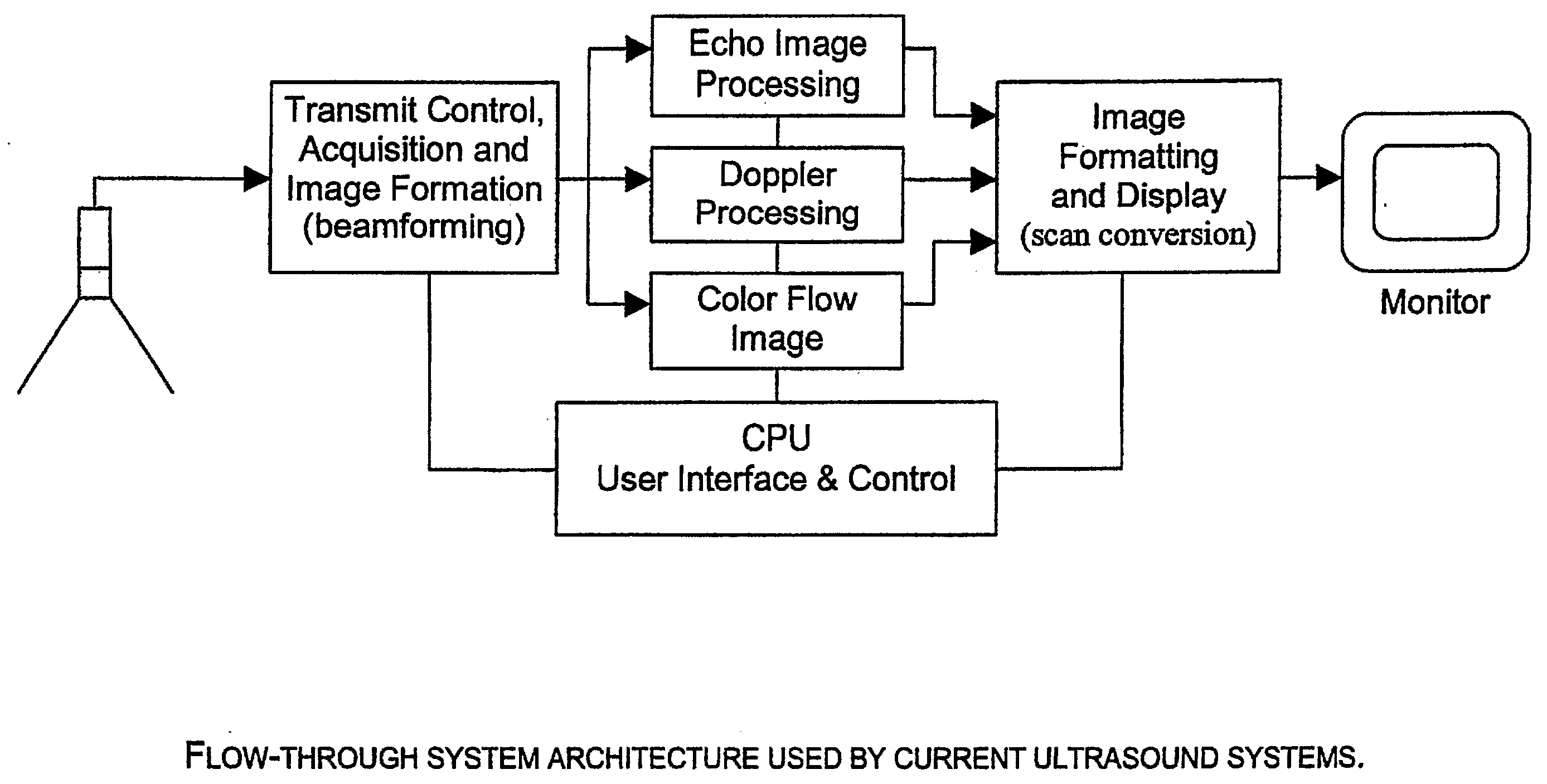

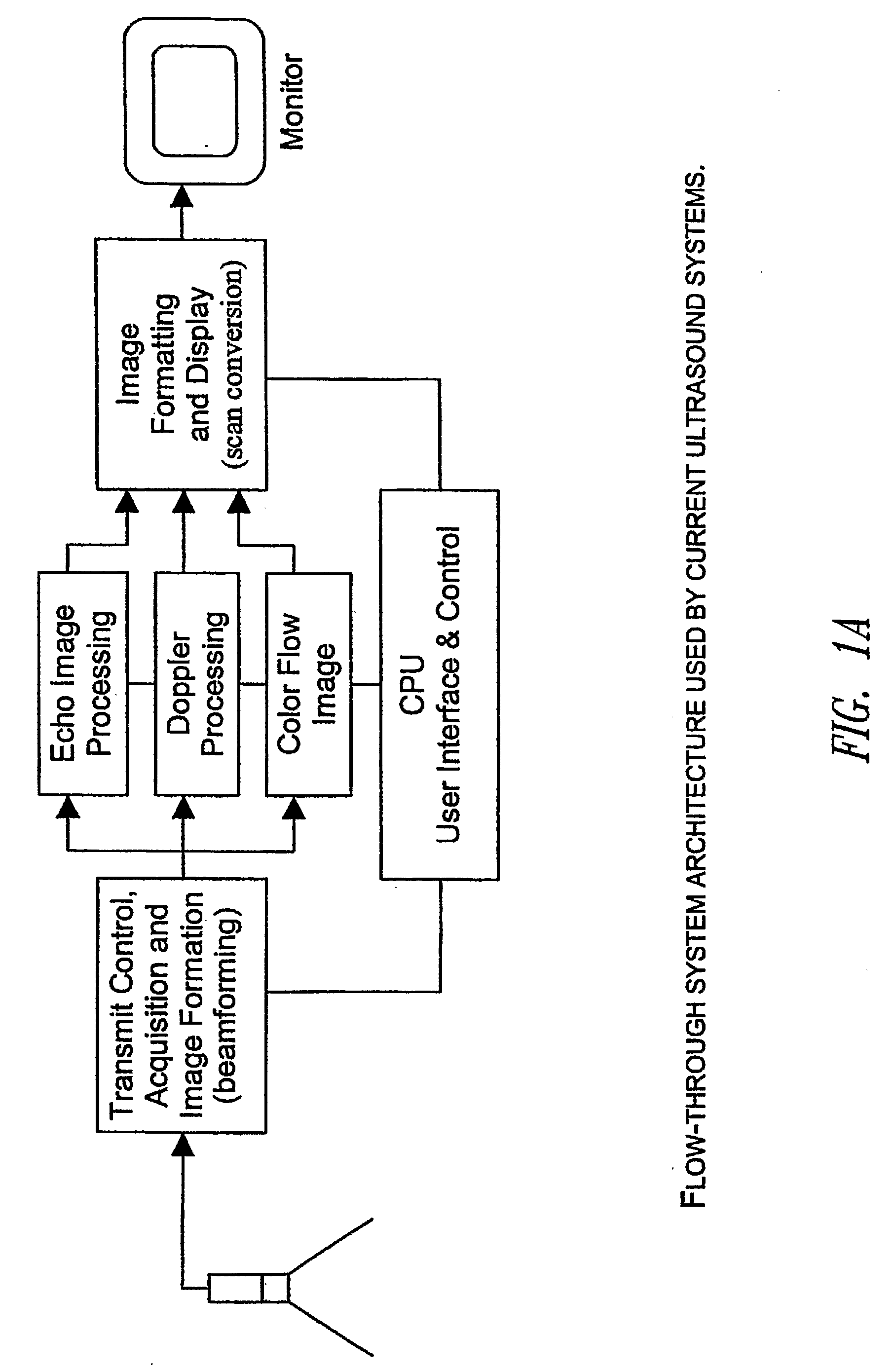

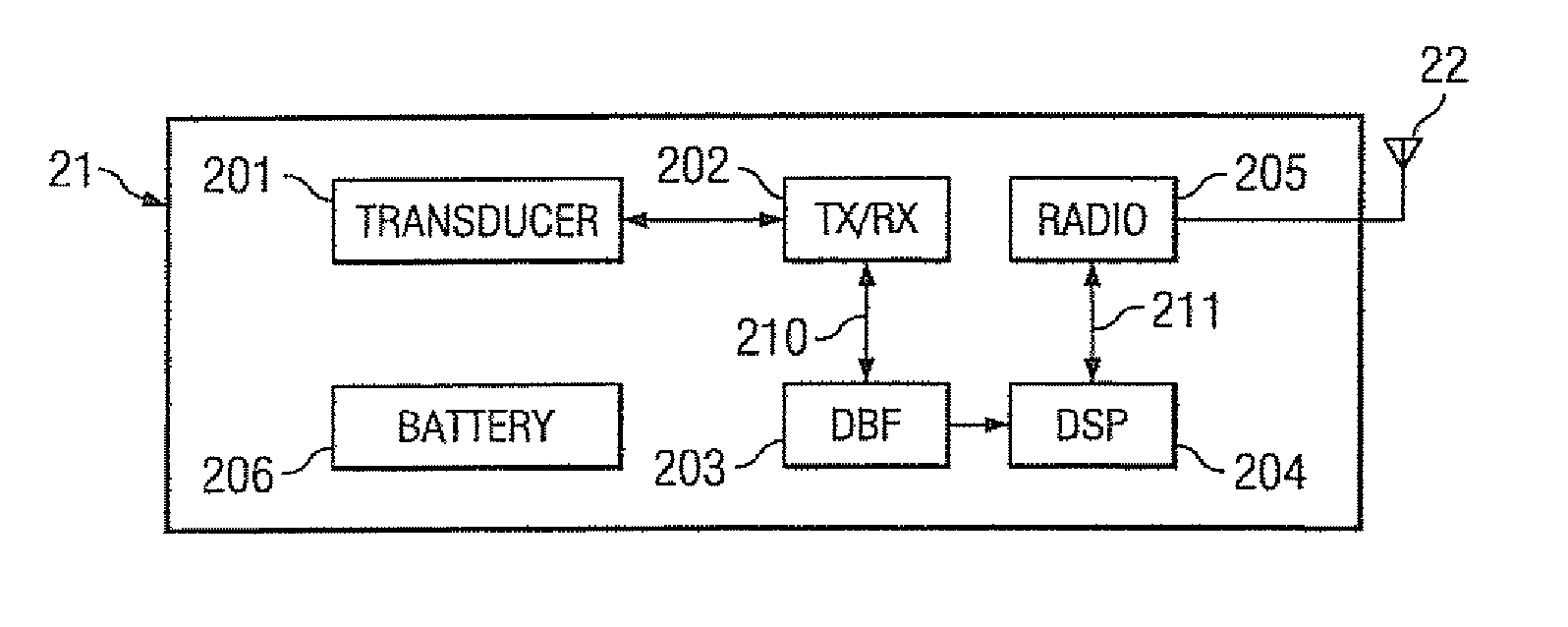

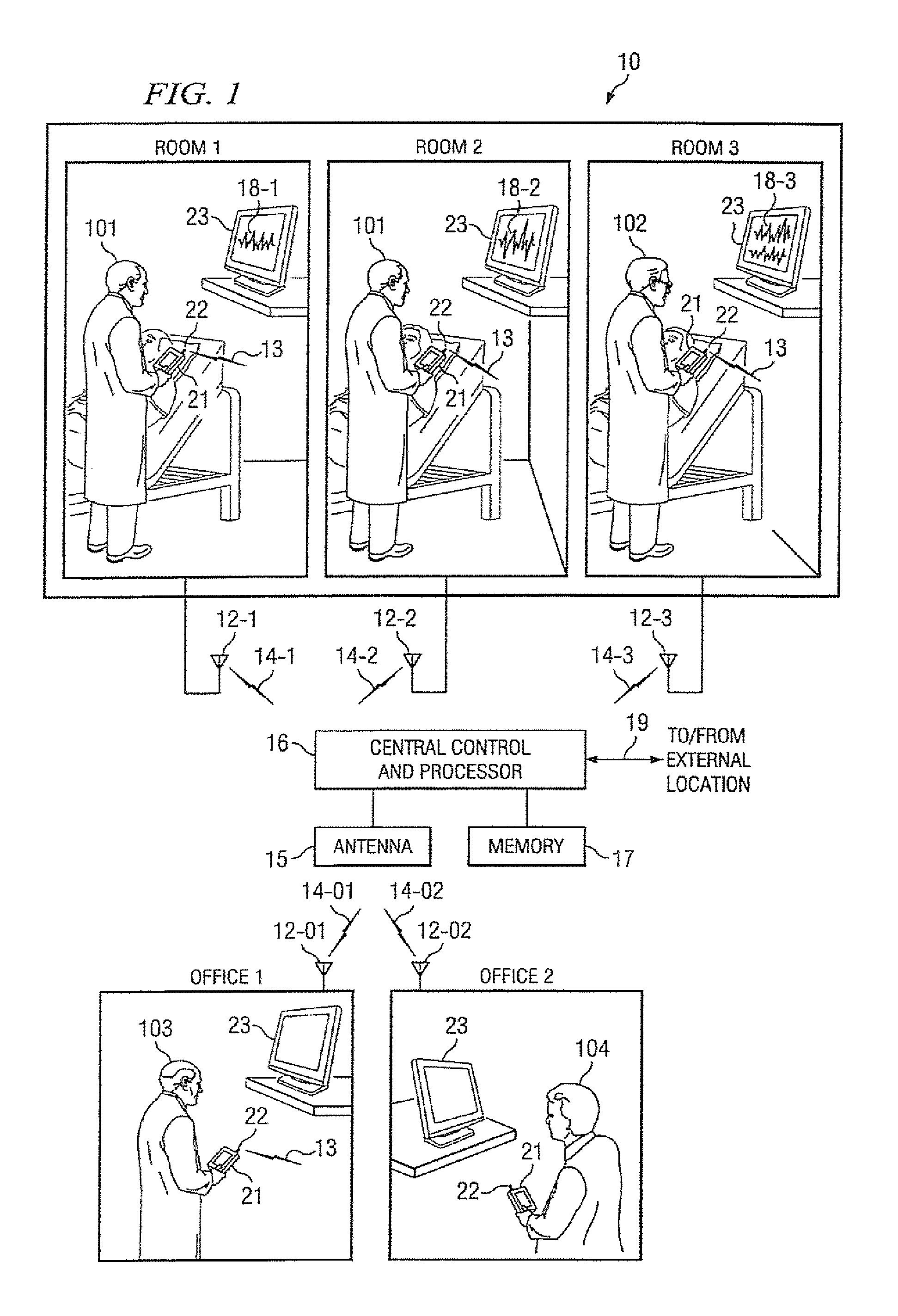

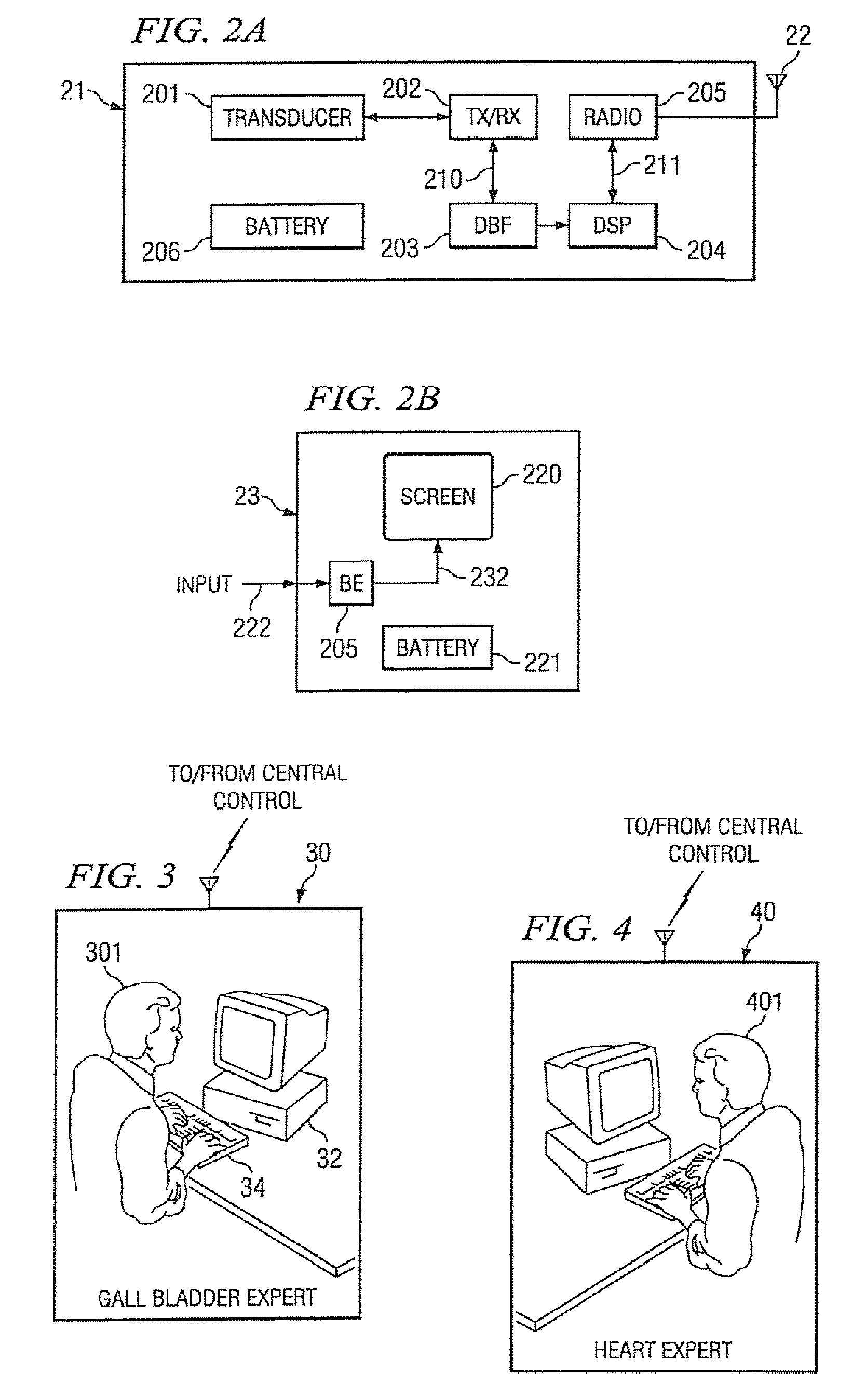

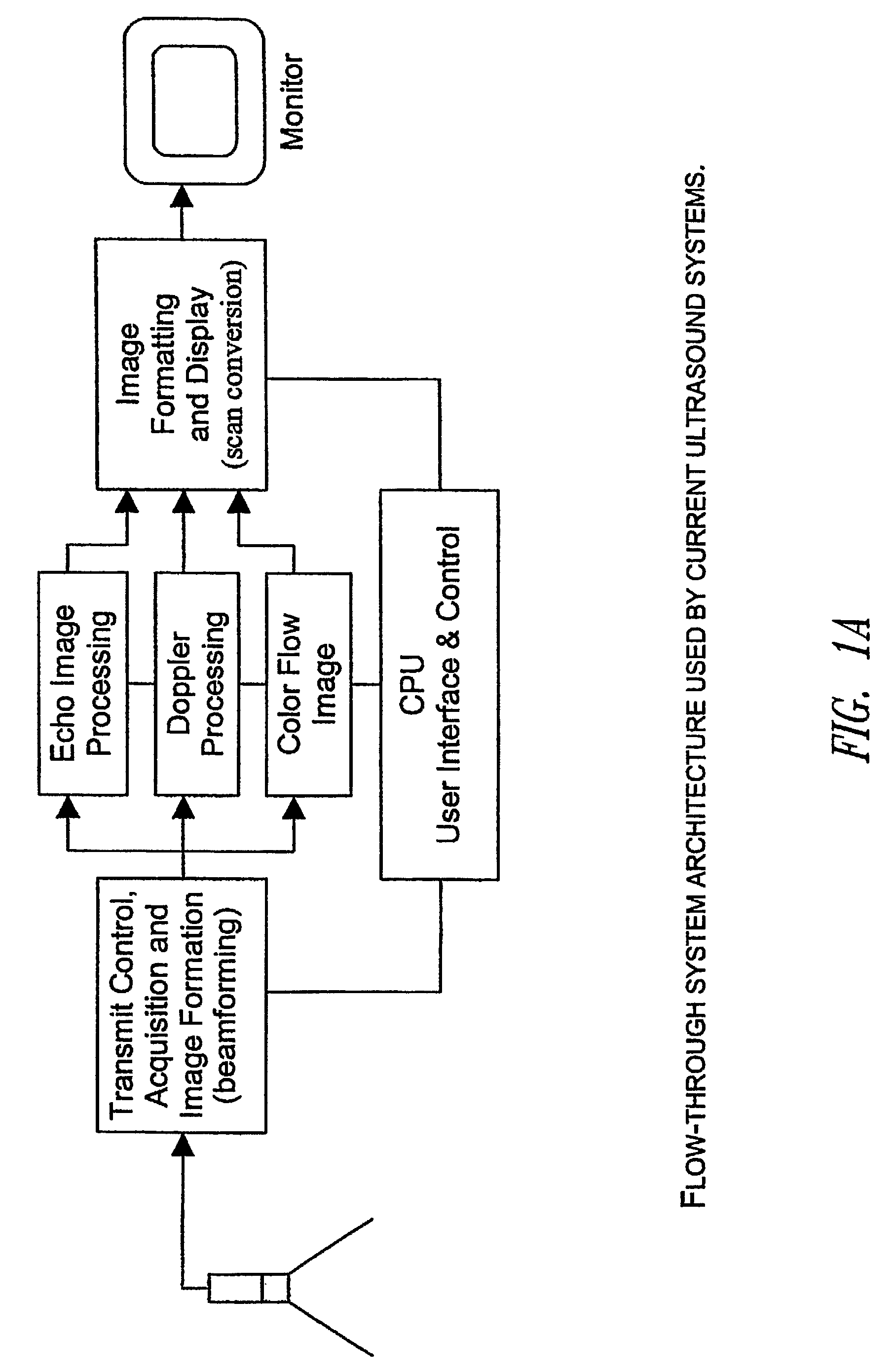

Processing of medical signals

ActiveUS20050265267A1Facilitate decisionFacilitate decision-makingUltrasonic/sonic/infrasonic diagnosticsDiagnostic recording/measuringBroadbandDoctor's office

The present invention is directed to a system and method in which real-time ubiquitous imaging is feasible in local areas, such as inside a clinic, hospital room or doctor office. This is achieved by designing a wireless network having a central processing server with, for example, distributed broadband acquisition and video bus capability. Remote access is possible using store-and-forward image transfer over a wide area network. With these capabilities, a physician can use a handheld transducer (such as an ultrasound transducer) as a basic tool to facilitate diagnostic decisions similar to the way a stethoscope is used today.

Owner:FUJIFILM SONOSITE

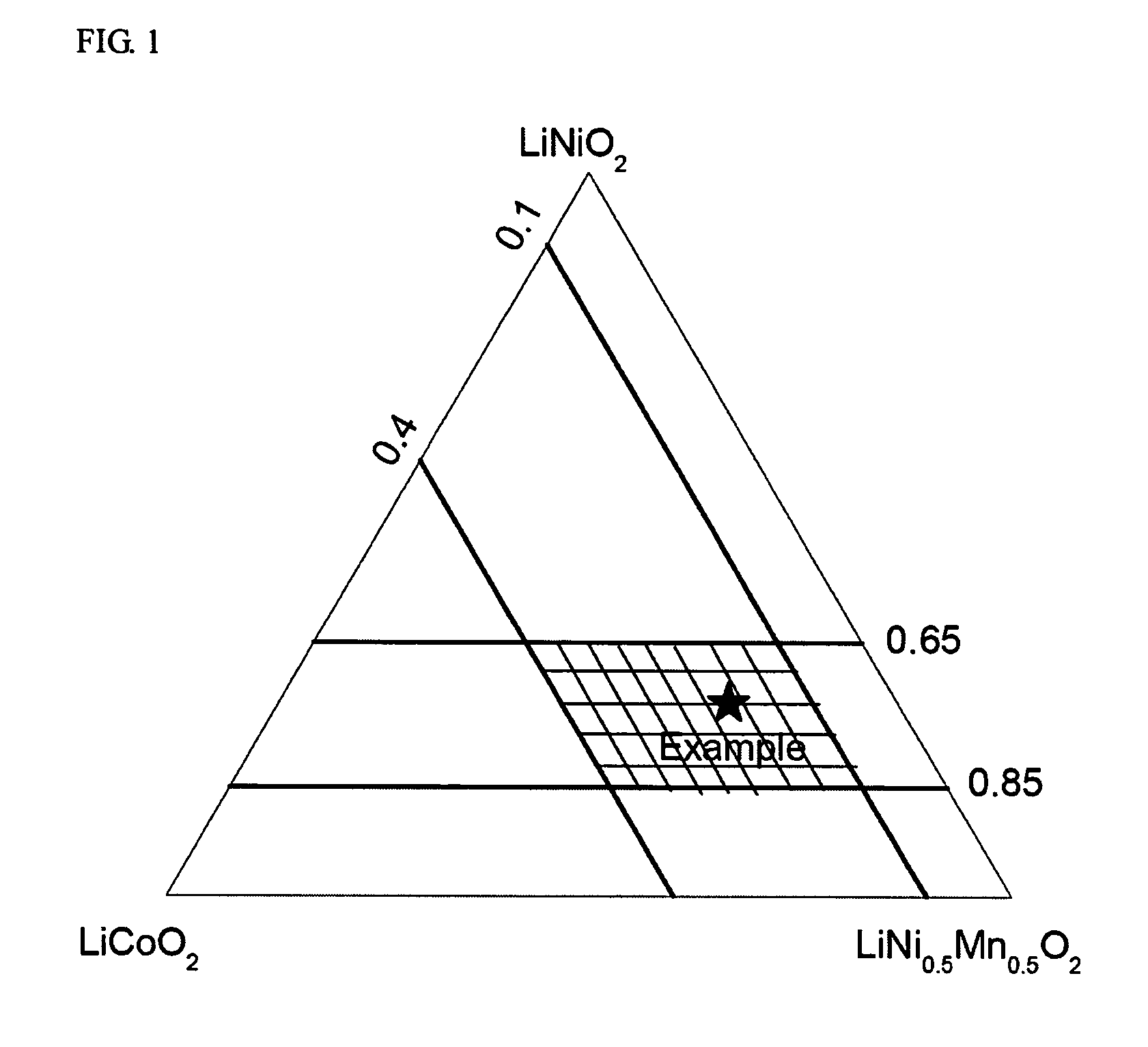

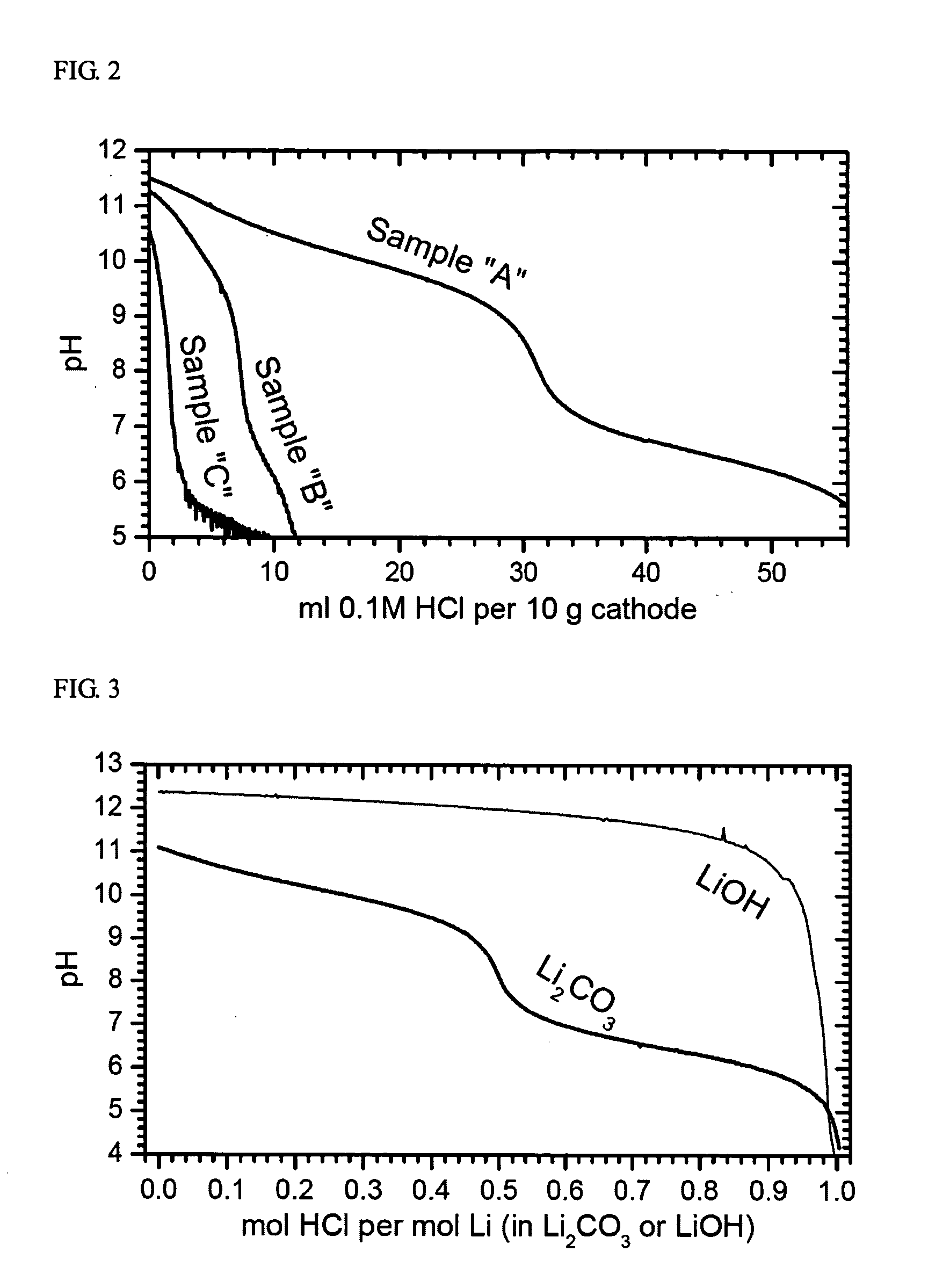

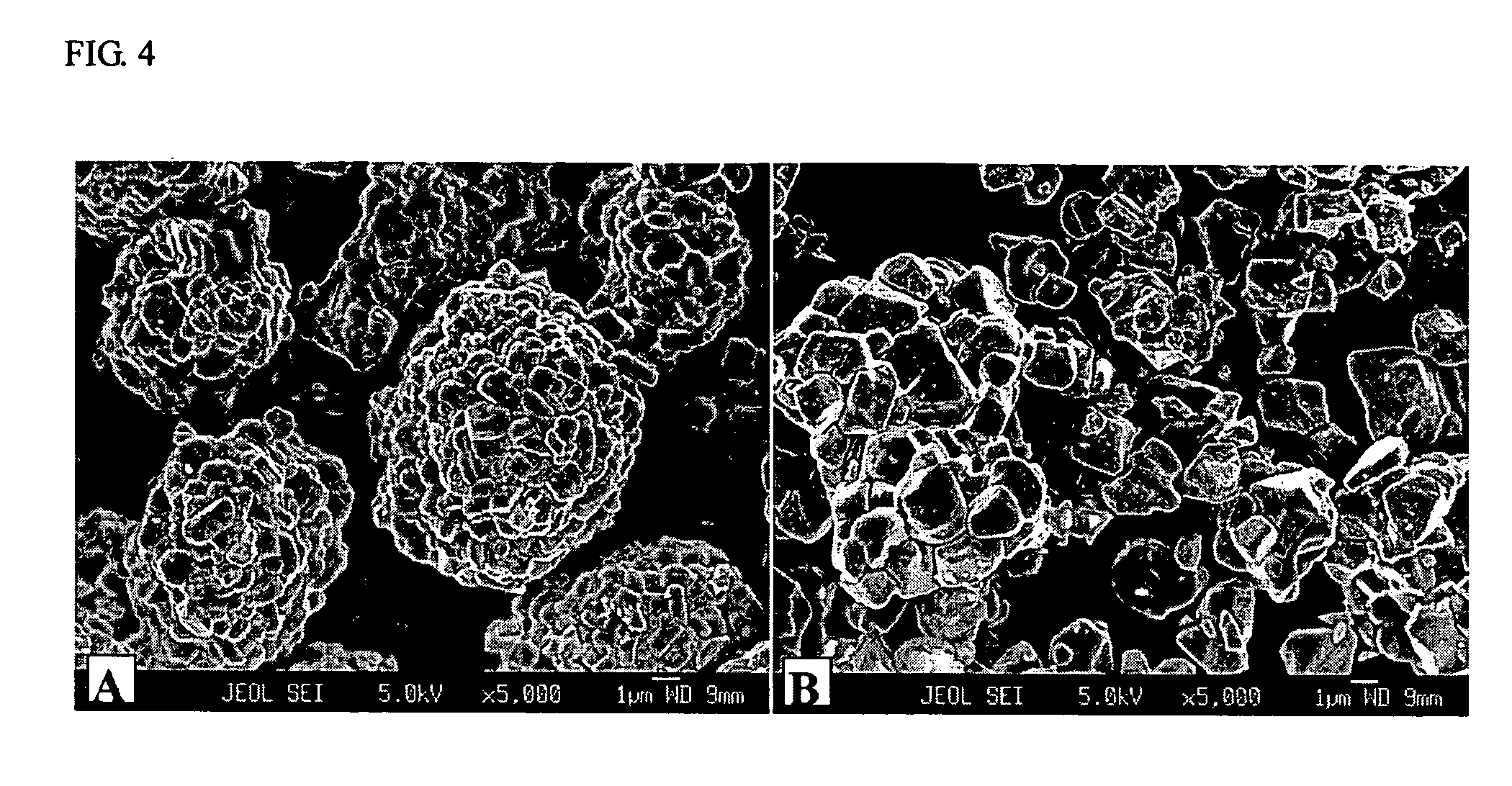

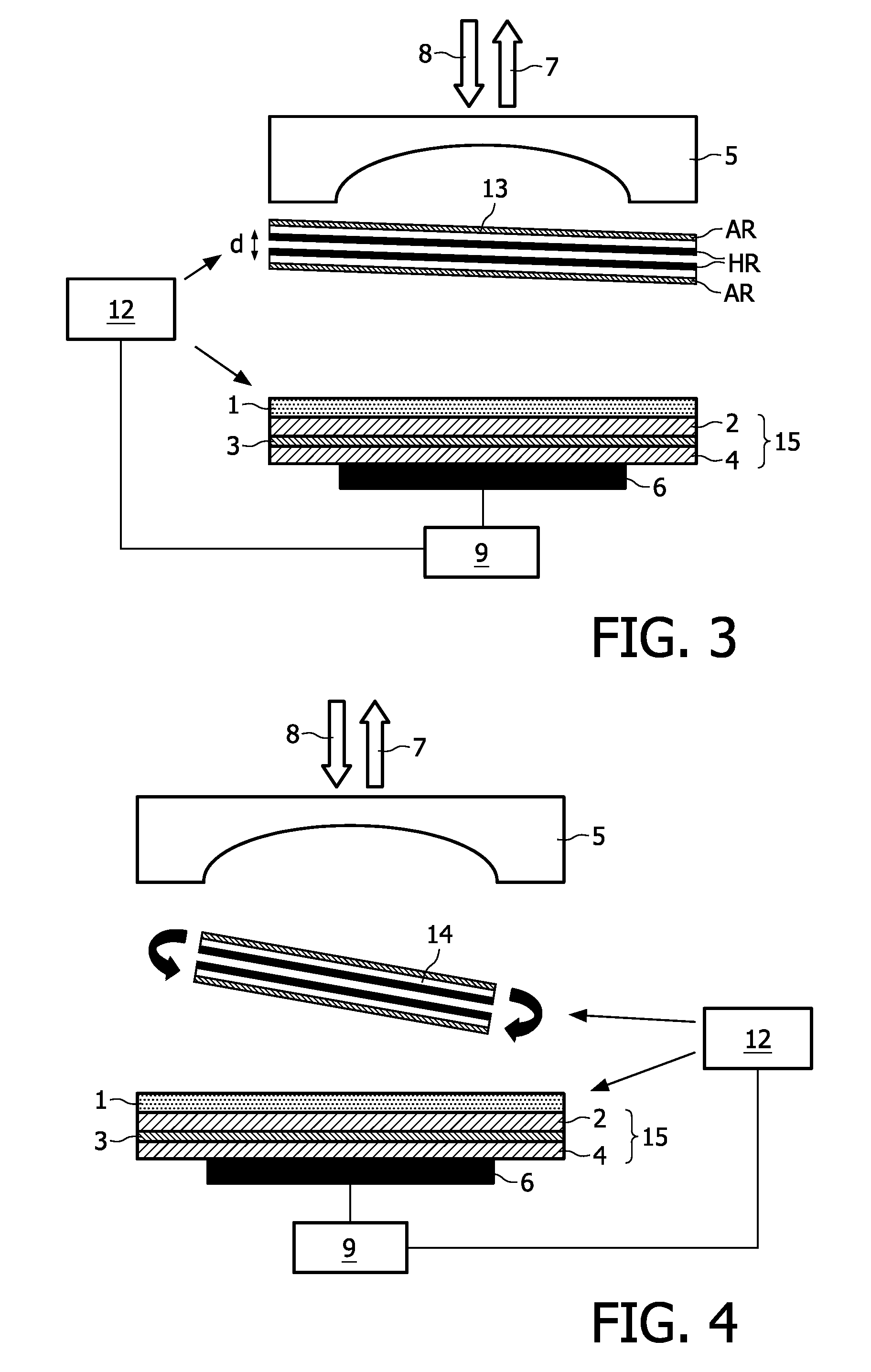

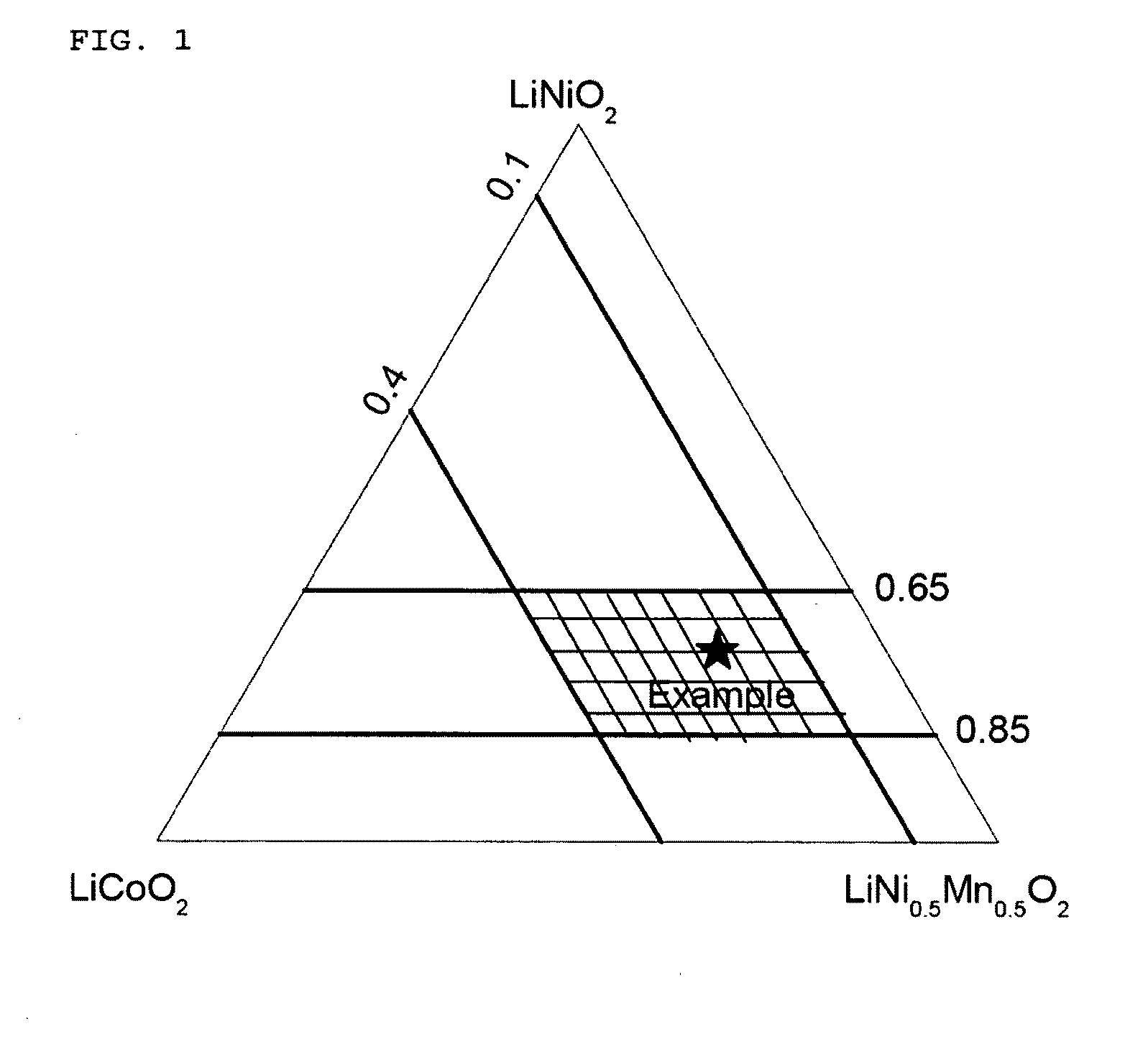

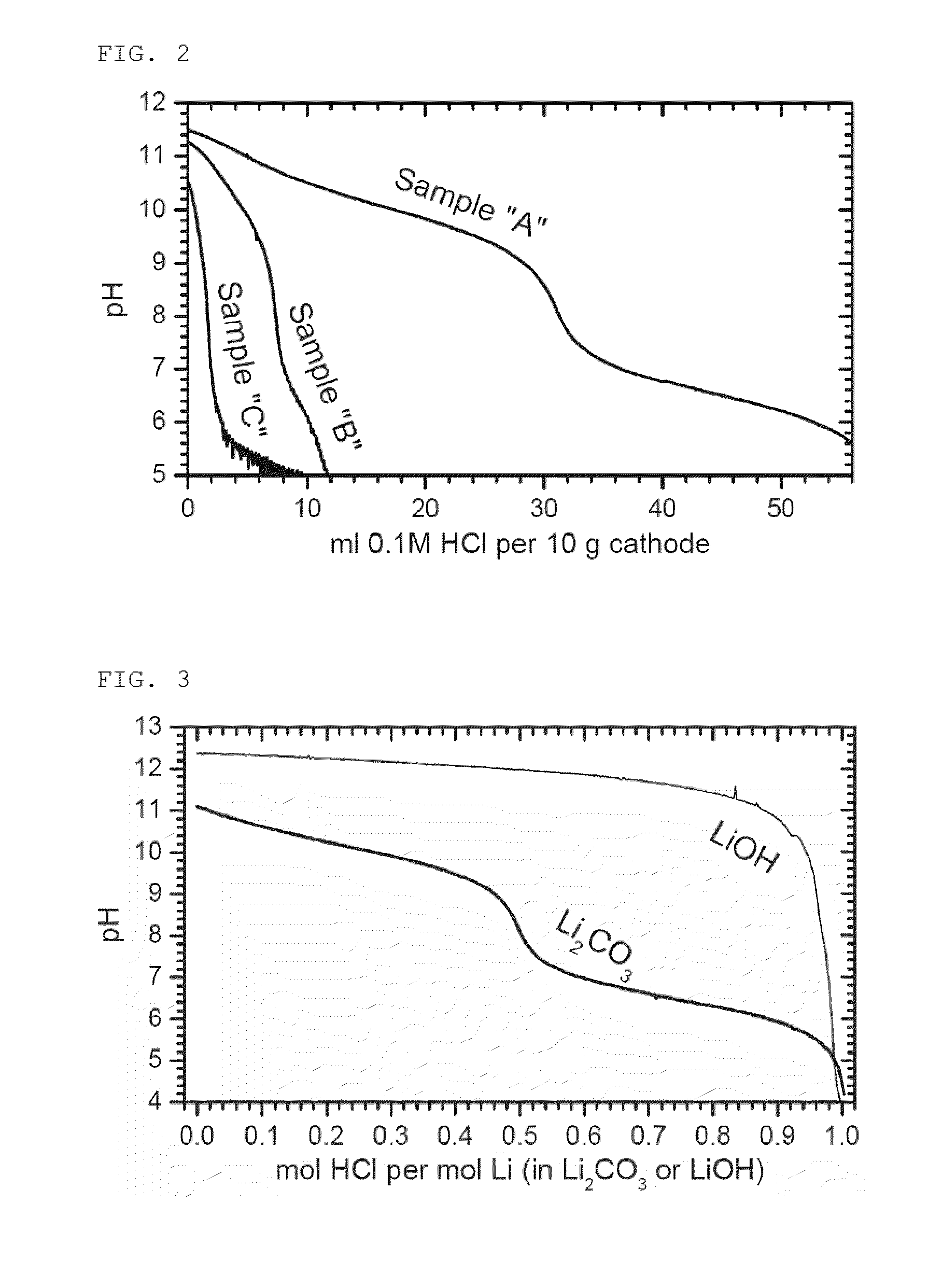

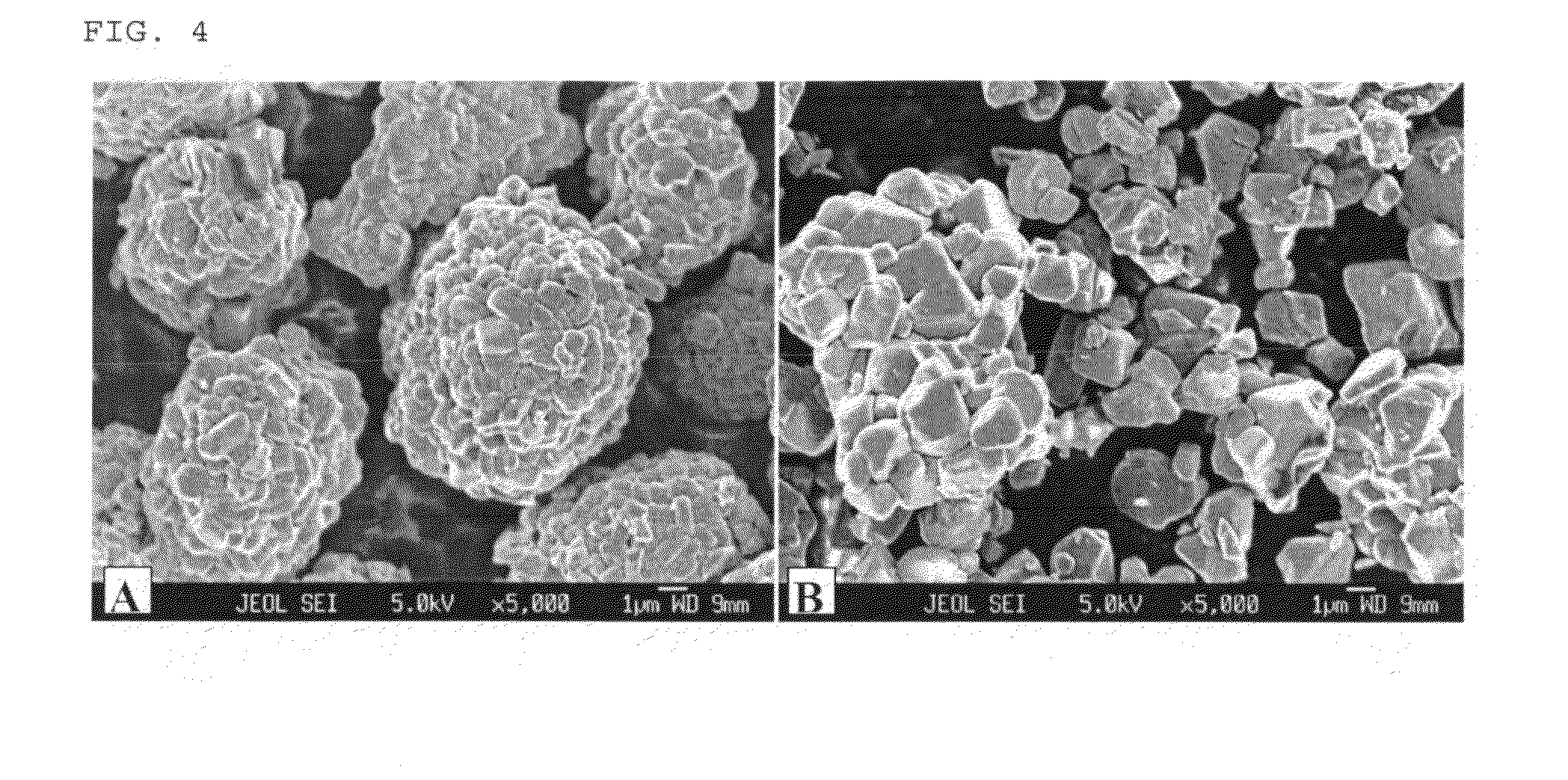

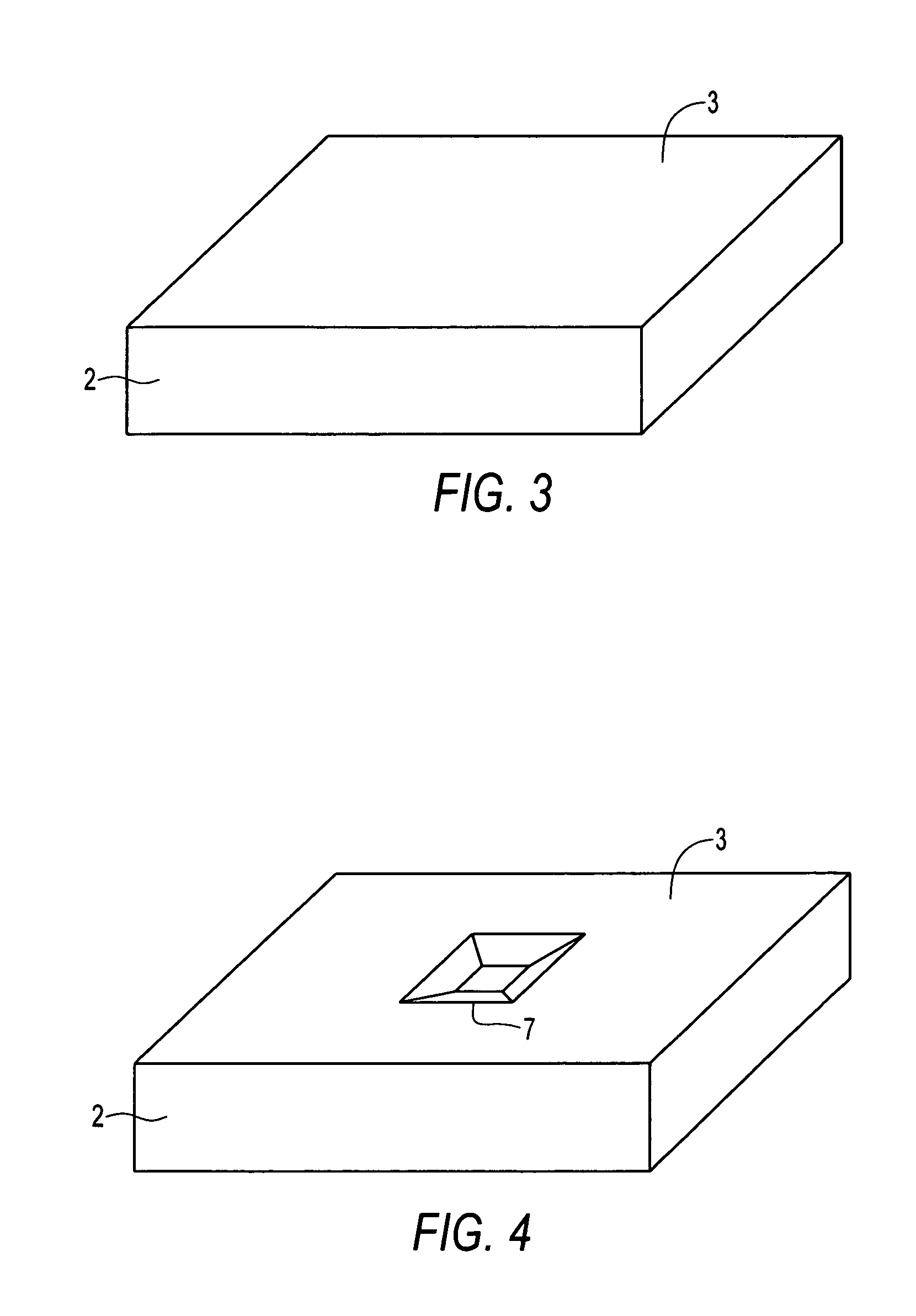

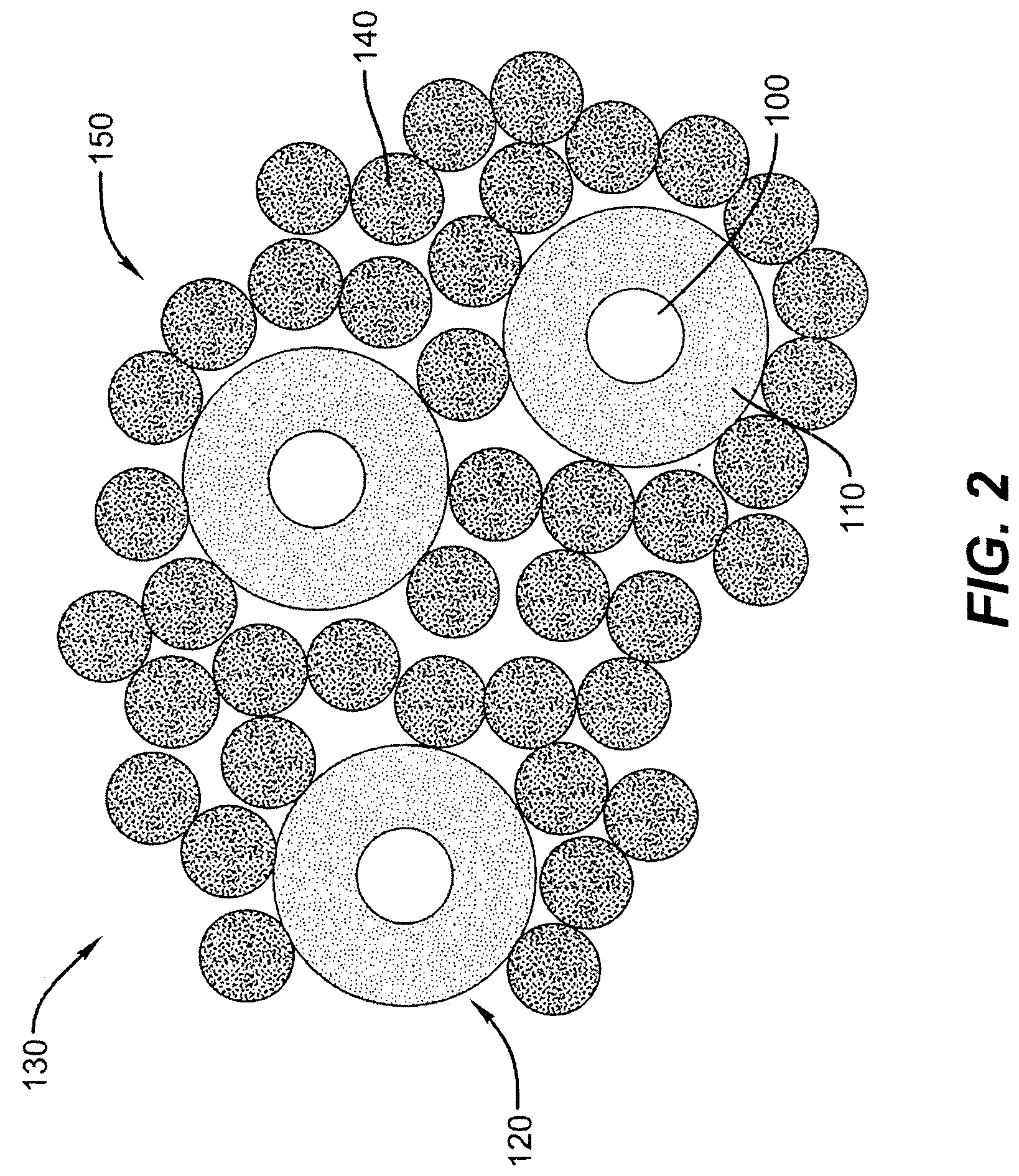

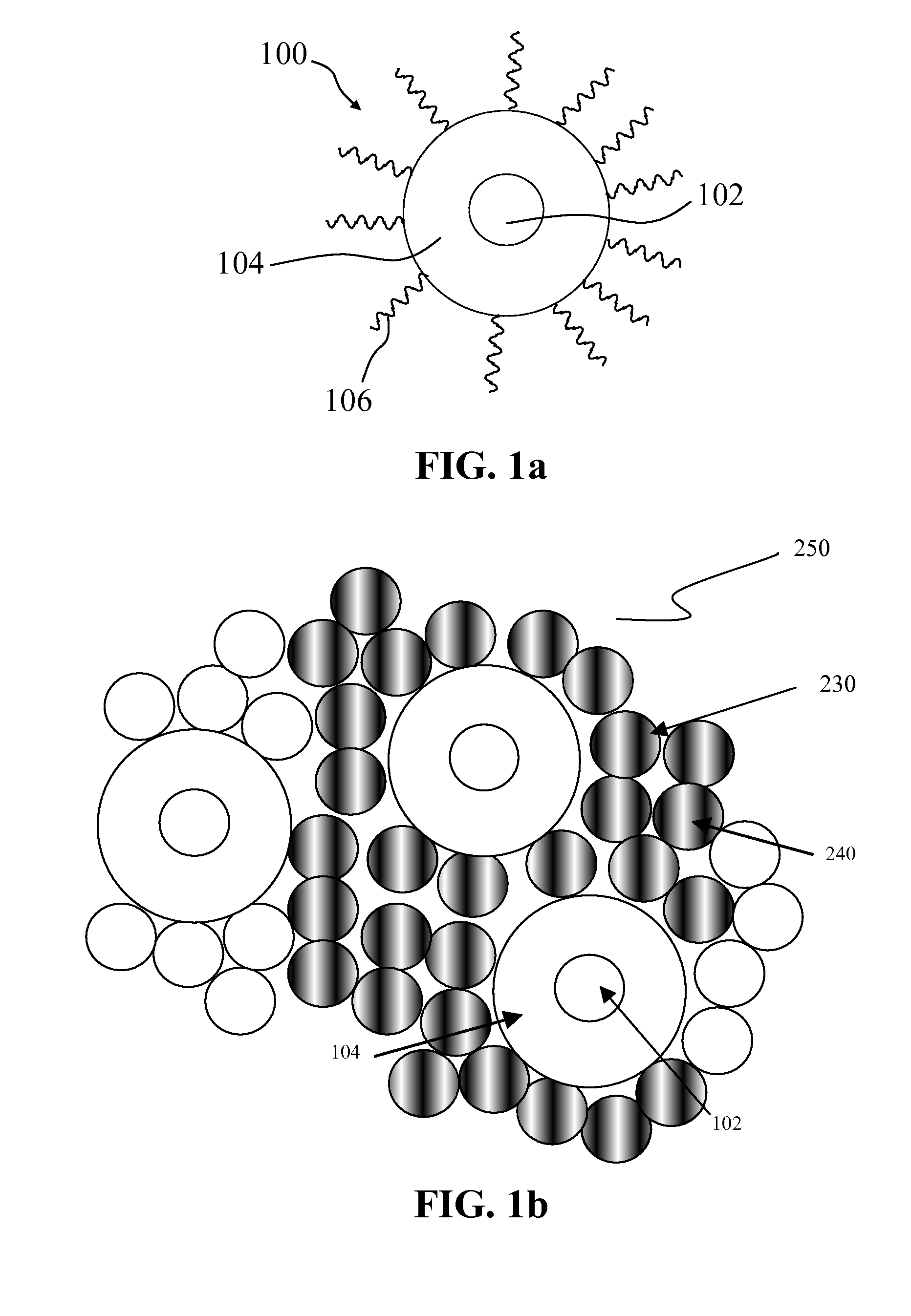

Ni-based lithium transition metal oxide

The present invention provides a powderous lithium transition metal oxide with the composition as represented by the below Formula and prepared by solid state reaction in air from a mixed transition metal precursor and Li2CO3, with being practically free of Li2CO3 impurity: LixMyO2 wherein M=M′l-kAk, where M′=Nil-a-b(Ni1 / 2Mn1 / 2)aCob on condition of 0.65≦a+b≦0.85 and 0.1≦b≦0.4; A is a dopant; and 0≦k≦0.05; and x+y=2 on condition of 0.95≦x≦1.05. The Ni-based lithium transition metal oxide according to the present invention has a well-layered structure, and also improved safety, cycling stability and stability against aging and low gas evolution during storage, when used as an active material for cathode of lithium secondary batteries, because it has a high sintering stability and is substantially free of soluble bases. Moreover, the lithium transition metal oxide of the present invention can be prepared by a low-cost process using a mixed transition metal precursor and Li2CO3 as raw stocks and under relatively unrestricted conditions.

Owner:LG ENERGY SOLUTION LTD

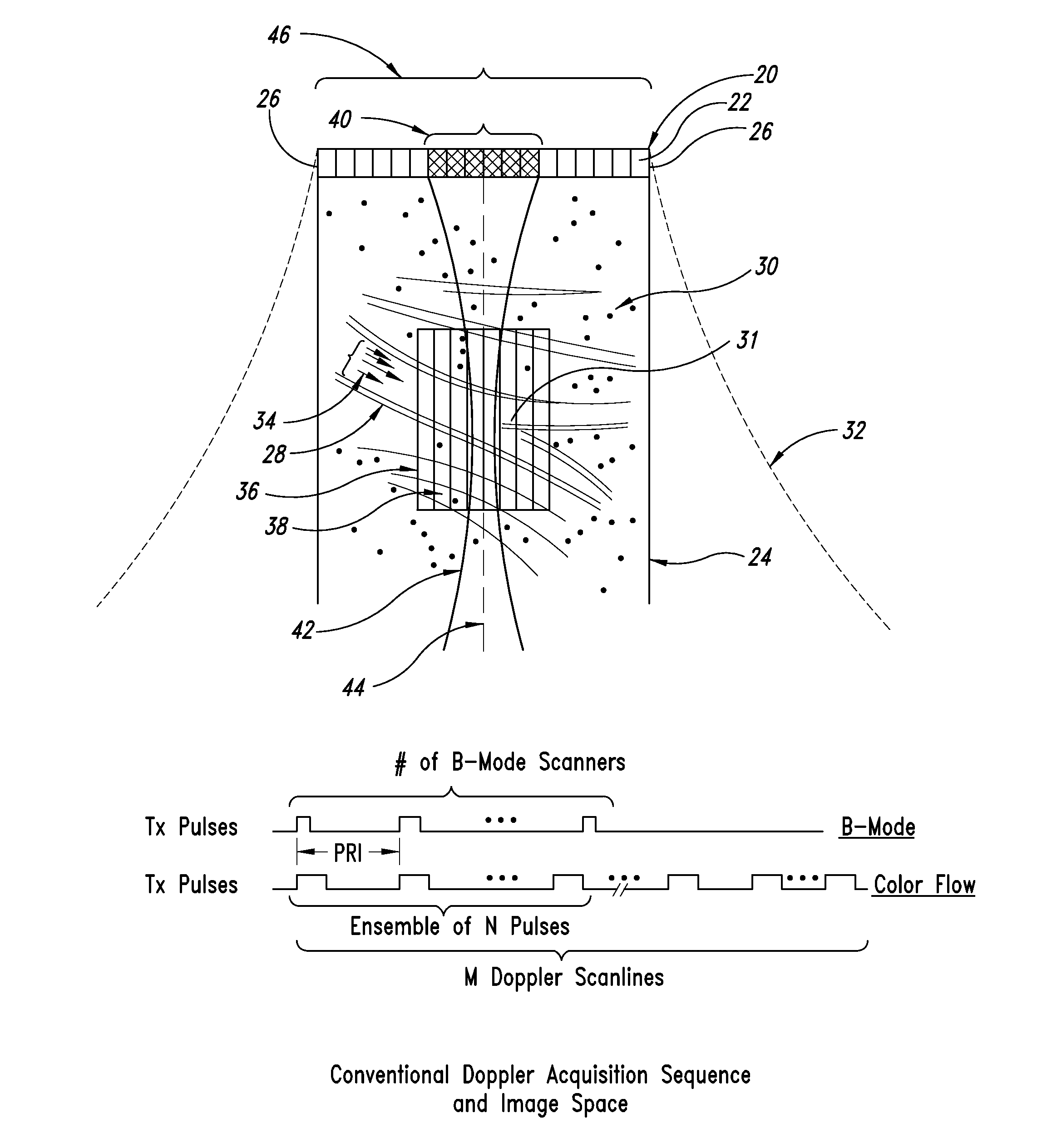

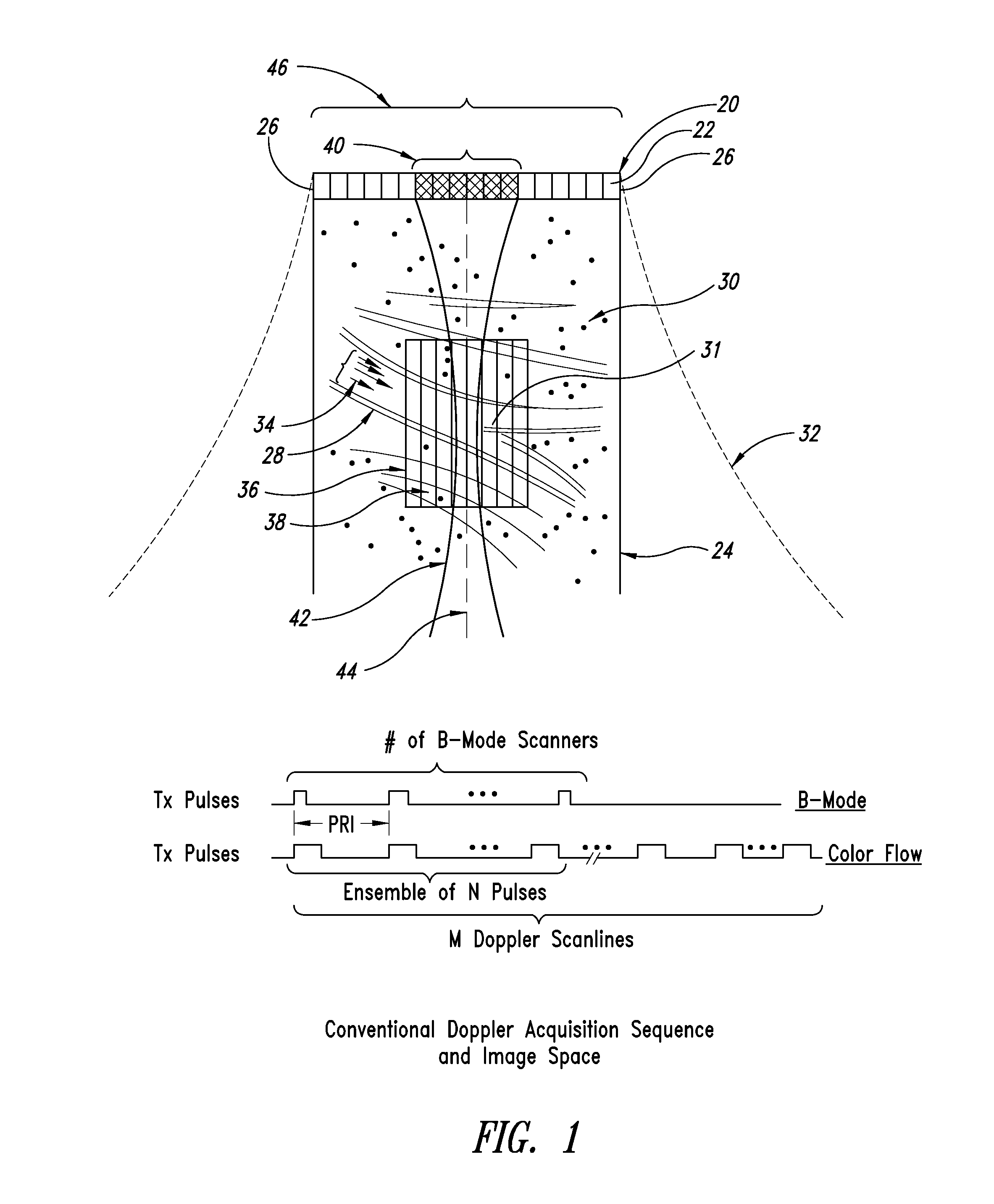

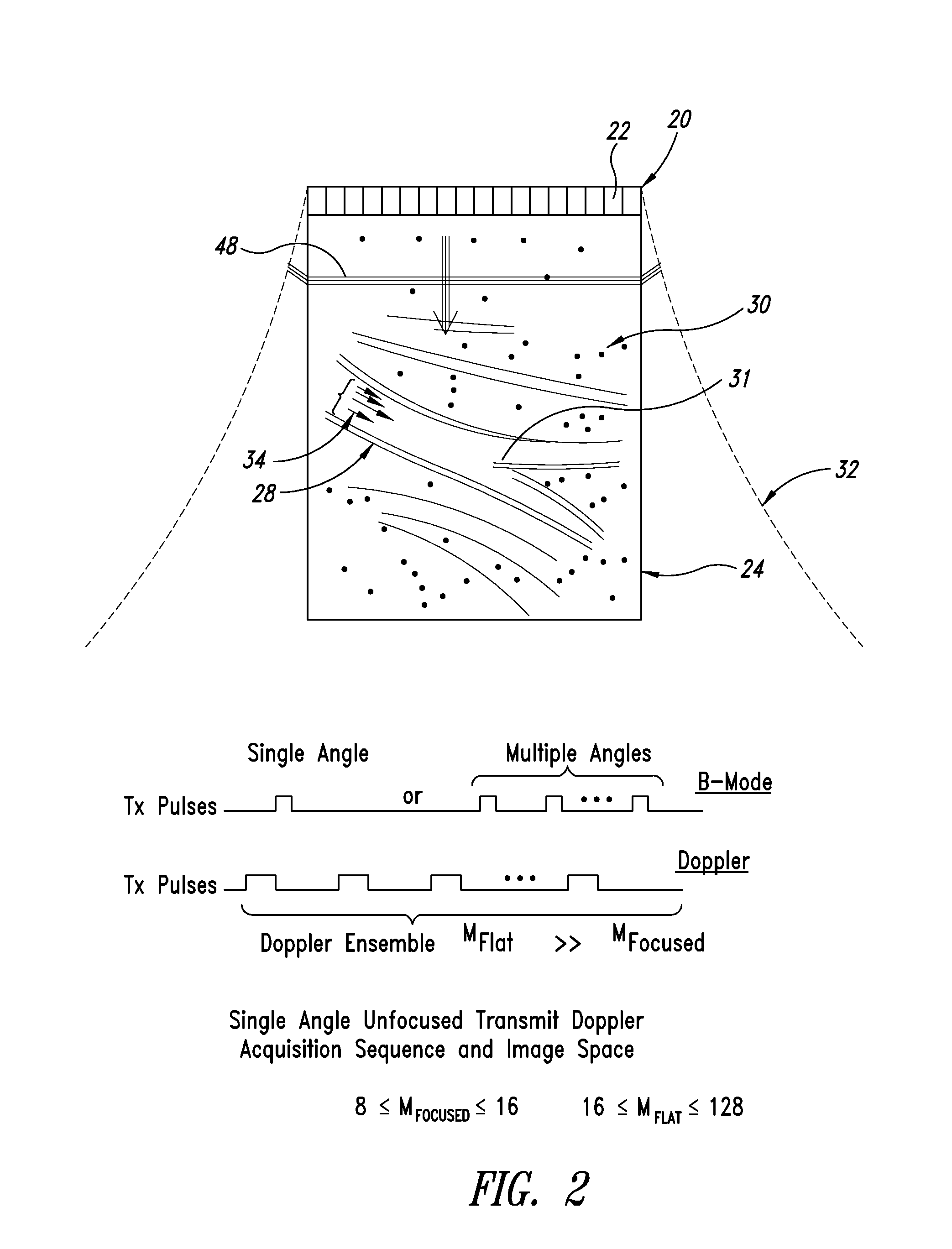

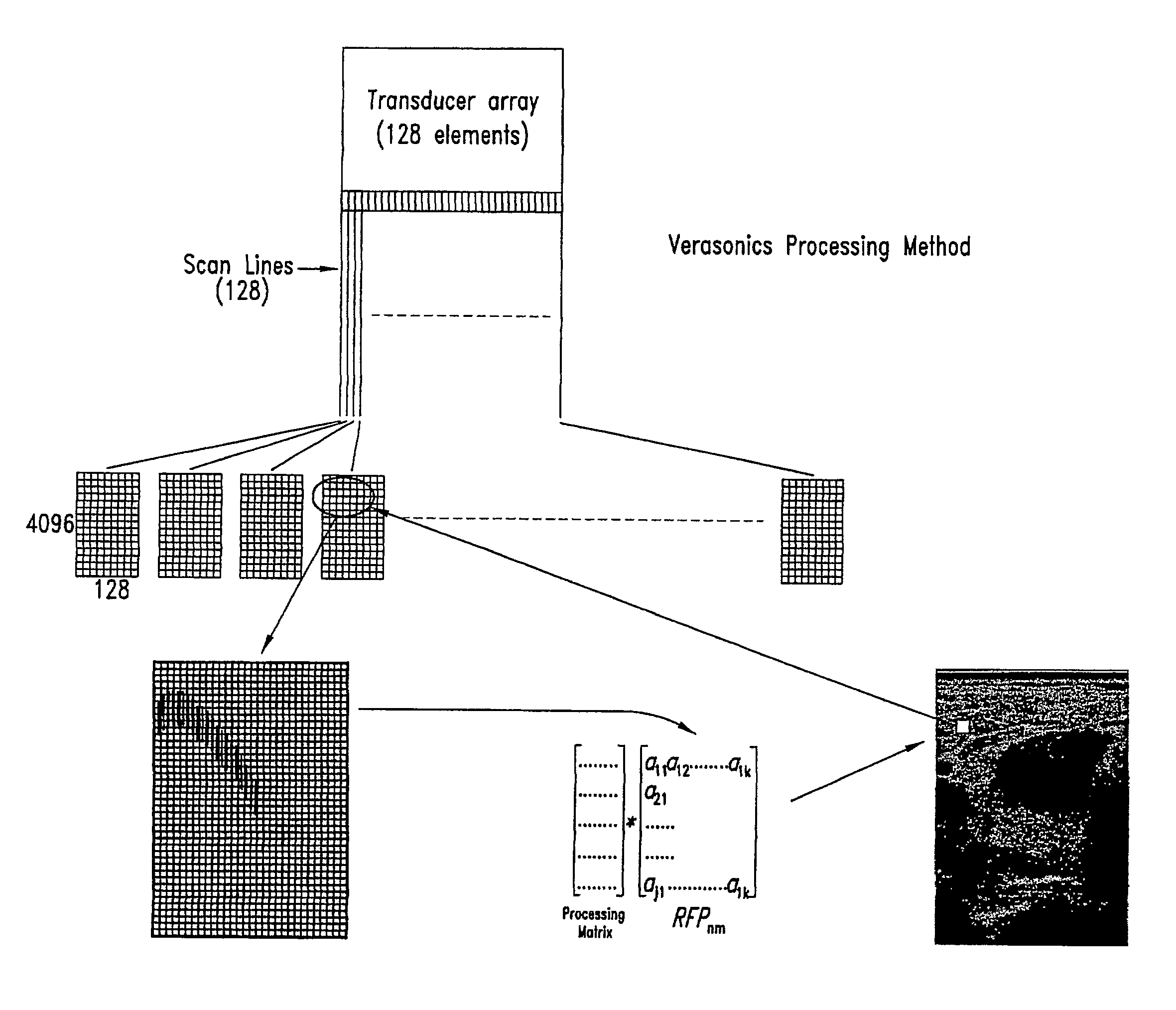

High frame rate quantitative doppler flow imaging using unfocused transmit beams

ActiveUS20090326379A1Enhanced acoustic informationImprovement of contrast resolutionBlood flow measurement devicesInfrasonic diagnosticsUltrasound imagingHigh frame rate

An ultrasound imaging system with pixel oriented processing is provided in which a method of producing a Doppler velocity image is accomplished by emitting unfocused acoustic signals into a medium over substantially an entire field; receiving scattered and reflected ultrasonic signals on a transducer array in response to the emission; processing the received ultrasonic signals to extract information to construct a Doppler velocity signal corresponding to at least one point in the medium; and generating on a display device the Doppler velocity image from the processed Doppler velocity signal. Acquisition sequences and signal processing algorithms are described that provide improved quantification of fluid flow parameters, including improved discrimination between regions of blood flow and tissue. Very high frame rate Spectral Doppler and Vector Doppler acquisition modes for real-time and post-acquisition visualization over a large field of view are described.

Owner:VERASONICS

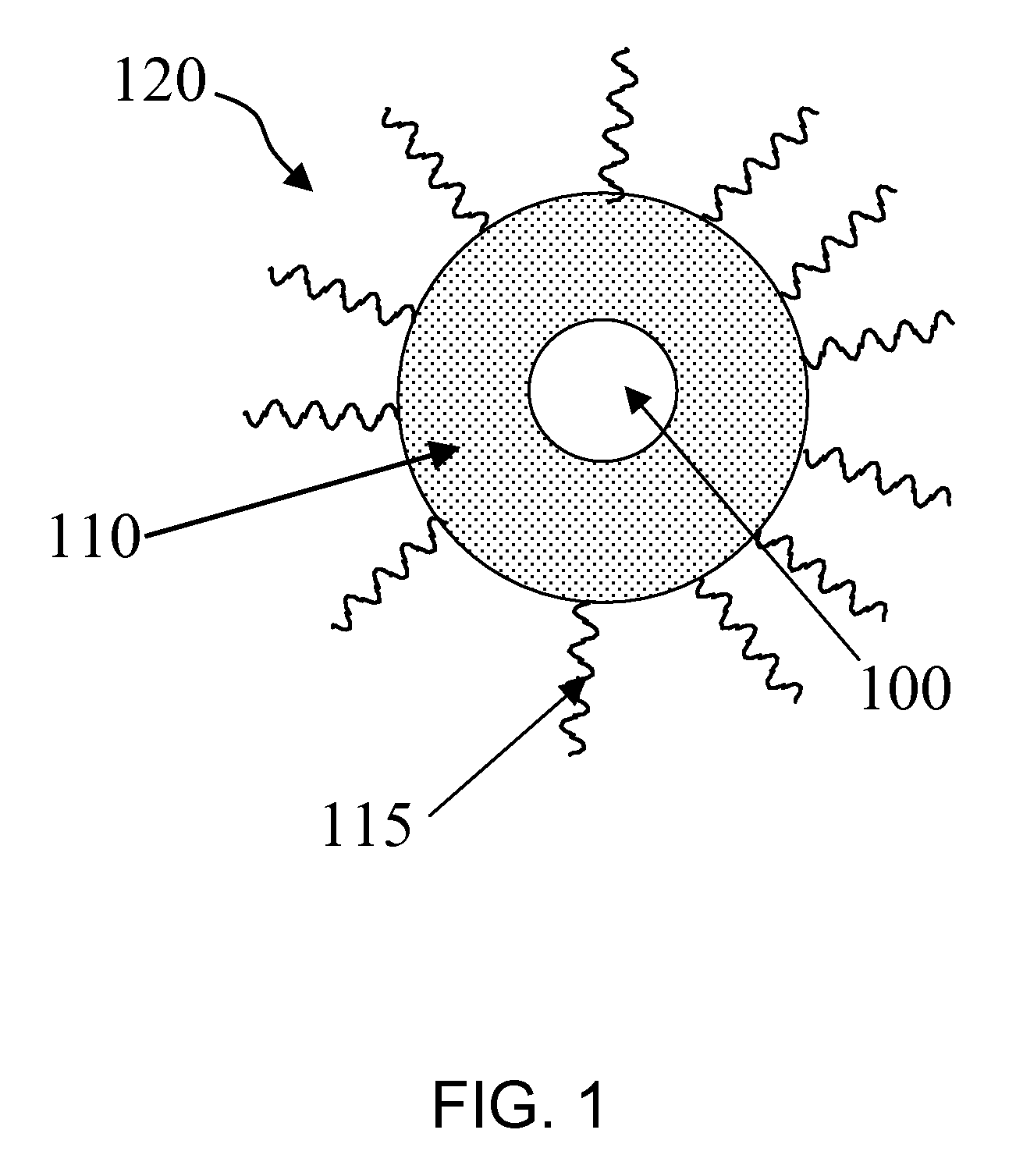

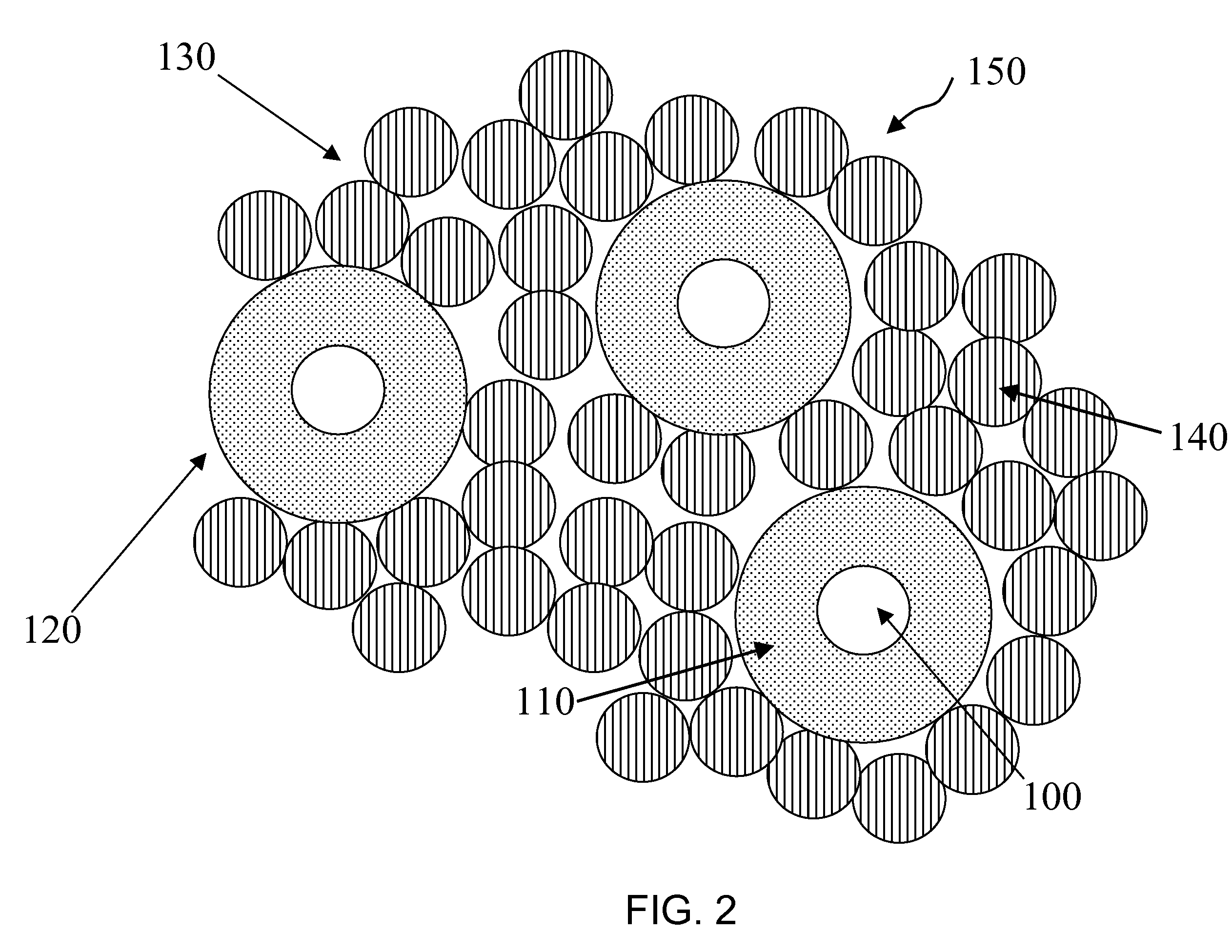

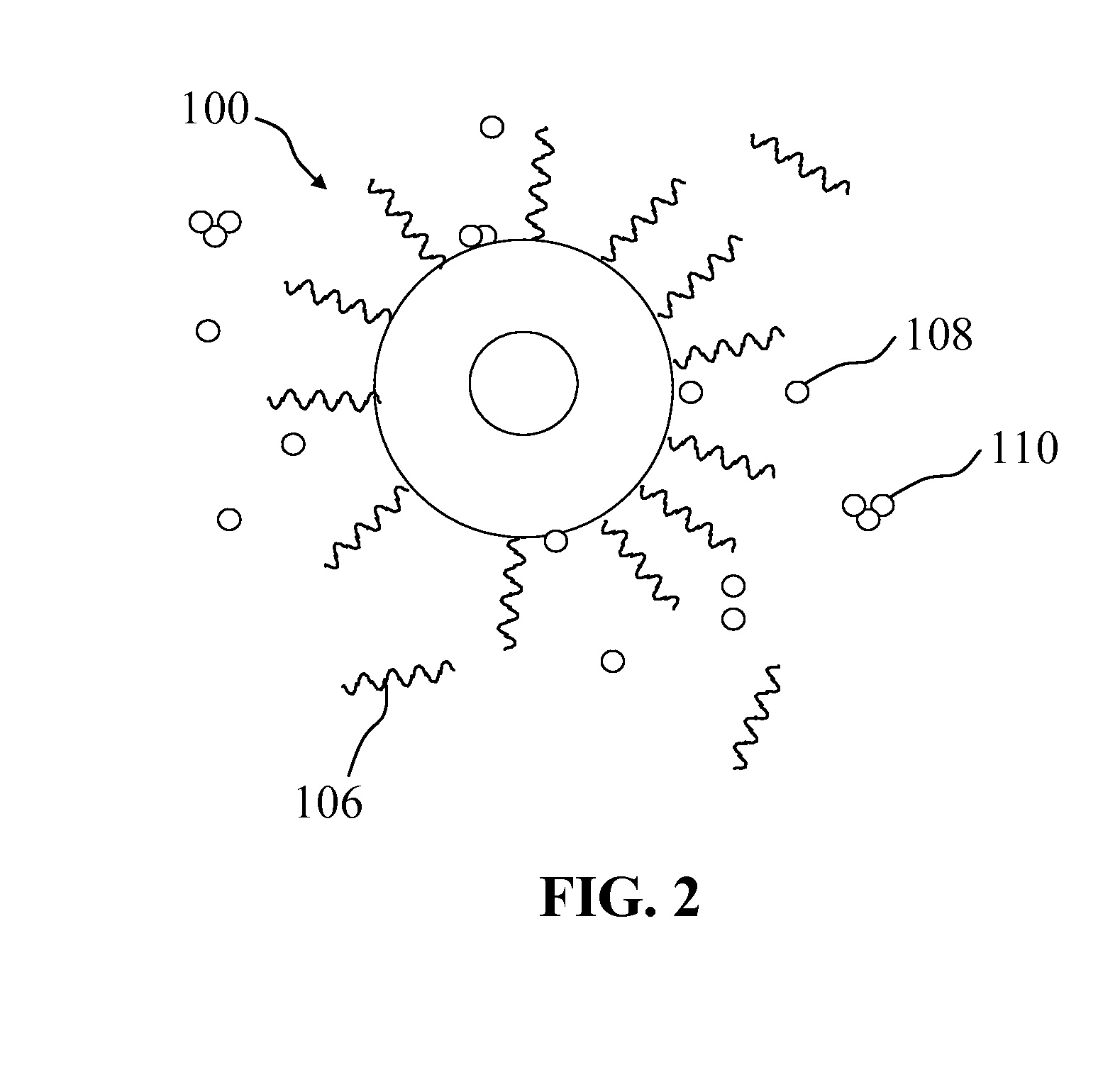

Quantum dot light emitting device

InactiveUS20080217602A1Without a loss in their fluorescent efficiencyImprove conductivityNanotechDischarge tube luminescnet screensQuantum dotLight emitting device

An inorganic light emitting device including a transparent substrate; a first electrode; a second electrode opposed to the first electrode; a polycrystalline inorganic light emitting layer including core / shell quantum dots within an inorganic semiconductor matrix and, wherein the first electrode is transparent and formed on the transparent substrate, the polycrystalline inorganic light emitting layer is formed over the first electrode, and the second electrode is formed over the light emitting layer.

Owner:NANOCO TECH LTD

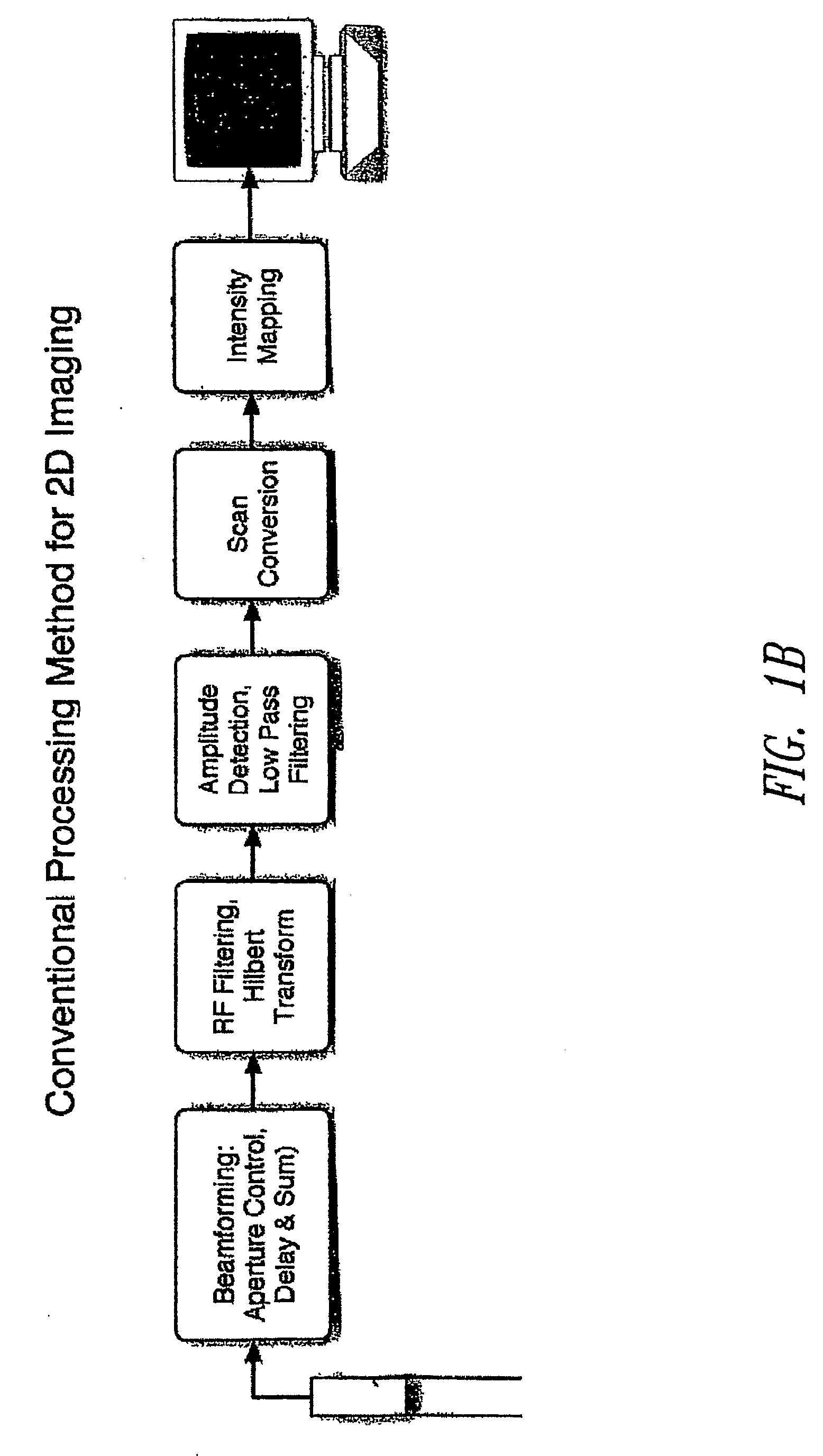

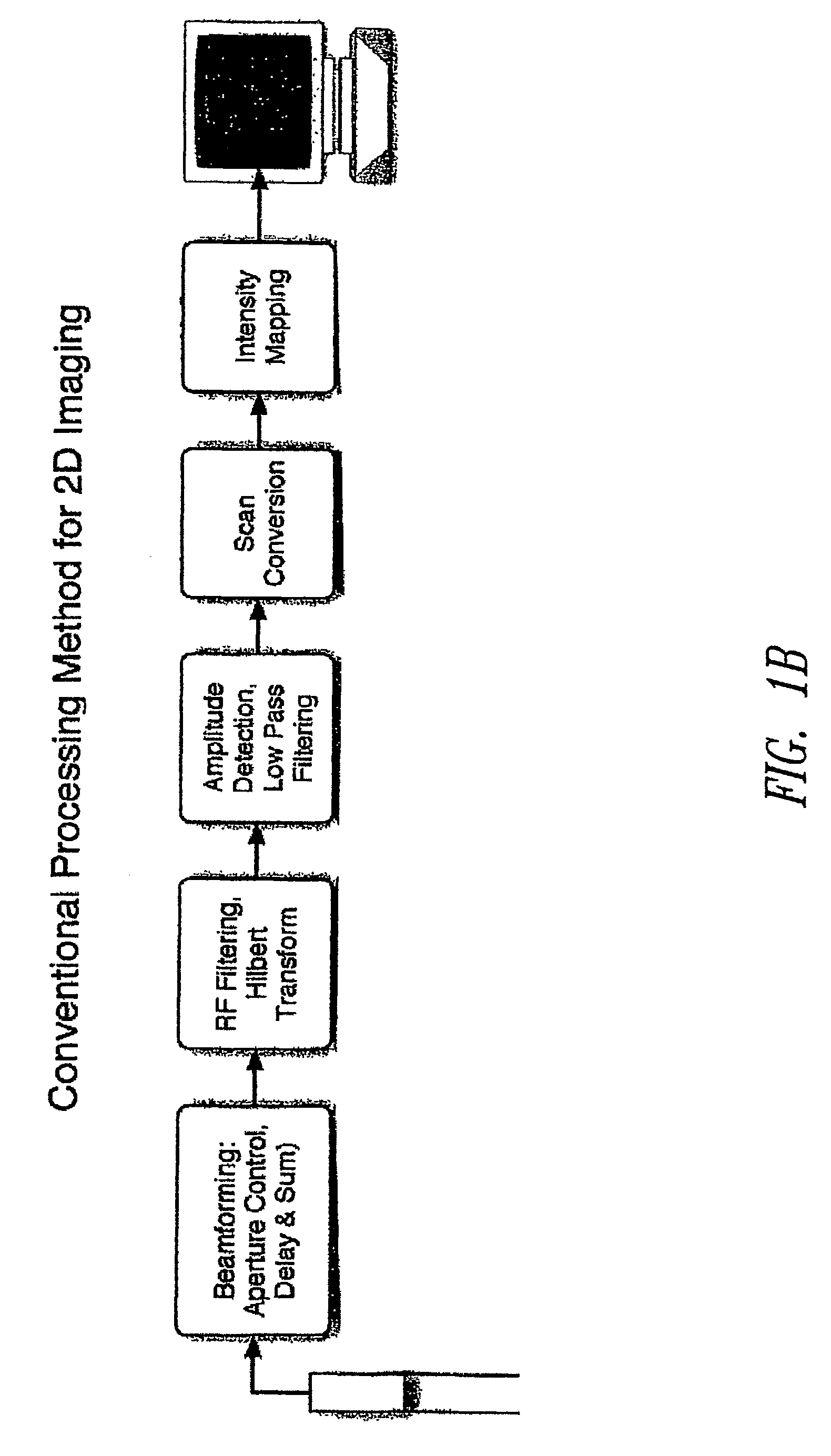

Ultrasound imaging system with pixel oriented processing

ActiveUS20090112095A1Reduce in quantityEliminate system latencyBlood flow measurement devicesInfrasonic diagnosticsHigh frame rateSonification

An ultrasound imaging system with pixel oriented processing is provided in which an acoustic signal is generated, echoes from the acoustic signal are received at a plurality of receiving elements to obtain echo signals that are then stored, a given pixel is mapped into a region of the stored signals, the mapped region of the stored echo signals is organized into array for the given pixel after which the array is processed to generate a signal response for the given pixel to obtain acoustic information for the given pixel. The system can be implemented entirely on plug-in cards for a commercial PC motherboard. The system and method can be implemented for pixel-oriented or voxel-oriented image processing and display, eliminating intermediate data computations and enabling extensive use of software processing methods. Advantages include improved acquisition of signal dynamic range, flexible acquisition modes for high frame rate 2D, 3D, and Doppler blood flow imaging.

Owner:VERASONICS

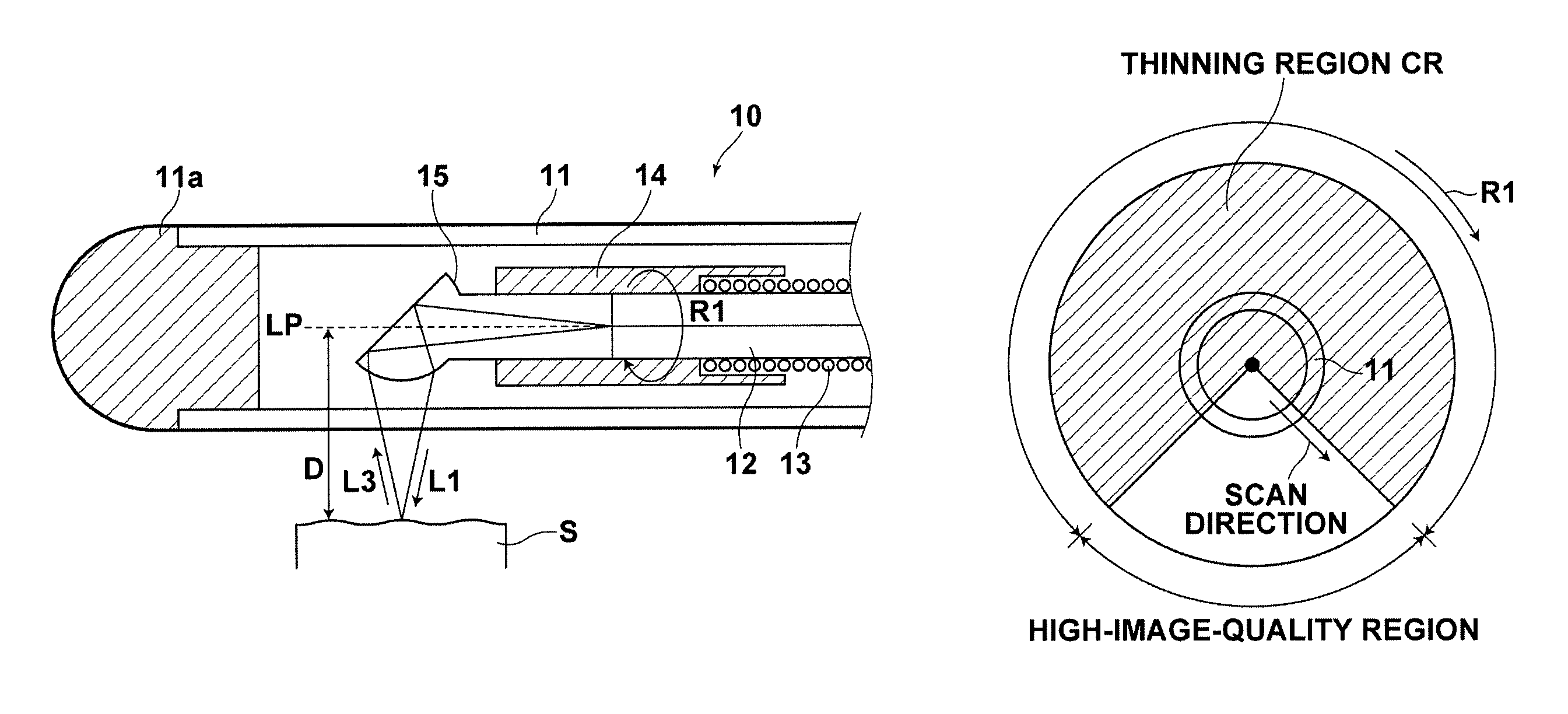

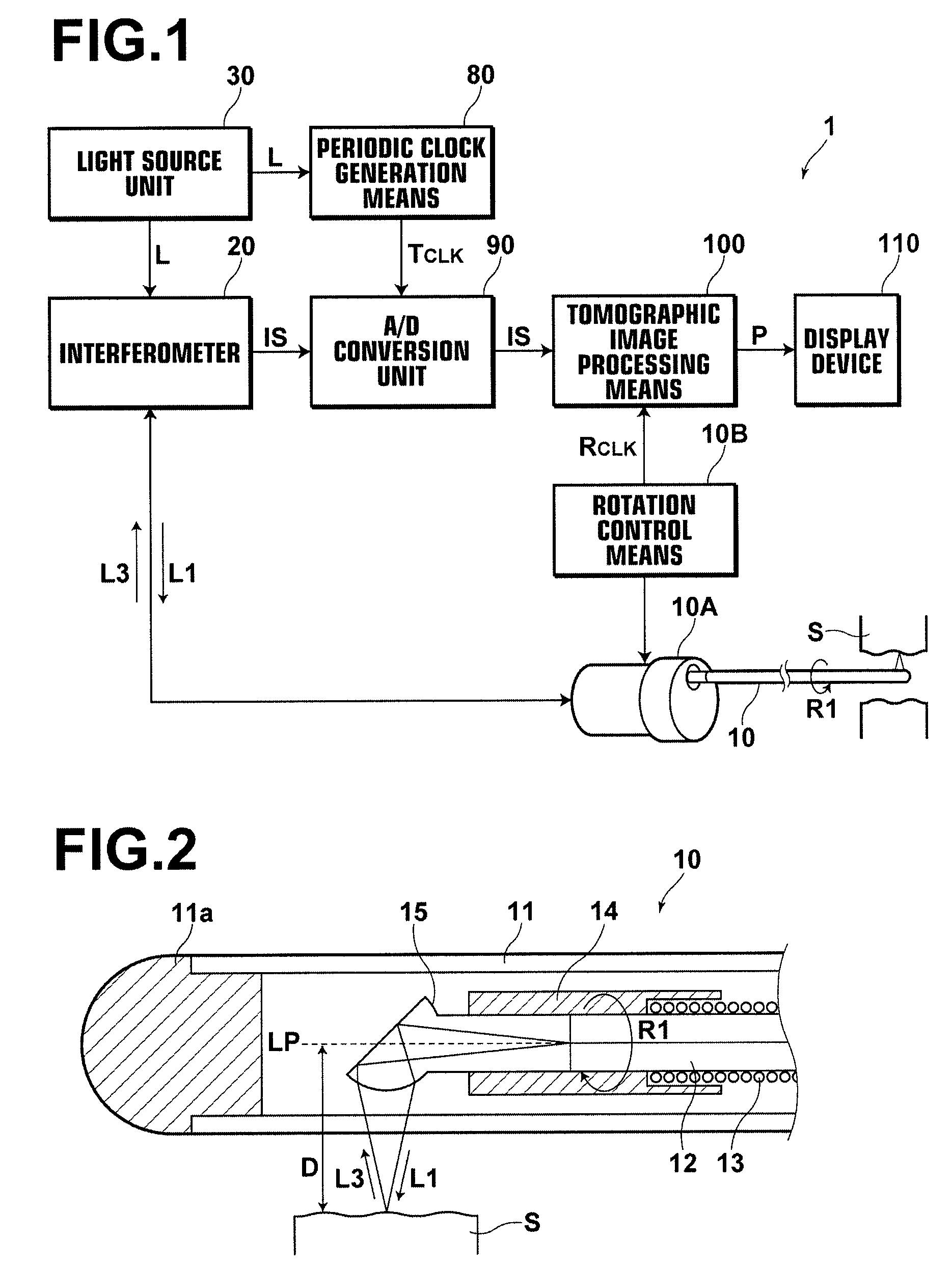

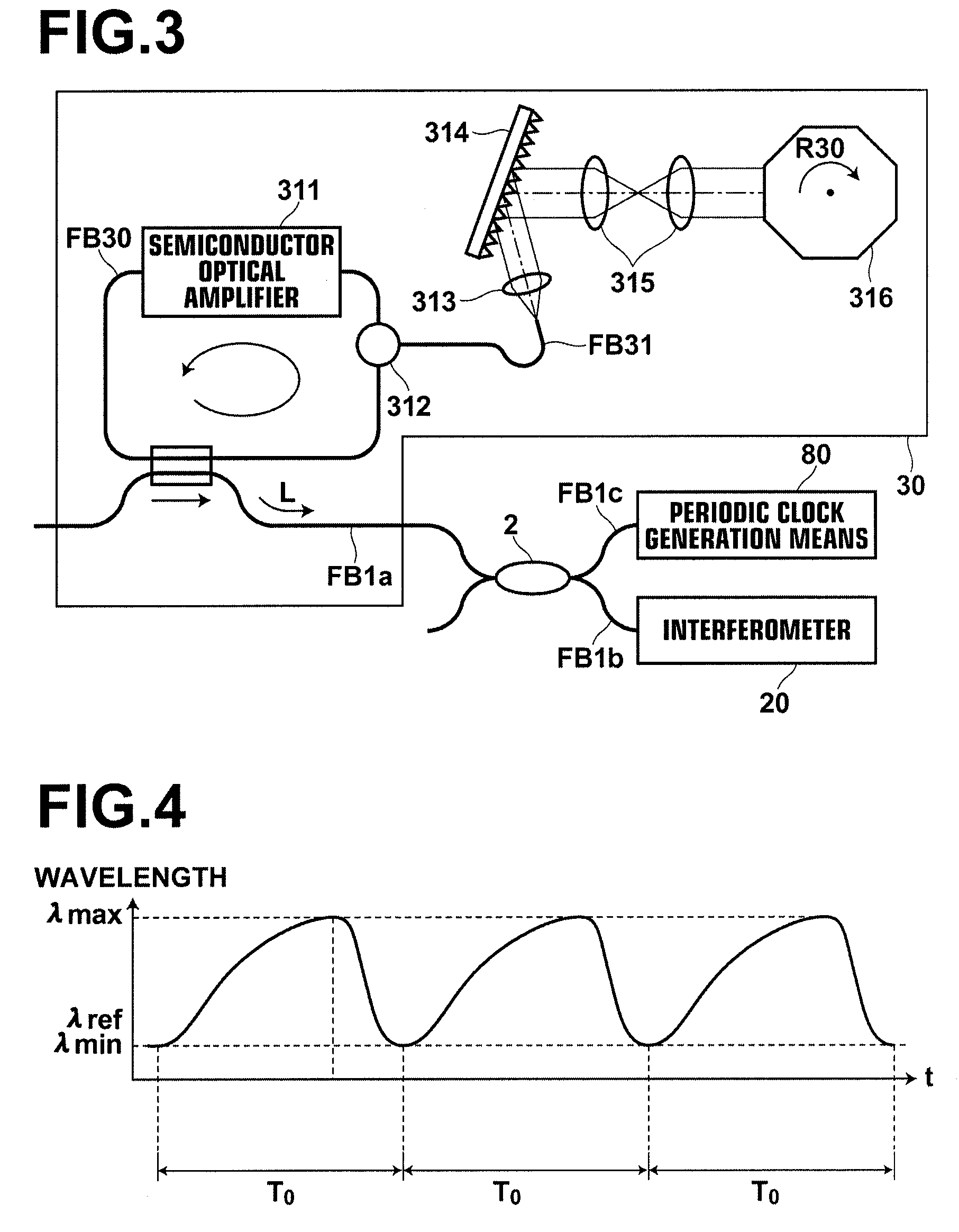

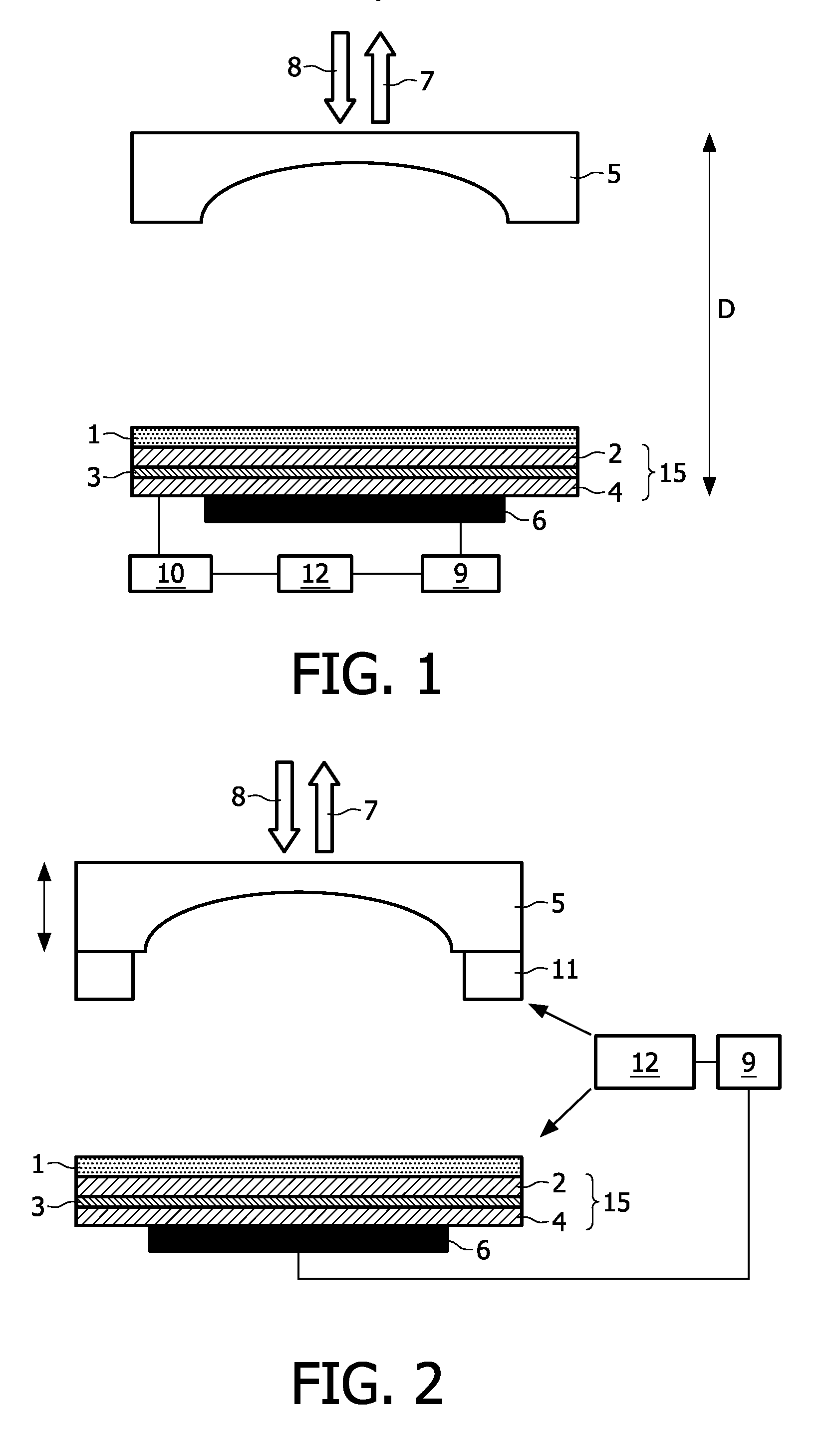

Method and system for producing tomographic image by optical tomography with processing of interference light signals

ActiveUS7944568B2High motion-image response characteristicLow cost processingInterferometersUsing optical meansOptical tomographyLength wave

When reflection light, reflected from a measurement target that has been irradiated with measurement light in such a manner to scan the measurement target, and reference light are combined in each wavelength sweep, interference light is detected as interference signals. When a thinning region in which the interference signals obtained by detecting the interference light in each wavelength sweep are thinned so that the interference signals that are used to produce the tomographic image remain is set, thinning is performed on the plurality of interference signals in the thinning region. Light intensity information about the measurement target in the thinning region is obtained, based on the interference signals for the respective wavelength sweeps, the interference signals remaining after thinning. The tomographic image in the thinning region is produced based on the obtained light intensity information.

Owner:KK TOPCON

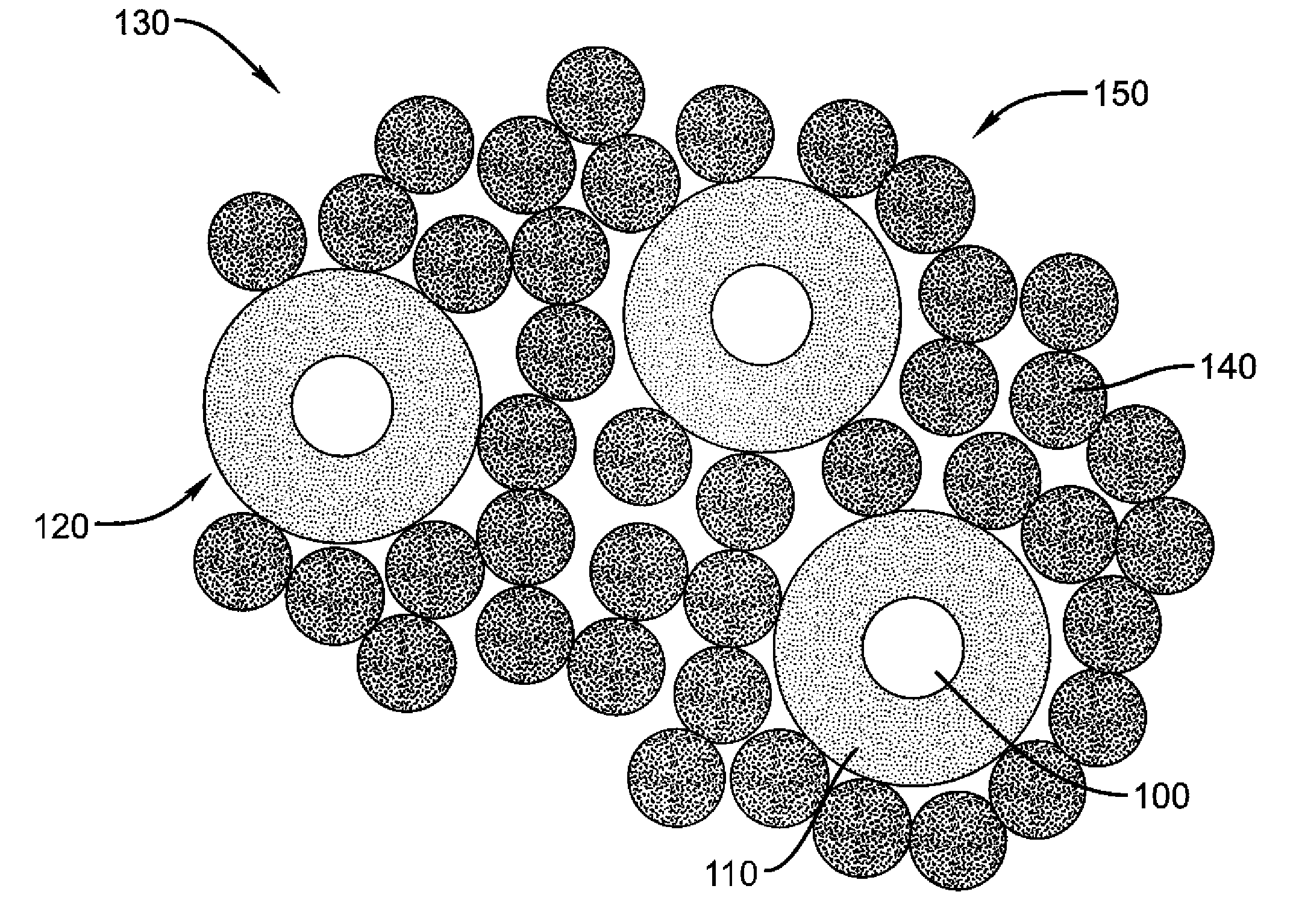

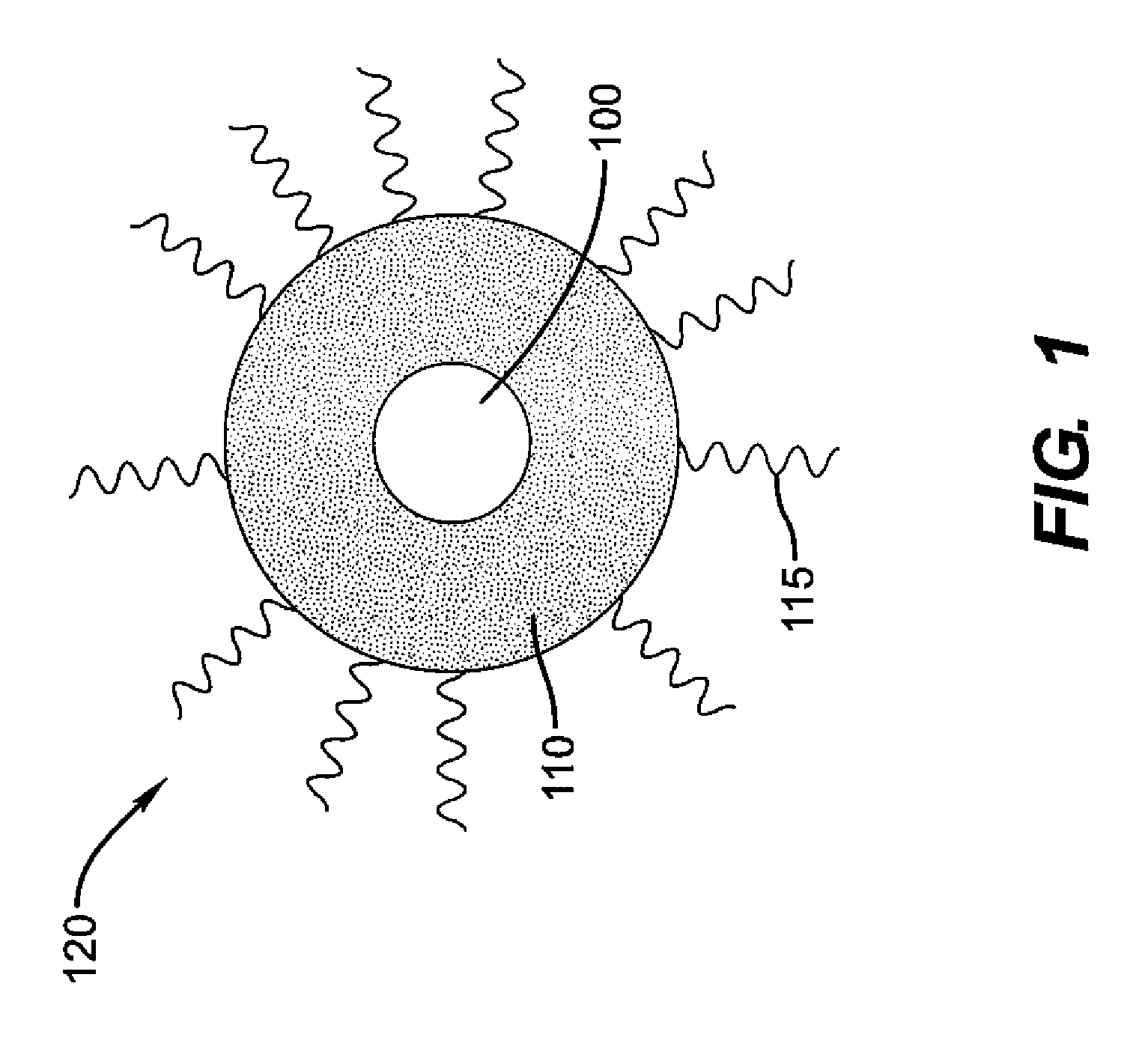

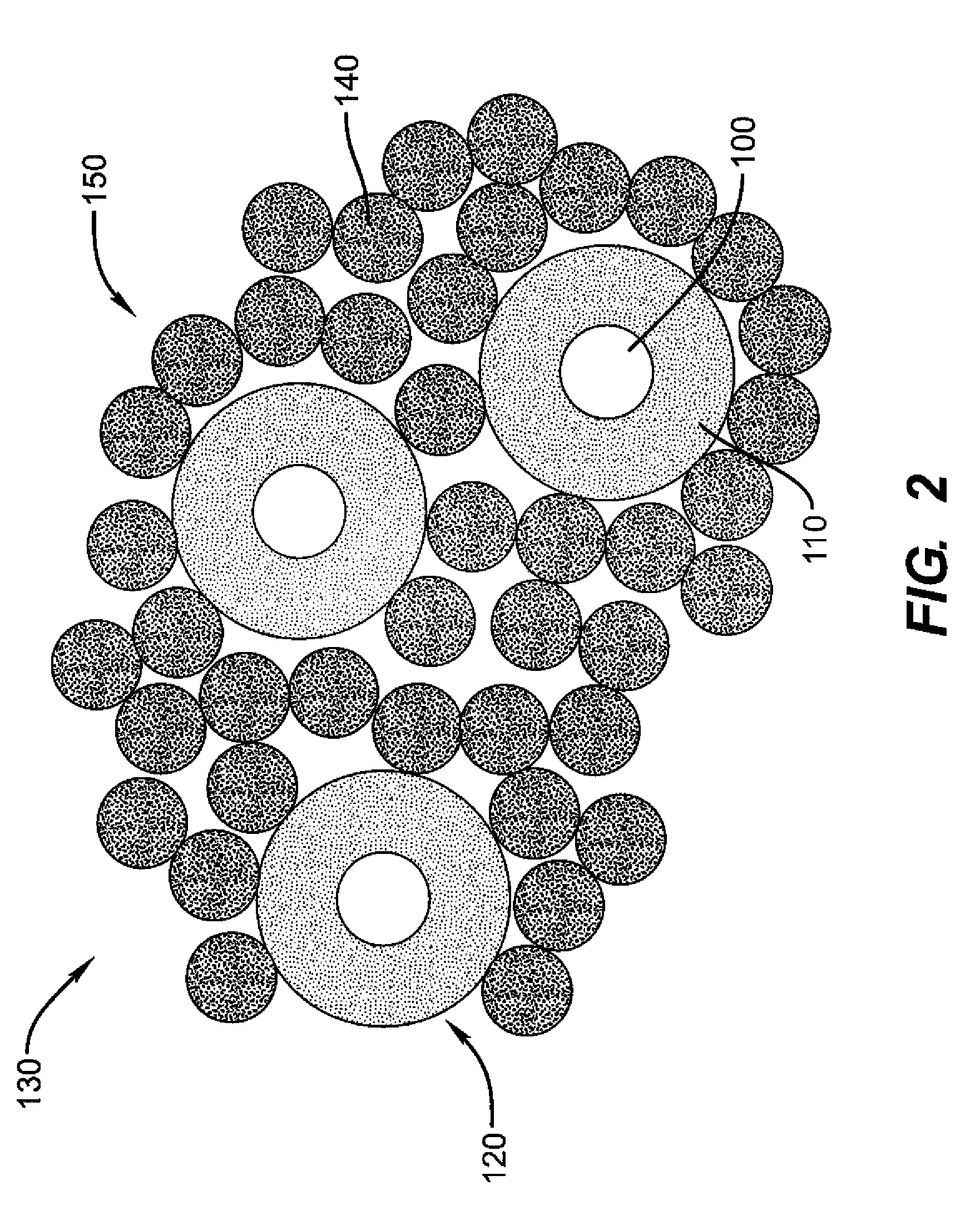

Quantum dot light emitting layer

InactiveUS7615800B2Without a loss in their fluorescent efficiencyImprove conductivityMaterial nanotechnologyElectroluminescent light sourcesSemiconductor materialsQuantum dot

An inorganic light emitting layer having a plurality of light emitting cores, each core having a semiconductor material that emits light in response to recombination of holes and electrons, each such light emitting core defining a first bandgap; a plurality of semiconductor shells formed respectively about the light emitting cores to form core / shell quantum dots, each such semiconductor shell having a second bandgap wider than the first bandgap; and a semiconductor matrix connected to the semiconductor shells to provide a conductive path through the semiconductor matrix and to each such semiconductor shell and its corresponding light emitting core so as to permit the recombination of holes and electrons.

Owner:NANOCO TECH LTD

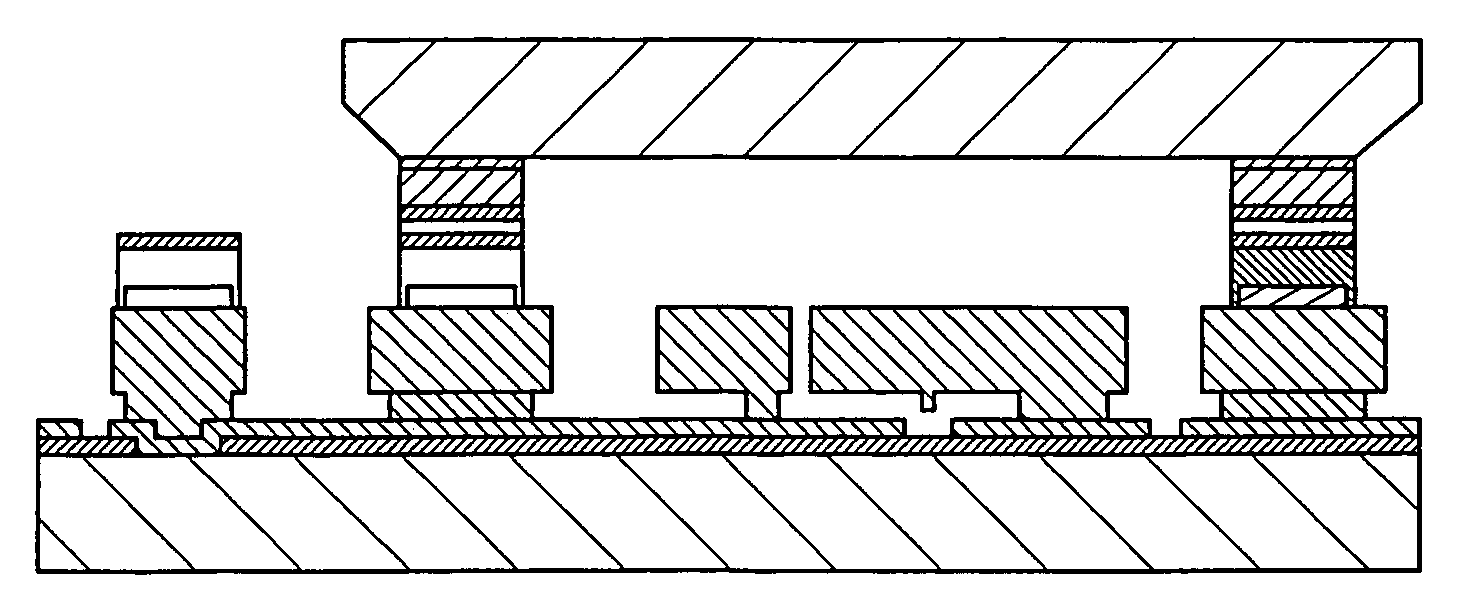

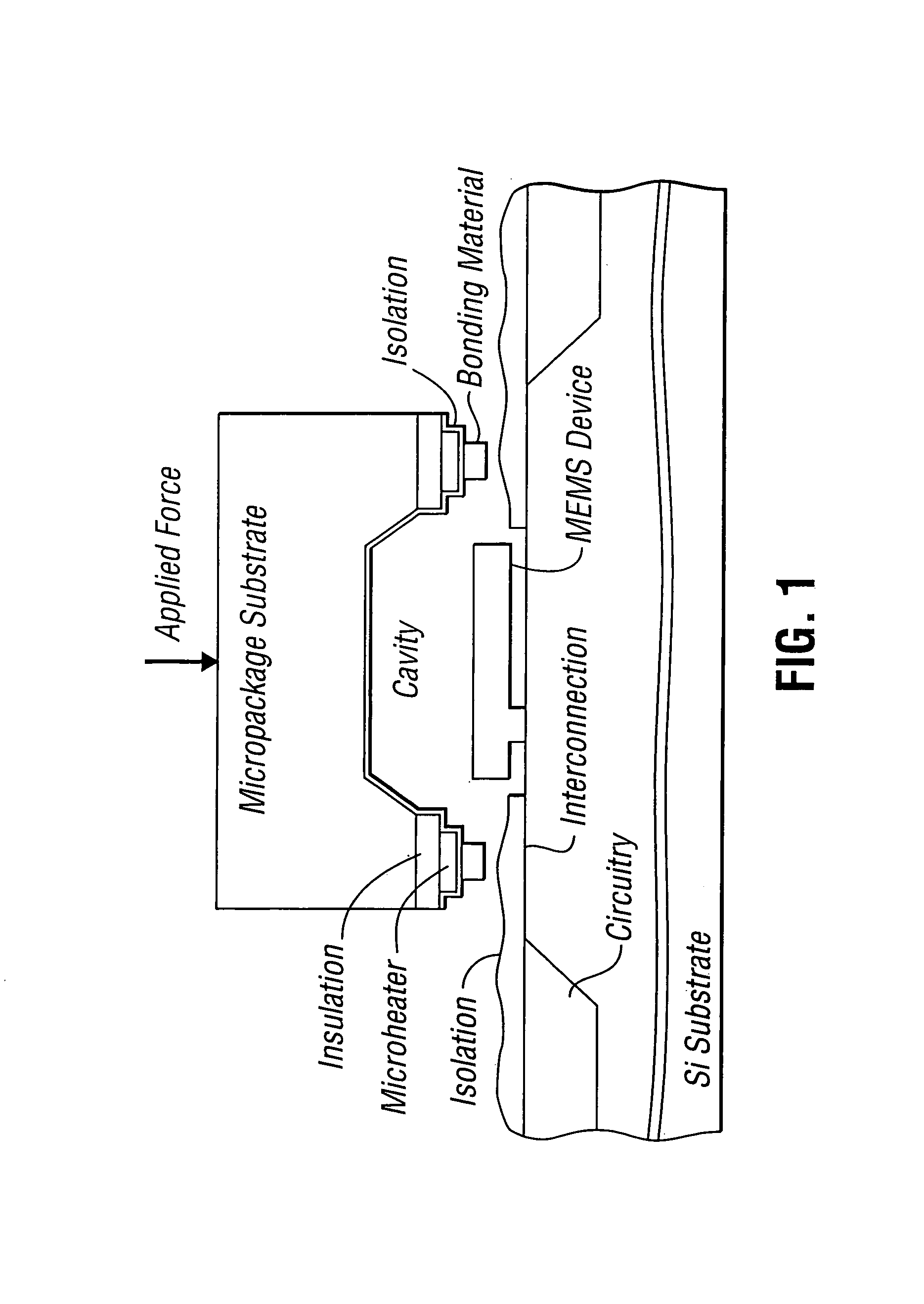

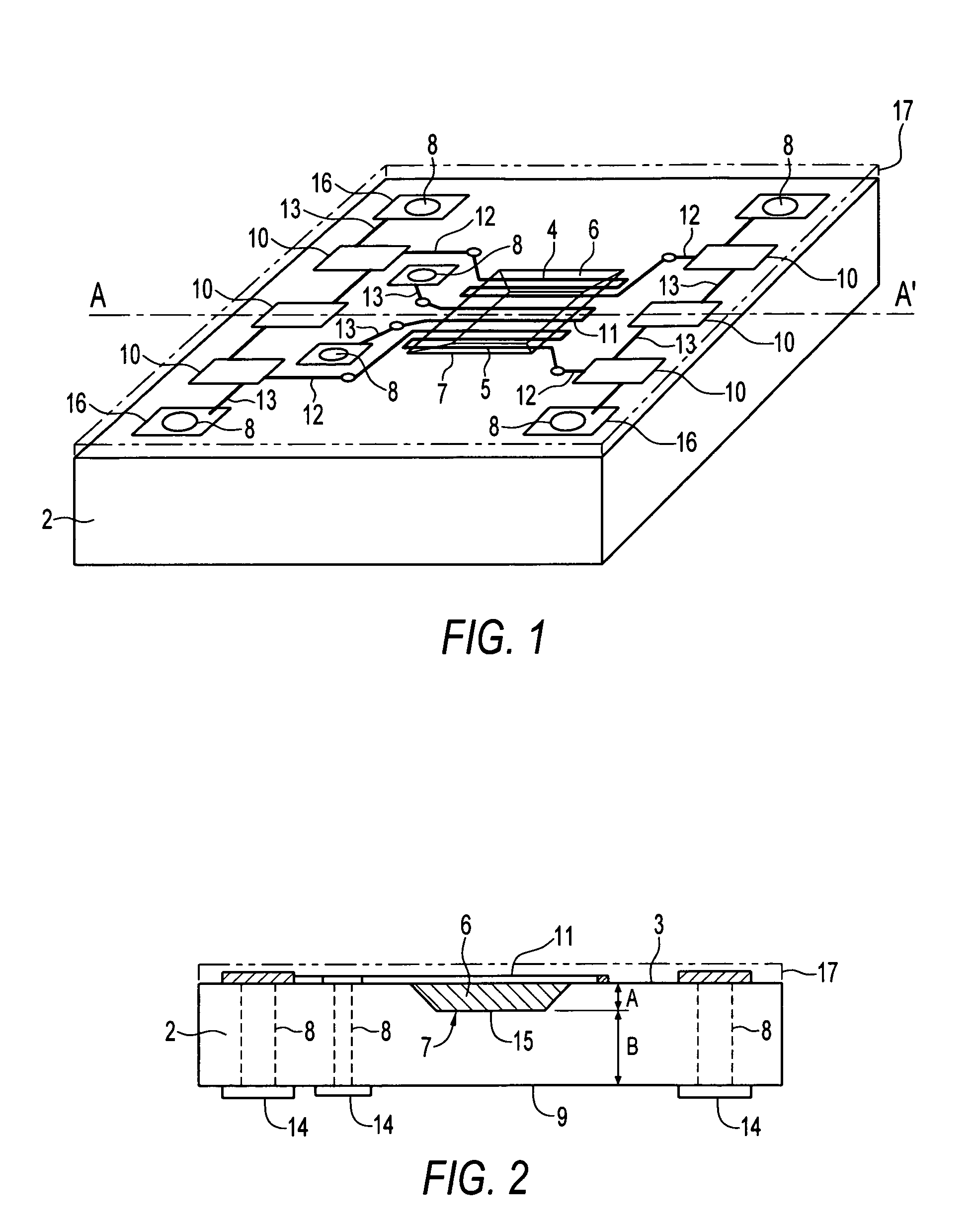

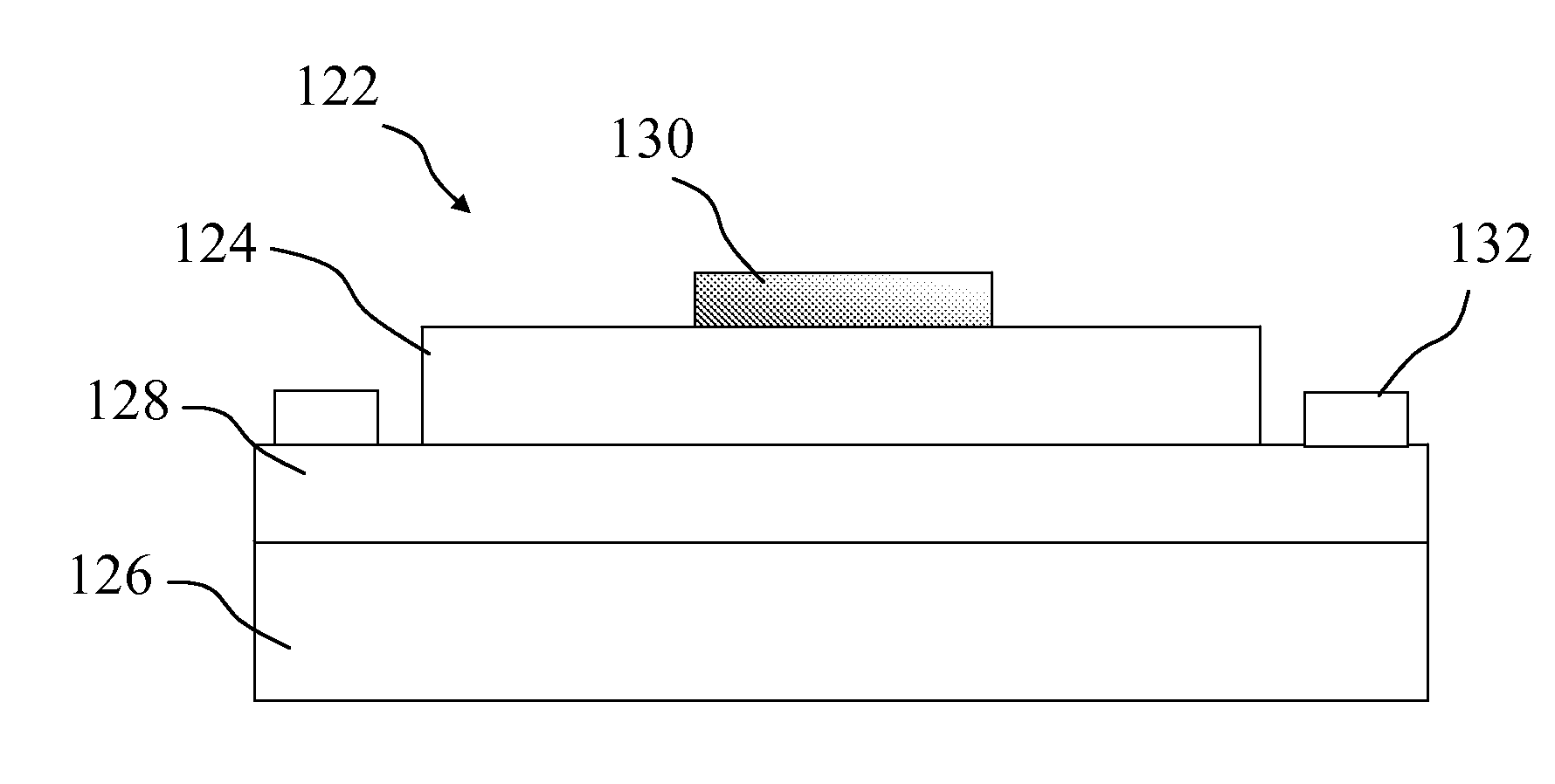

Wafer level packaging technique for microdevices

InactiveUS7138293B2Low cost processingLow costDecorative surface effectsSemiconductor/solid-state device detailsCadmium CationTin

A method is disclosed for fabricating a integrated device, such as a MEMS device. A first wafer is provided on an exposed surface with a layer of gold, gold alloy or gold compound. A second wafer is provided on its exposed surface with under-layer of gold, gold alloy or gold compound; and an over- of bismuth, bismuth alloy, a compound of bismuth, cadmium, cadmium alloy, a compound of cadmium compound, tin, tin alloy, or a compound of tin. The wafers are then brought into contact and bonded at their surfaces through the deposited layers.

Owner:TELEDYNE DIGITAL IMAGING INC

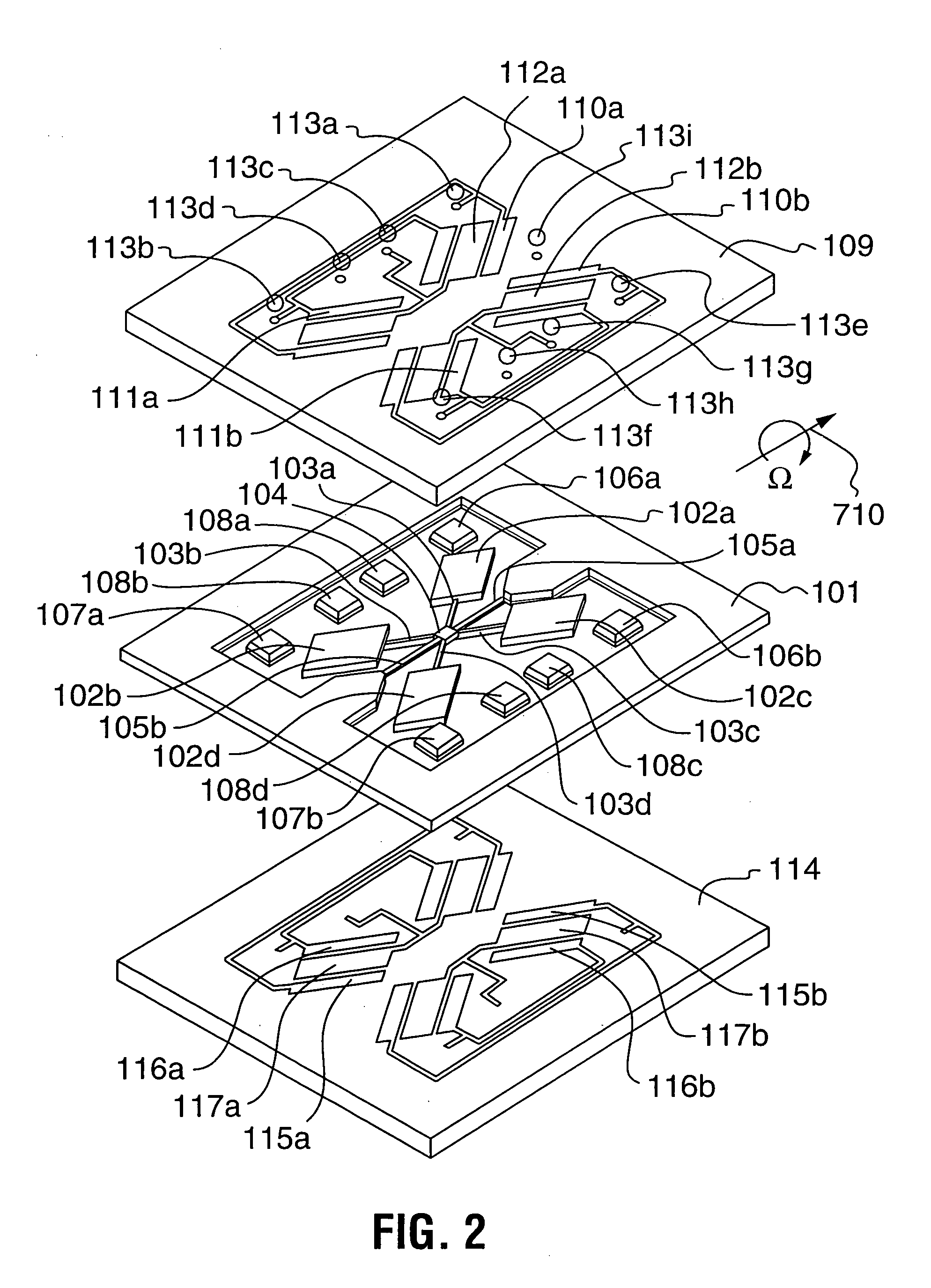

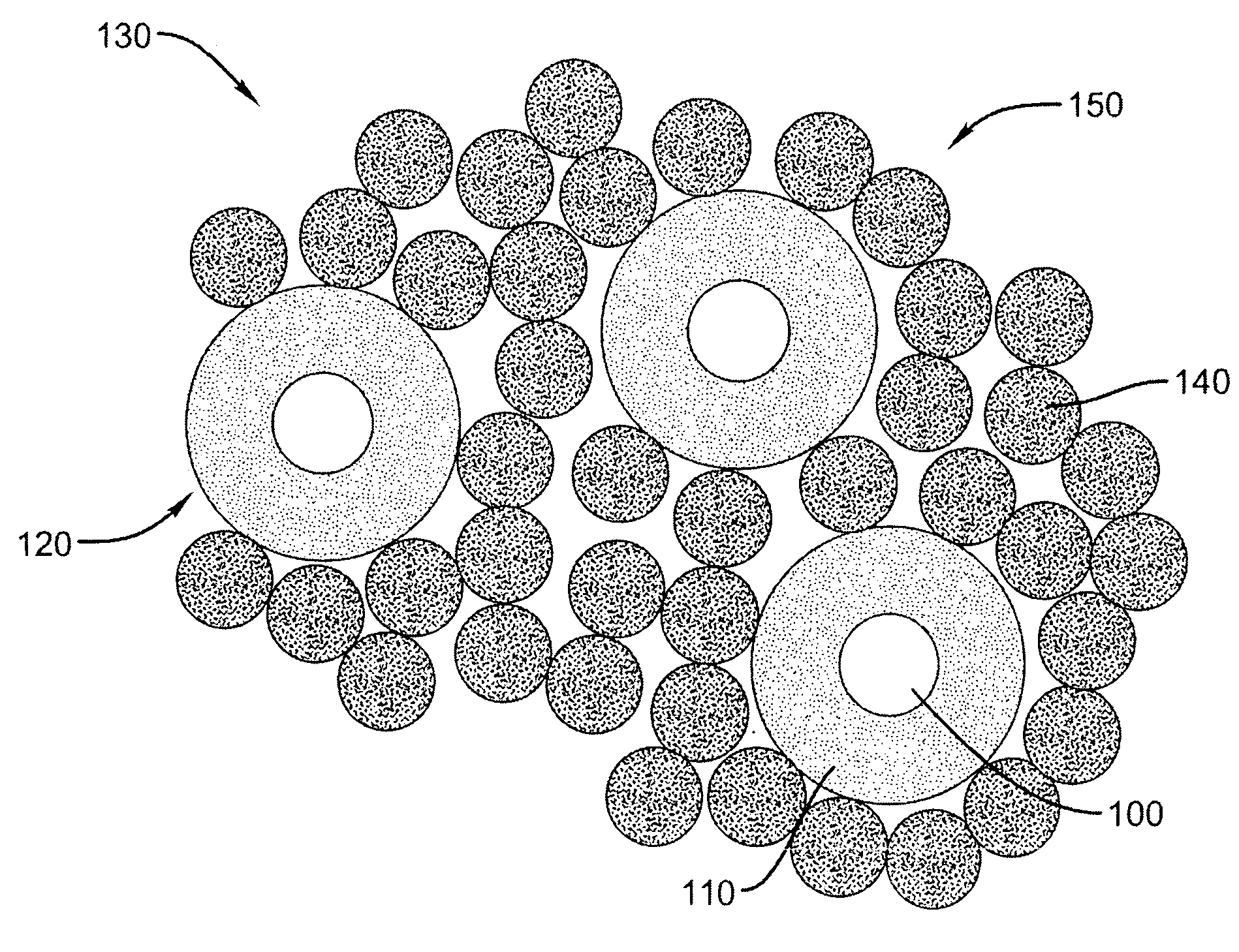

Laser sensor for self-mixing interferometry with increased detection range

ActiveUS20100134803A1Low cost processingIncrease cavity lengthLaser detailsLaser optical resonator constructionPhotovoltaic detectorsPhotodetector

The present invention relates to a laser sensor for self-mixing interferometry. The laser sensor comprises at least one semiconductor laser light source emitting laser radiation and at least one photodetector (6) monitoring the laser radiation of the laser light source. The laser light source is a VECSEL having a gain medium (3) arranged in a layer structure (15) on a front side of a first end mirror (4), said first end mirror (4) forming an external cavity with an external second end mirror (5). The proposed laser sensor provides an increased detection range and can be manufactured in a low-cost production process.

Owner:TRUMPF PHOTONIC COMPONENTS GMBH

Battery containing ni-based lithium transition metal oxide

ActiveUS20090226810A1Increase hierarchyImprove securityEnergy inputAlkali metal oxidesElectrical batteryOxide cathode

Owner:LG ENERGY SOLUTION LTD

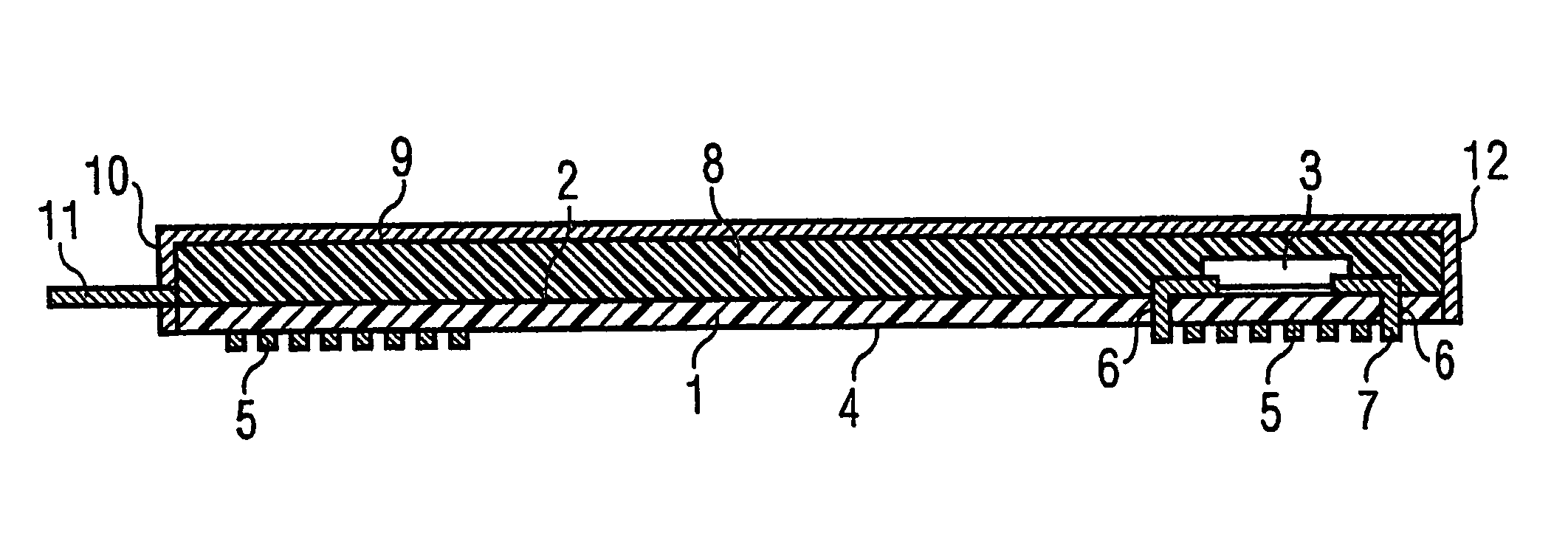

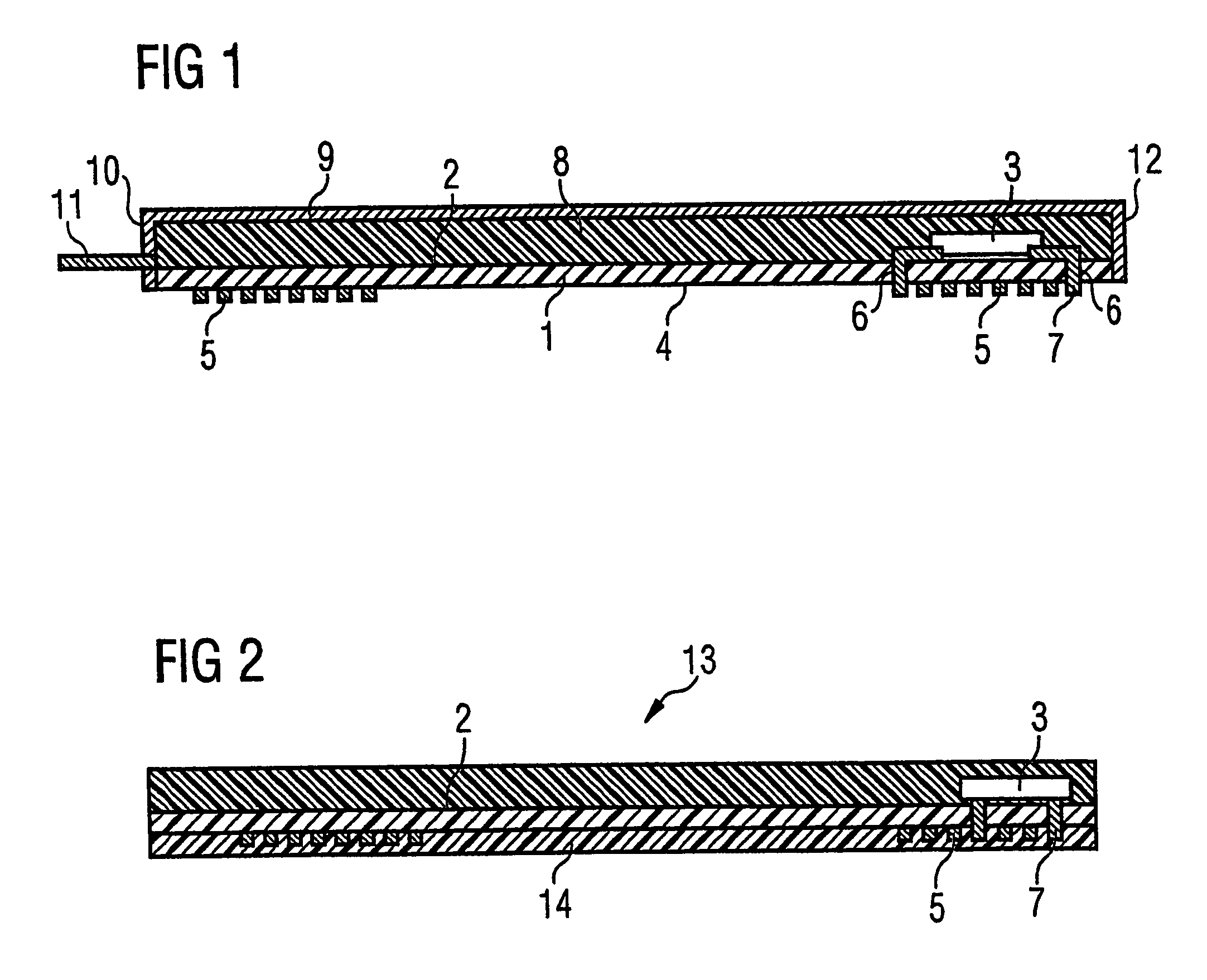

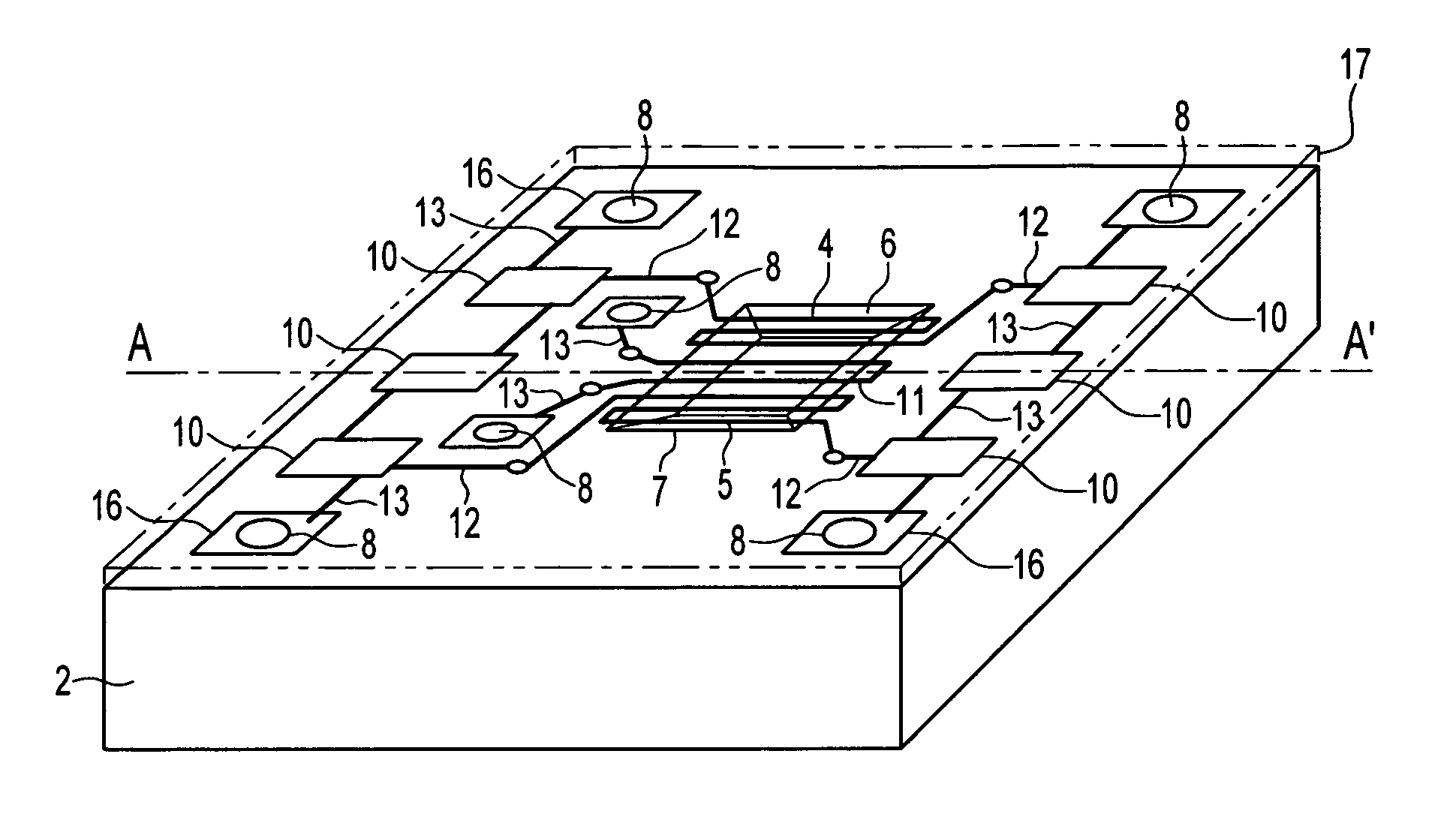

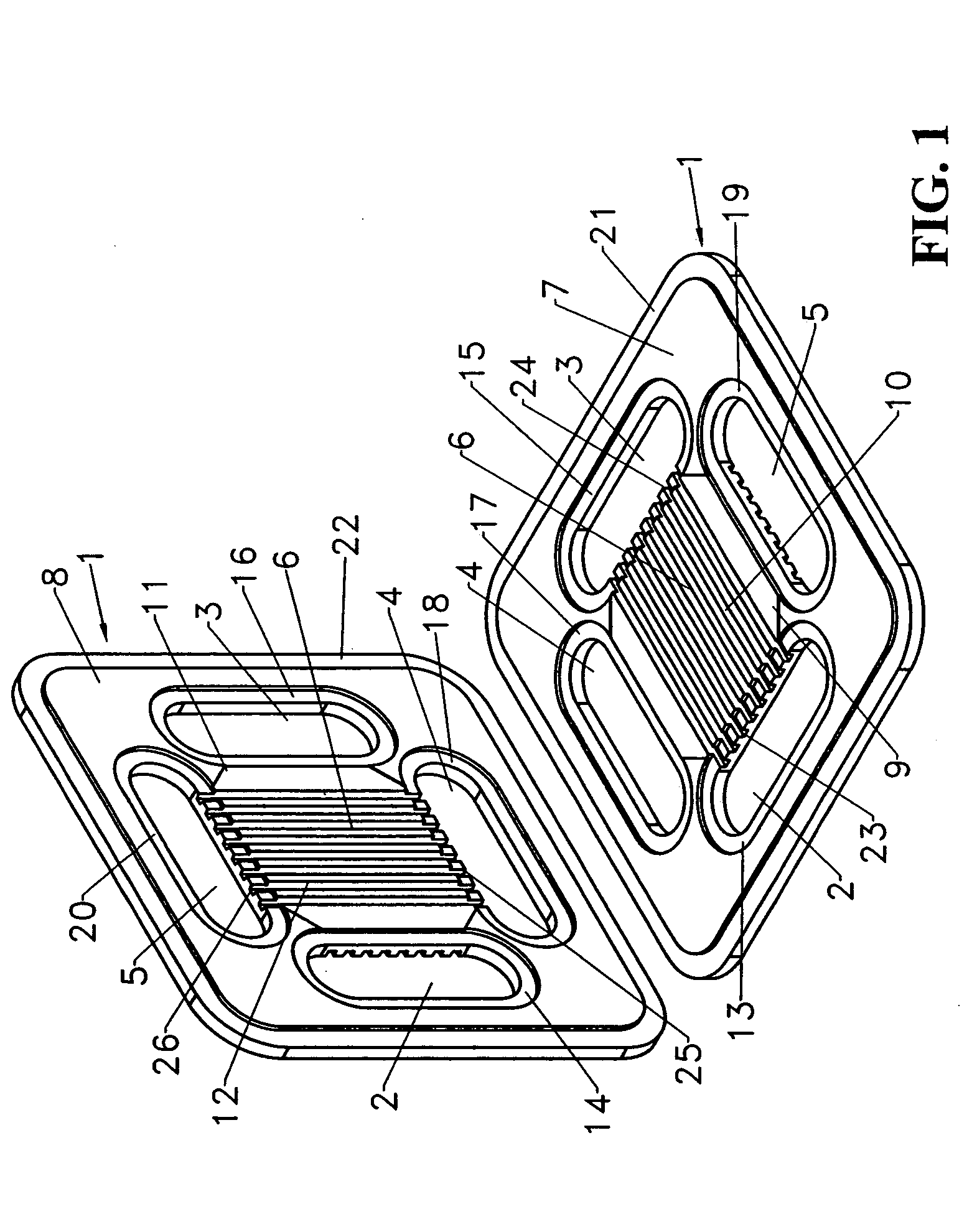

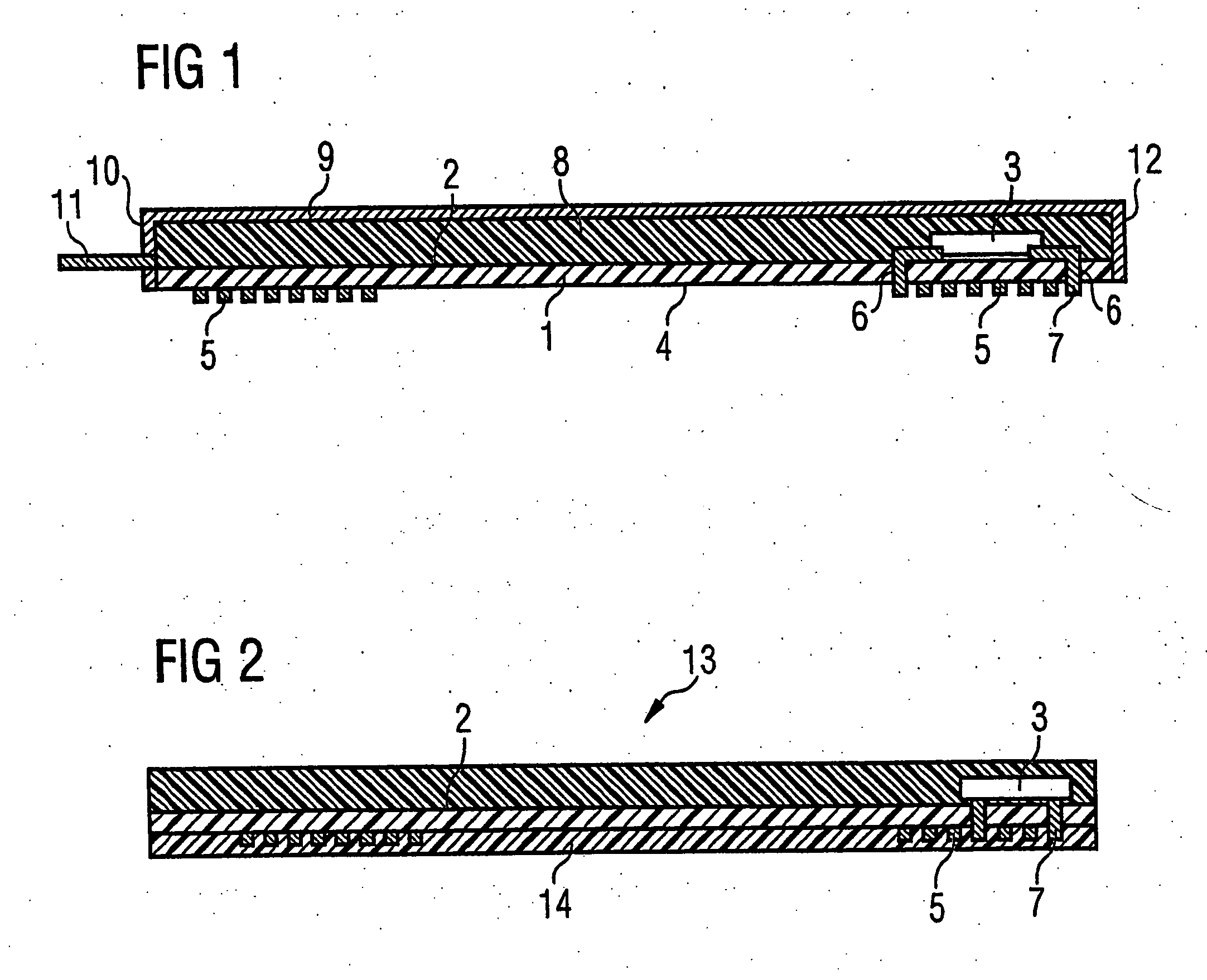

Chip card

InactiveUS7240847B2Simple and low-costNot to damageOther printing matterSemiconductor/solid-state device detailsElectrical connectionEngineering

A contactless chip card and a method for producing a contactless chip card in which a plastic carrier having clearances is provided, on which an antenna coil is arranged on an upper side of the plastic carrier and a device having an integrated circuit is arranged on a rear side of the plastic carrier that is opposite from the upper side, an electrical connection is produced between the coil and the device, the plastic carrier is introduced into an injection mold and a card body is molded onto the rear side of the plastic carrier by the injection-molding process.

Owner:CIRCLE SMART CARD +1

Thermal fluid flow sensor and method of forming same technical field

InactiveUS7255001B1Improve sensor performancePath resistanceVolume/mass flow by thermal effectsSignal conditioningThermal fluids

A thermal fluid flow sensor and method of forming same. The flow sensor has an integrated circuit substrate, such as a silicon substrate, and a region of low thermal conductivity material carried on the top surface of the integrated circuit substrate. One or more pairs of temperature sensing elements are disposed on the low thermal conductivity region together with a heating element so that a robust flow sensor can be provided at low cost. Signal conditioning circuitry is disposed on the same surface as the temperature sensing elements and connected to the sensing elements thereby further reducing costs and improving the flow sensor sensitivity.

Owner:HONEYWELL INT INC

Quantum dot light emitting device

InactiveUS7888700B2Without a loss in their fluorescent efficiencyImprove conductivityNanotechDischarge tube luminescnet screensQuantum dotLight emitting device

An inorganic light emitting device including a transparent substrate; a first electrode; a second electrode opposed to the first electrode; a polycrystalline inorganic light emitting layer including core / shell quantum dots within an inorganic semiconductor matrix and, wherein the first electrode is transparent and formed on the transparent substrate, the polycrystalline inorganic light emitting layer is formed over the first electrode, and the second electrode is formed over the light emitting layer.

Owner:NANOCO TECH LTD

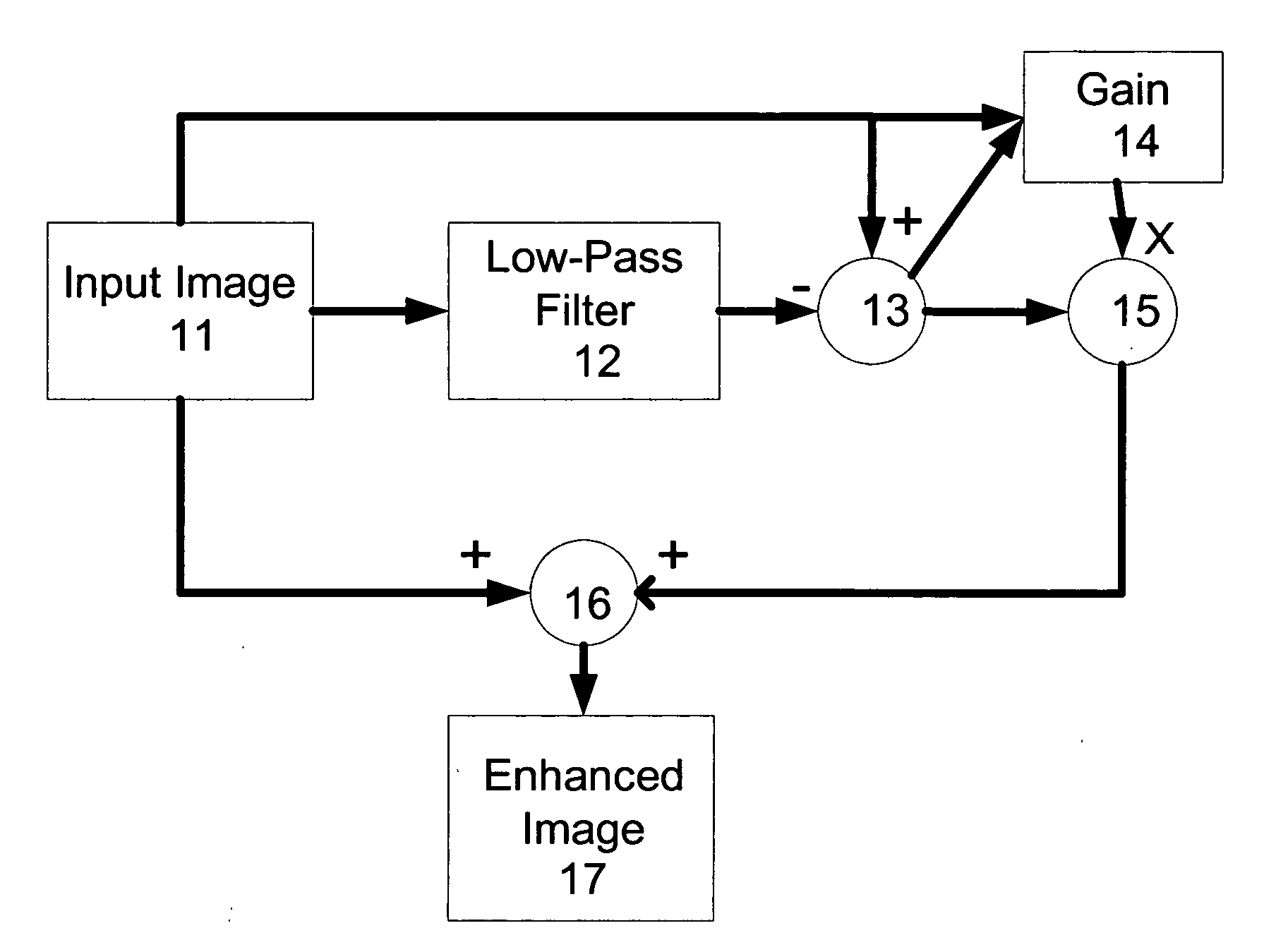

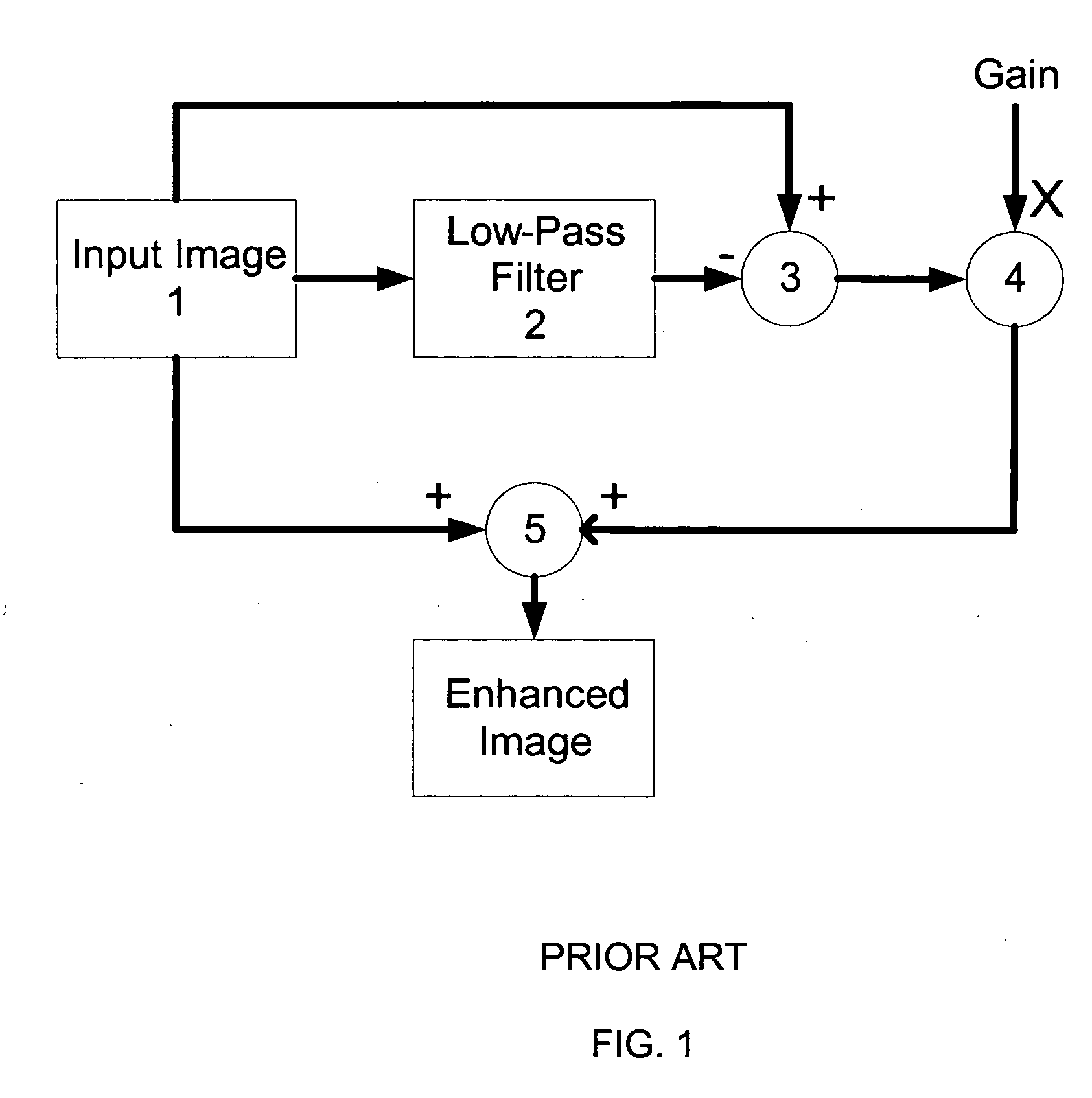

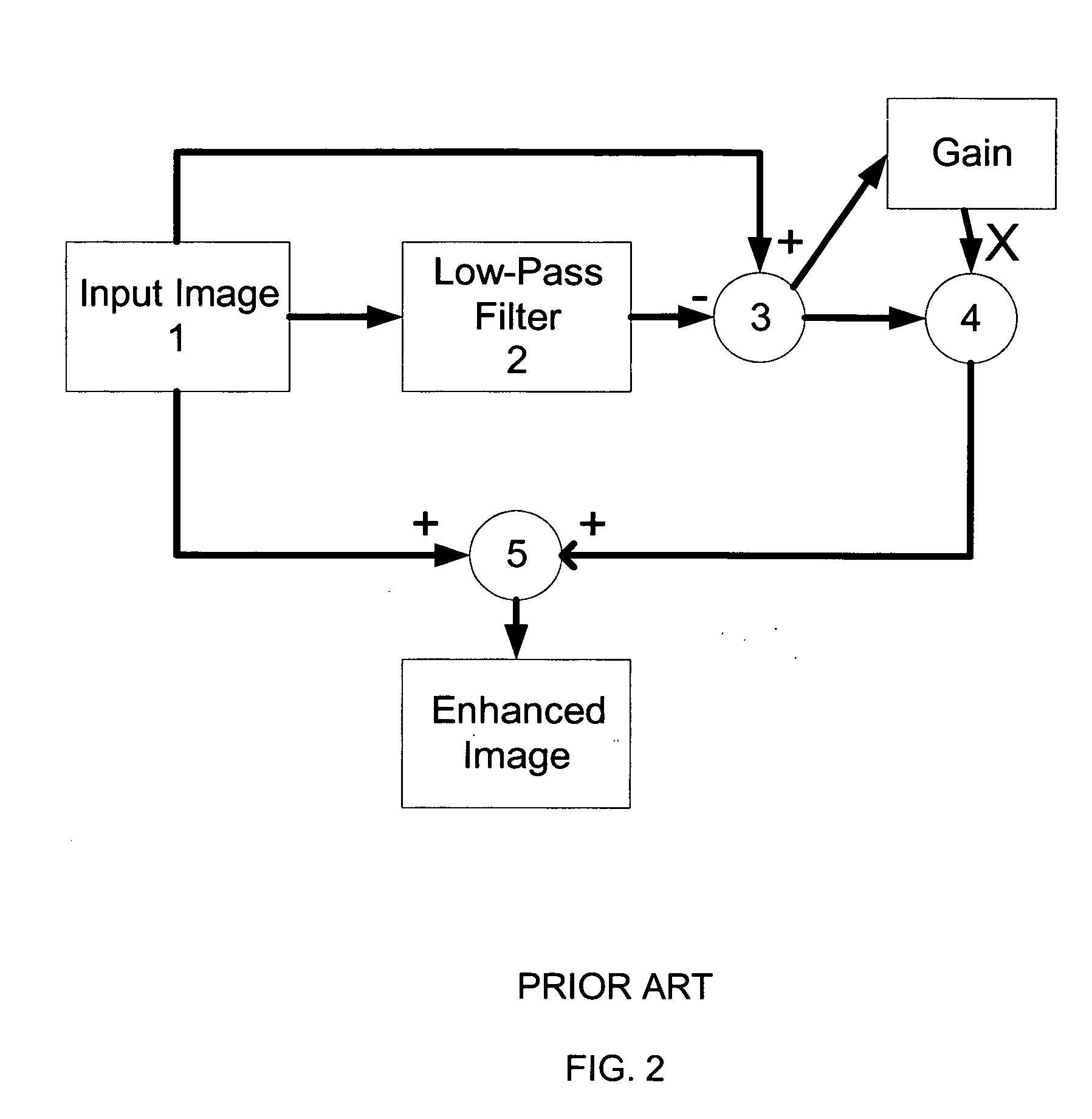

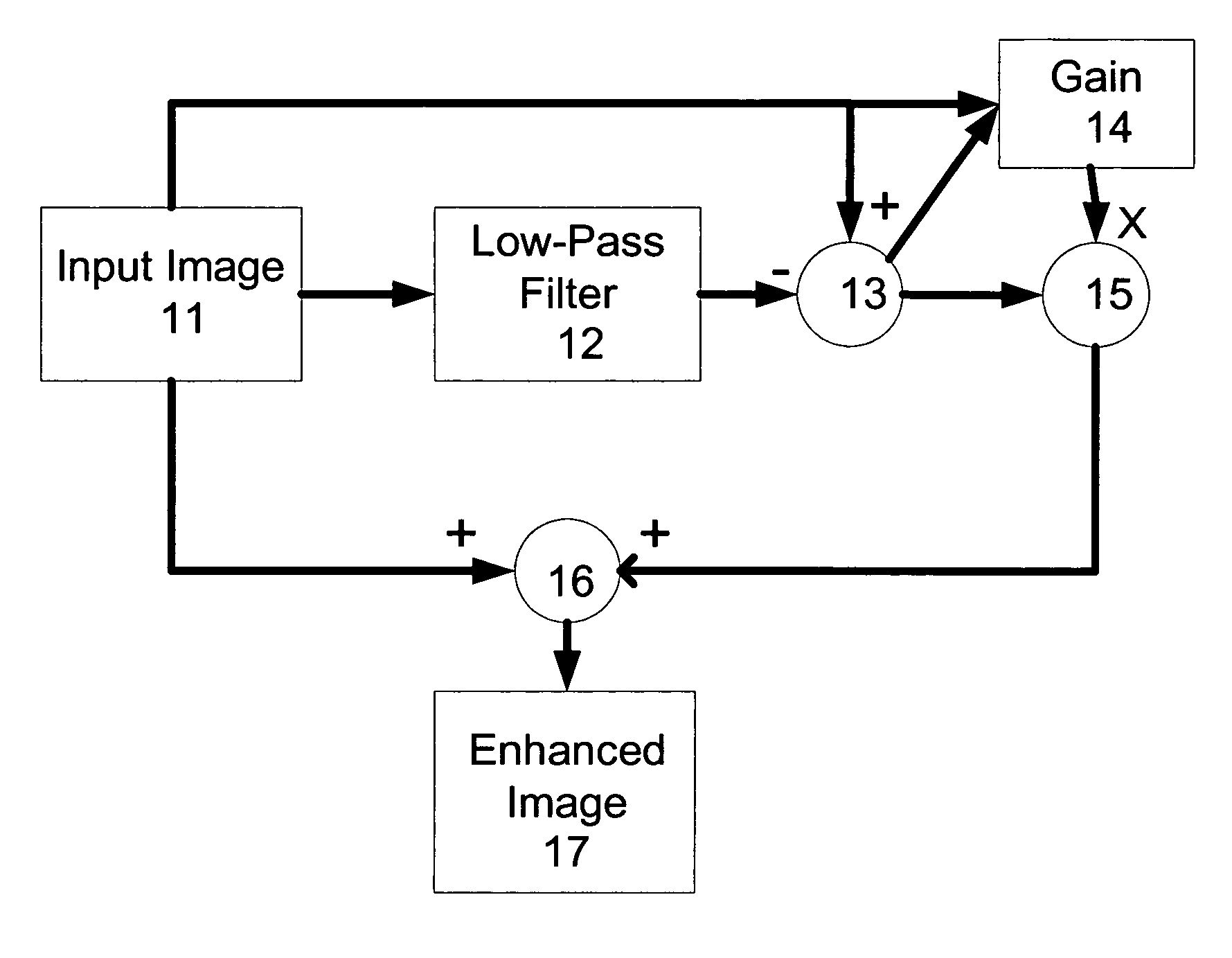

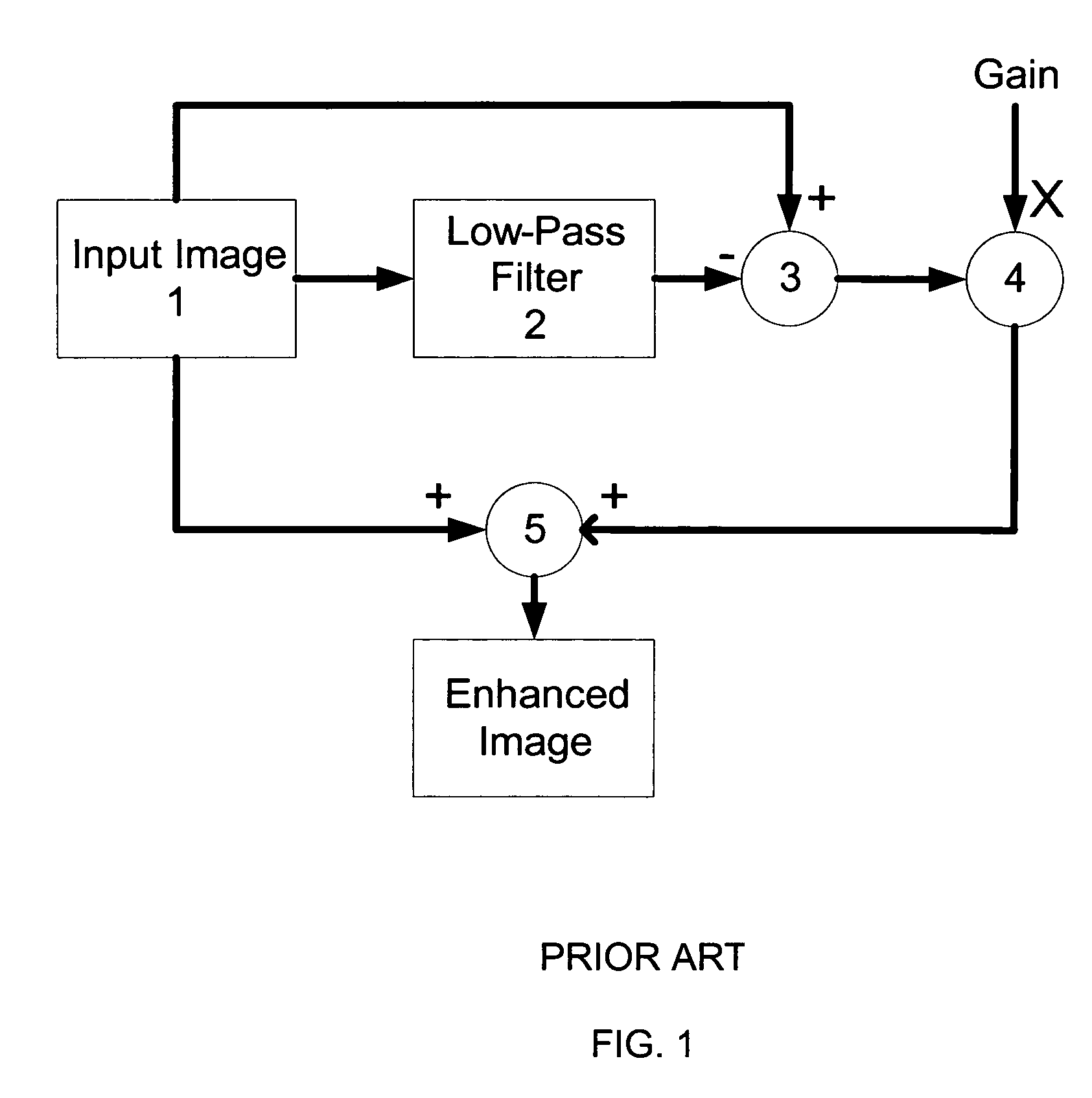

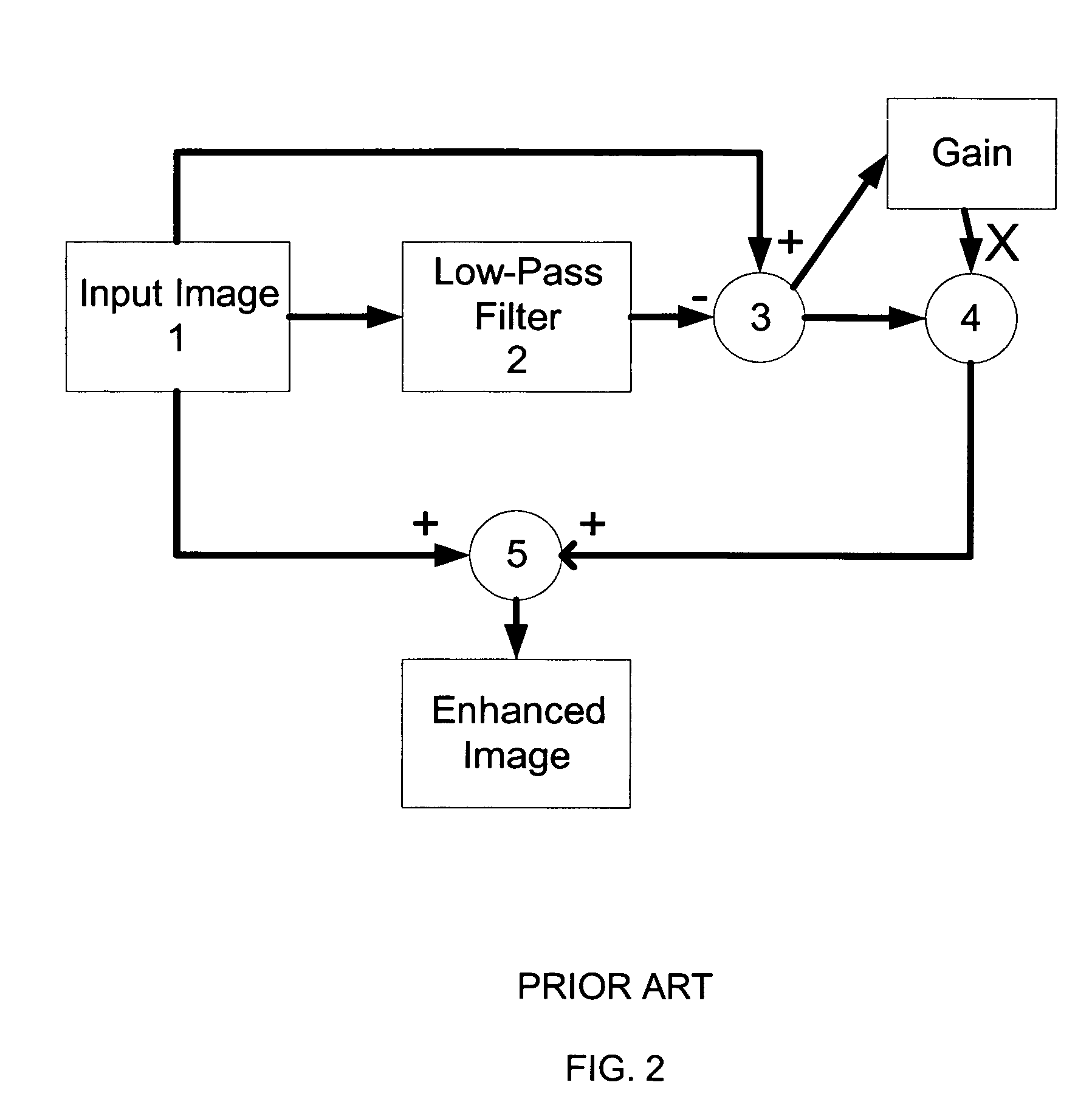

Method and apparatus for adjusting the contrast of an image

ActiveUS20070171310A1Easy to adaptIncrease contrastImage enhancementTelevision system detailsLevel dataComputer science

A method and apparatus for adjusting the contrast of an input image is disclosed. Brightness level data of the input image is filtered to obtain at least a low frequency component and a high frequency component. The high frequency component is amplified. The low frequency component and the amplified high frequency component are summed to produce brightness level data of the output image. The filtering is carried out by at least one recursive infinite impulse response filter having a single delay coefficient that is adaptive to areas of high contrast in the input image.

Owner:VESTEL ELEKTRONIK SANAYI & TICARET ANONIM SIRKETI

Light-emitting nanocomposite particles

InactiveUS20090001349A1Reliable electrical connectionImprove conductivityElectroluminescent light sourcesSemiconductor/solid-state device manufacturingQuantum dotColloid

A method of making an inorganic light emitting layer includes combining a solvent for semiconductor nanoparticle growth, a solution of core / shell quantum dots, and semiconductor nanoparticle precursor(s); growing semiconductor nanoparticles to form a crude solution of core / shell quantum dots, semiconductor nanoparticles, and semiconductor nanoparticles that are connected to the core / shell quantum dots; forming a single colloidal dispersion of core / shell quantum dots, semiconductor nanoparticles, and semiconductor nanoparticles that are connected to the core / shell quantum dots; depositing the colloidal dispersion to form a film; and annealing the film to form the inorganic light emitting layer.

Owner:NANOCO TECH LTD

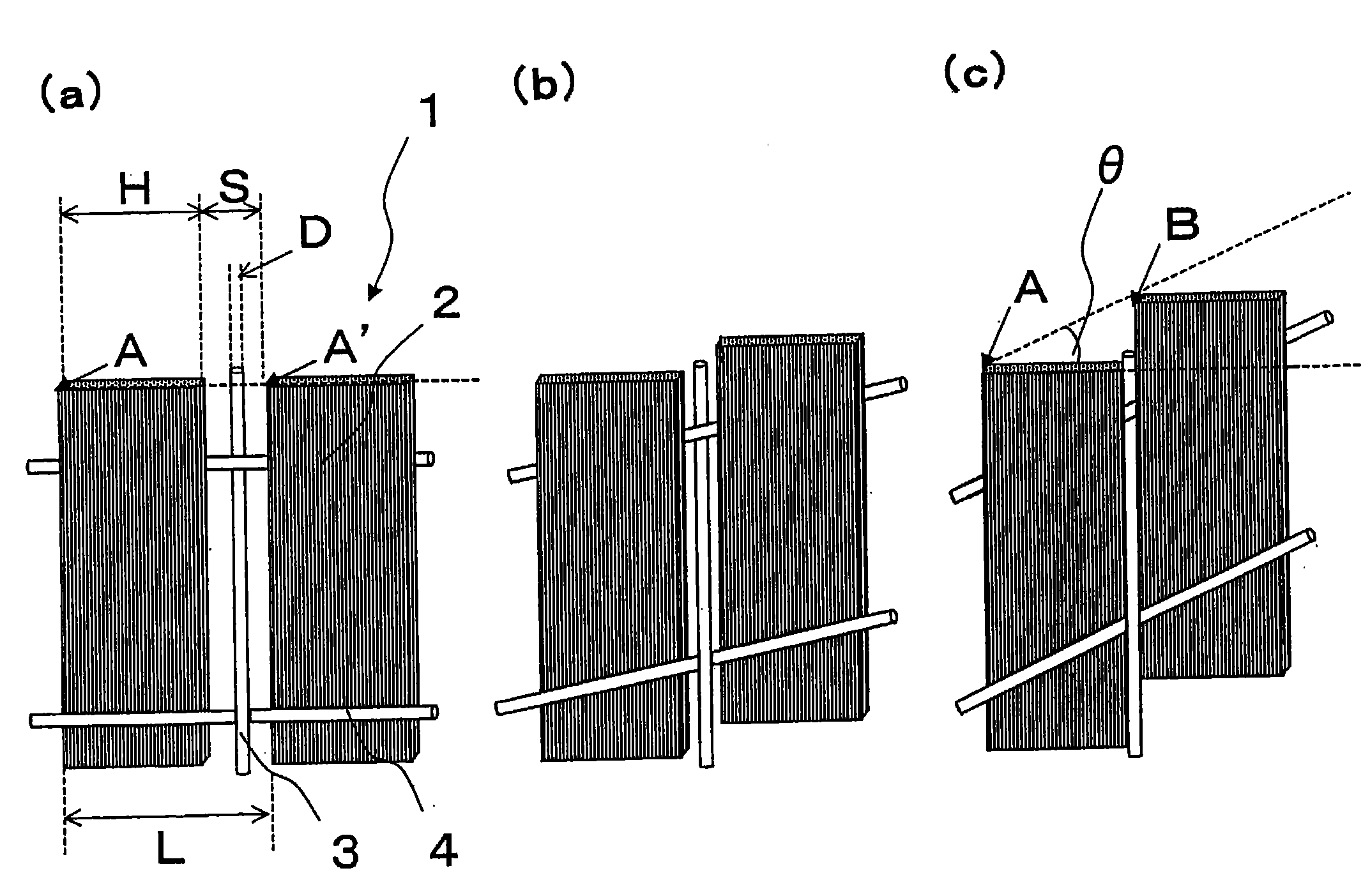

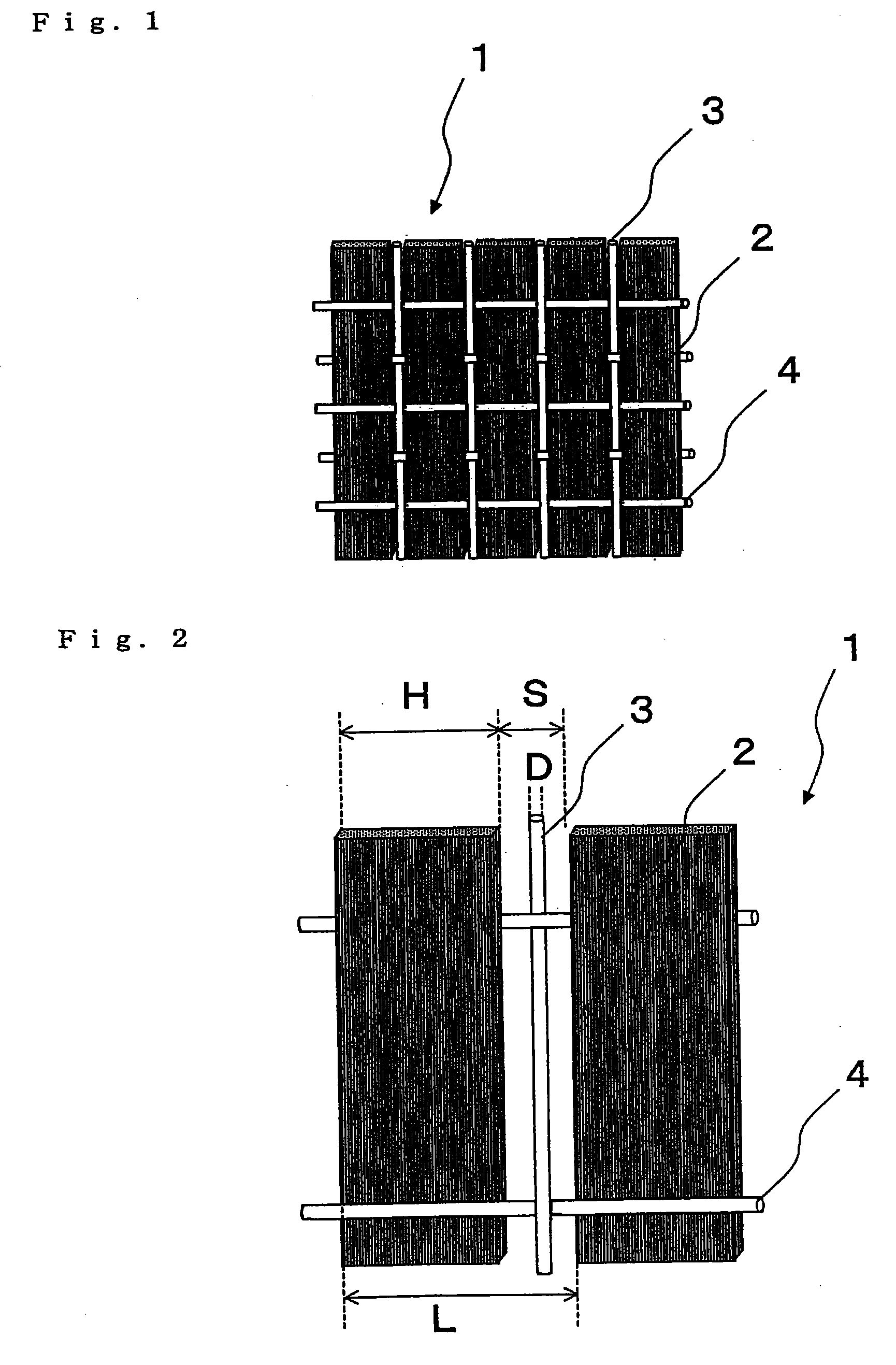

Reinforcing fiber base material for preforms, process for the production of laminates thereof, and so on

ActiveUS20090068428A1Excellent characteristicsGood drapabilityPaper/cardboard layered productsNon-woven fabricsVitrificationYarn

The invention provides (1) a reinforcing fiber base material having a weave constituted of both reinforcing fiber filaments arranged in one direction in parallel with each other and auxiliary yarns arranged in another direction, which satisfies the relationship: L=H / cos θ (wherein L is the length of auxiliary yarn covering one reinforcing fiber filament and H is the width of the filament as determined in such a state where the reinforcing fiber filaments are unified only with the auxiliary yarns; and 3°≦θ (in-plane shear strain)≦30°) and wherein 2 g / m2 to 40 g / m2 of an adhesive resin having a glass transition temperature between 0° C. and 95° C. is adhesed to at least one side thereof in spots, lines, or discontinuous lines; (2) a laminate obtained by laminating layers of the above reinforcing fiber base material, wherein the adhesive resin adhesed to each layer of base material partially bonds to a facing layer of base material over the whole surface thereof, with the maximum length of each bonding joint being not less than 1 mm and not more than the width H of a reinforcing fiber filament; and (3) a preform, obtained by shaping the laminate, having a reinforcing fiber volume fraction (Vpf) of 45% to 62%.

Owner:TORAY IND INC

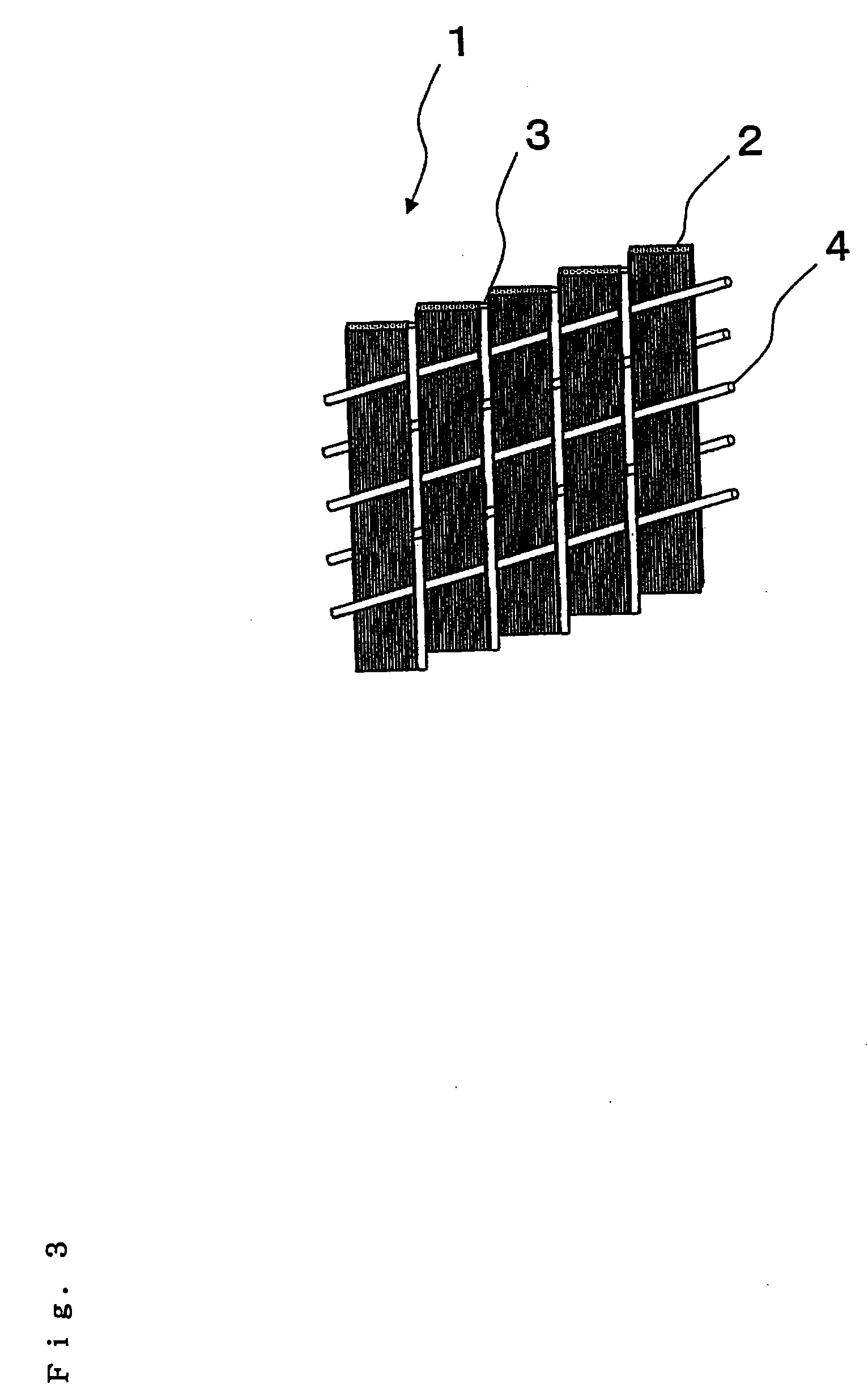

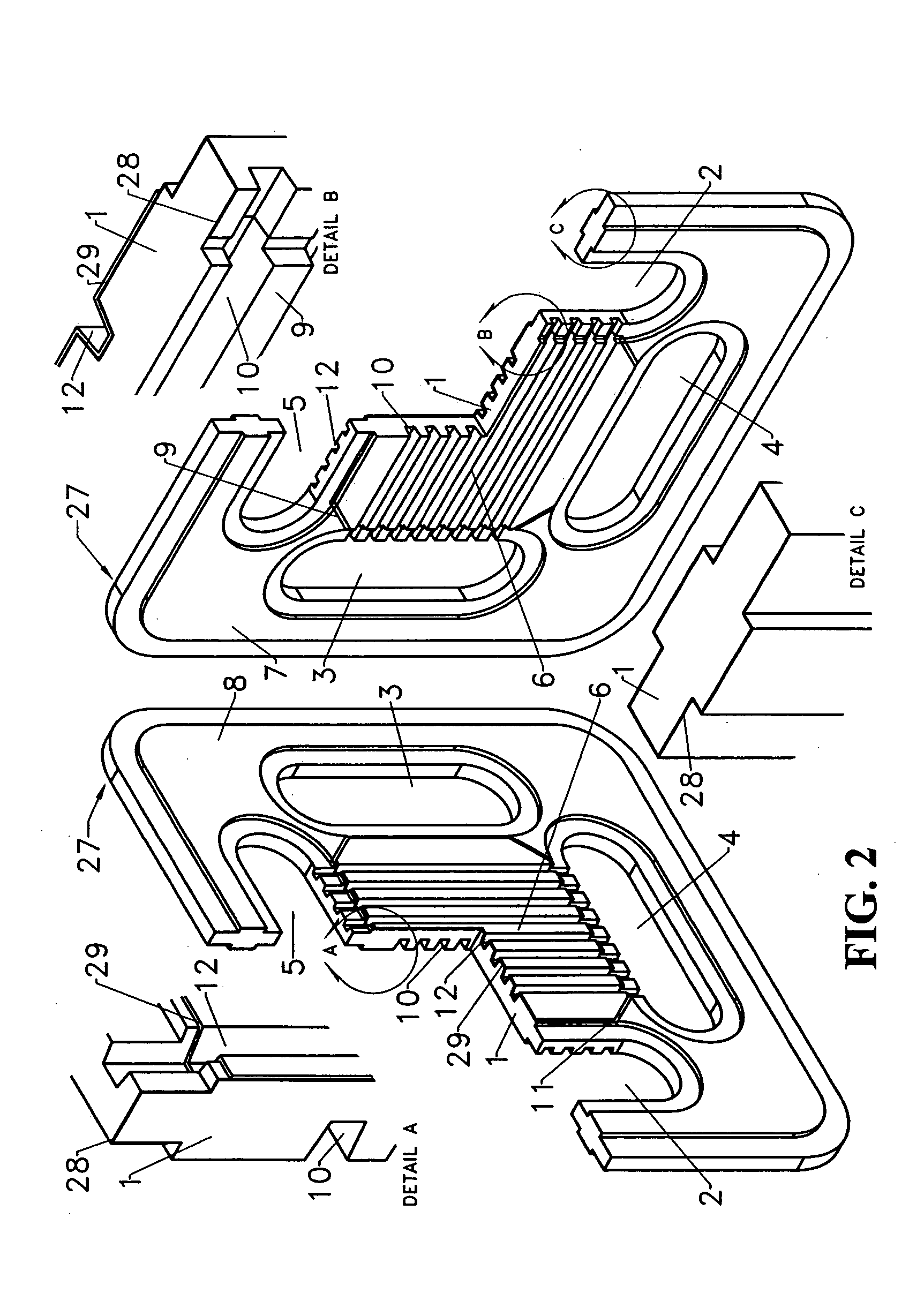

Fuel cell assemblies using metallic bipolar separators

InactiveUS20050249996A1Increased durabilityImprove performanceFuel cells groupingFuel cell auxillariesFuel cellsEngineering

High temperature solid oxide fuel cells (SOFC) and fuel cell stacks incorporating metallic bipolar separators with integral edge seals are provided. The electrochemical cells include reactant manifolds and flow passages, and may have either cathode or anode supported structures. The bipolar separators are thin metallic sheets that minimize thermal expansion stress in the electrochemical cells. The tubular bead edge seals are formed as an integral part of the bipolar separator by a low-cost sheet metal stamping process.

Owner:MEACHAM G B KIRBY

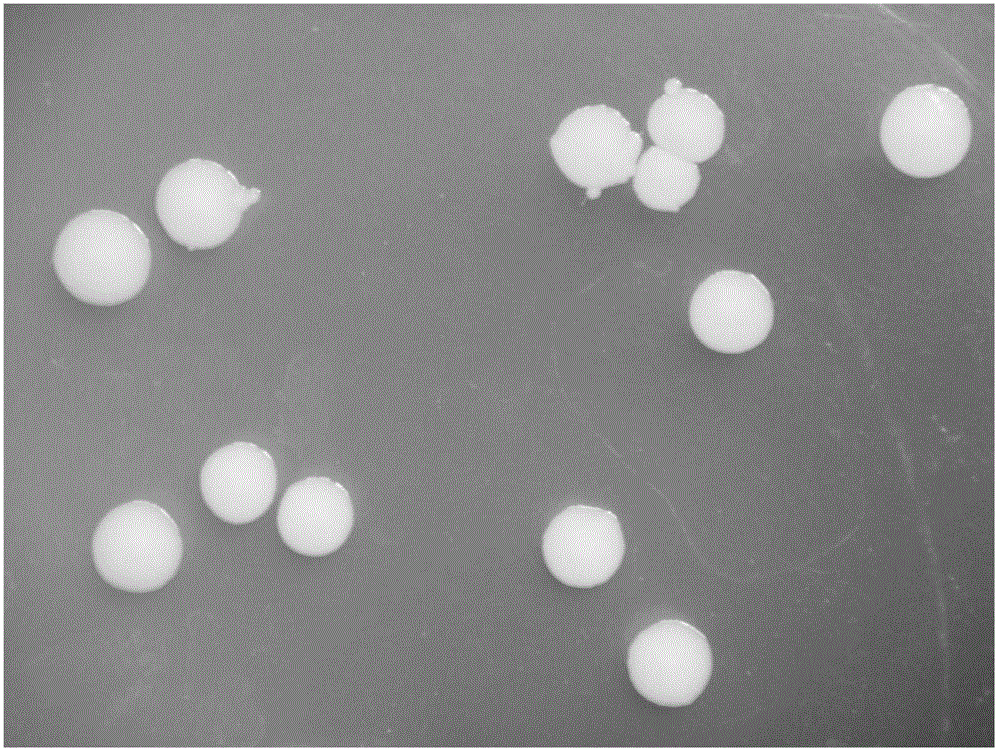

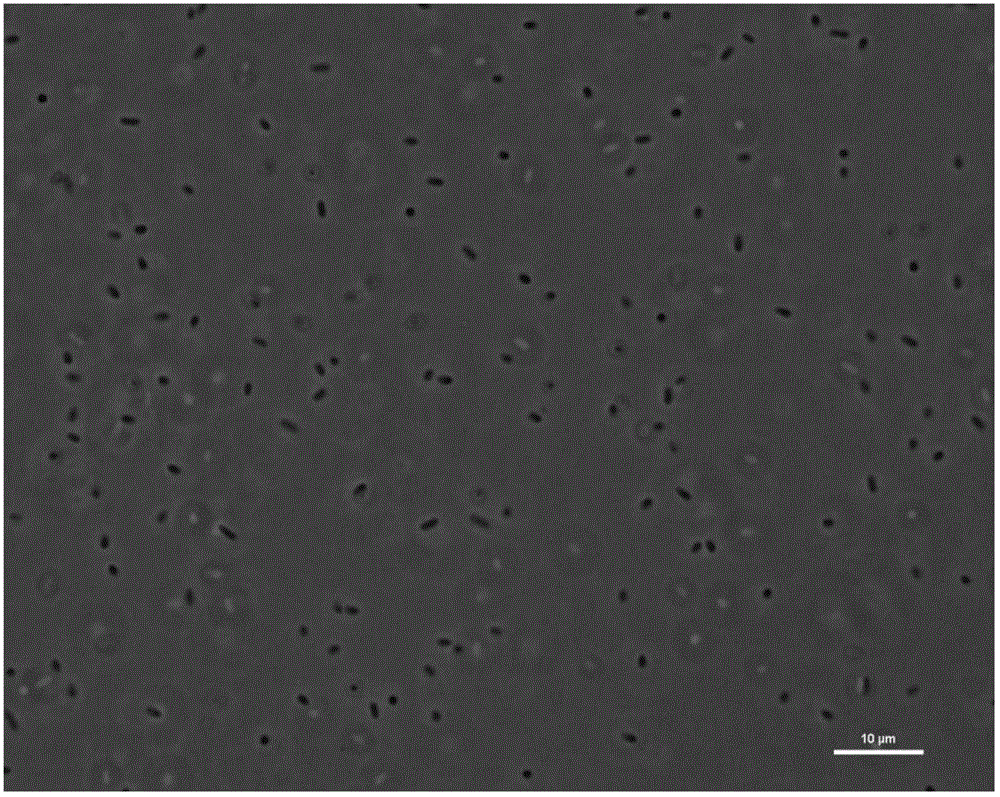

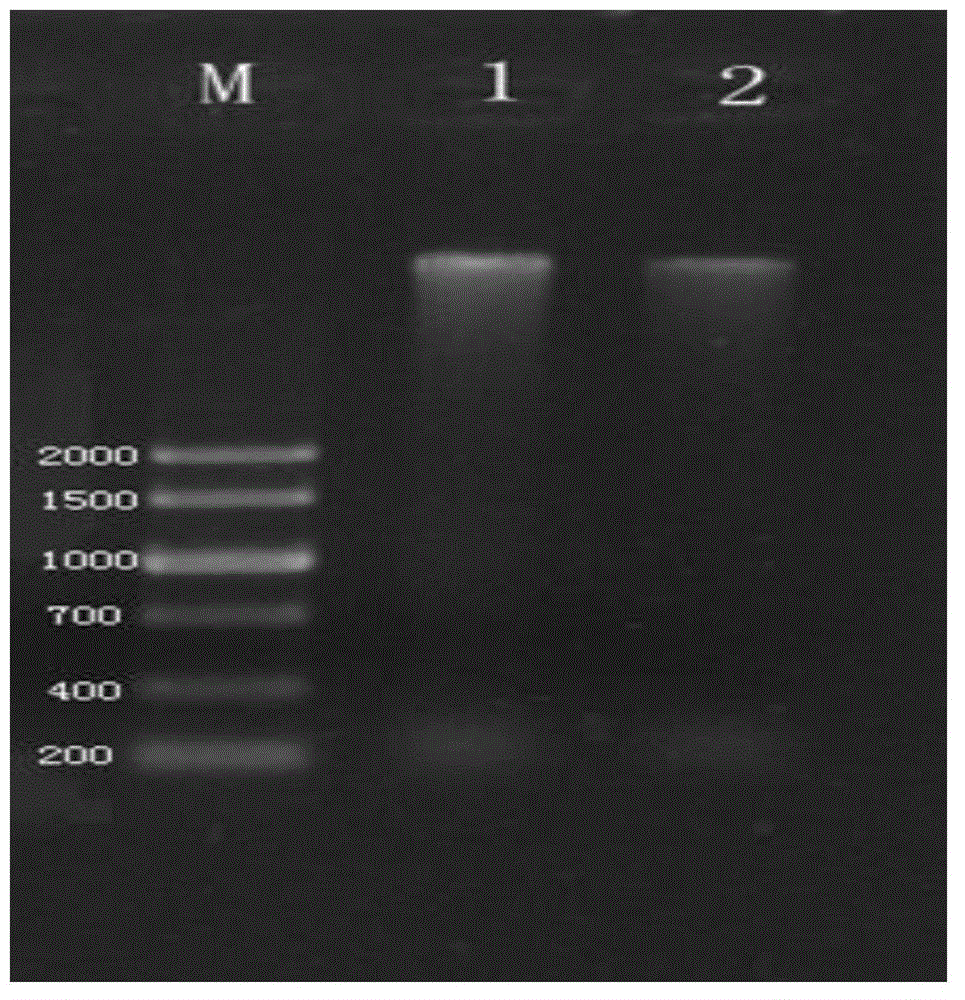

Denitrification acinetobacters and use thereof

InactiveCN102747015AReduce accumulationEasy to handleBacteriaWater contaminantsOxygenMicrobiological culture

The invention relates to denitrification acinetobacters and a use thereof, and belongs to the field of environmental microbiology. The denitrification acinetobacters have a category name of Acinetobacter schindleri LN5, are preserved in the China general microbiological culture collection center of the China microbiological preservation management committee on May 30th, 2012, and has a preservation number of CGMCC No.6165. The denitrification acinetobacters have heterotrophic nitrification-aerobic denitrification functions, have high aureomycin resistance, can be used for simultaneous nitrification and denitrification (SND) treatment on nitrogen-containing sewage and especially on nitrogen and aureomycin-containing sewage, realize removal of a large part of ammonia nitrogen in nitrogen-containing sewage, realize small accumulation amounts of nitrite and nitrate nitrogen, realize nitrification-denitrification and COD removal in the same reactor, and realize environmentally-friendly, low-consumption and high-efficiency treatment on nitrogen-containing sewage.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method and apparatus for adjusting the contrast of an image

ActiveUS7602447B2Computational complexity of the filtering process is minimisedLow cost processingTelevision system detailsImage enhancementComputer visionLevel data

A method and apparatus for adjusting the contrast of an input image is disclosed. Brightness level data of the input image is filtered to obtain at least a low frequency component and a high frequency component. The high frequency component is amplified. The input image and the amplified high frequency component are summed to produce brightness level data of the output image. The filtering is carried out by at least one recursive infinite impulse response filter having a single delay coefficient that is adaptive to areas of high contrast in the input image.

Owner:VESTEL ELEKTRONIK SANAYI & TICARET ANONIM SIRKETI

Epoxy resin composition for fiber reinforced composite material, prepreg, and fiber reinforced composite material

ActiveUS20130217283A1Reduced trapped airMinimize amount of water vaporLaminationLamination apparatusEpoxyPolymer science

An epoxy resin composition having components (A), (B), (C), and (D), wherein the epoxy resin composition has a viscosity at 40° C. of about 1×103 to about 1×104 Pa·s, a curing start temperature of about 90 to about 110° C., and a minimum viscosity at the curing start temperature of about 2 to about 20 Pa·s, wherein the components (A), (B), (C), and (D) are as follows: (A) About 60 weight parts or more of a tetraglycidyl amine type epoxy resin per 100 weight parts of the epoxy resin blend; (B) Dicyandiamide; (C) Diaminodiphenyl sulfone and (D) Urea compound.

Owner:TORAY IND INC

Processing of medical signals

InactiveUS7809400B1Facilitate decision-makingLow costUltrasonic/sonic/infrasonic diagnosticsComputer-assisted treatment prescription/deliveryComputer hardwareUltrasonic sensor

The present invention is directed to a system and method in which real-time ubiquitous imaging is feasible in local areas, such as inside a clinic, hospital room or doctor office. This is achieved by designing a wireless network having a central processing server with, for example, distributed broadband acquisition and video bus capability. Remote access is possible using store-and-forward image transfer over a wide area network. With these capabilities, a physician can use a handheld transducer (such as an ultrasound transducer) as a basic tool to facilitate diagnostic decisions similar to the way a stethoscope is used today.

Owner:FUJIFILM SONOSITE

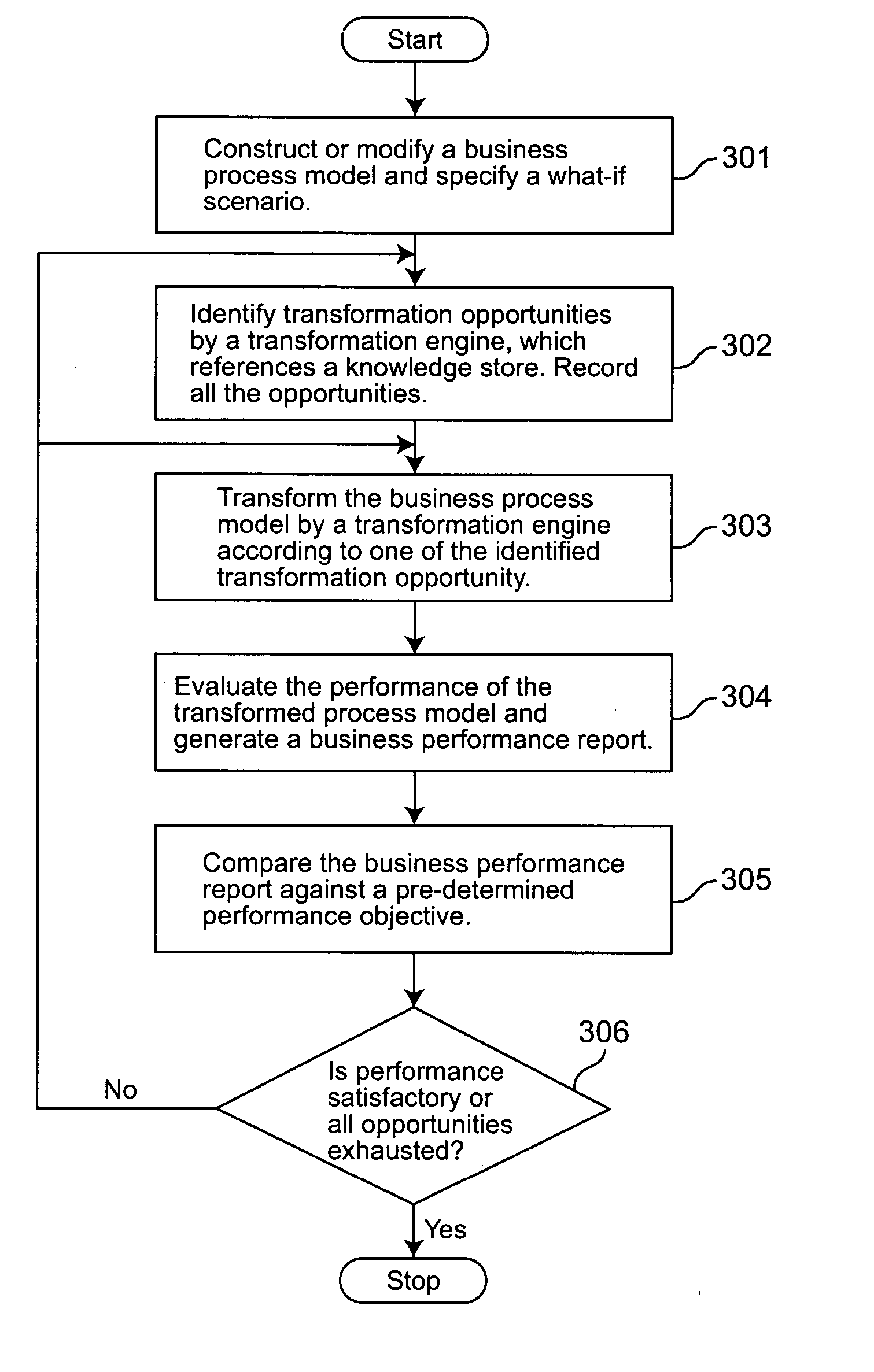

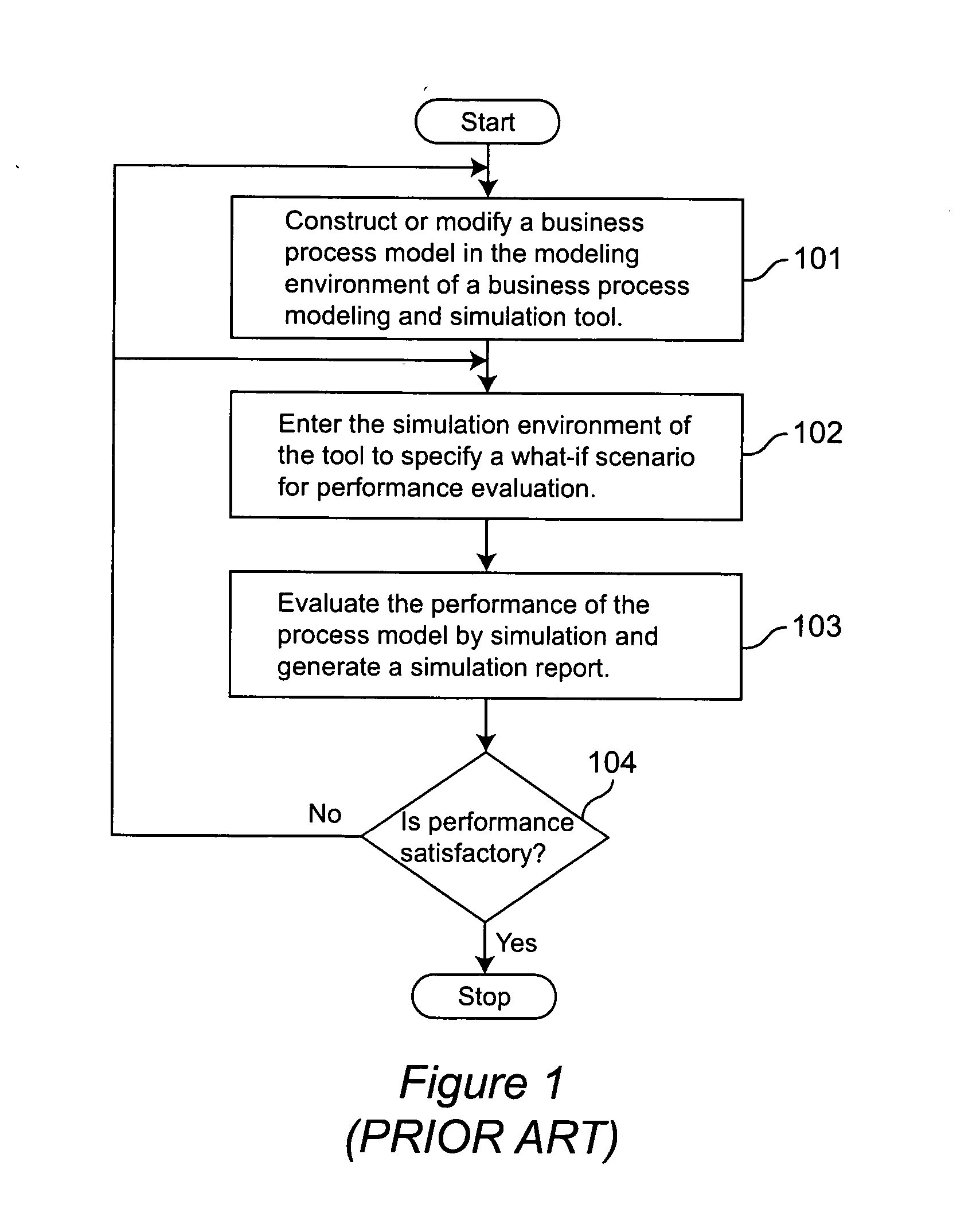

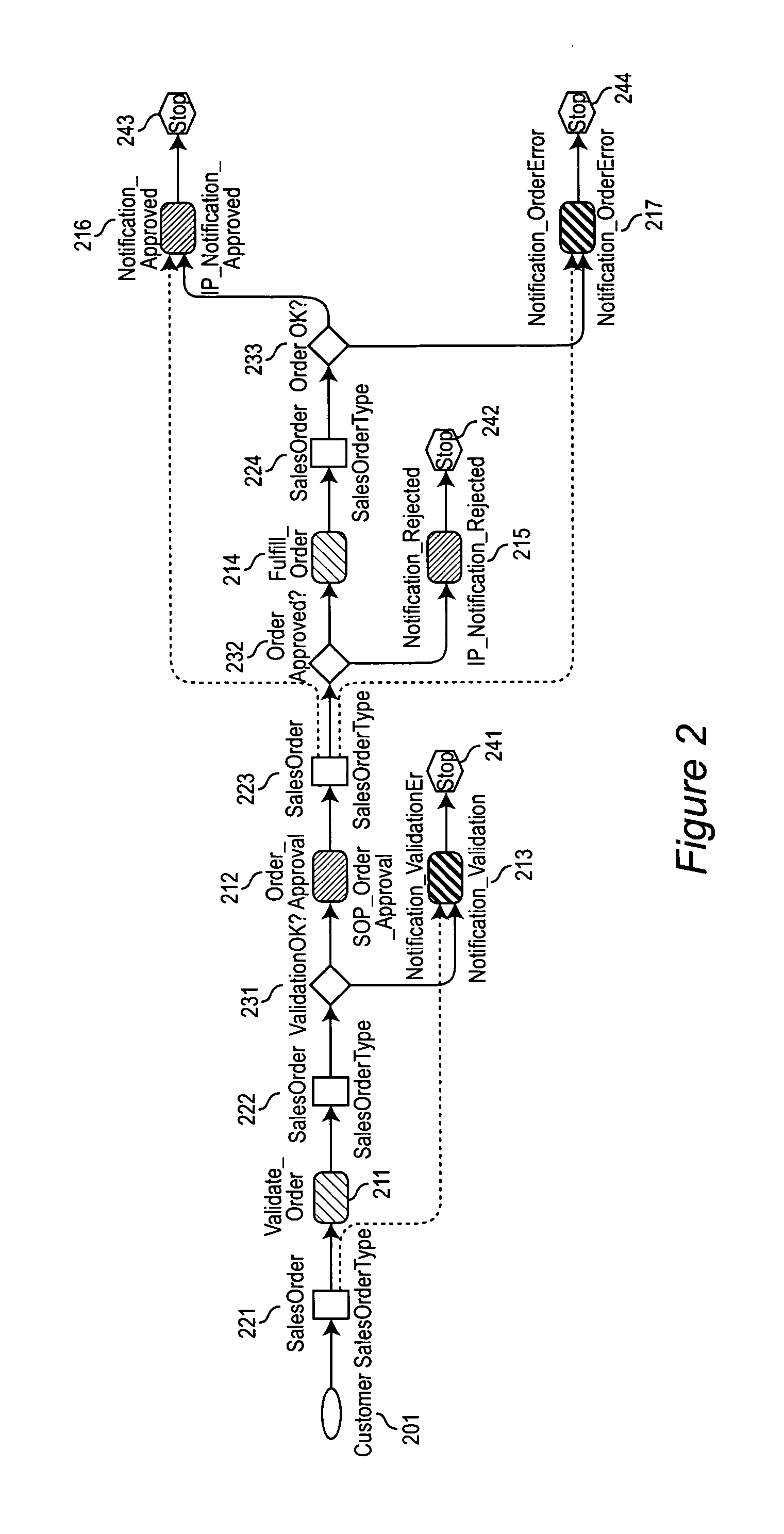

System and method for analyzing and managing business performance

InactiveUS20060155562A1Method be lackNot properlyForecastingCash registersPerformance indexBusiness artifacts

A system and method for analyzing and managing business performance by designing and evaluating the performance of a business process model comprising a flow of business tasks and artifact sources that generate business artifacts. Business processes may be parsed to identify transformation opportunities meeting transformation conditions specified in a transformation knowledge. One or more identified transformation opportunities may be adopted, and parts of the process may be transformed according to transformation rules specified in a transformation knowledge. Analytics and computer simulation may be employed to evaluate business performance metrics of each of said transformed business processes. Iterative changes may be made to said business processes to manage business performance, reiterating transformation and evaluation steps until a satisfactory business process model is obtained. The resulting output is finally produced as a business process model in machine-readable format and can be deployed to a business environment.

Owner:IBM CORP

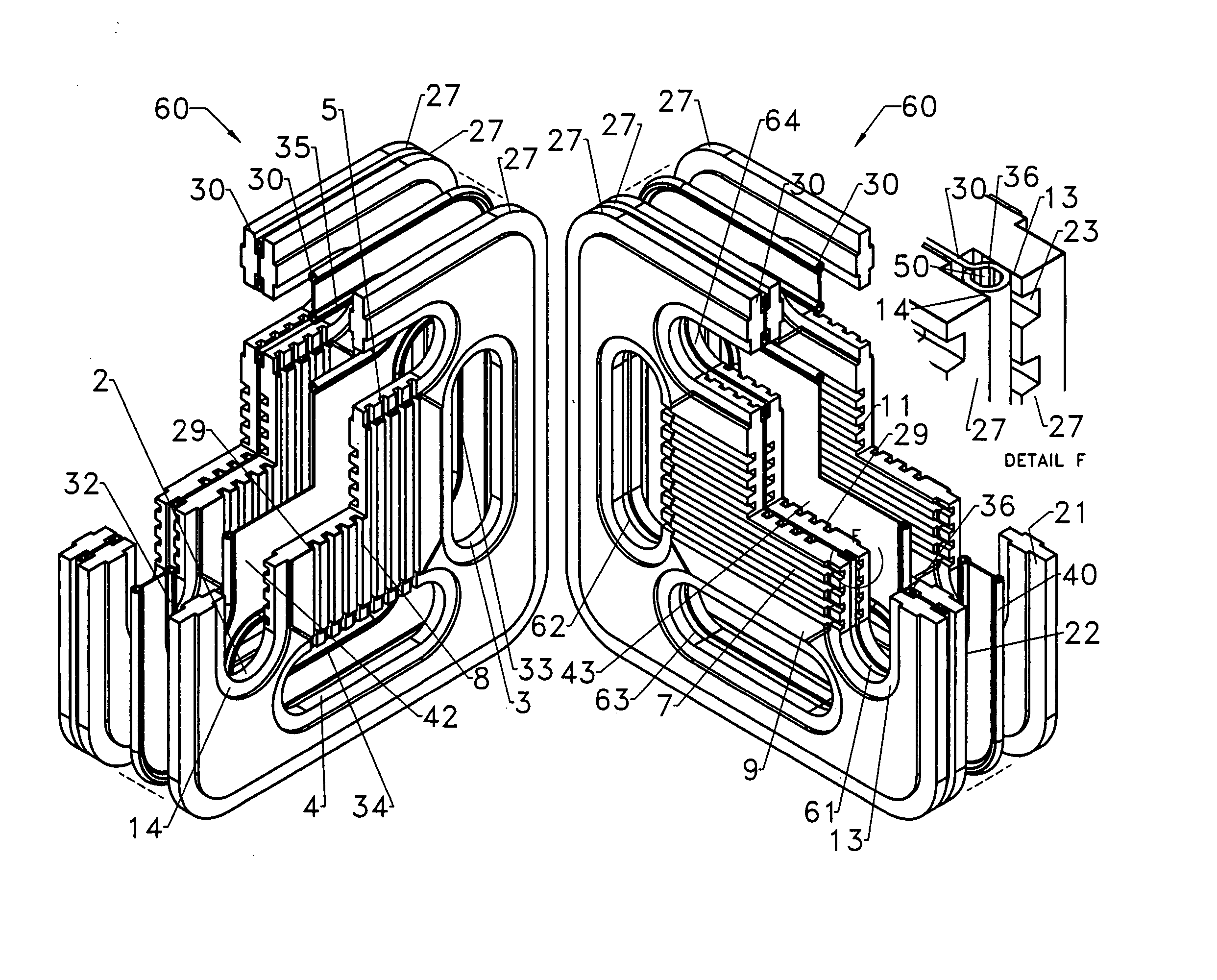

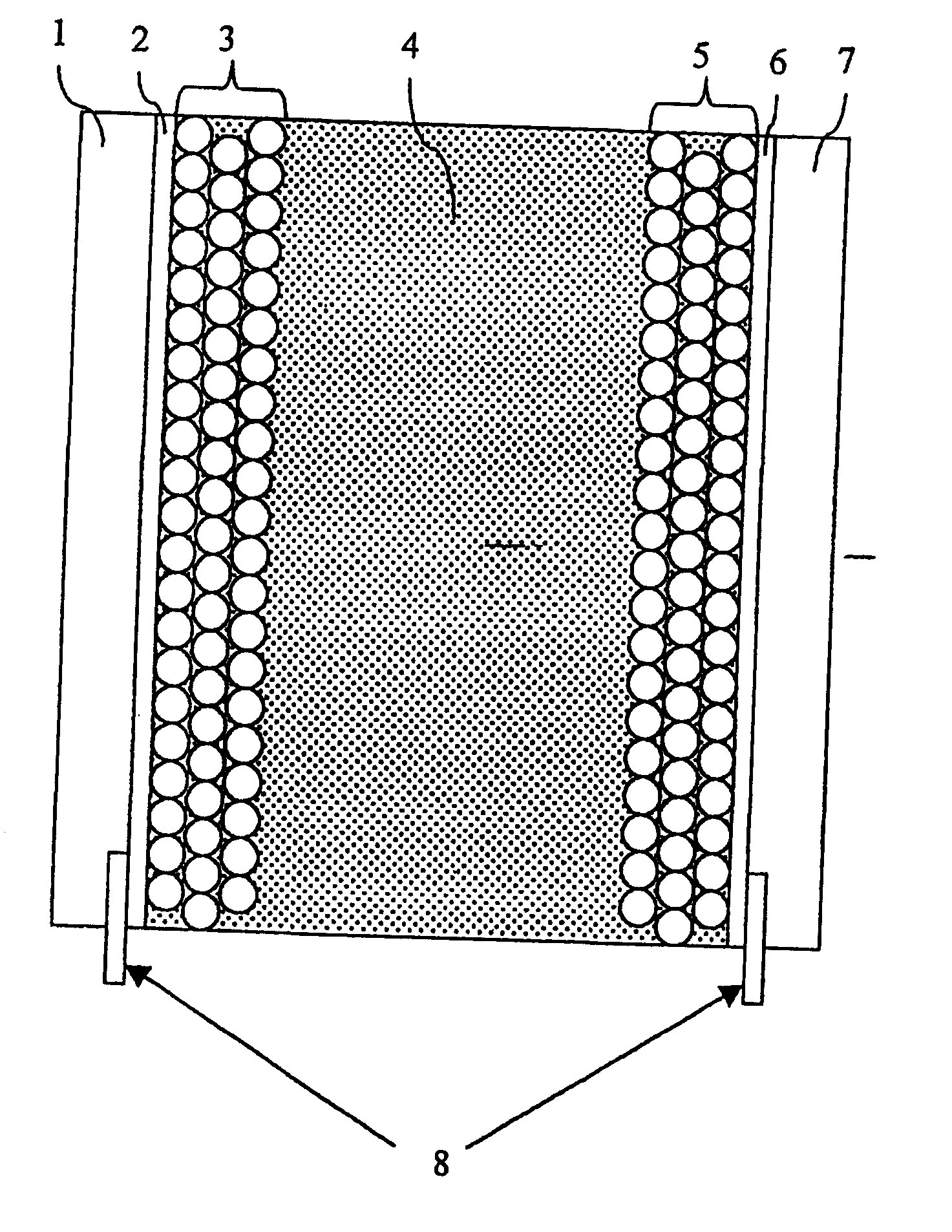

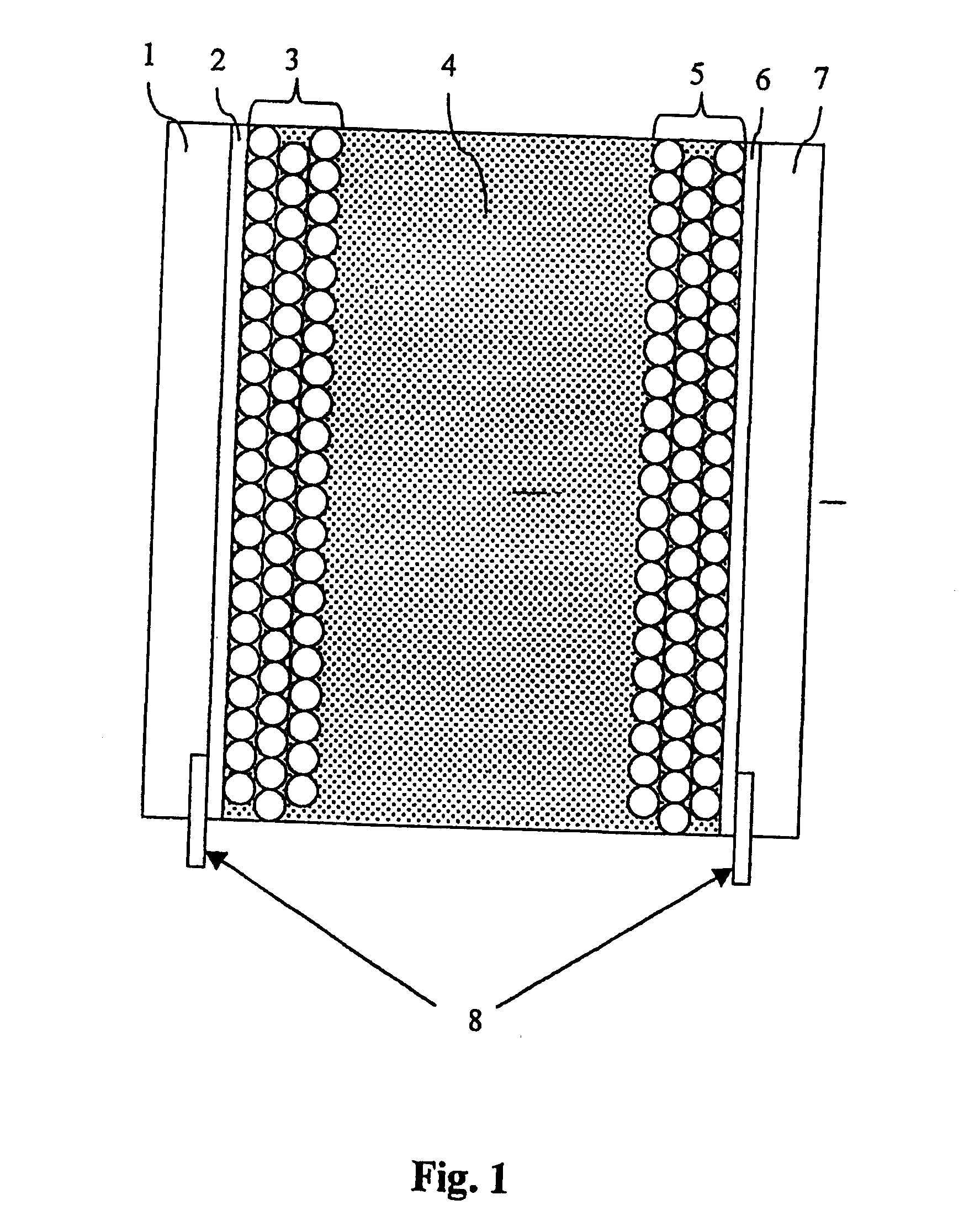

Electrochromic device based on nanocrystalline materials

InactiveUS20050104136A1Change color quicklyEnhance memoryTransistorSolid-state devicesPotential differenceEngineering

An electrochromic device, comprising a first electrode (3), a second electrode (5) and an electrolyte (4) separating the electrodes (3, 5), where at least one of said first and second electrodes includes an electrically active structure which have an at least dual state visual appearance depending on the potential difference between the first and the second electrode.

Owner:NTERA LTD (IE)

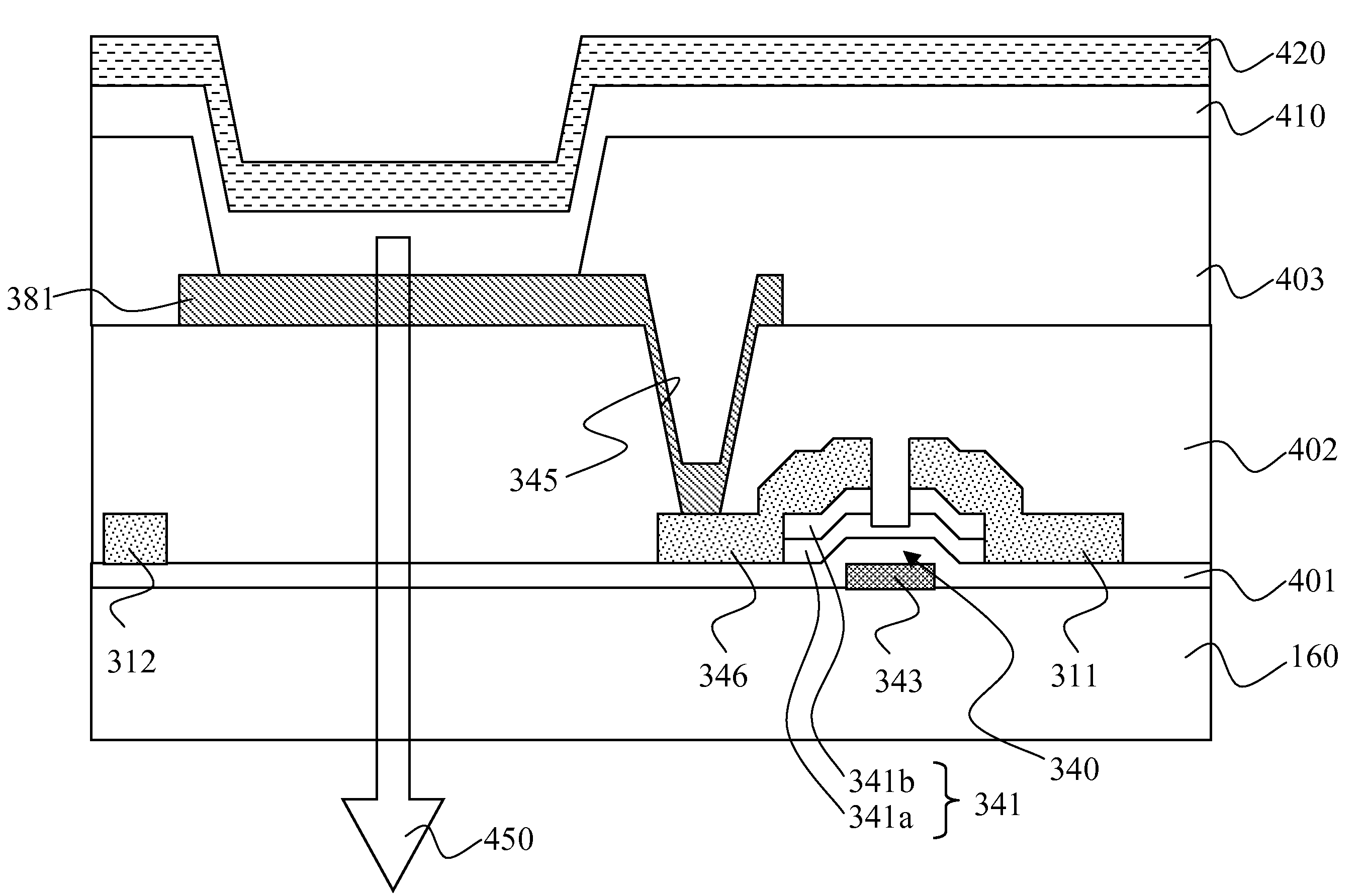

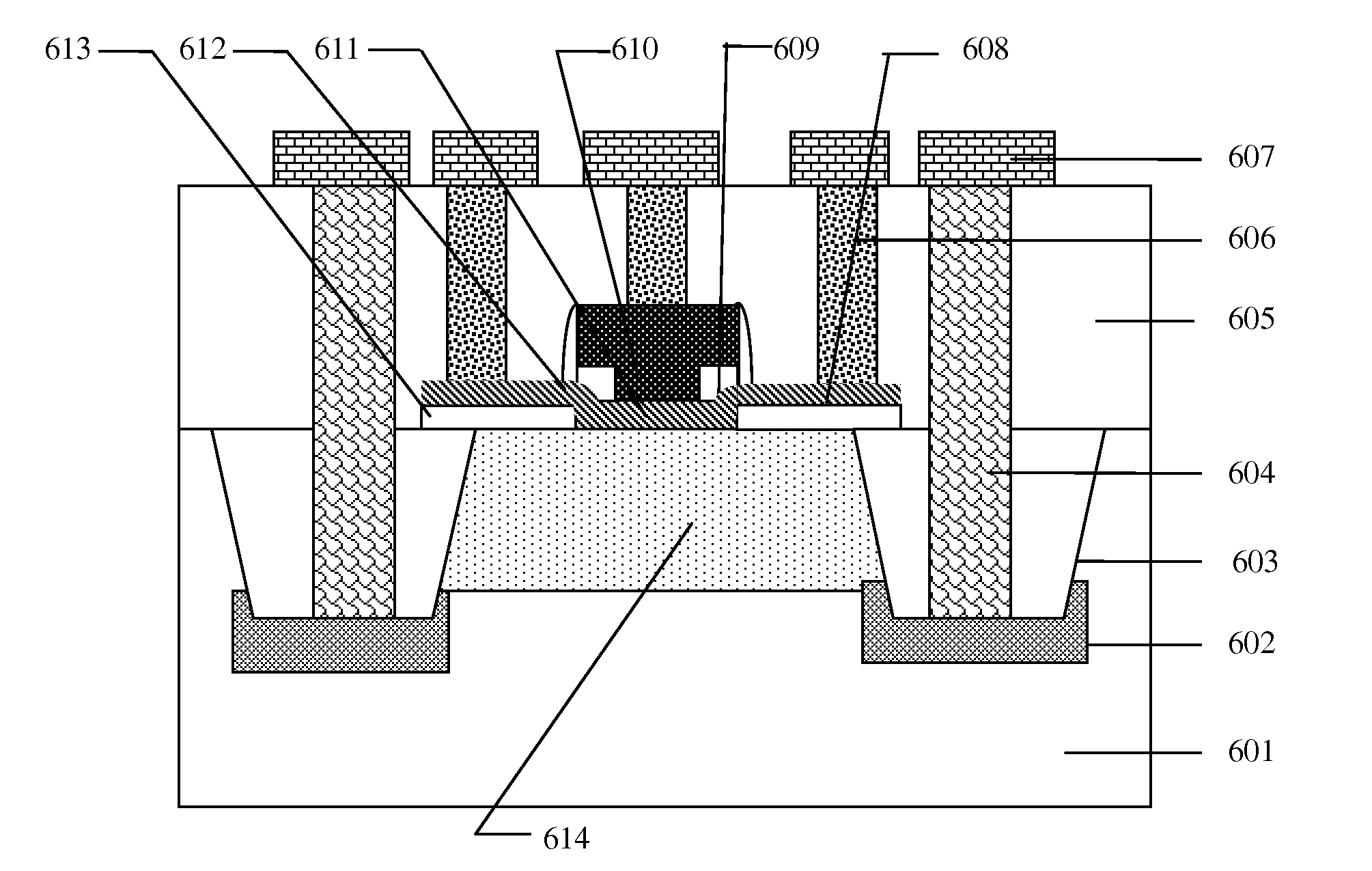

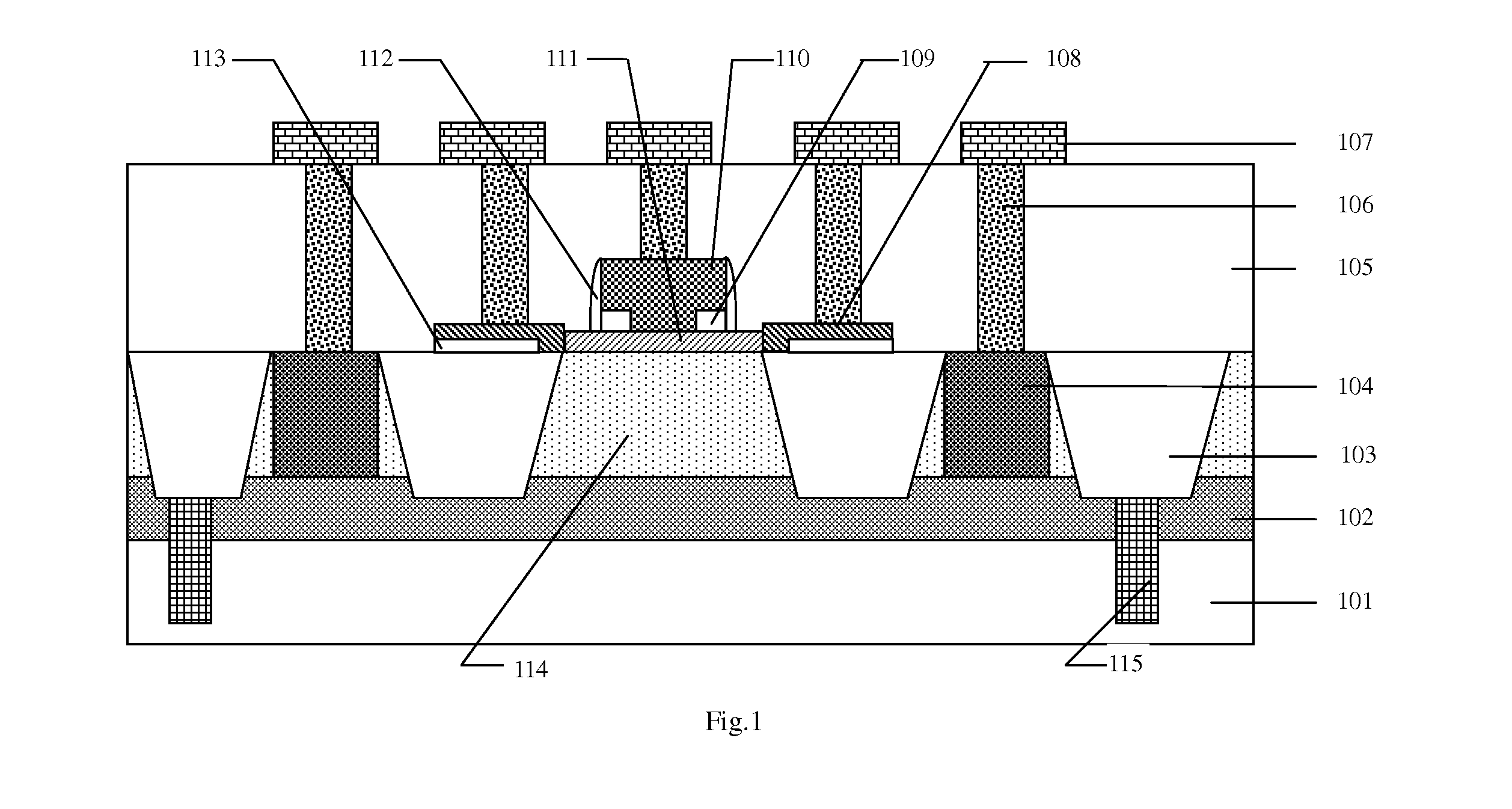

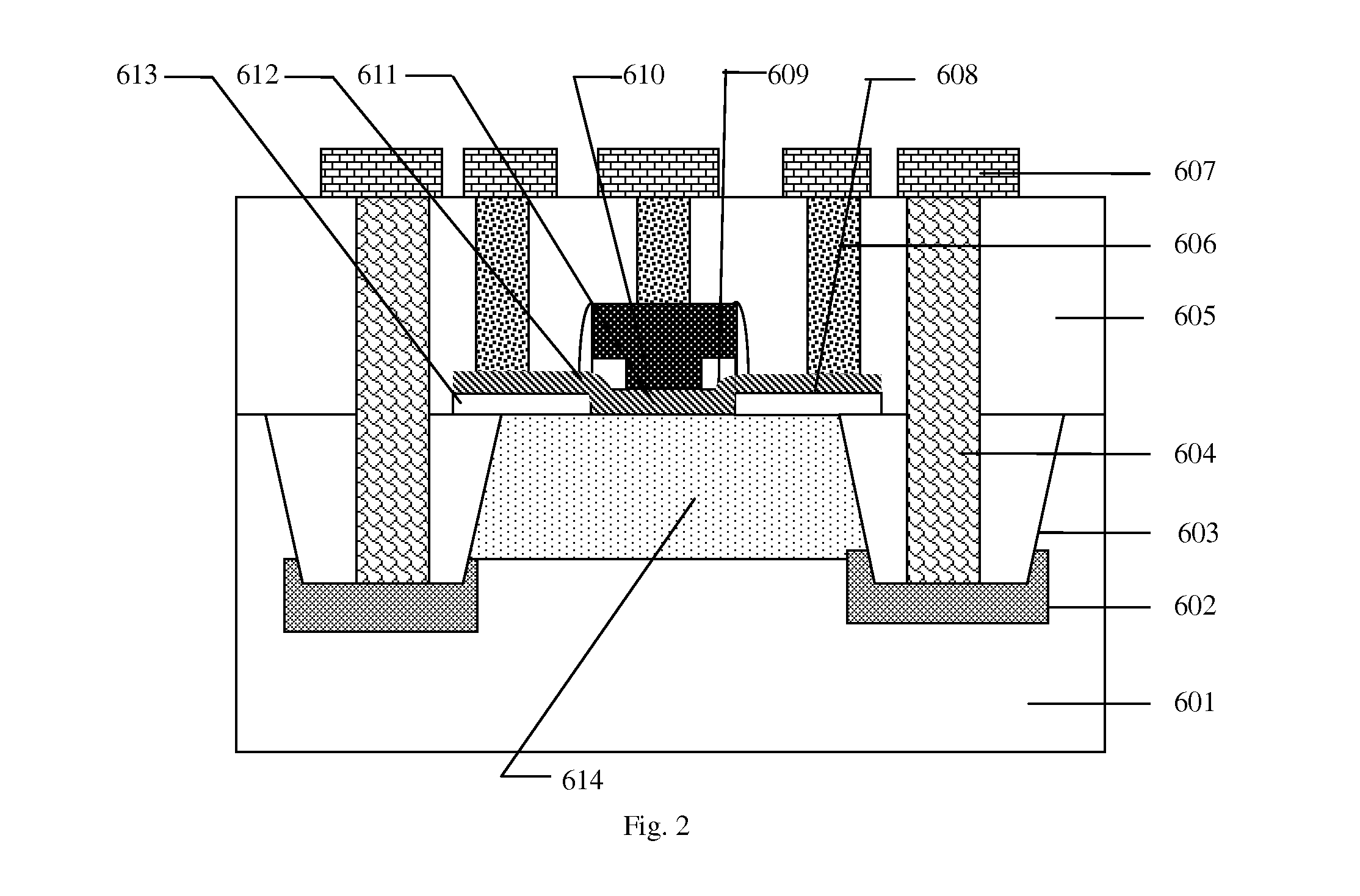

High Voltage Bipolar Transistor with Pseudo Buried Layers

ActiveUS20110140239A1Low costImprove breakdown voltageTransistorSemiconductor/solid-state device manufacturingHigh dosesEngineering

A high voltage bipolar transistor with shallow trench isolation (STI) comprises the areas of a collector formed by implanting first electric type impurities into active area and connected with pseudo buried layers at two sides; Pseudo buried layers which are formed by implanting high dose first type impurity through the bottoms of STI at two sides if active area, and do not touch directly; deep contact through field oxide to contact pseudo buried layers and pick up the collectors; a base deposited on the collector by epitaxial growth and in-situ doped by second electric type impurity, in which the intrinsic base touches local collector and extrinsic base is used for base pick-up; a emitter which is a polysilicon layer deposited on the intrinsic base and doped with first electric type impurities. This invention makes the depletion region of collector / base junction from 1D (vertical) distribution to 2D (vertical and lateral) distribution. The bipolar transistor's breakdown voltages are increased by only enlarge active critical dimension (CD). This is low-cost process.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

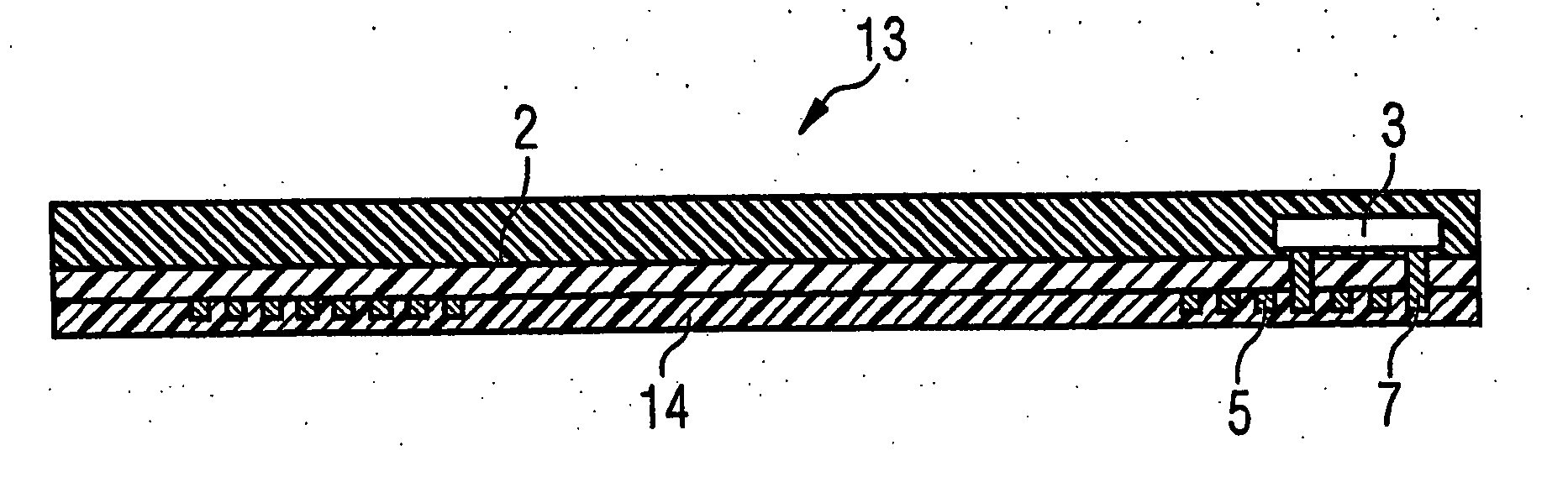

Chip card

InactiveUS20050199734A1Simple and low-costNot to damageOther printing matterSemiconductor/solid-state device detailsElectrical connectionEngineering

A contactless chip card and a method for producing a contactless chip card in which a plastic carrier having clearances is provided, on which an antenna coil is arranged on an upper side of the plastic carrier and a device having an integrated circuit is arranged on a rear side of the plastic carrier that is opposite from the upper side, an electrical connection is produced between the coil and the device, the plastic carrier is introduced into an injection mold and a card body is molded onto the rear side of the plastic carrier by the injection-molding process.

Owner:CIRCLE SMART CARD +1

Aqueous additive systems for polymeric matrices

InactiveUS20030199628A1No long manufacturedEliminates dust and compaction problemOrganic dyesPolymer scienceButadiene Dioxide

Aqueous-form additive systems, and methods of blending the same with a matrix resin, are disclosed whereby acrylic-based impact modifier compositions, butadiene-based impact modifier compositions and acrylic-based processing aids are used in aqueous form without the need for isolation to the traditional powder-form. The aqueous additive systems of the present invention provide a means for the design of novel additive compositions. The aqueous additive systems of the present invention also provide a great degree of flexibility in preparation of matrix resin blends and formulations. Additionally, the aqueous additive systems of the present invention allow for the reduced cost of manufacturing additives and reduced cost in blending matrix resin formulations.

Owner:ROHM & HAAS CO

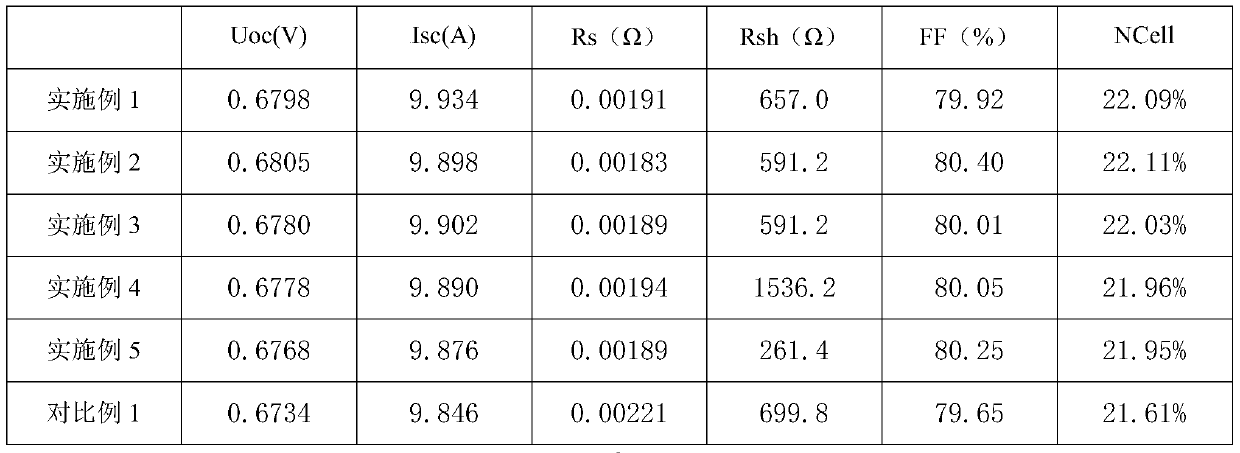

Preparation method of SE-PERC solar cell with high conversion efficiency

InactiveCN110828607AReduce usageReduce cost processingFinal product manufactureSemiconductor/solid-state device manufacturingPhysicsDoping

The invention discloses a preparation method of an SE-PERC solar cell with high conversion efficiency, and relates to the technical field of solar cells. The method comprises preparation steps of 1) texturing; 2) phosphorus diffusion; 3) laser heavy doping; 4) oxidation; (5) PSG removal; 6) alkali etching and polishing, carrying out alkali etching and polishing on a back surface of a silicon wafer; 7) removing the phosphorosilicate glass on a front surface of the silicon wafer; 8) annealing; 9) plating a double-sided aluminum oxide passivation film on a surface of the silicon wafer; 10) depositing an antireflection film on the front surface; 11) depositing a passivation film on a back surface; 12) performing back laser grooving; 13) silk-screen printing; and 14) sintering. The method is advantaged in that the alkali etching technology is utilized, compared with acid etching, the use amount of etching acid can be reduced, acid wastewater cost treatment is reduced, environmental protection is facilitated, an oxidation procedure is added after laser heavy doping and before PSG removal, PN junctions can be prevented from being damaged, the good passivation effect can be achieved on thesilicon wafer, and conversion efficiency is obviously improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

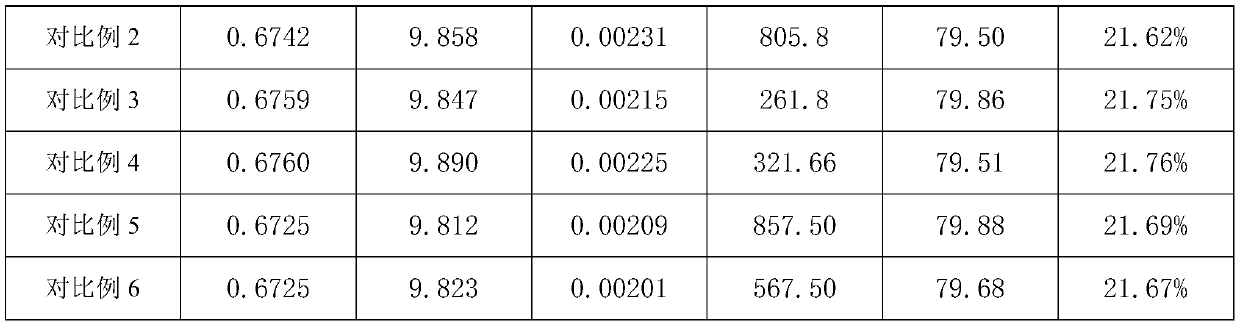

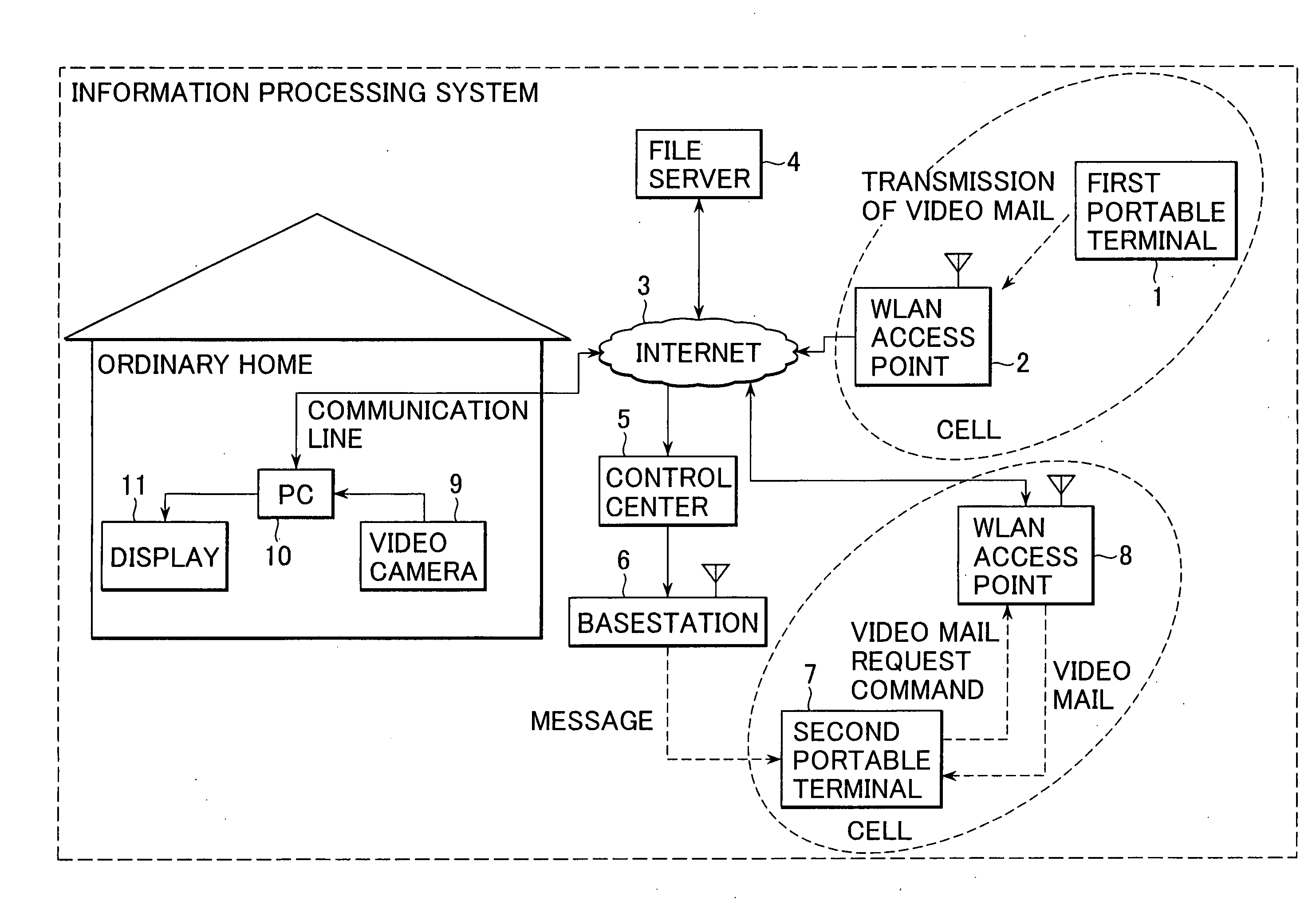

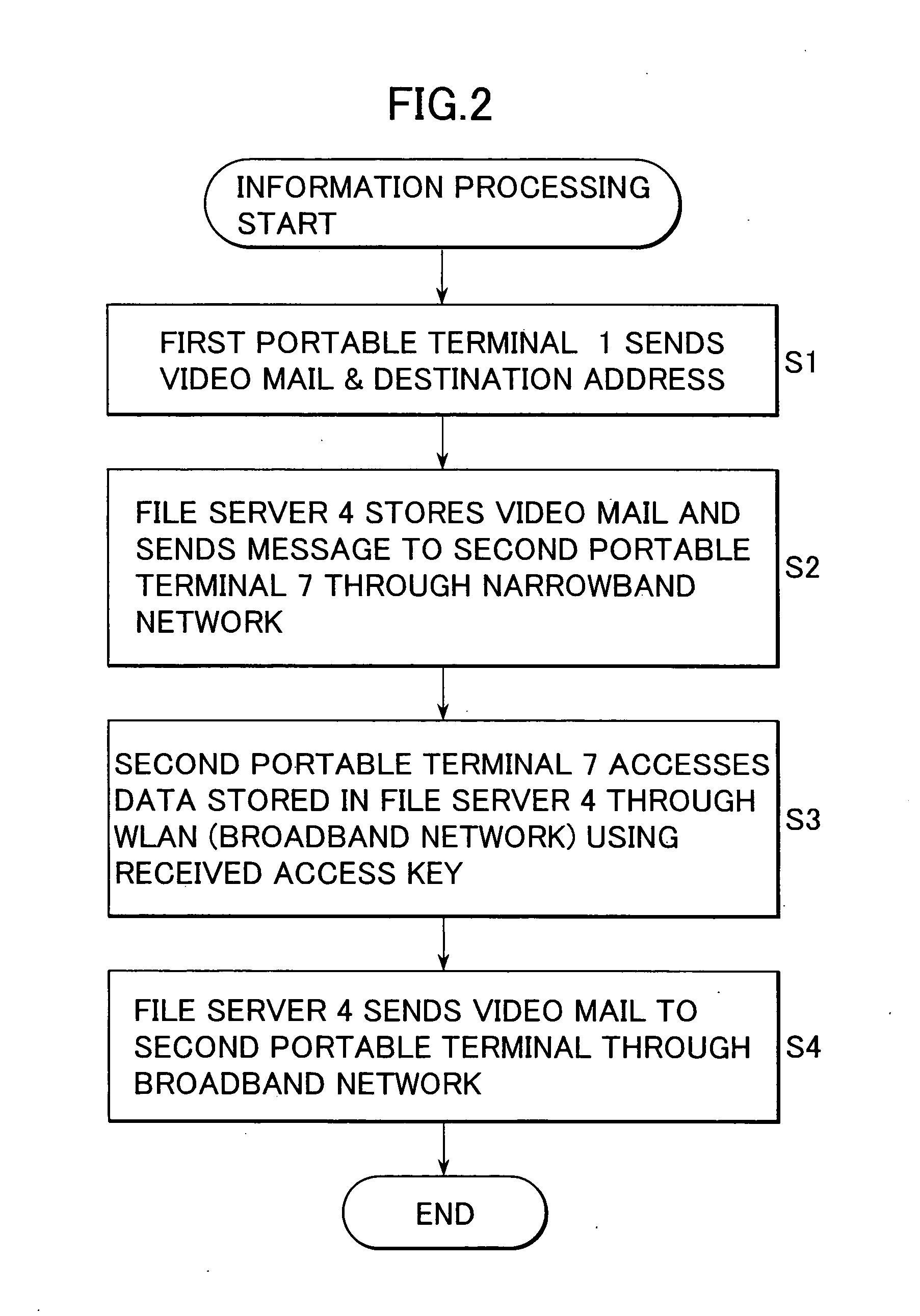

Information processing system, information processor, information processing method, receiver, receiving method, and program

InactiveUS20050008130A1Low cost processingQuality improvementNetwork traffic/resource managementMultiplex communicationInformation processorHandling system

The present invention provides an information processing system enabled to transmit and receive video mails at a higher transfer rate and at reduced cost. In this system, a file server sends a low capacity notification mail, which notifies the presence of a video mail sent from a portable terminal, to another portable terminal. This portable terminal accesses the file server in response to the notification mail, and downloads the video mail therefrom via a WLAN network that is a broadband communication line.

Owner:SONY CORP

Ultrasound imaging system with pixel oriented processing

ActiveUS8287456B2Reduce in quantitySignificant utilityBlood flow measurement devicesInfrasonic diagnosticsSonificationHigh frame rate

An ultrasound imaging system with pixel oriented processing is provided in which an acoustic signal is generated, echoes from the acoustic signal are received at a plurality of receiving elements to obtain echo signals that are then stored, a given pixel is mapped into a region of the stored signals, the mapped region of the stored echo signals is organized into array for the given pixel after which the array is processed to generate a signal response for the given pixel to obtain acoustic information for the given pixel. The system can be implemented entirely on plug-in cards for a commercial PC motherboard. The system and method can be implemented for pixel-oriented or voxel-oriented image processing and display, eliminating intermediate data computations and enabling extensive use of software processing methods. Advantages include improved acquisition of signal dynamic range, flexible acquisition modes for high frame rate 2D, 3D, and Doppler blood flow imaging.

Owner:VERASONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com