Patents

Literature

72results about How to "Low cost design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

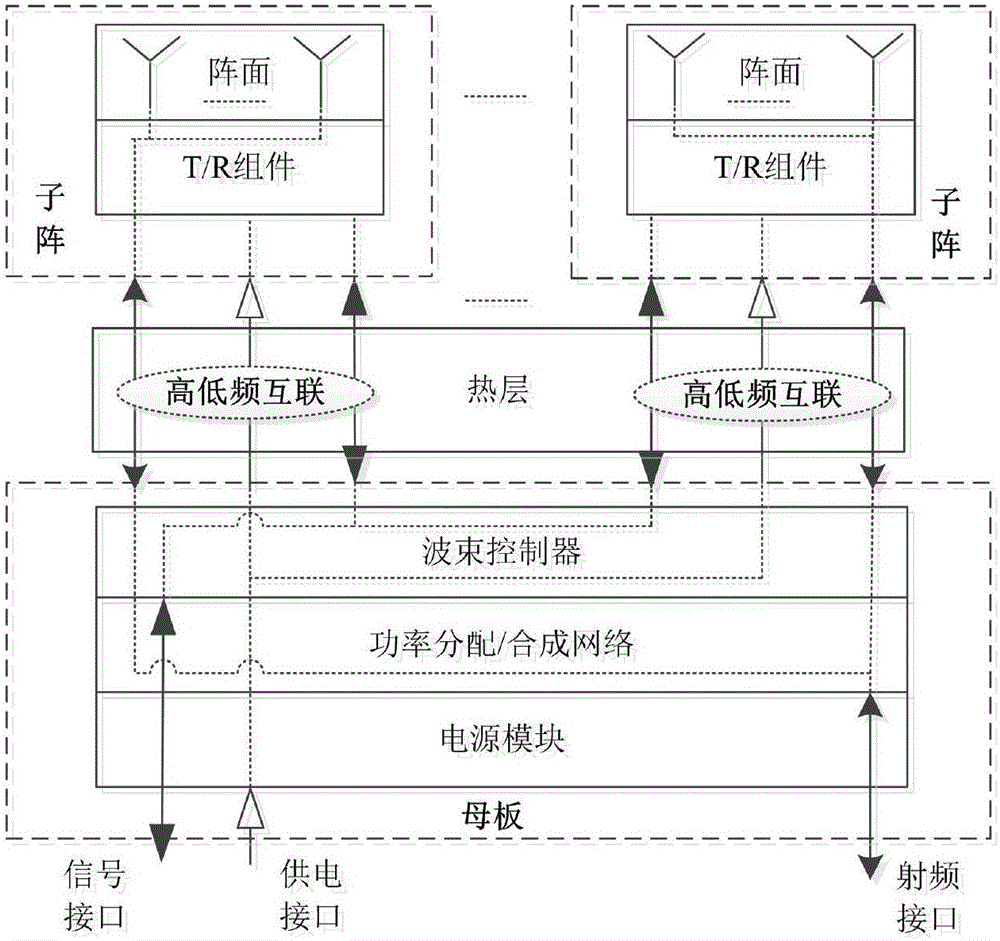

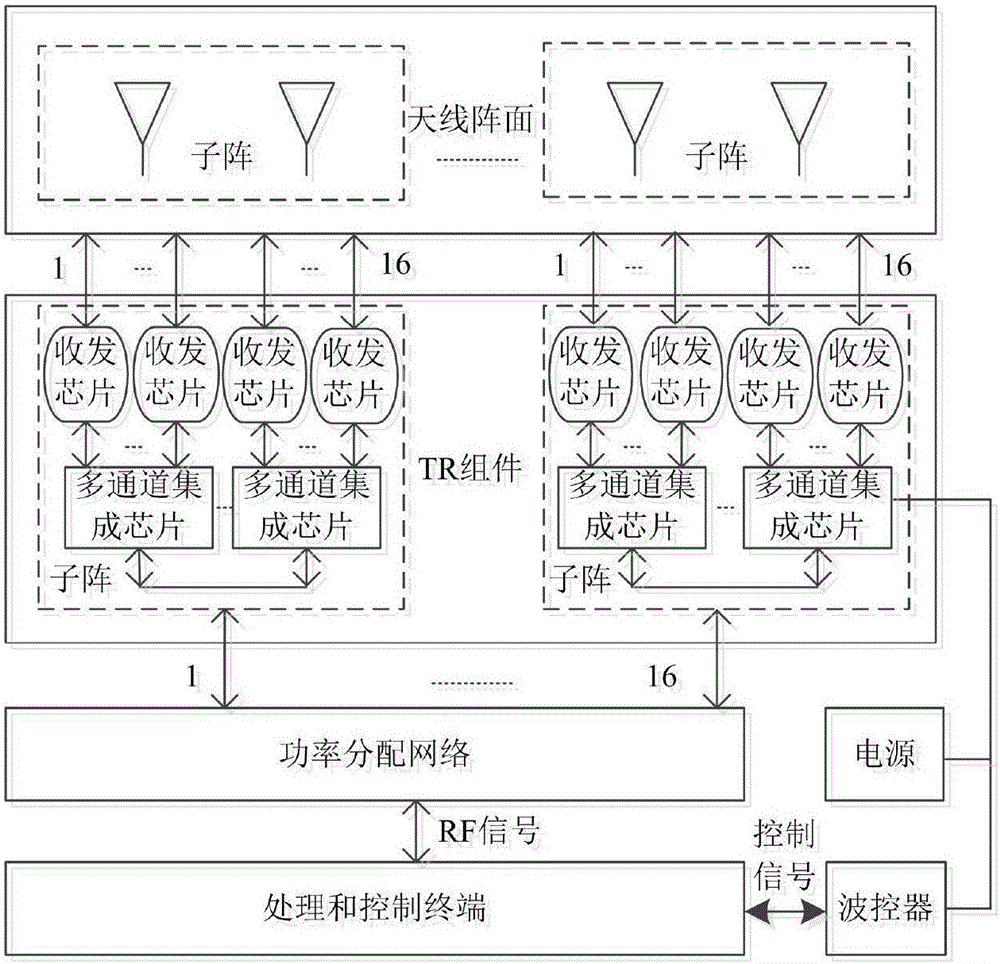

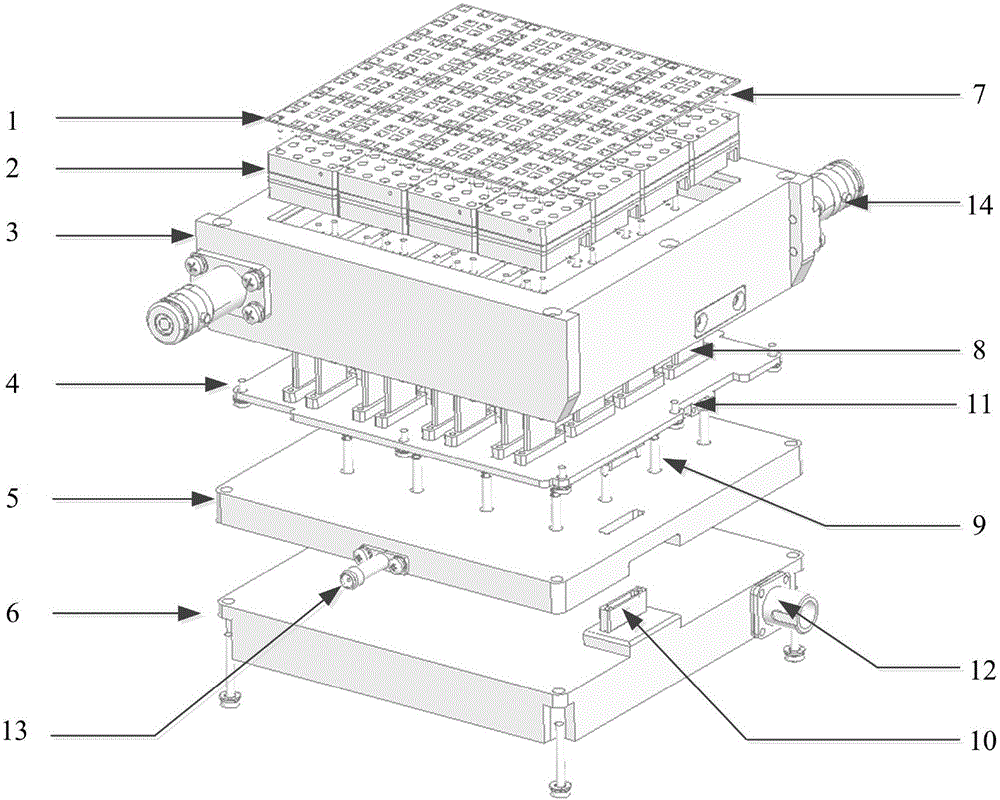

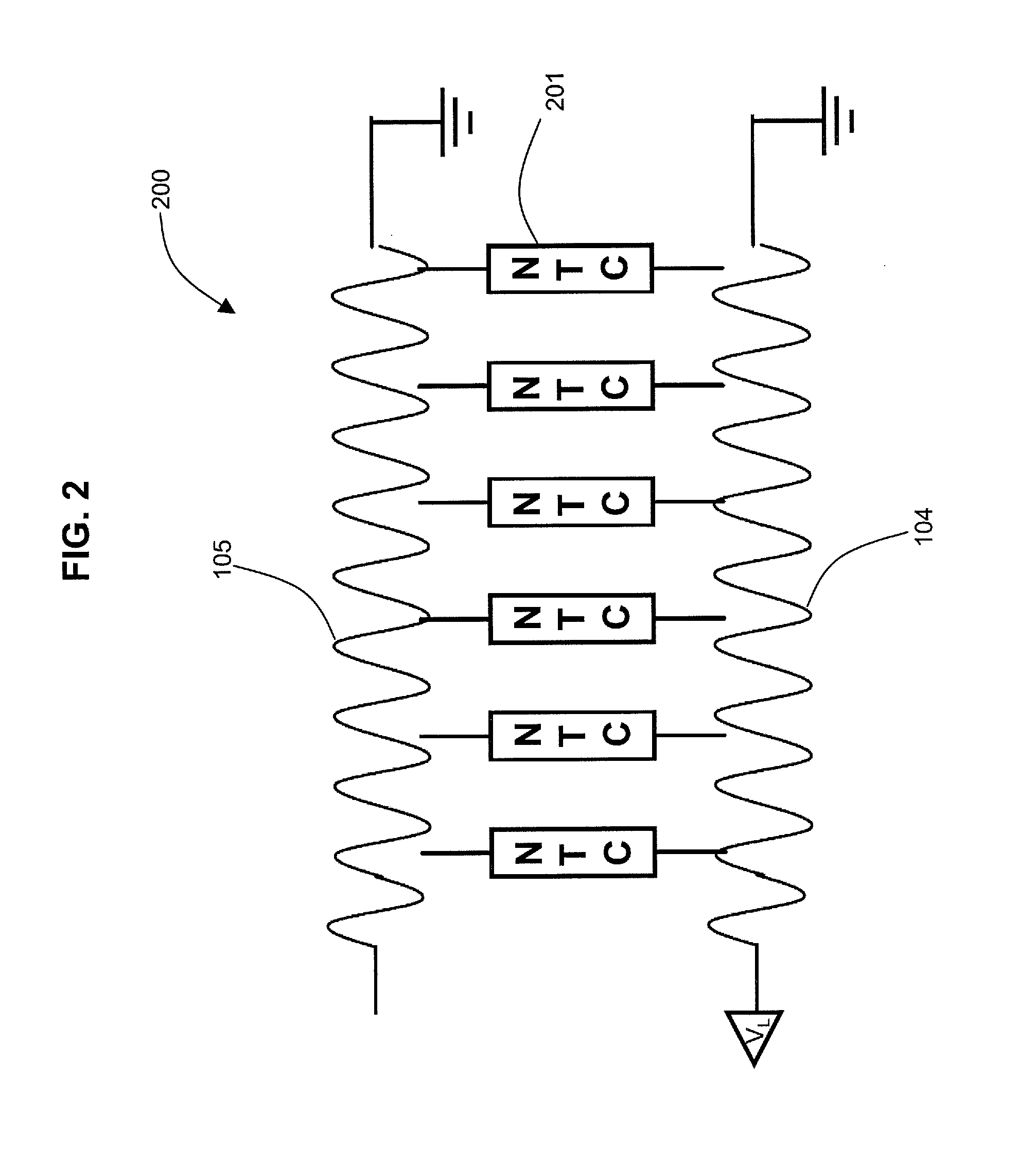

Ka-band tilt-structure active phased array antenna

InactiveCN105914476AHighly integratedImprove performanceAntenna arraysAntennas earthing switches associationArray elementActive phase

The invention provides a Ka-band tilt-structure active phased array antenna, so as to provide an active phased array antenna which is high in integration density and can improve maintainability and interchangeability. According to the technical scheme, one path of RF signals transmitted by a transmitting signal processing terminal are transmitted to a power distribution / synthesis network (5) via a signal interface and a radio frequency interface to be divided into M paths of signals; according to information of an azimuth angle and a pitch angle of the phased array antenna provided by the transmitting signal processing terminal in real time, a beam controller (4) calculates and obtains beam pointing of the phased array antenna in real time through an FPGA; the beam pointing of the phased array antenna is converted into phase data needed by each array element under control of the beam controller (4); the data are transmitted to tilt-type TR assembly sub array modules in N channels respectively via a high and low-frequency interconnected multi-core high and low-frequency socket, and under control of the beam controller, M*N paths of signals are transmitted to an antenna array, and thus signal transmission is completed, and synchronous electric control scanning of beams transmitted by the phased array antenna is realized.

Owner:10TH RES INST OF CETC

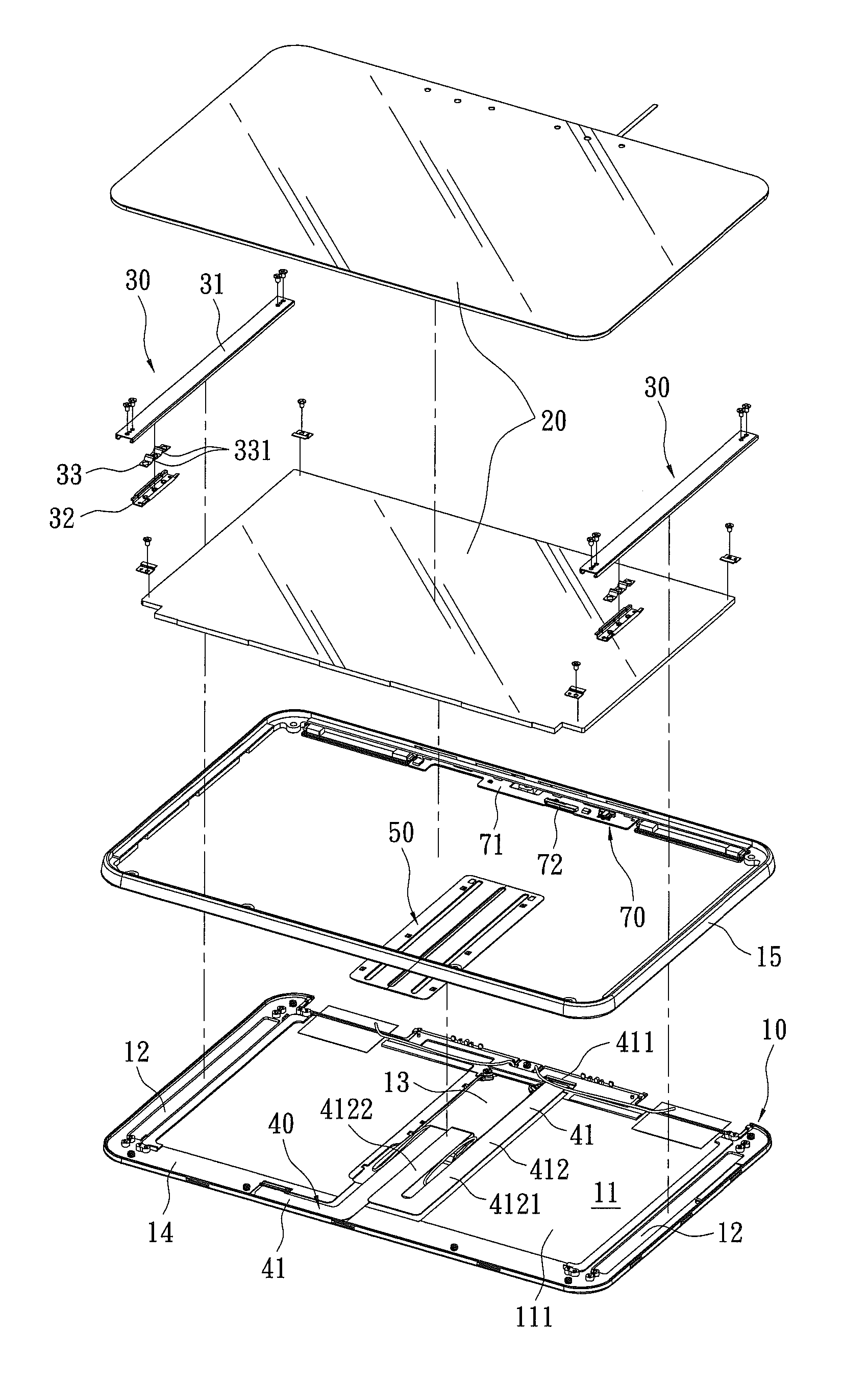

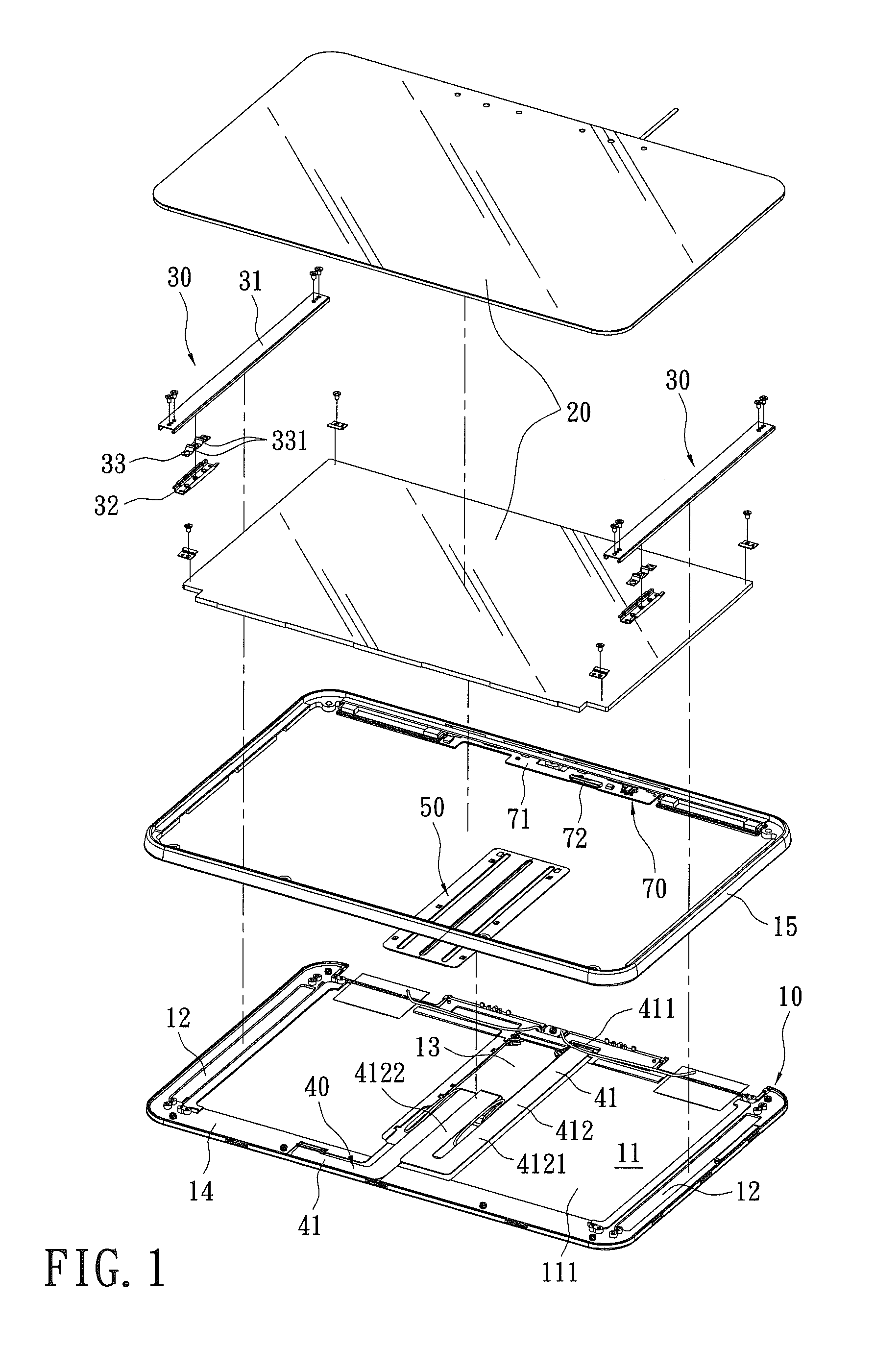

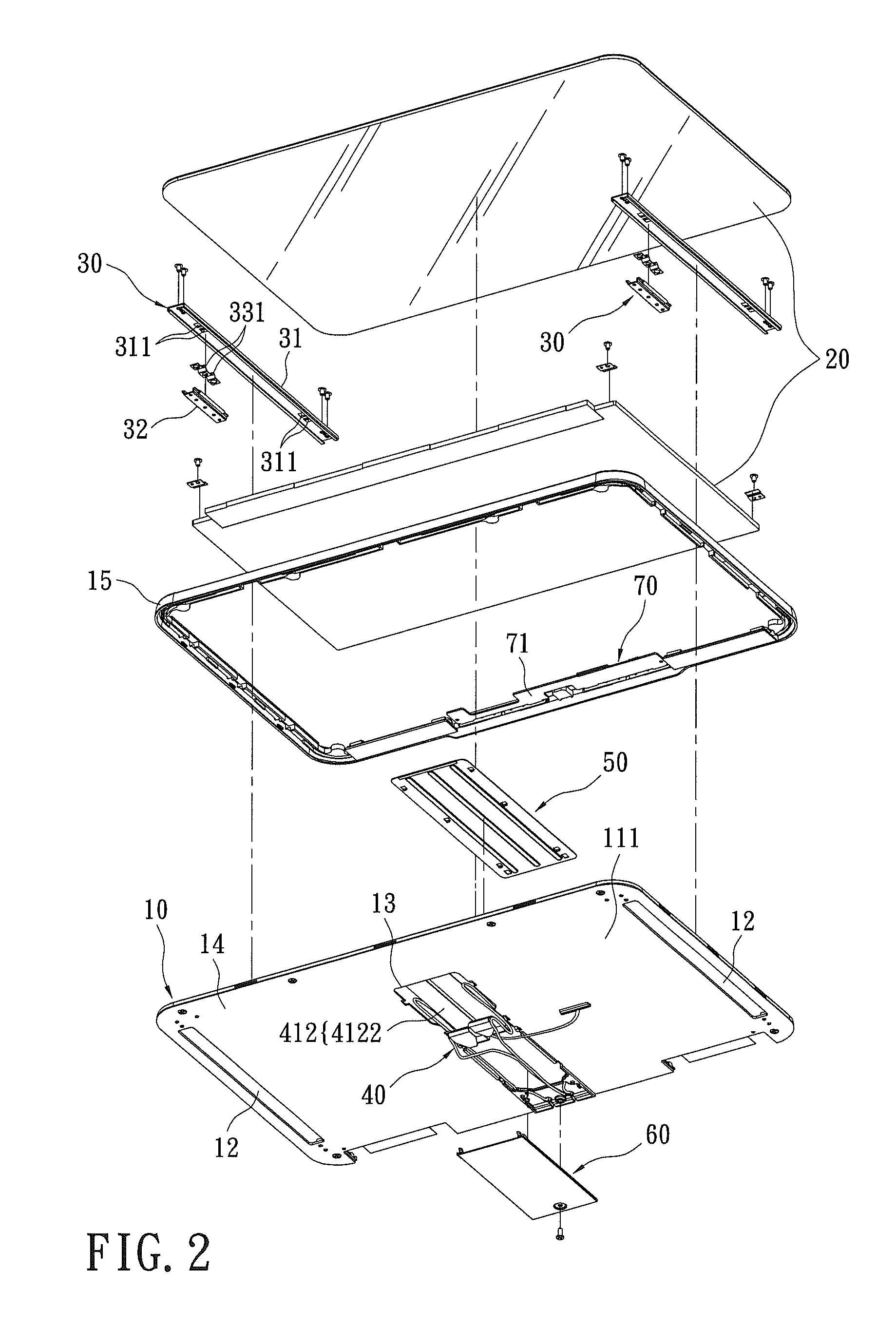

Display structure of slip-cover-hinge electronic device

ActiveUS8116073B2Simple structureImprove adaptabilityPiezoelectric/electrostrictive microphonesDigital data processing detailsElectrical connectionHinge angle

Owner:AMTEK SYST

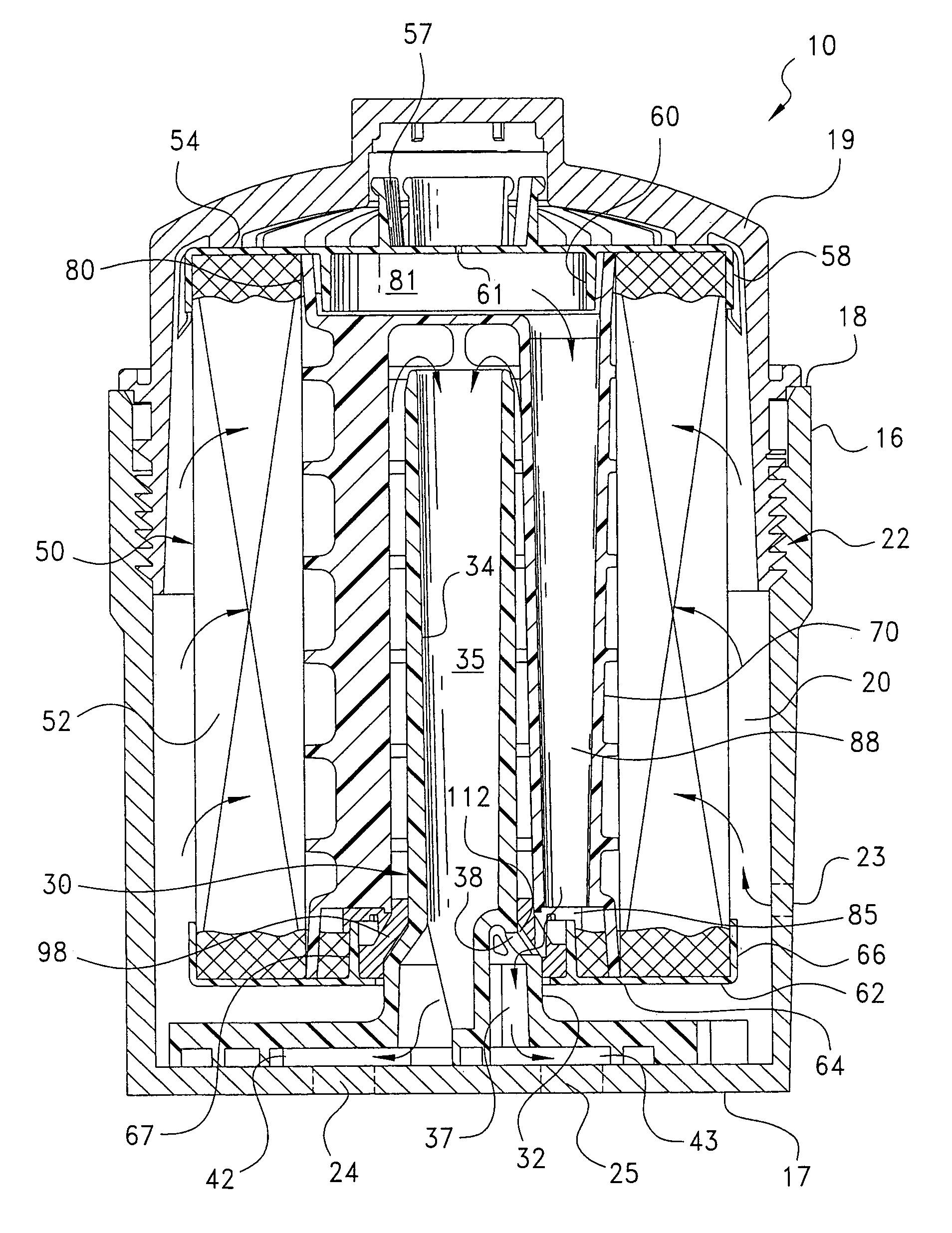

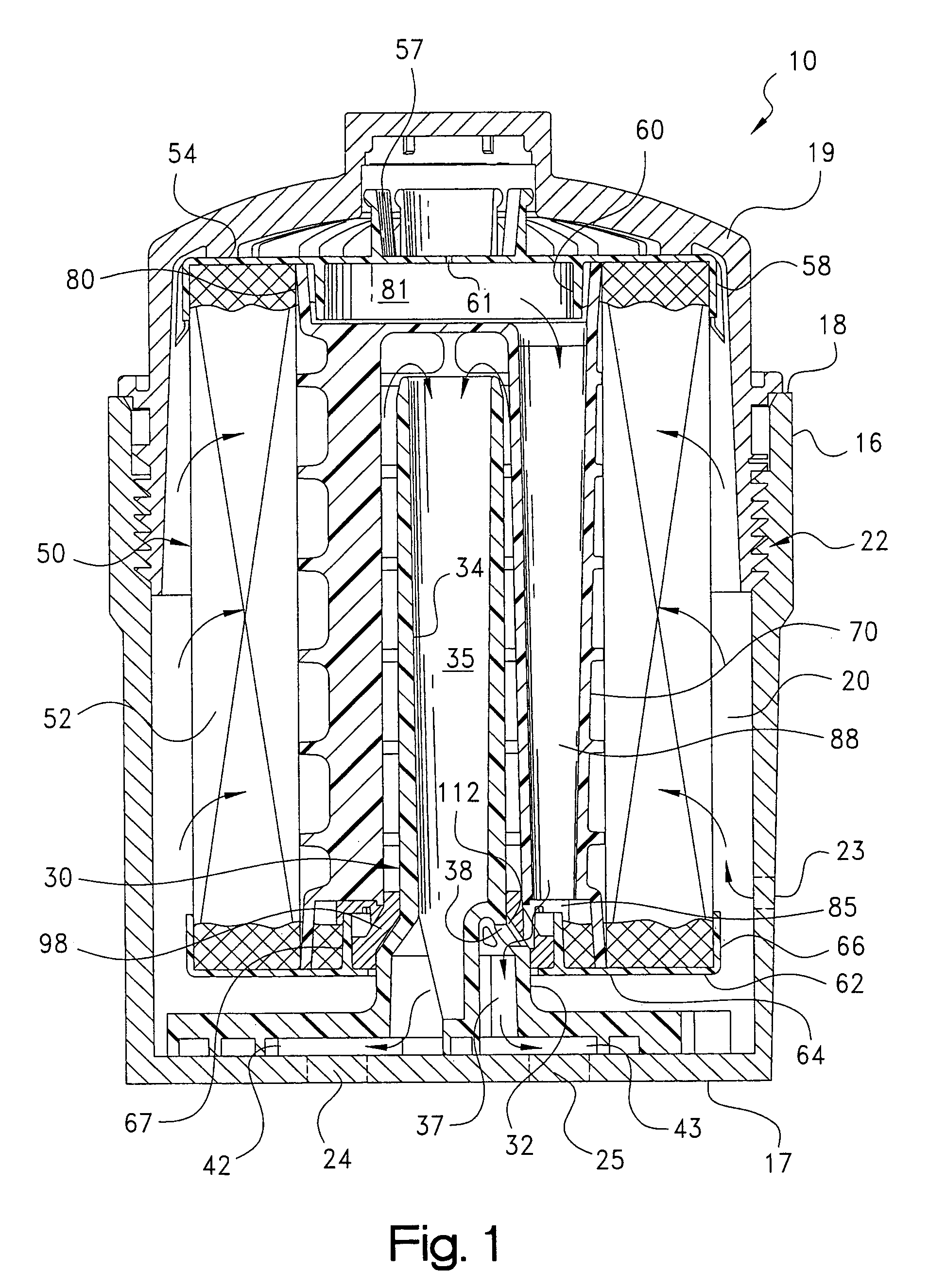

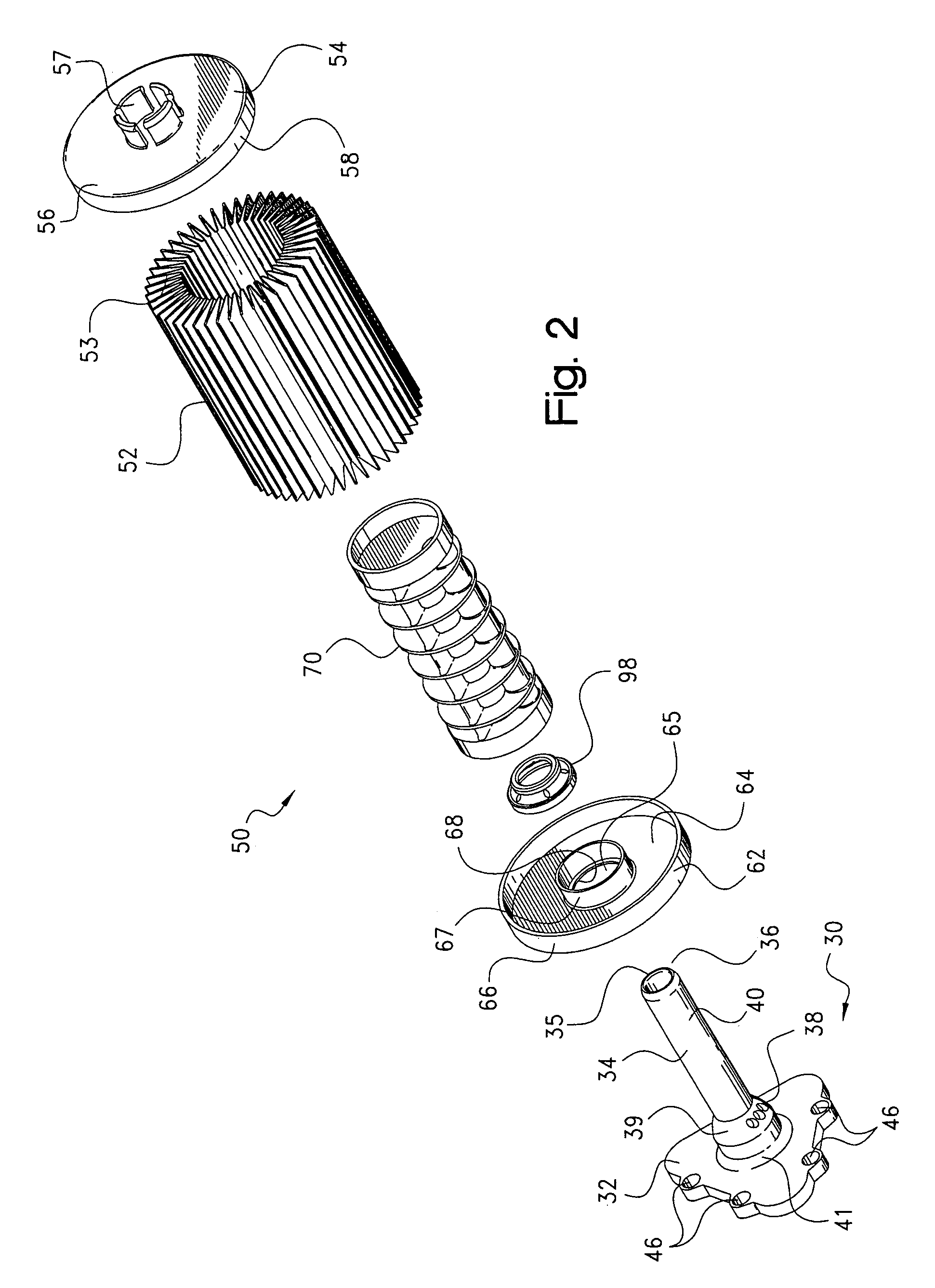

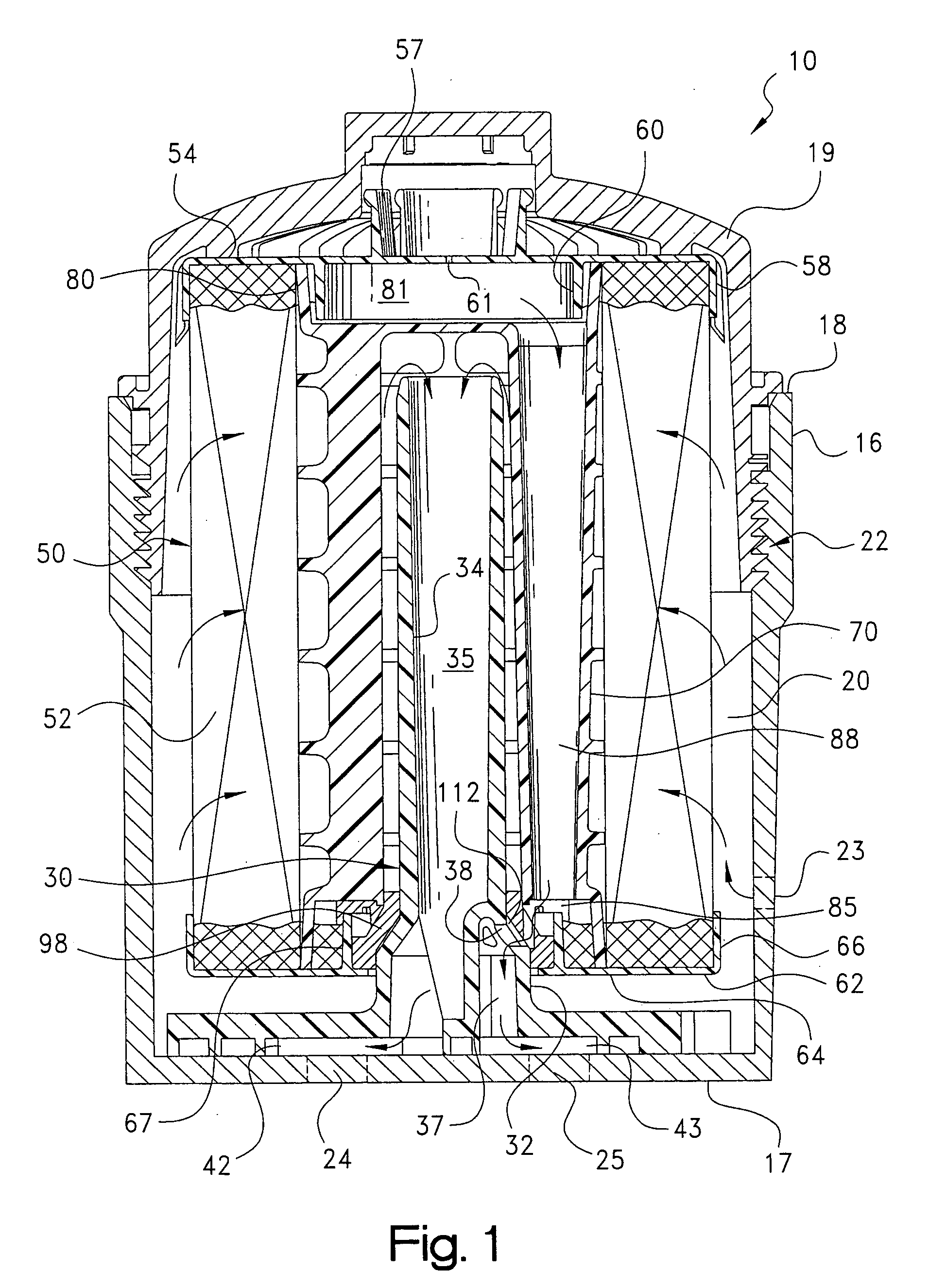

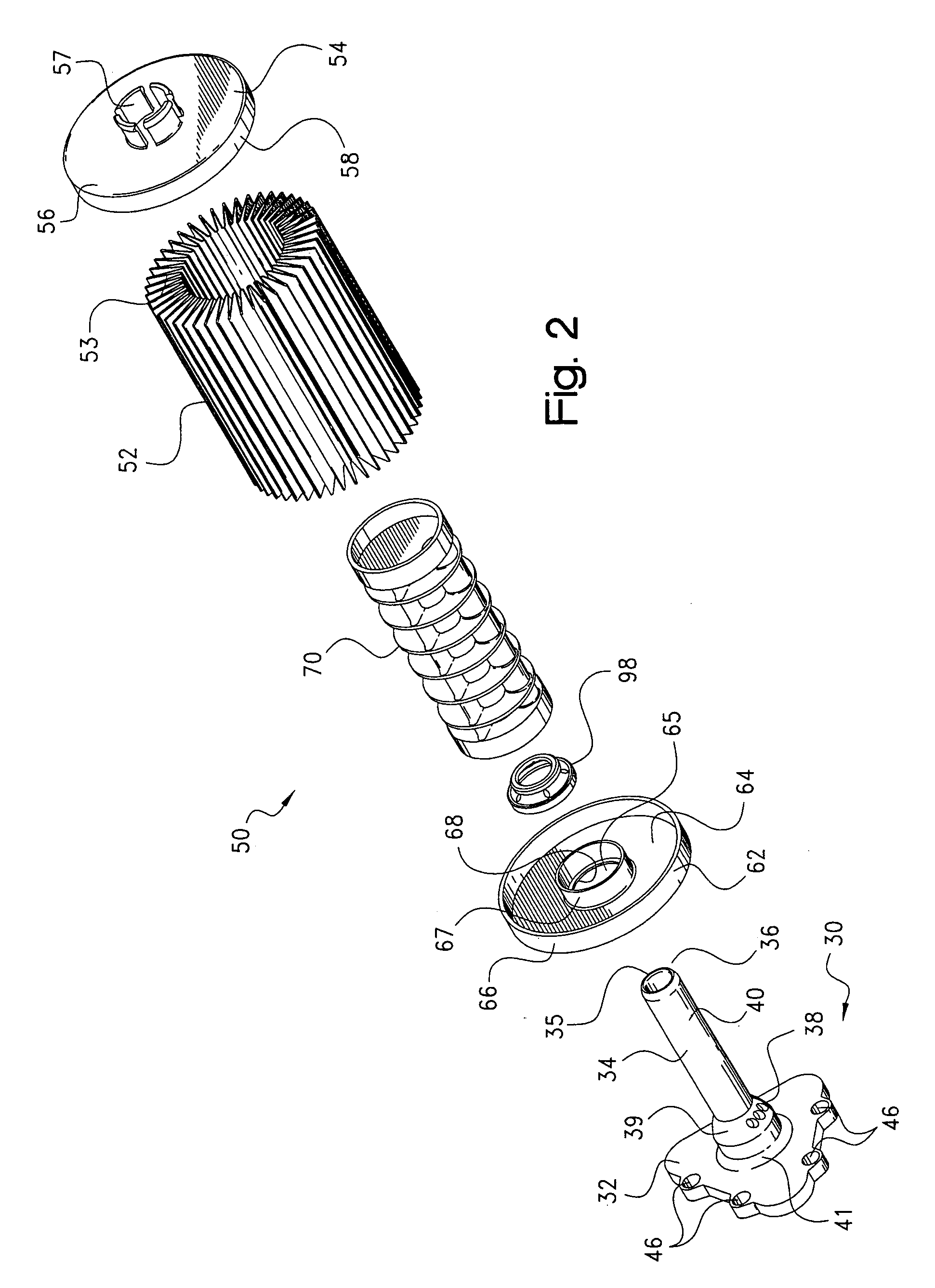

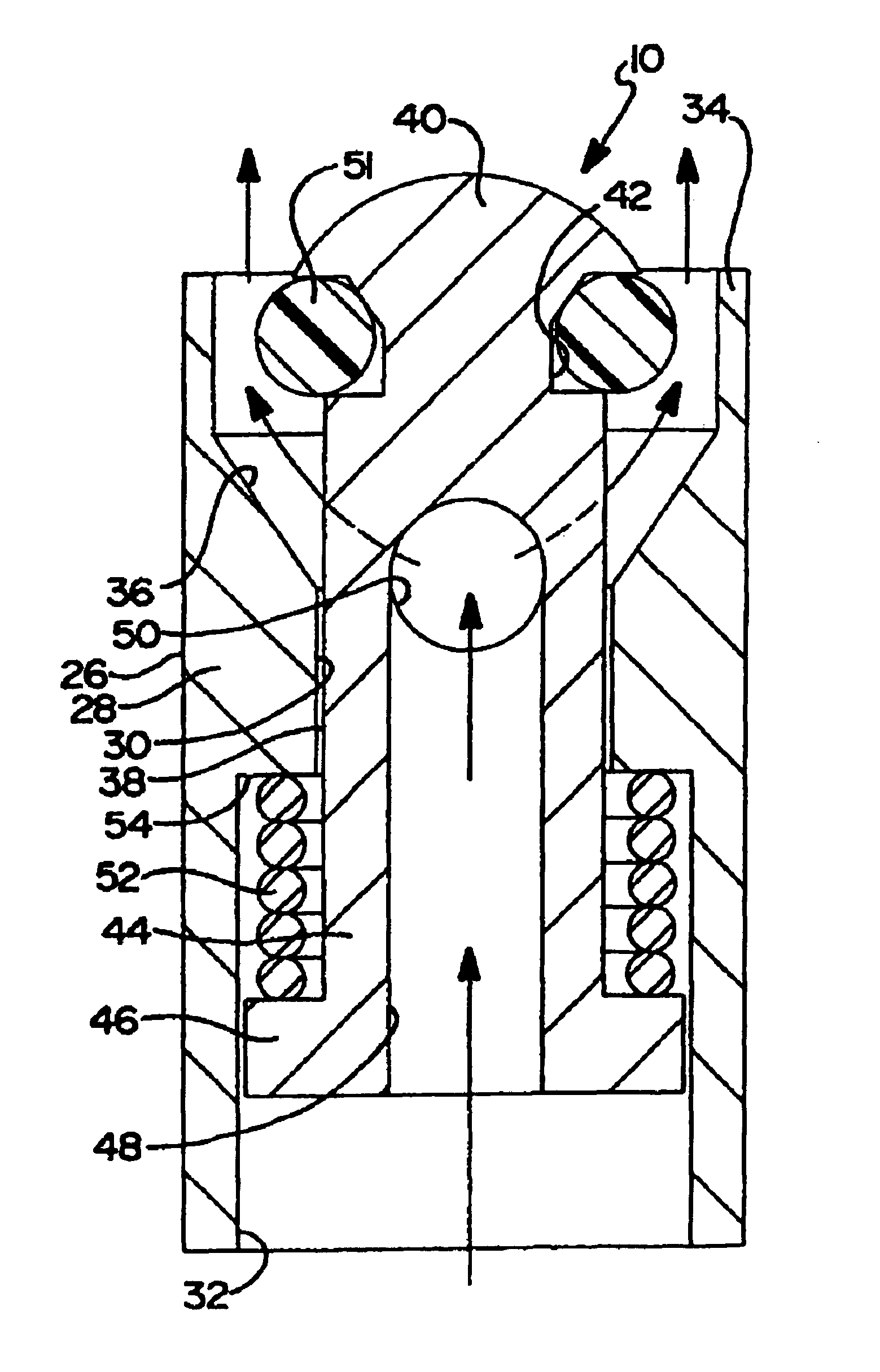

Filter assembly with vented filter element

ActiveUS7147110B2Simple and low cost designReduce riskMembrane filtersMachines/enginesFiltrationEngineering

A filter assembly includes a housing with a central standpipe, and cover for enclosing a filter element. The filter element includes a ring of filtration media and first and second end caps. A vent orifice is formed in the first end cap into the central cavity of the media ring. A support core is disposed centrally in the media ring and extends between the first and second end caps. The core includes a separate and independent fluid channel extending from the first end cap that is fluidly connected with the vent orifice, to the second end cap. The second end cap has a central opening, and an annular sealing device bounding the opening which receives and seals to the standpipe and includes through-passages fluidly interconnecting the fluid channel in the core with flow opening(s) along the standpipe or in the lower end of the housing to a drain port.

Owner:PARKER INTANGIBLES LLC

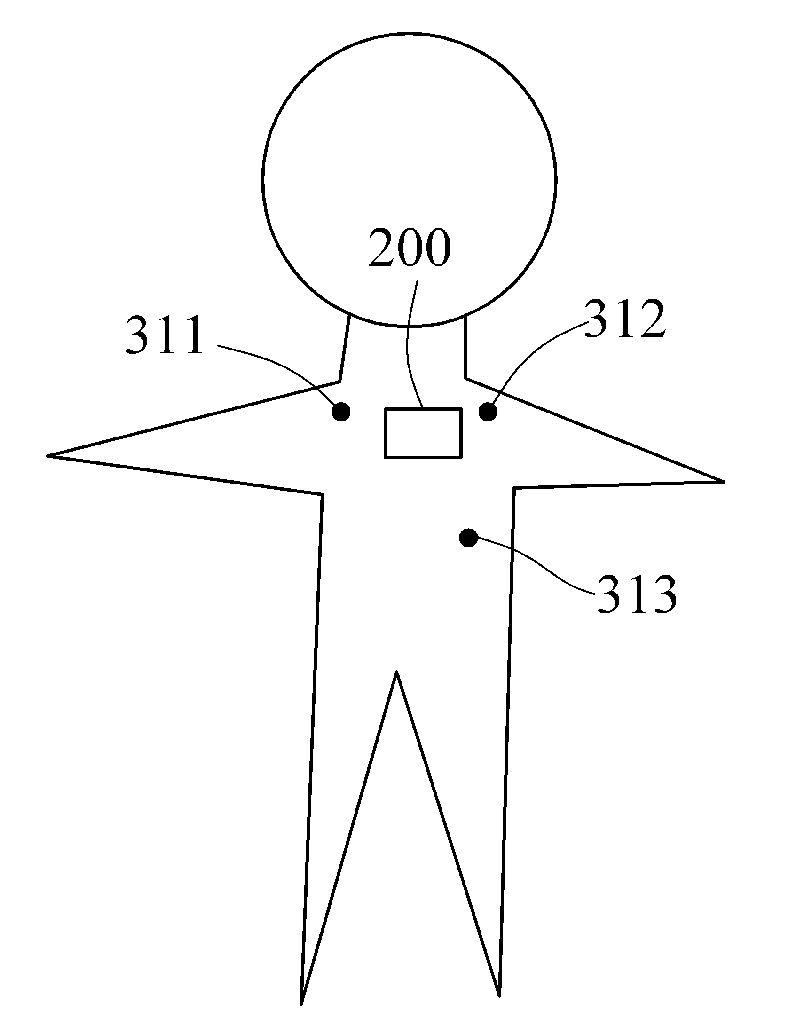

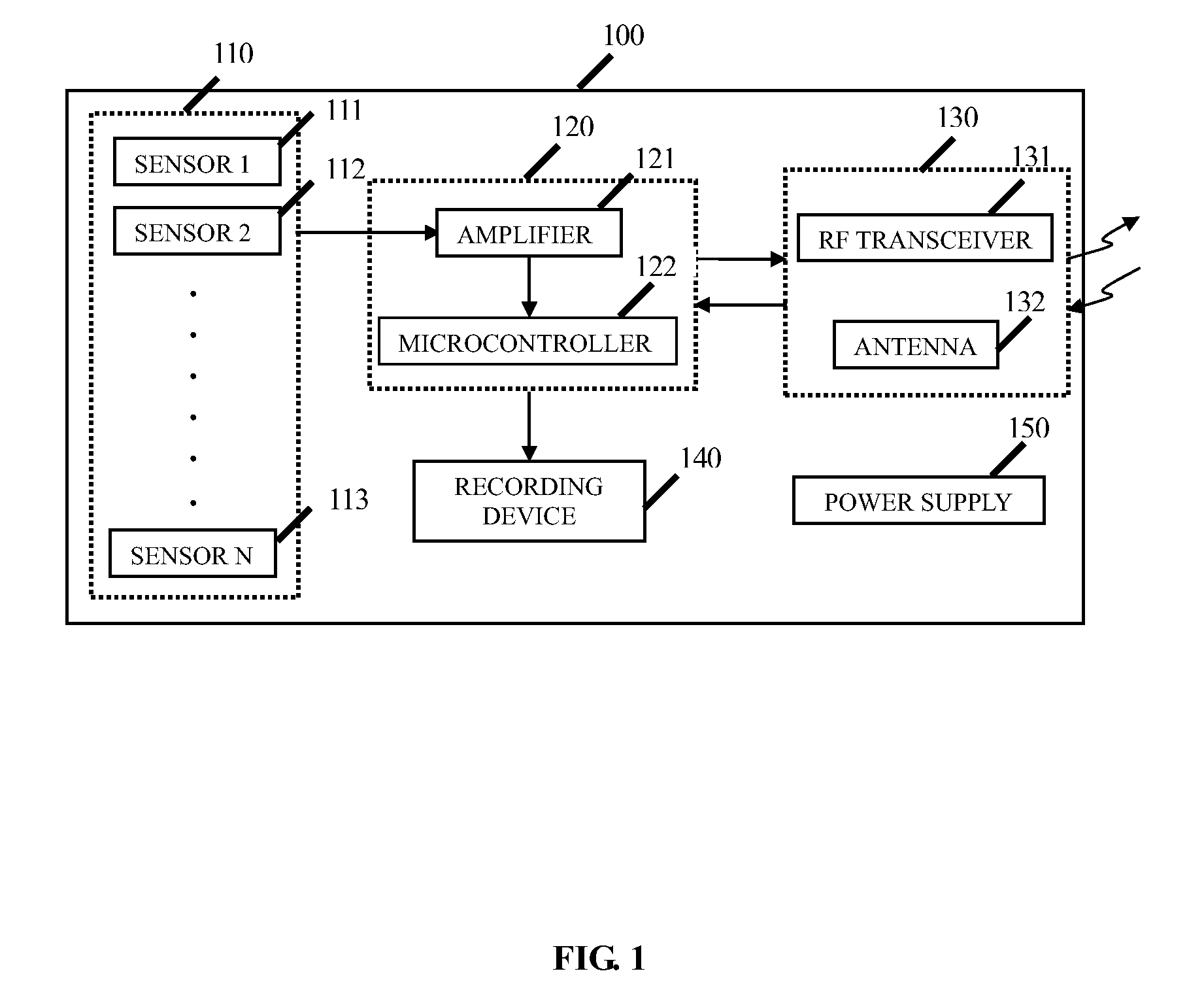

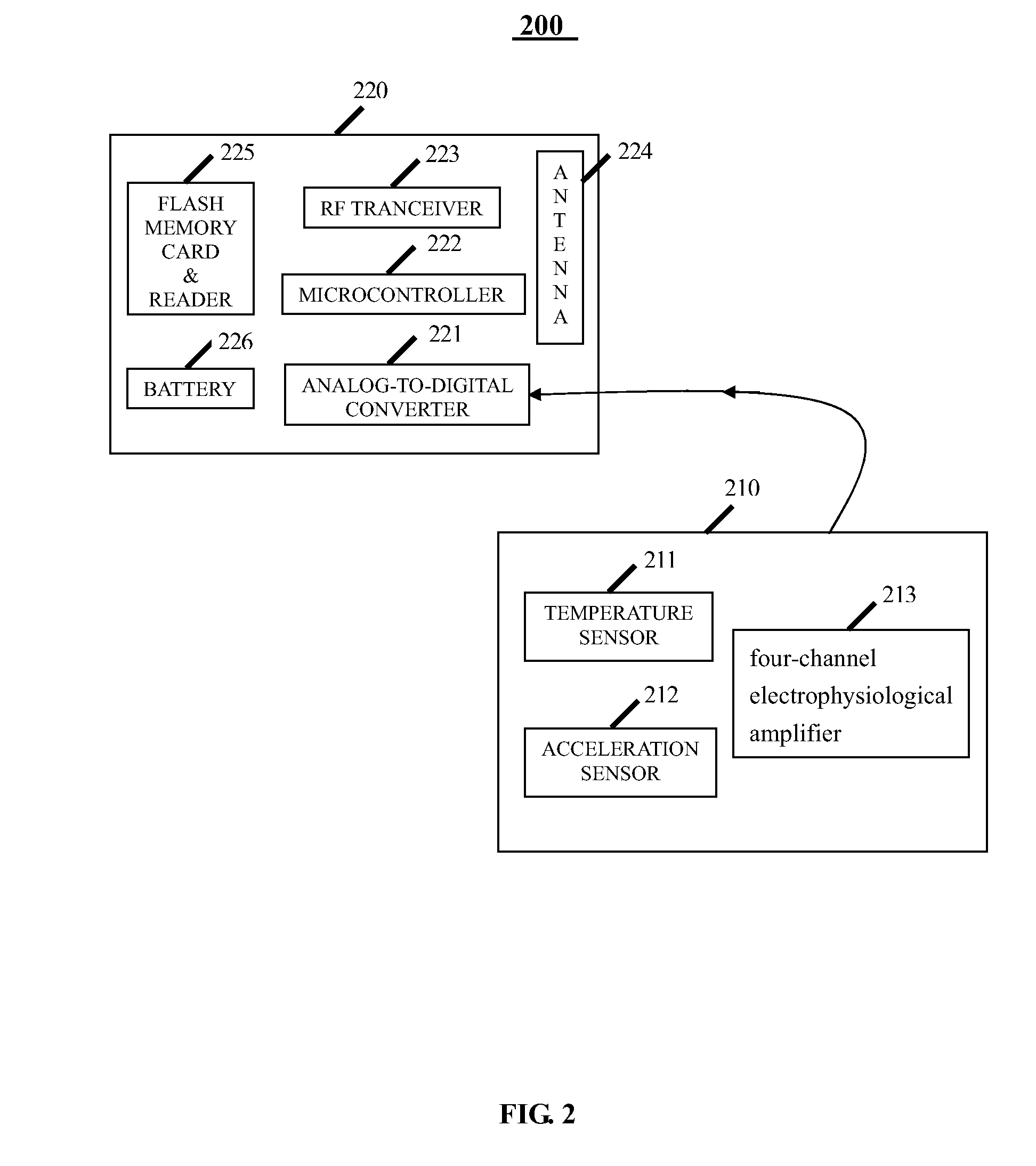

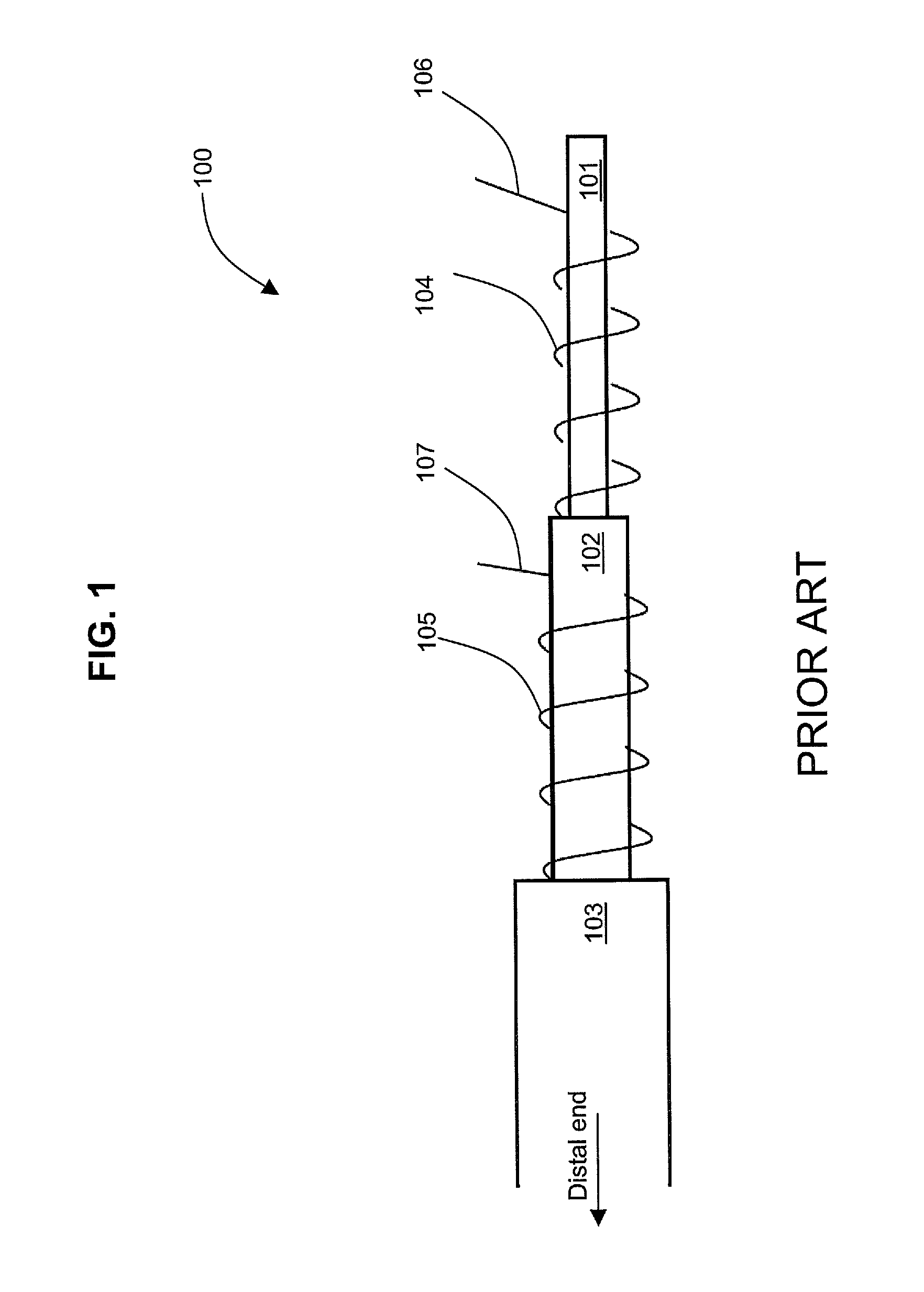

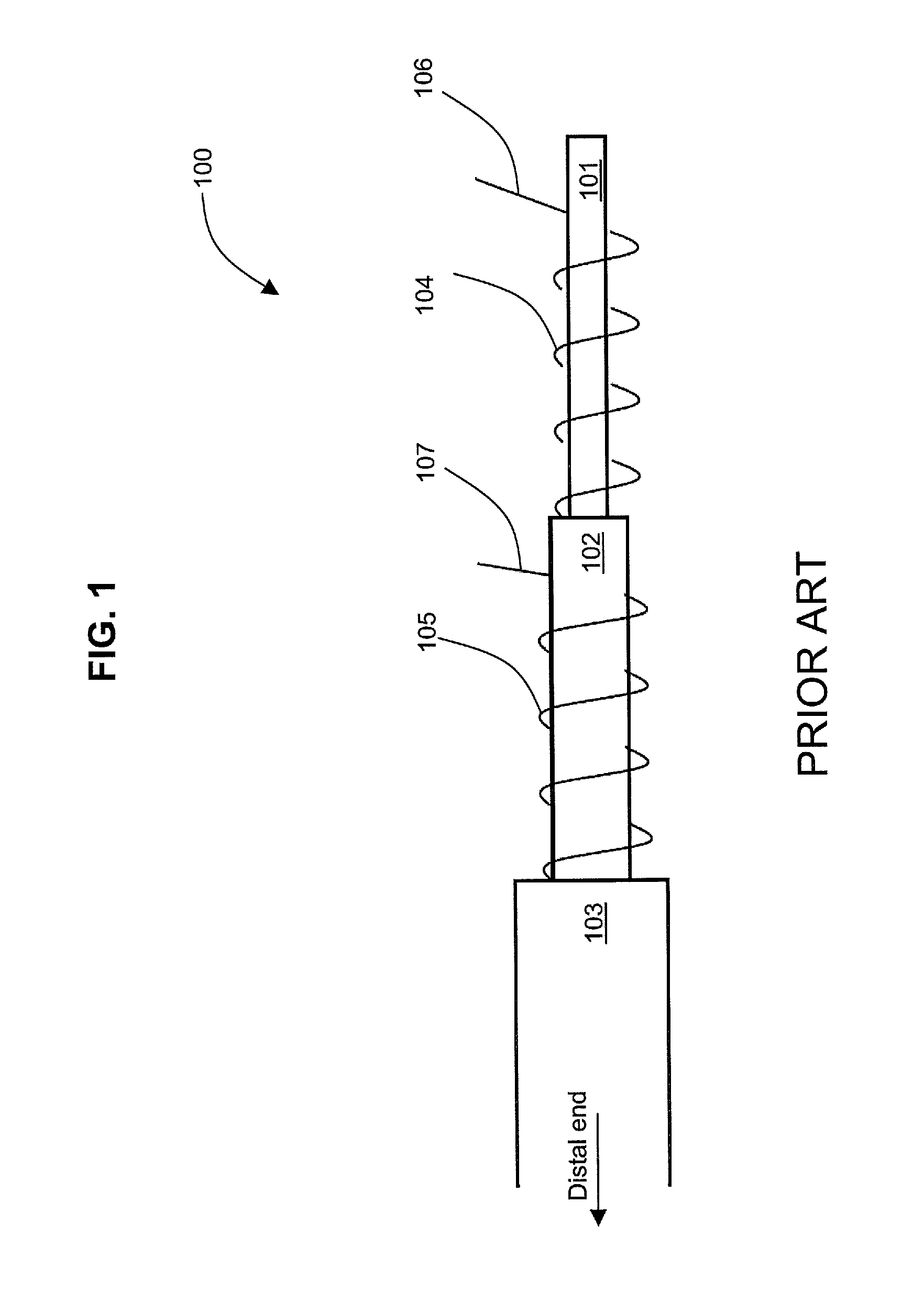

Miniature wireless apparatus for recording physiological signals of humans and use thereof

InactiveUS20080306348A1Accurate analysisUse minimizedSensorsTelemetric patient monitoringEngineeringSignal processing

A miniature wireless apparatus for recording and remote monitoring physiological signals and use thereof are described. The miniature wireless apparatus comprises a signal collecting module, a signal processing module, a wireless module, and a recording device. The methods for recording and remote monitoring physiological signals comprising collecting physiological signals by a signal collecting module, processing the said physiological signals by a signal processing module and recording the processed signals by a recording device, modulating the said processed signals and synchronously transmitting and receiving the modulated signals by a wireless module to integrate the physiological signals, receiving the signals by a remote receiver, and recording, monitoring, and analyzing the physiological signals by the remote receiver and further transmitting the physiological signals to the remote monitoring station through a network. Methods for sleep monitoring and evaluating and for monitoring and evaluating of autonomic nerve function using the miniature wireless apparatus are further described.

Owner:NATIONAL YANG MING UNIVERSITY

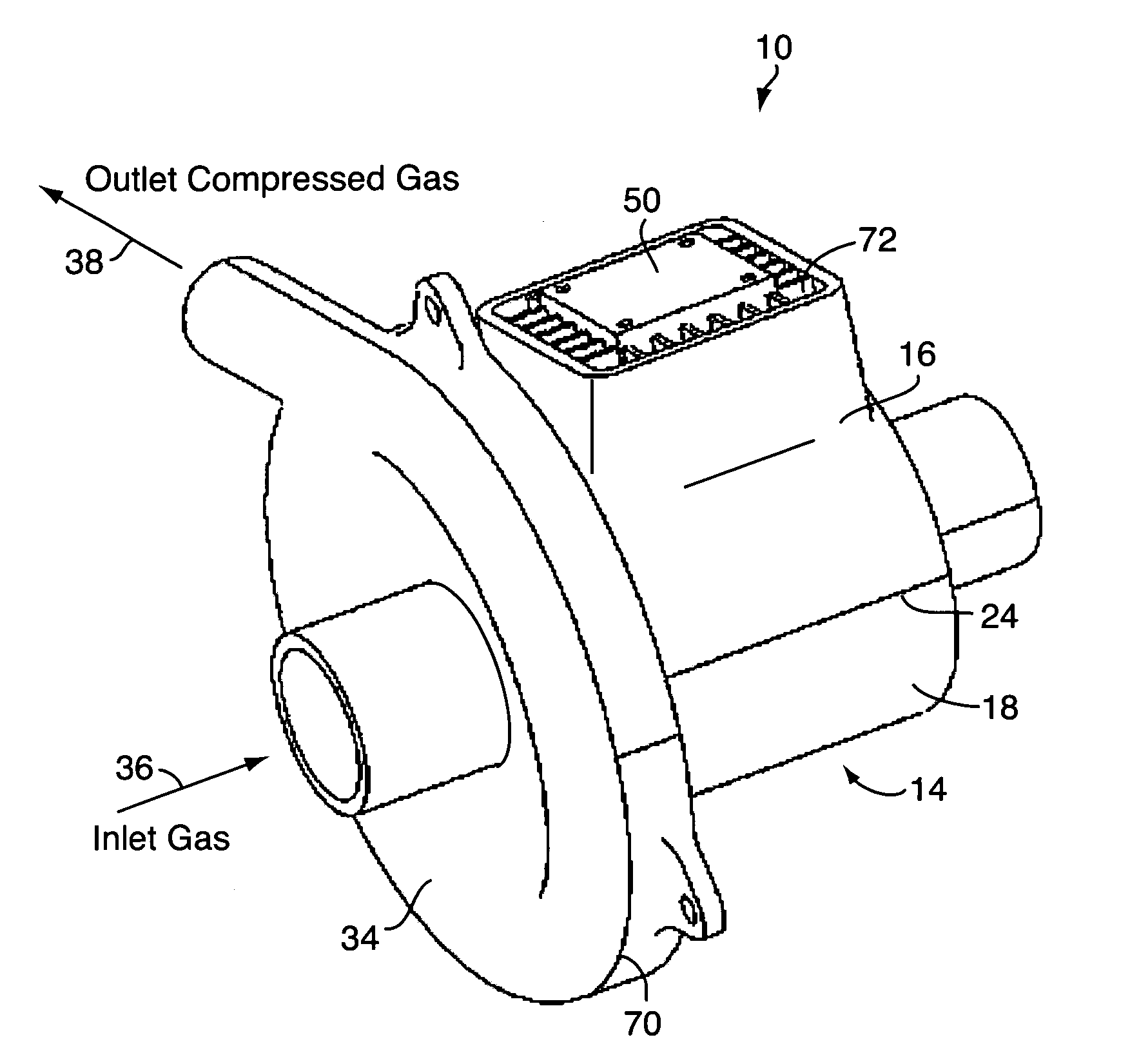

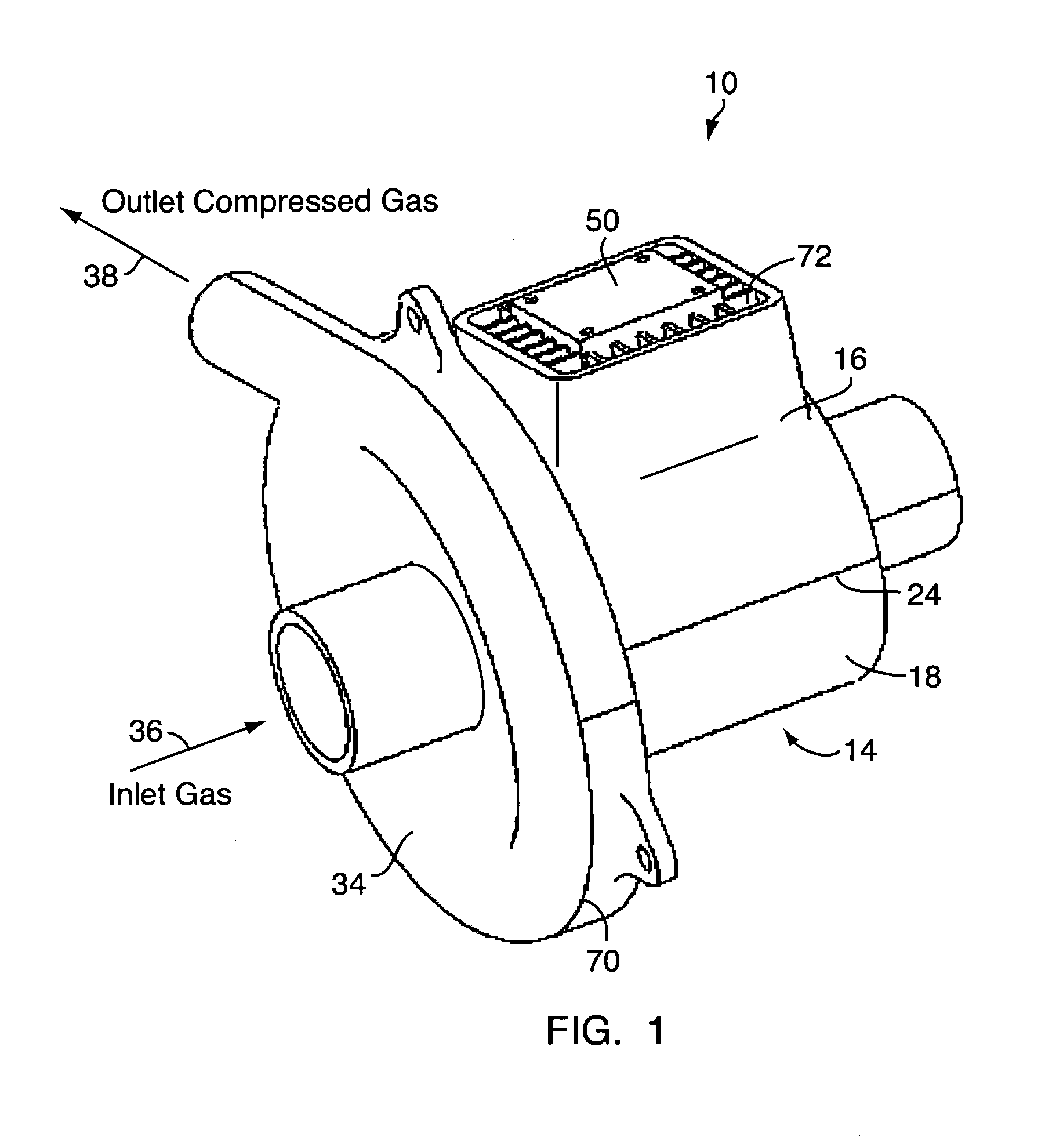

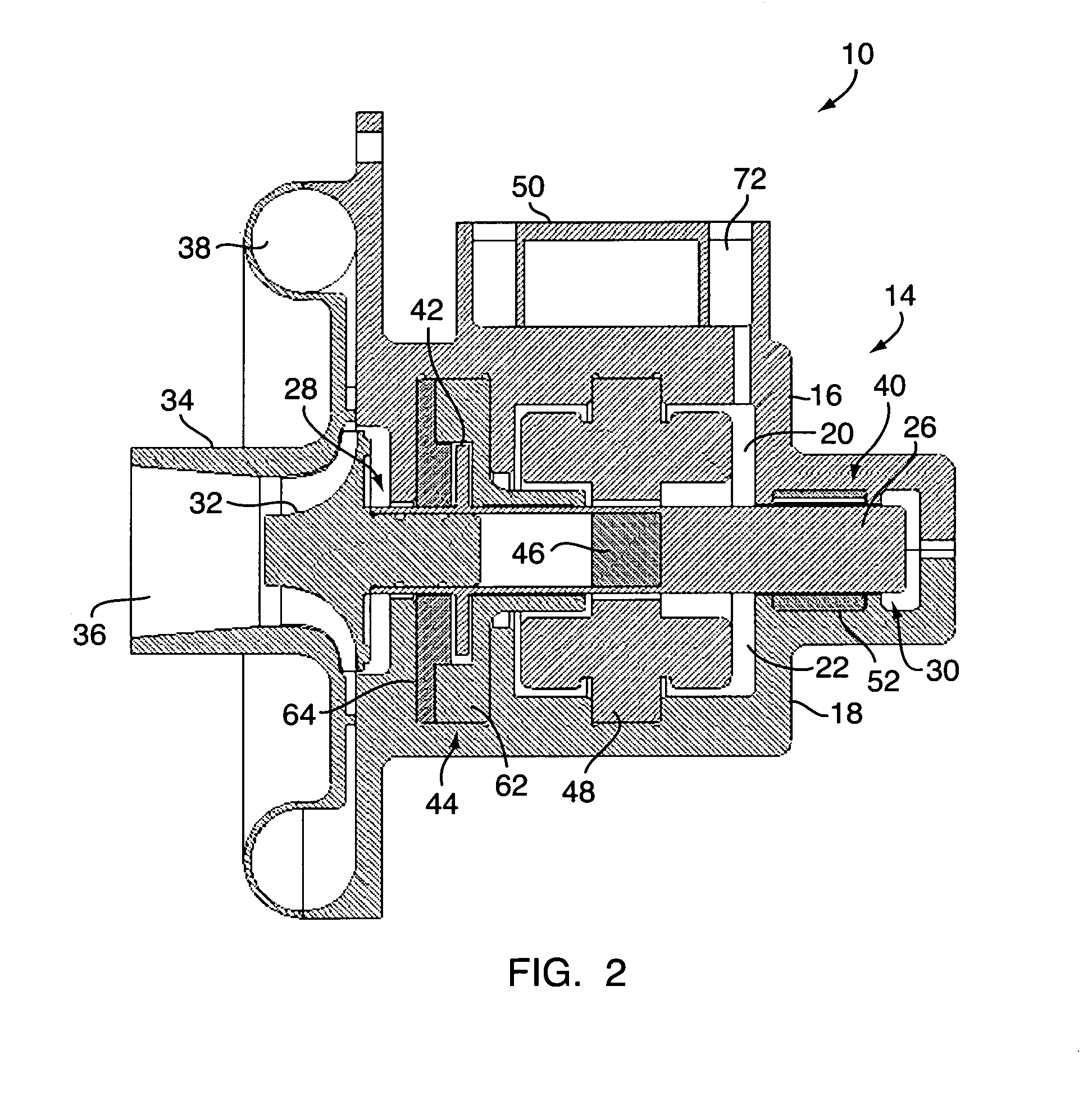

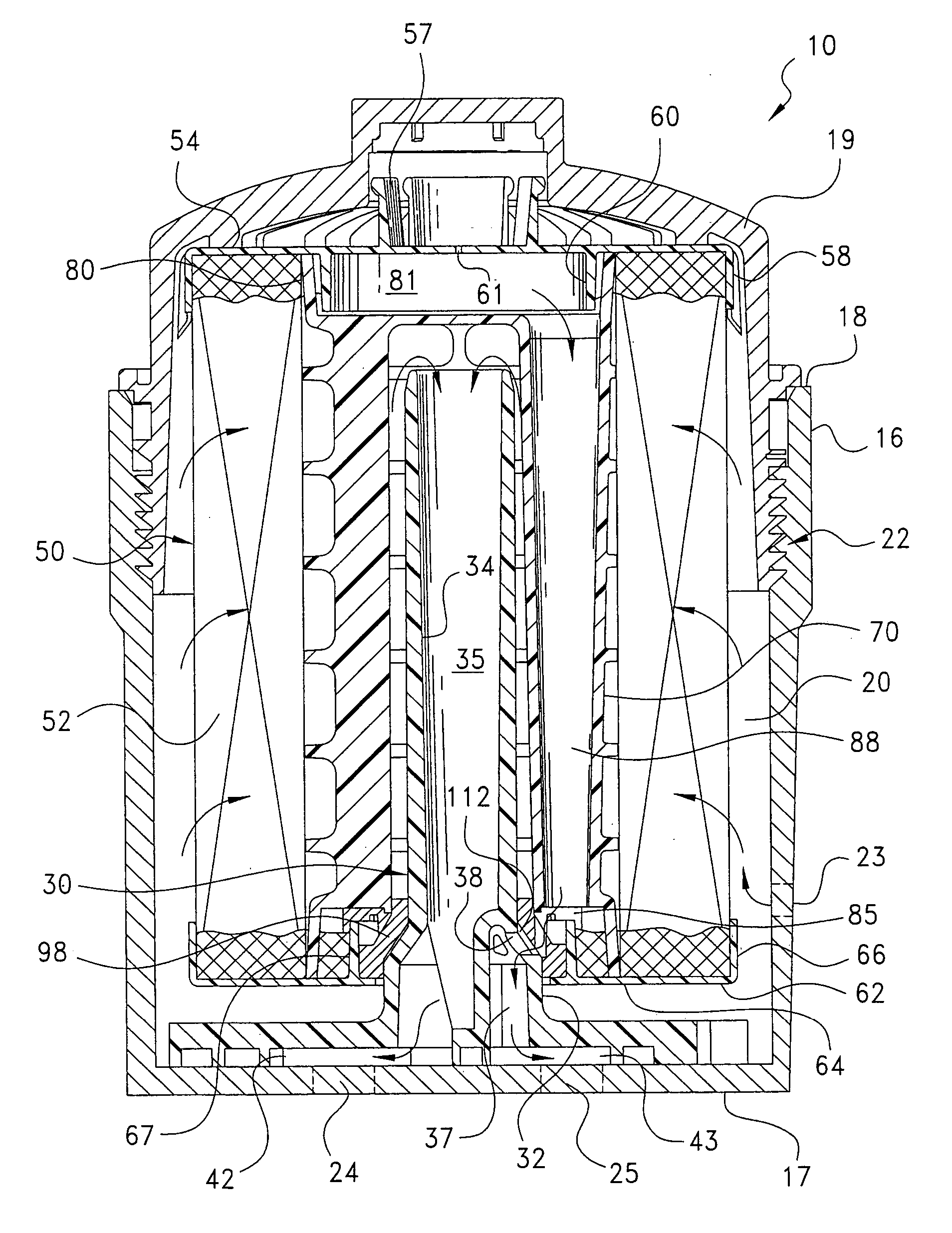

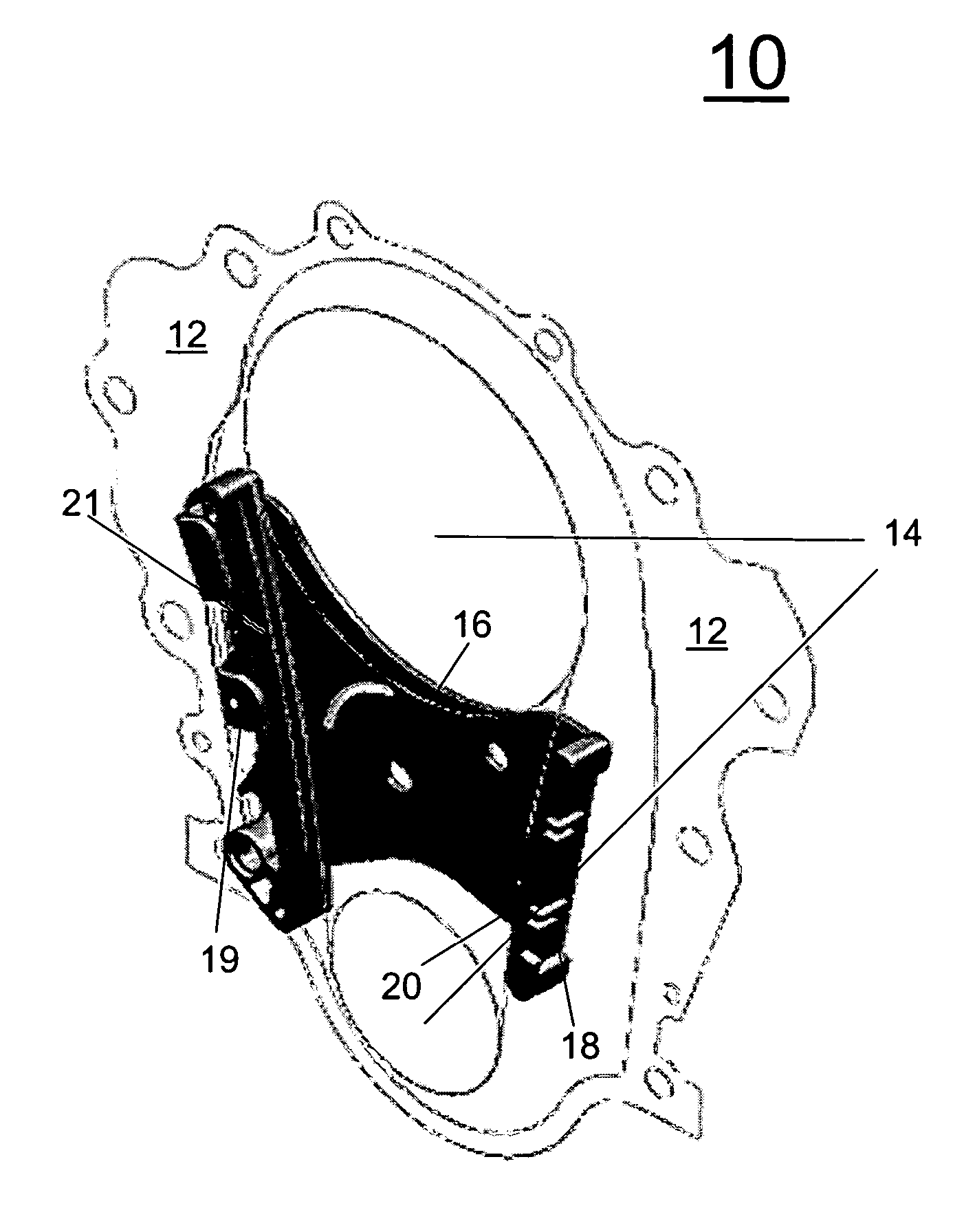

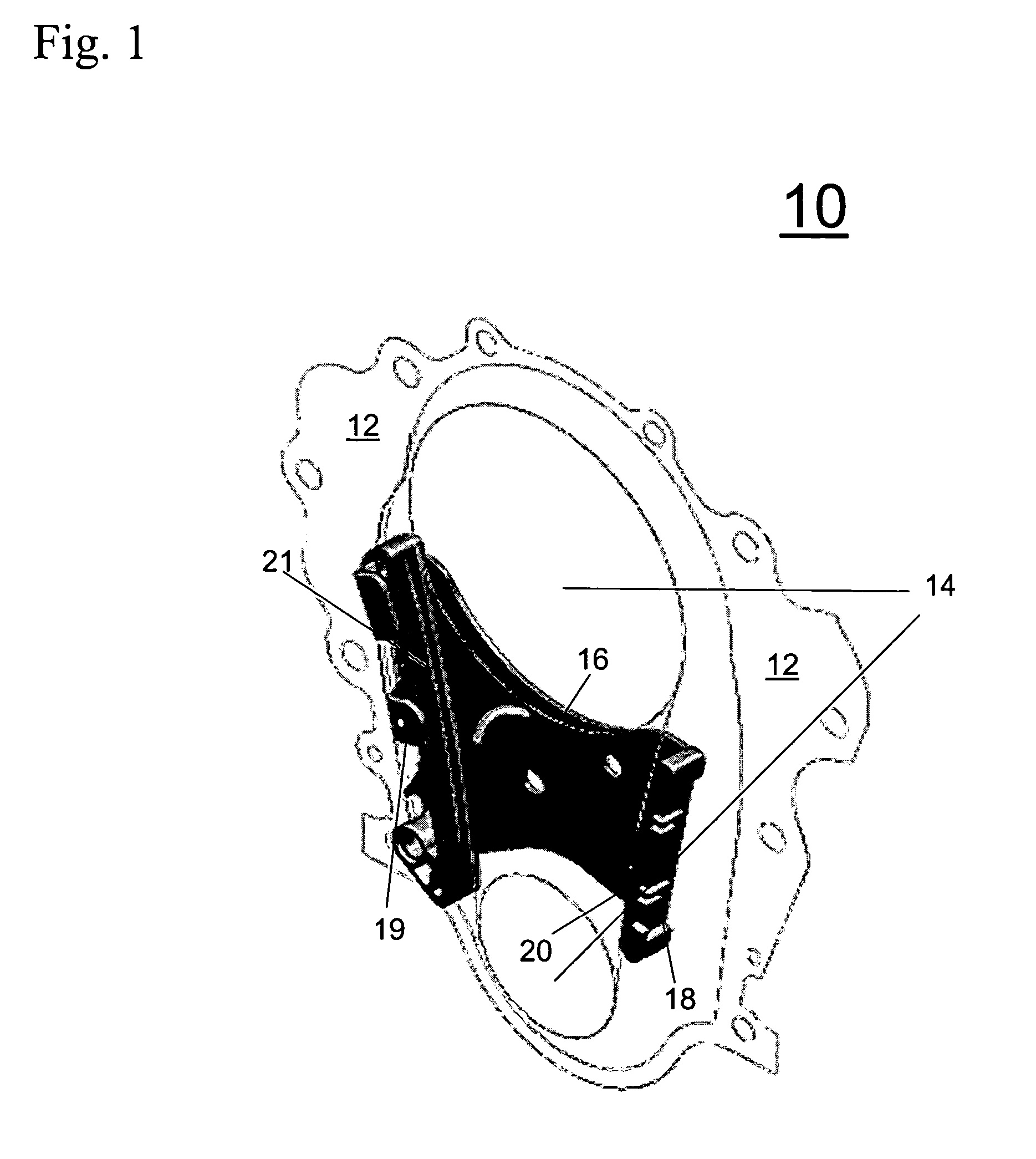

Turbomachine and method for assembly thereof using a split housing design

InactiveUS20080232962A1Easy to manufactureOptimize assembly processPump componentsBlade accessoriesImpellerEngineering

The present invention provides an improved design for turbomachinery, such as blowers and compressors, for providing pressurized process gas. The improved design comprises two housing portions that fit together to form an interior cavity in which a preassembled rotating assembly may be installed and balanced. Each housing portion includes an interior compartment designed and shaped to correspond to desired positions of components of the rotating assembly. After the preassembled rotating assembly is seated within the interior compartment of the lower housing portion and balanced, the upper housing portion can be fitted to the lower housing portion to complete the machine housing and encompass and hold the rotating assembly in place without the need to remove or disassemble the rotating assembly. A collector cover can thereafter be attached to the assembled machine housing to enclose an impeller operatively mounted on a rotating shaft of the rotating assembly.

Owner:R & D DYNAMICS

Filter assembly with vented filter element

ActiveUS20050023209A1Simple and low cost designReduce riskMembrane filtersMachines/enginesFilter mediaEngineering

A filter assembly includes a housing with a central standpipe, and cover for enclosing a filter element. The filter element includes a ring of filtration media and first and second end caps. A vent orifice is formed in the first end cap into the central cavity of the media ring. A support core is disposed centrally in the media ring and extends between the first and second end caps. The core includes a separate and independent fluid channel extending from the first end cap that is fluidly connected with the vent orifice, to the second end cap. The second end cap has a central opening, and an annular sealing device bounding the opening which receives and seals to the standpipe and includes through-passages fluidly interconnecting the fluid channel in the core with flow opening(s) along the standpipe or in the lower end of the housing to a drain port.

Owner:PARKER INTANGIBLES LLC

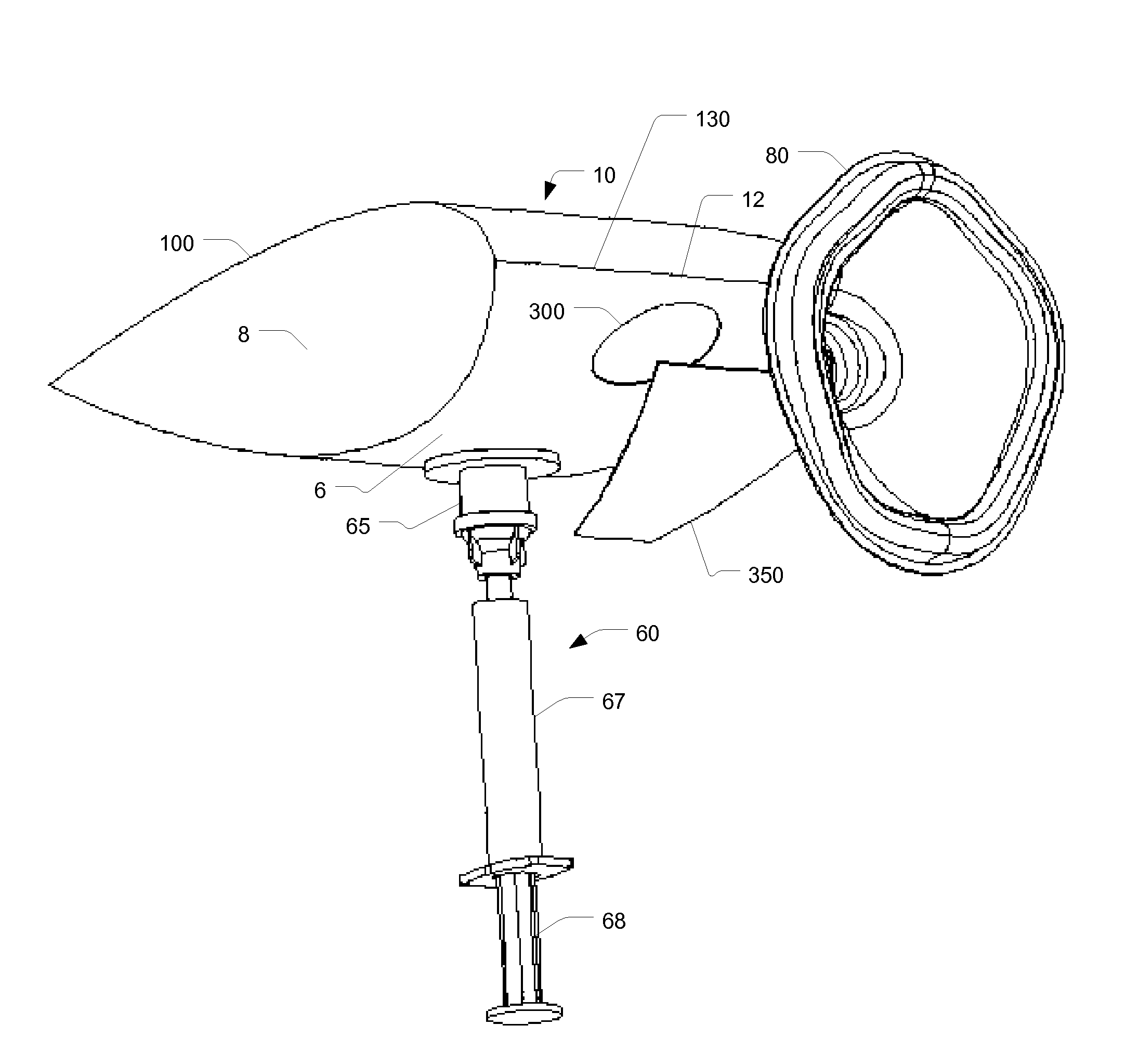

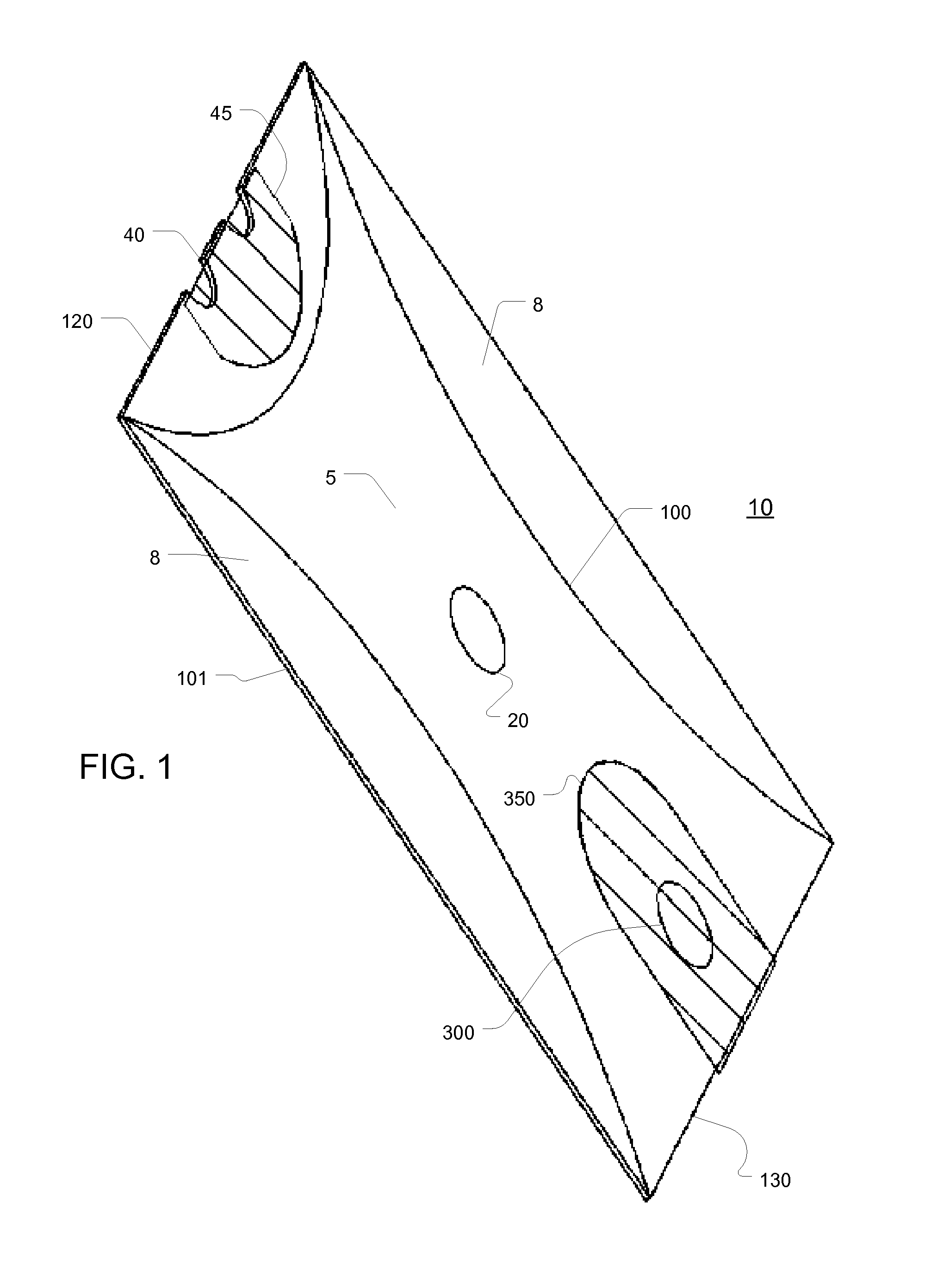

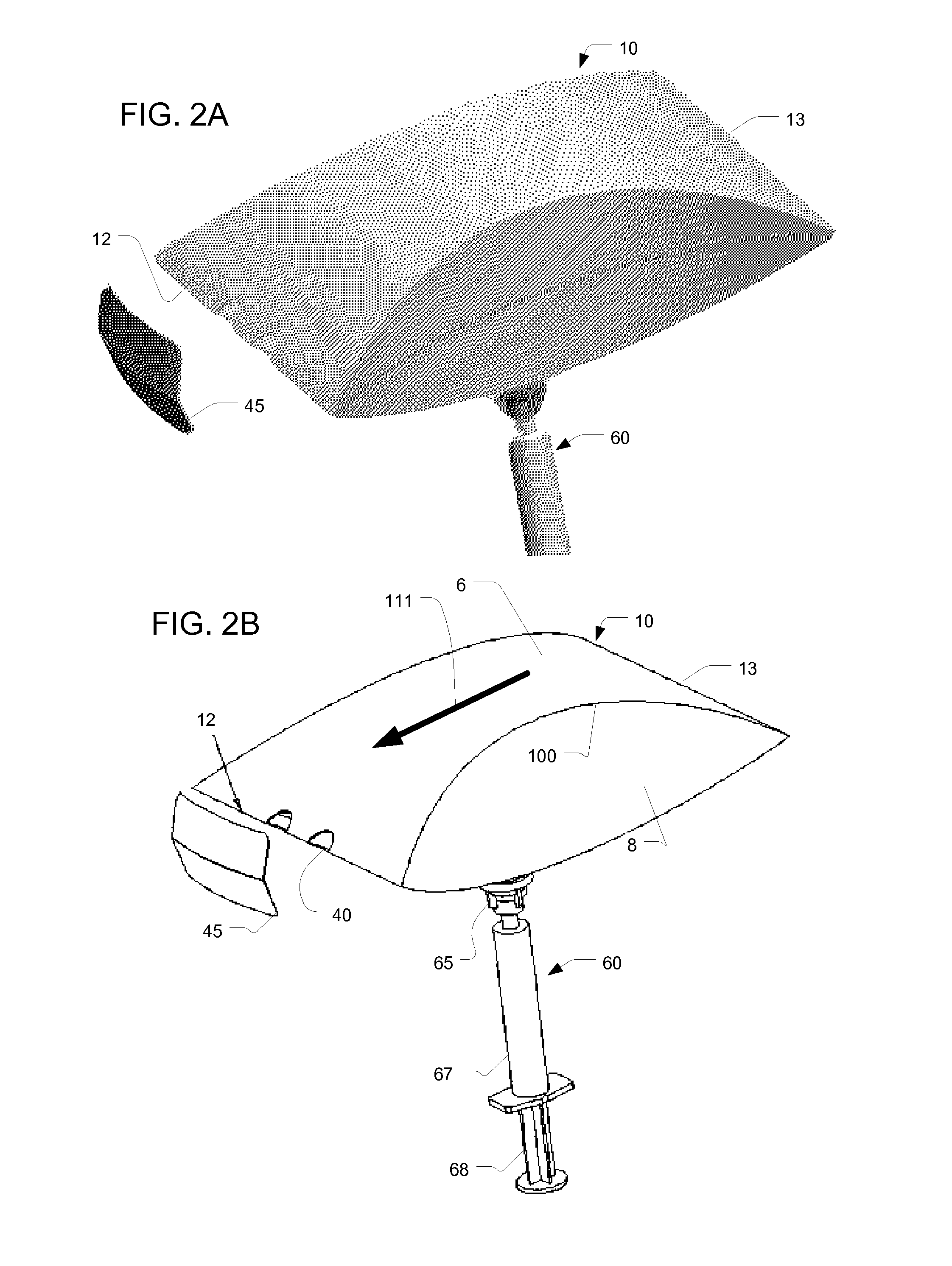

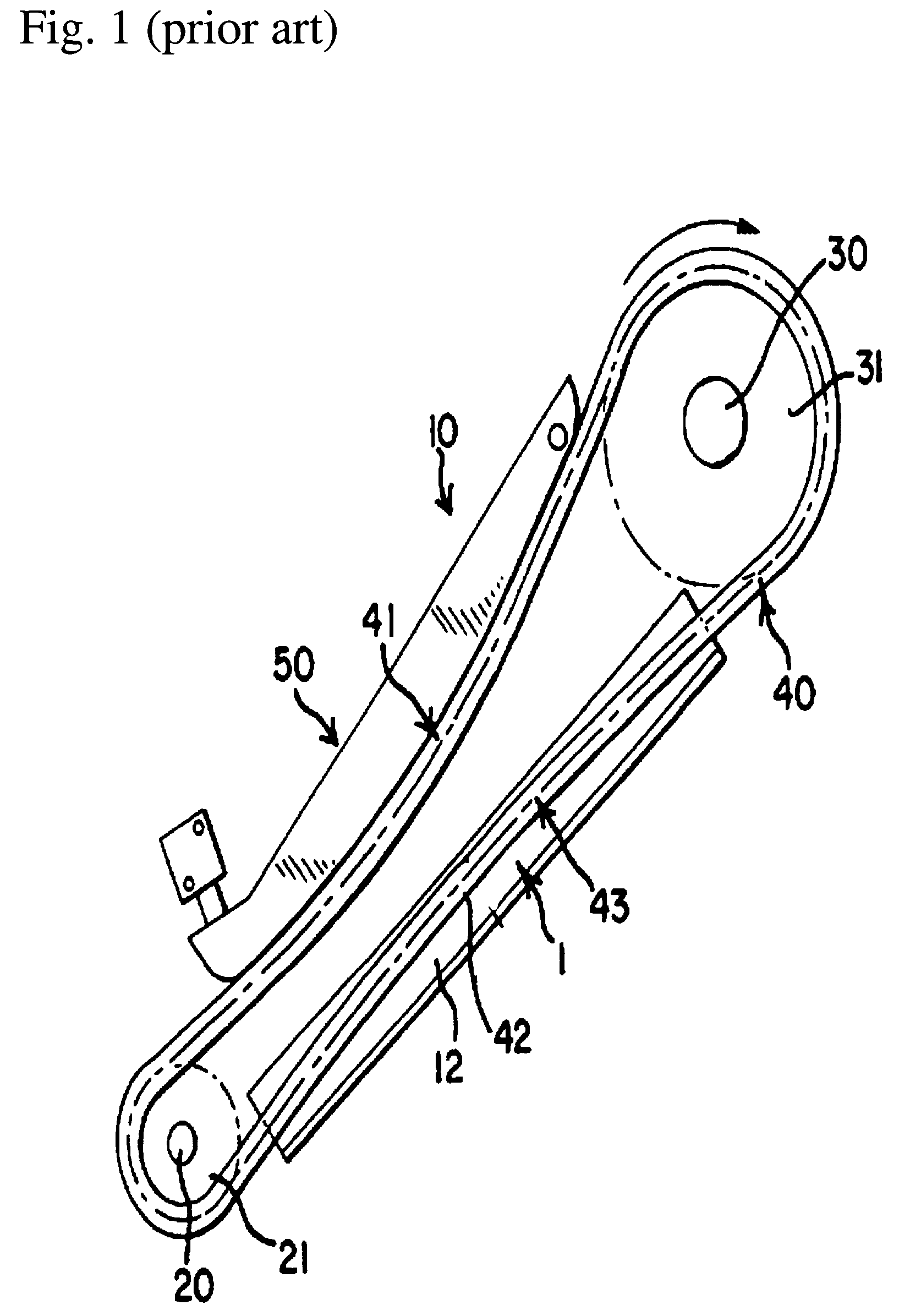

Disposable spacer for inhalation delivery of aerosolized drugs and vaccines

InactiveUS20100163045A1Improve efficiencyIncrease volumeLiquid surface applicatorsPowdered material dispensingInhalationBiomedical engineering

A device, system and method is provided for dispersing an aerosol formulation comprising a medicament. The device may be useful in administering inhaleable vaccines and the like. The device designed for low cost and applicability to a multitude of patient populations. The device has a spacer (10) is suitable for use with a wide range of aerosolized formulations, particularly powders. The spacer (10) may be an expandable volume spacer (10). The spacer (10) may also be used with other inhalation aids (80). The spacer (10) may include a multi-purpose outlet (40) for use with different groups within the target patient population.

Owner:BECTON DICKINSON & CO

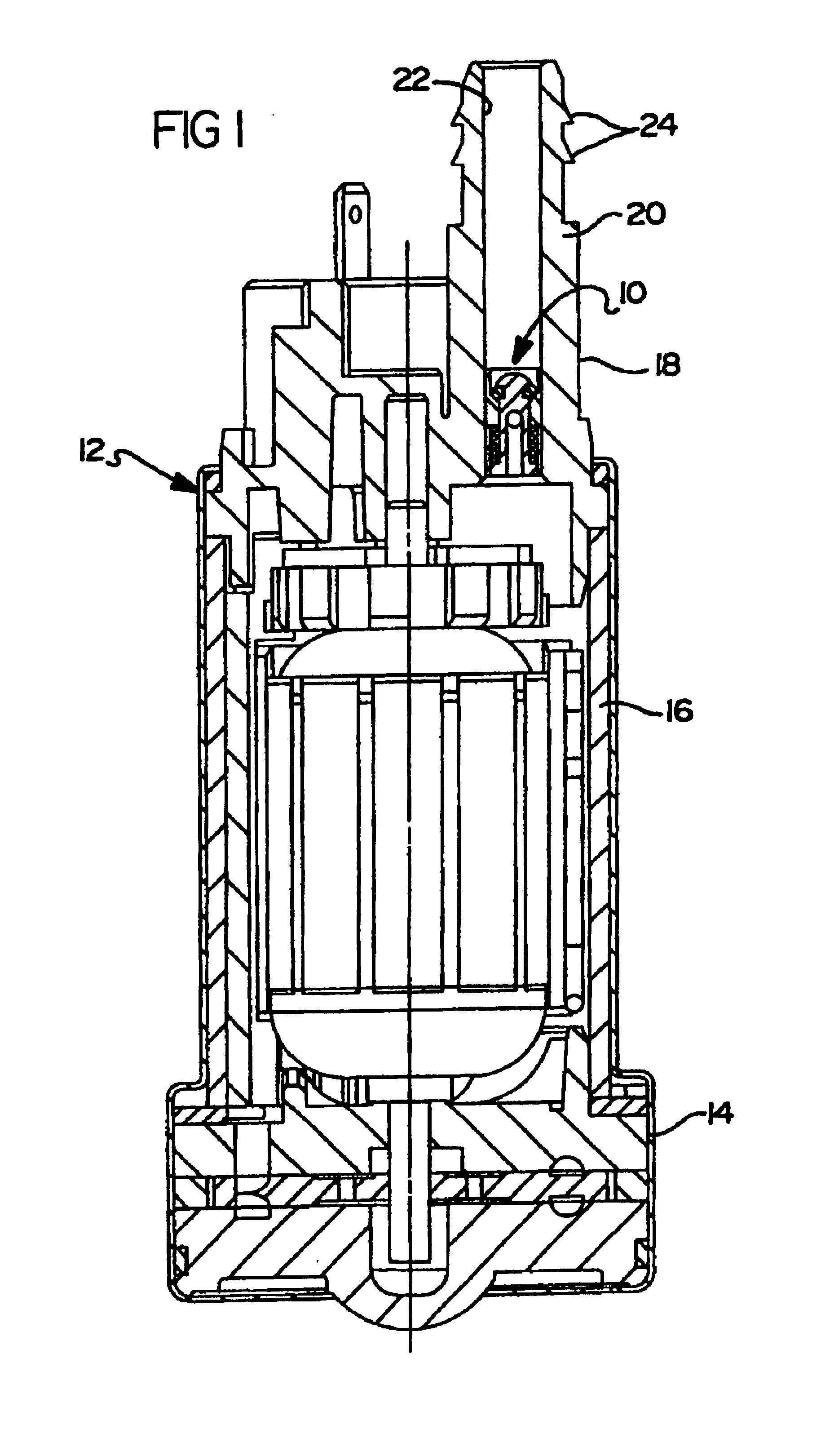

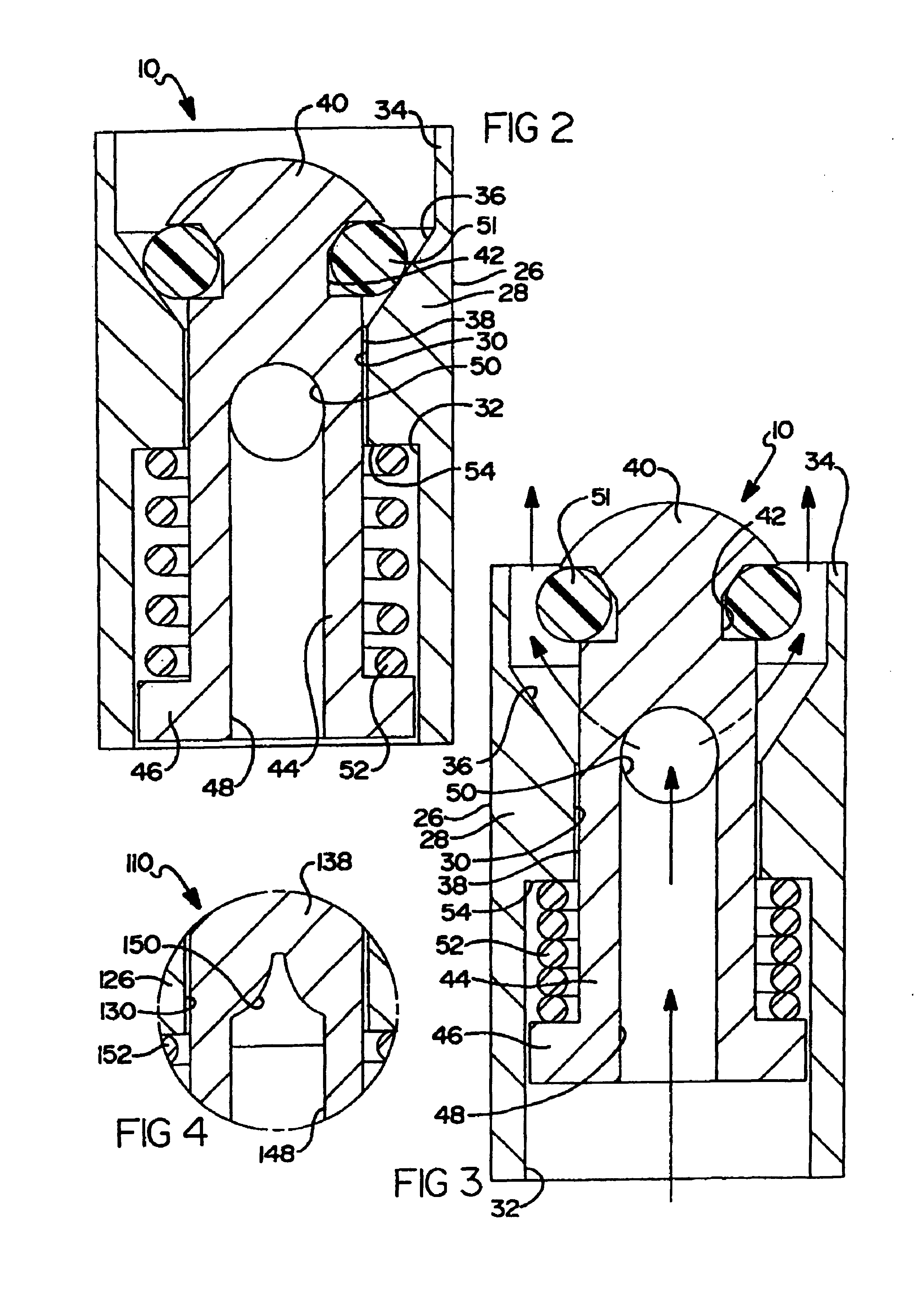

Check valve for fuel pump

InactiveUS6877525B2Low cost designIncrease the circulation areaCheck valvesEqualizing valvesEngineeringCheck valve

A check valve for a fuel pump of a vehicle includes a valve housing adapted to be disposed in an outlet member of the fuel pump and a valve seat formed on the valve housing. The check valve also includes a valve member disposed in the valve housing and having a closed position to engage the valve seat to prevent fuel from flowing through the outlet member and an open position to allow fuel to flow through the outlet member. The valve member has at least one outlet port a predetermined dwell distance from the valve seat when the valve member is in the closed position and allows fluid flow past the valve seat when the valve member is in the open position.

Owner:DELPHI TECH IP LTD

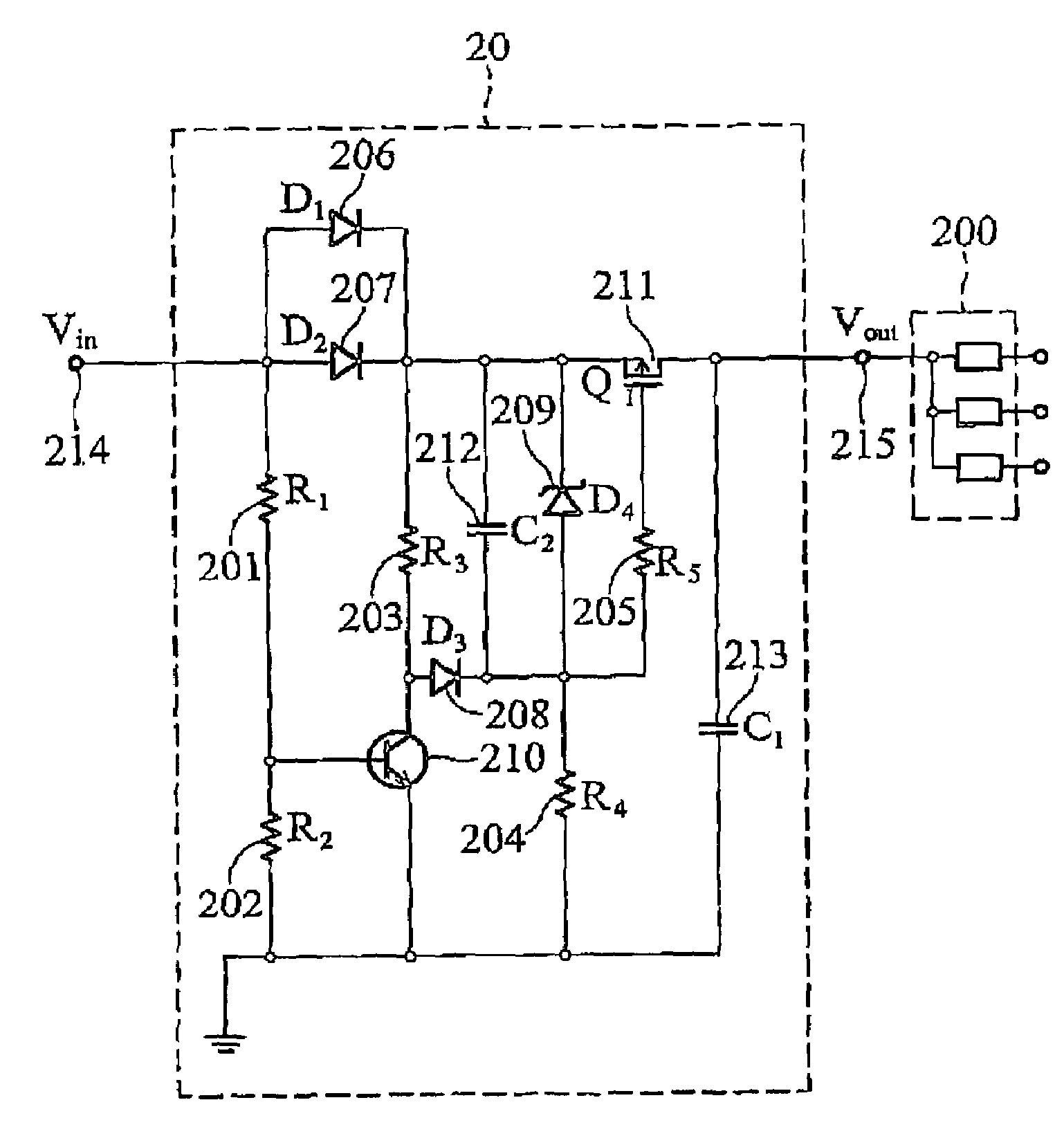

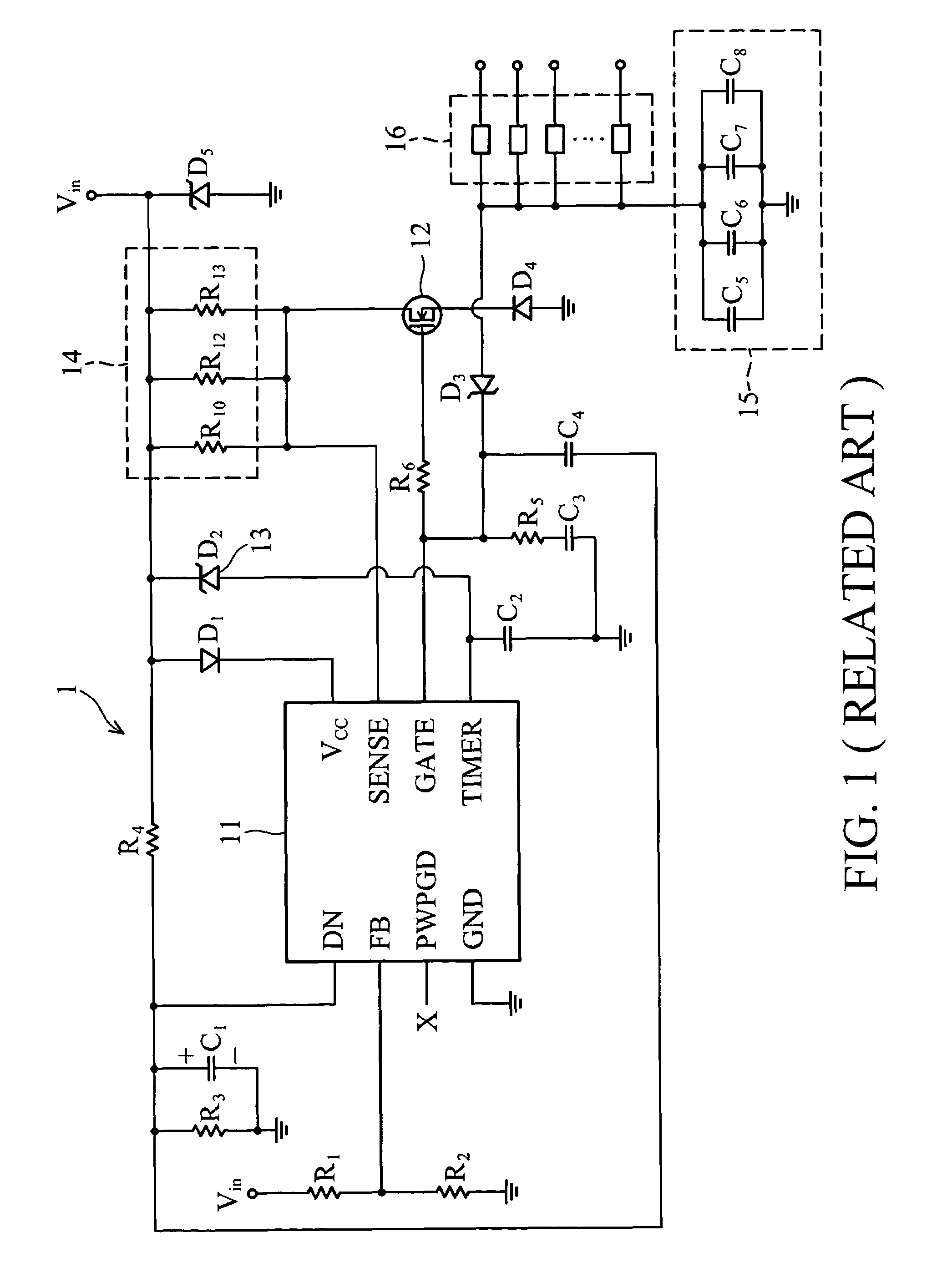

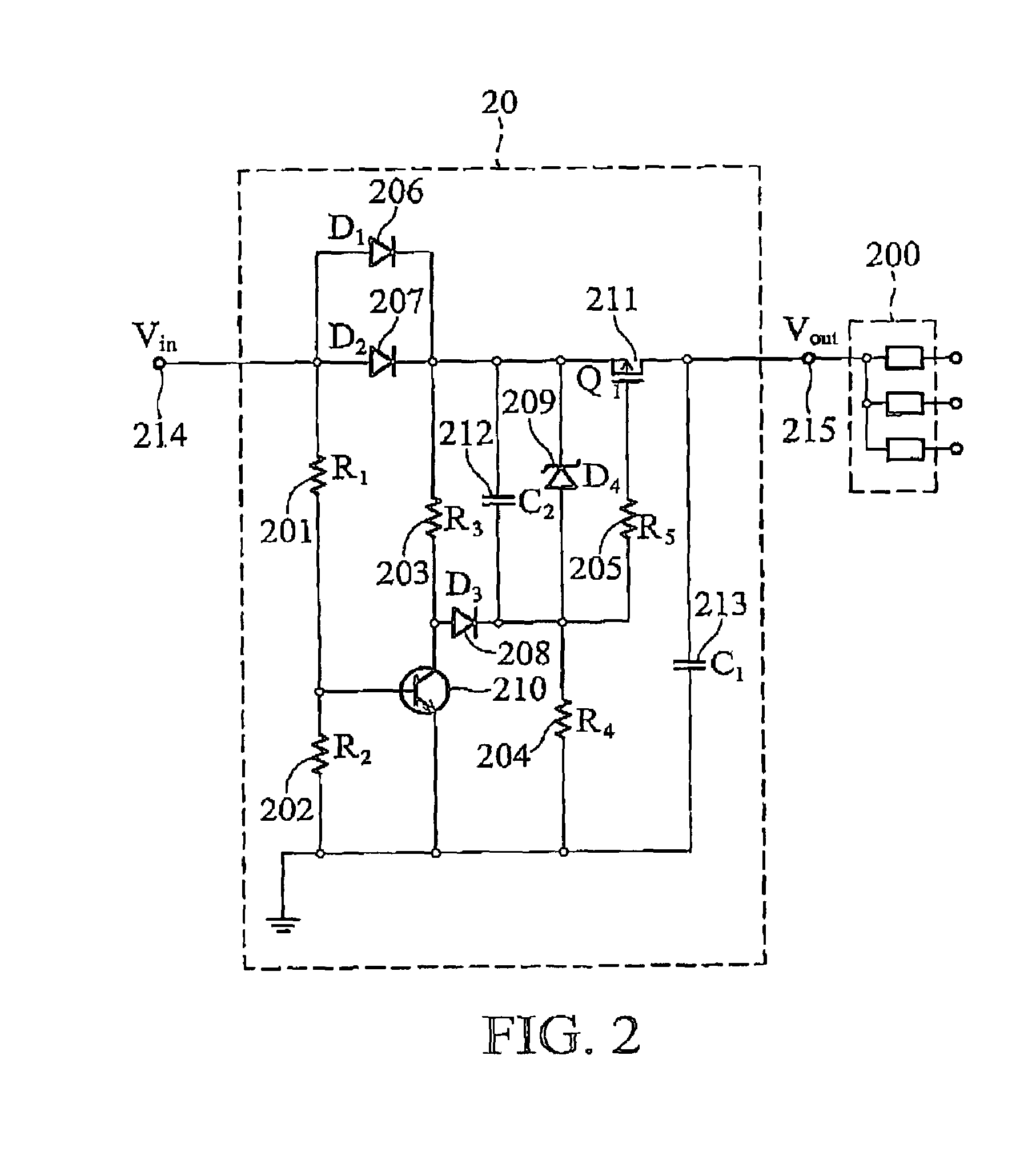

Hot-swap circuit system for fan tray module

ActiveUS7324316B2Reduce manufacturing costLarge currentDc network circuit arrangementsDC motor speed/torque controlComputer moduleEngineering

A hot-swap circuit system for fan tray module includes a soft-start circuit module in charge of the power start of the fan tray module hot-plugged into an application system. The soft-start circuit module includes a capacitor and a field effect transistor. The capacitor discharges and the field effect transistor turns off when an input voltage is changed from a certain value to zero.

Owner:DELTA ELECTRONICS INC

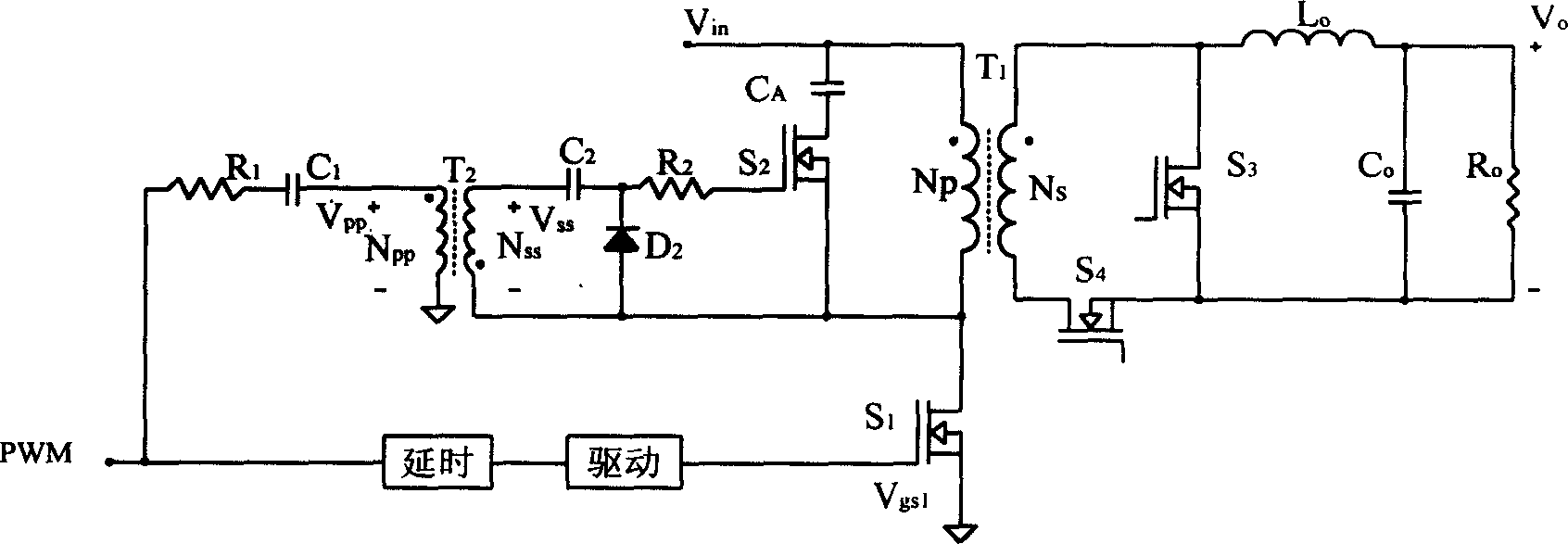

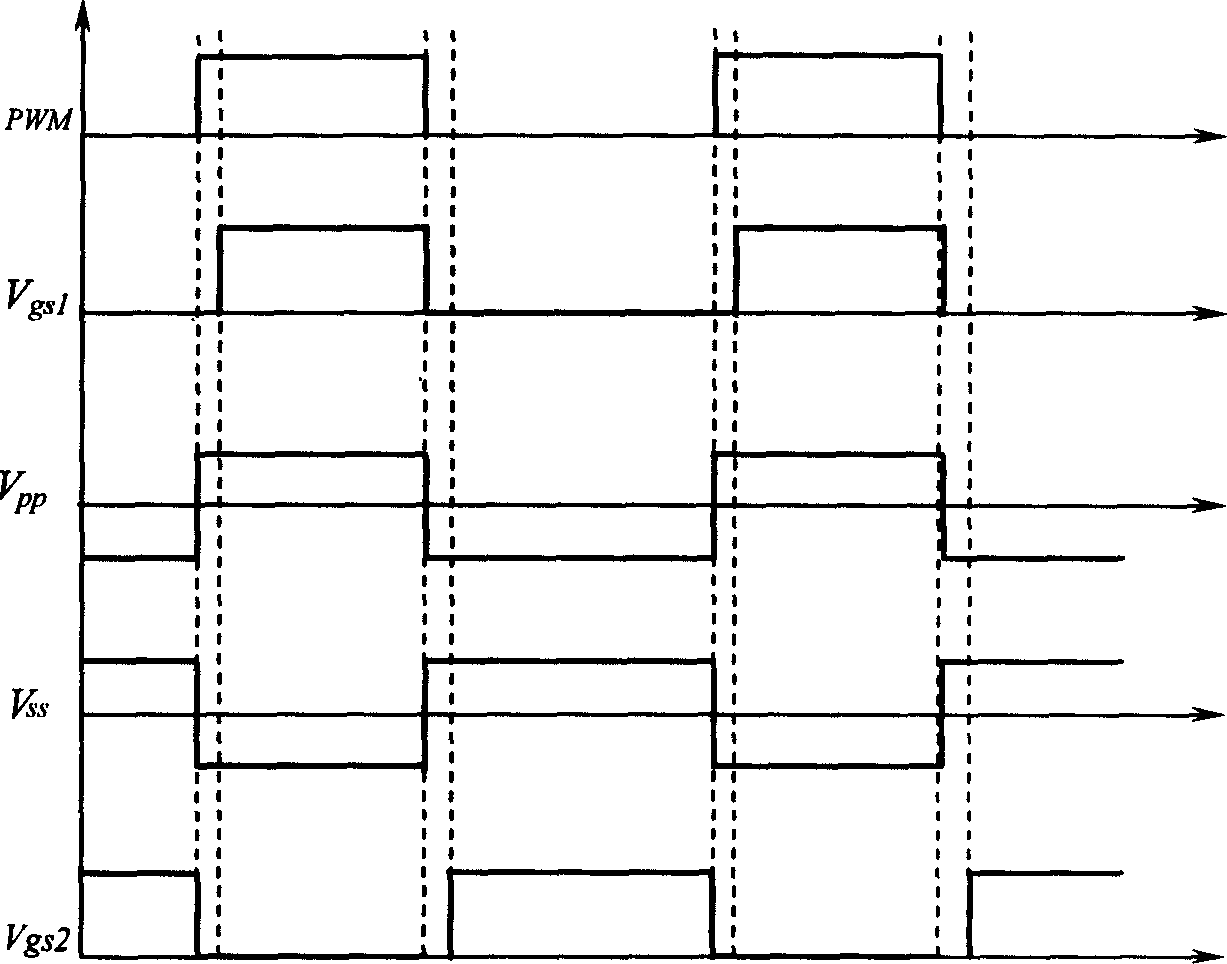

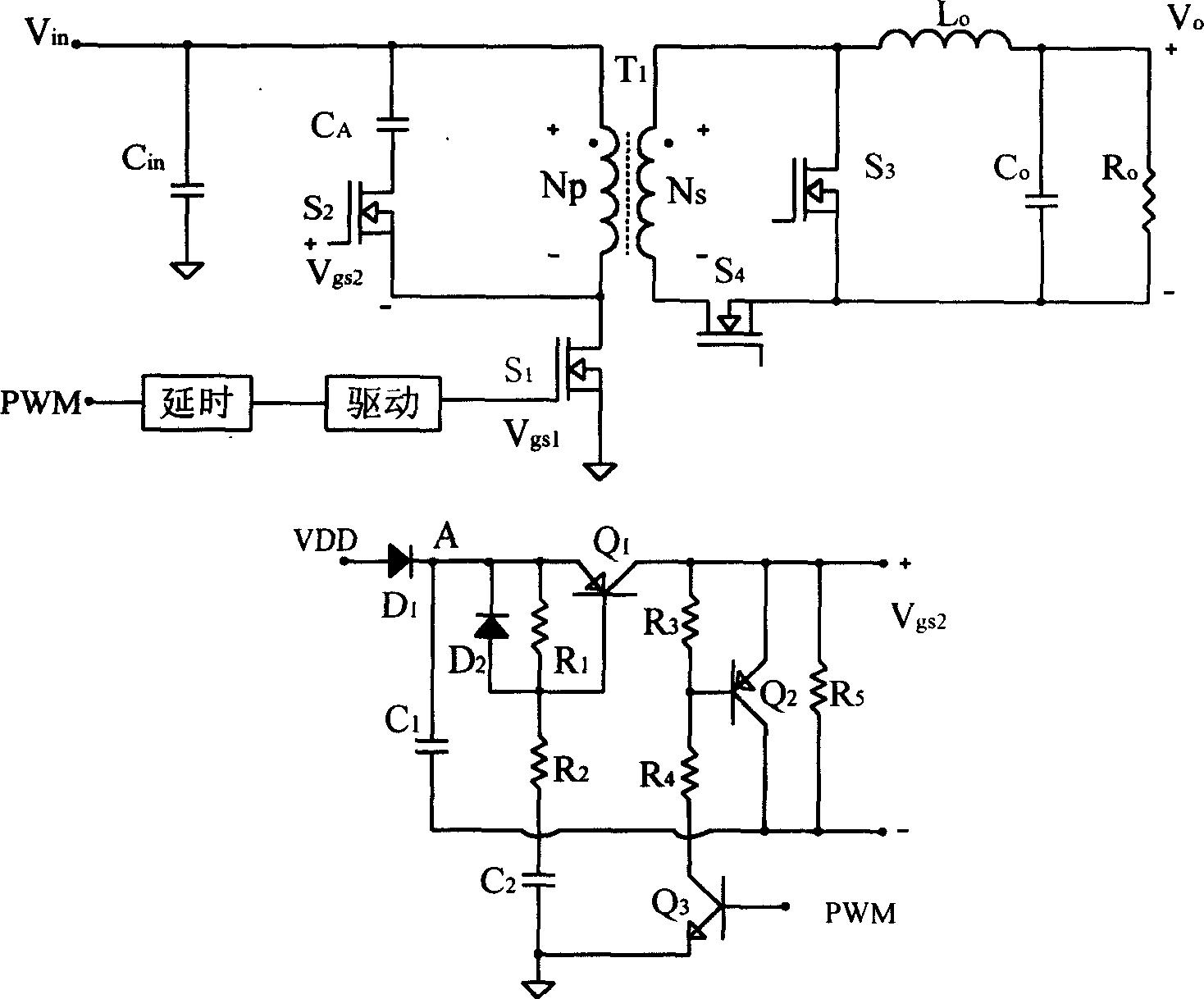

Self-drive circuit for switch power supply

InactiveCN1722593AAvoid commonImprove power densityDc-dc conversionElectric variable regulationCapacitanceTime delays

This invention relates to an automatic drive circuit for power switch, whose changer circuit comprises main horsepower MOSFET, synchronous rectifying tube, and the said automatic drive circuit comprises a time-delay drive circuit with its two ends separately attached to PWM signal and main power tube, a cut-out circuit including a PNP transistor, a NPN transistor and two electric resistance, a drive sustaining circuit including two diodes, three electric resistances, two capacitors and a PNP transistor. The invention makes the high power density and low cost design easier in the case of low power application.

Owner:YIBO POWER SUPPLY CO LTD HANGZHOU

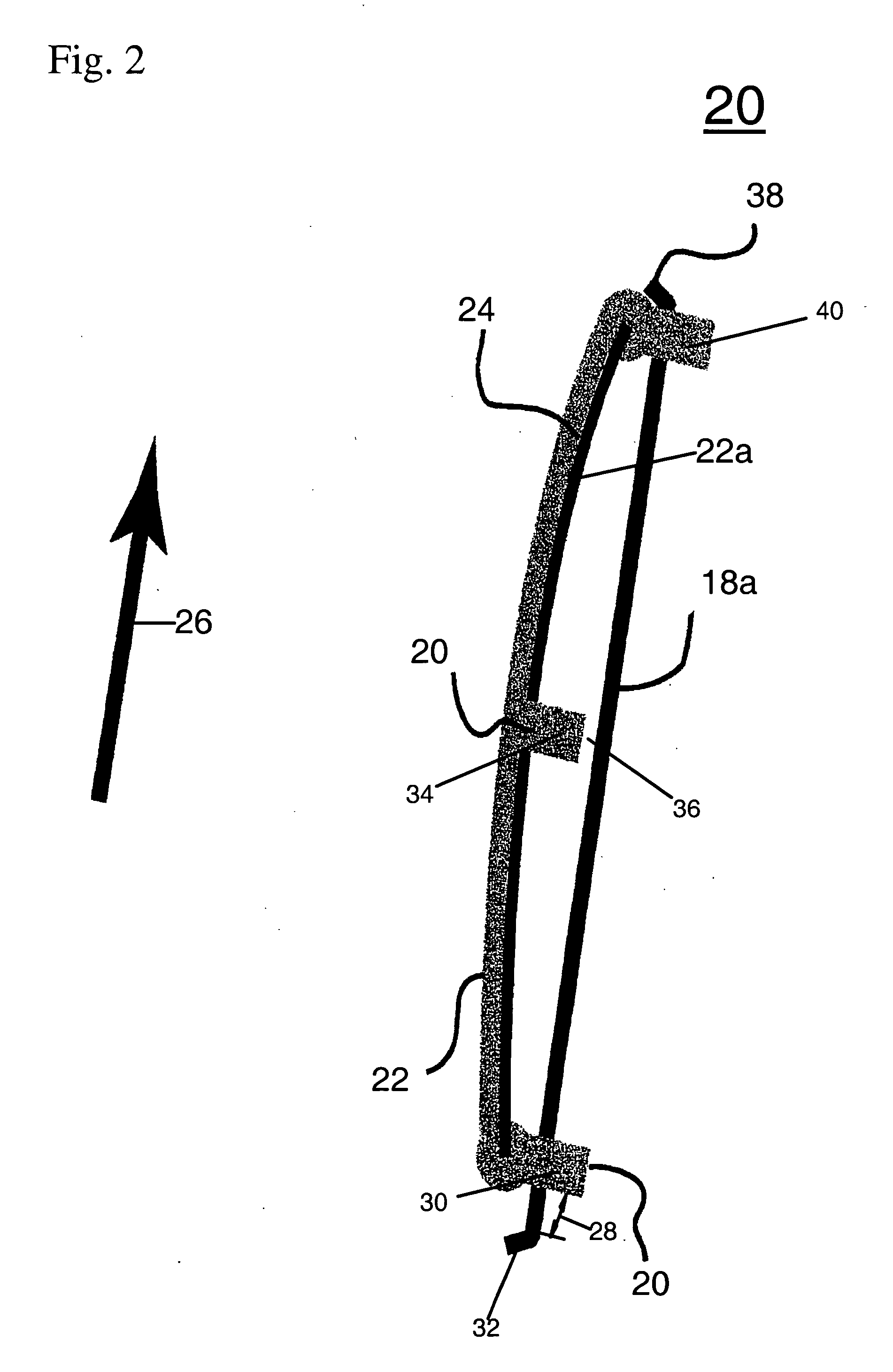

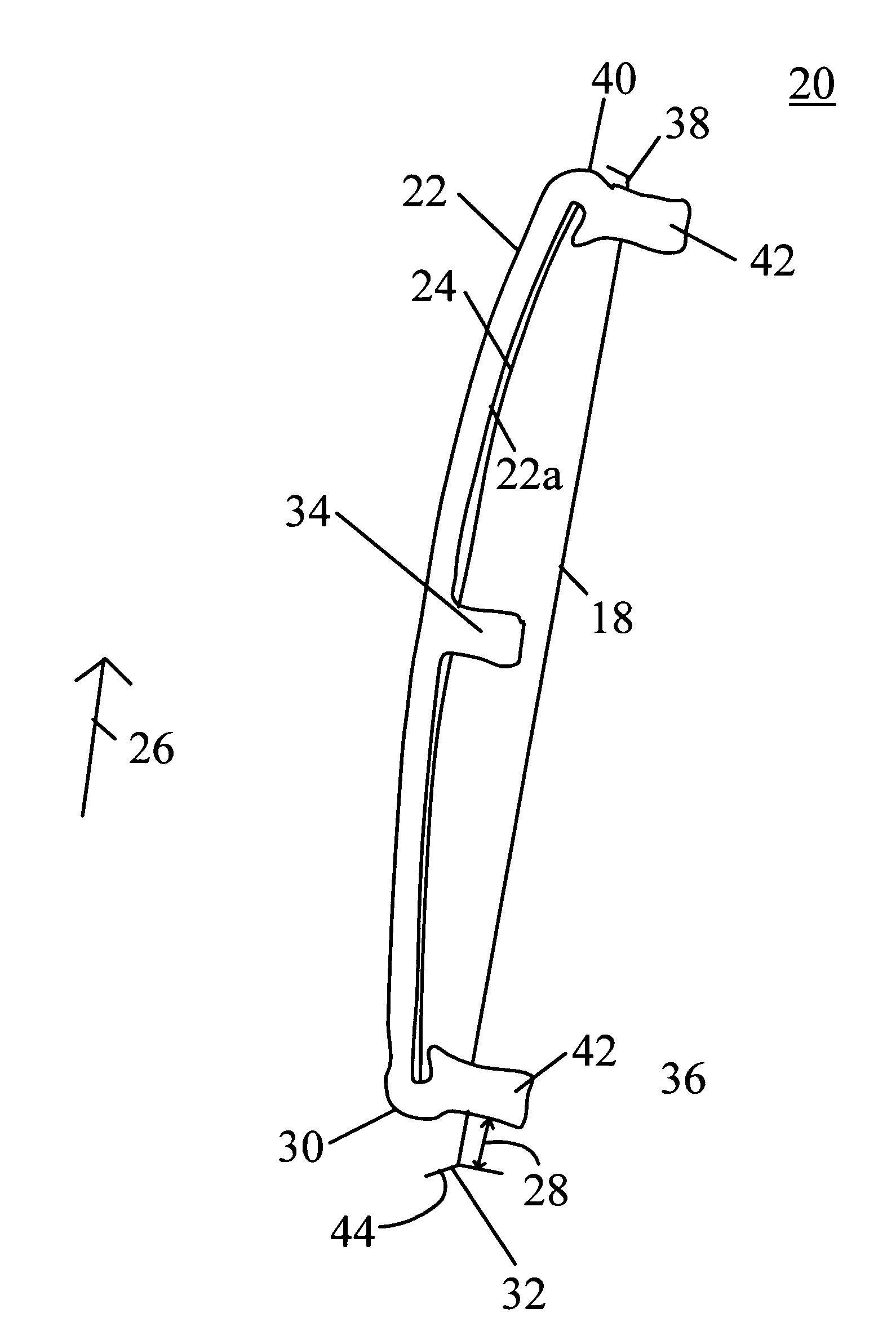

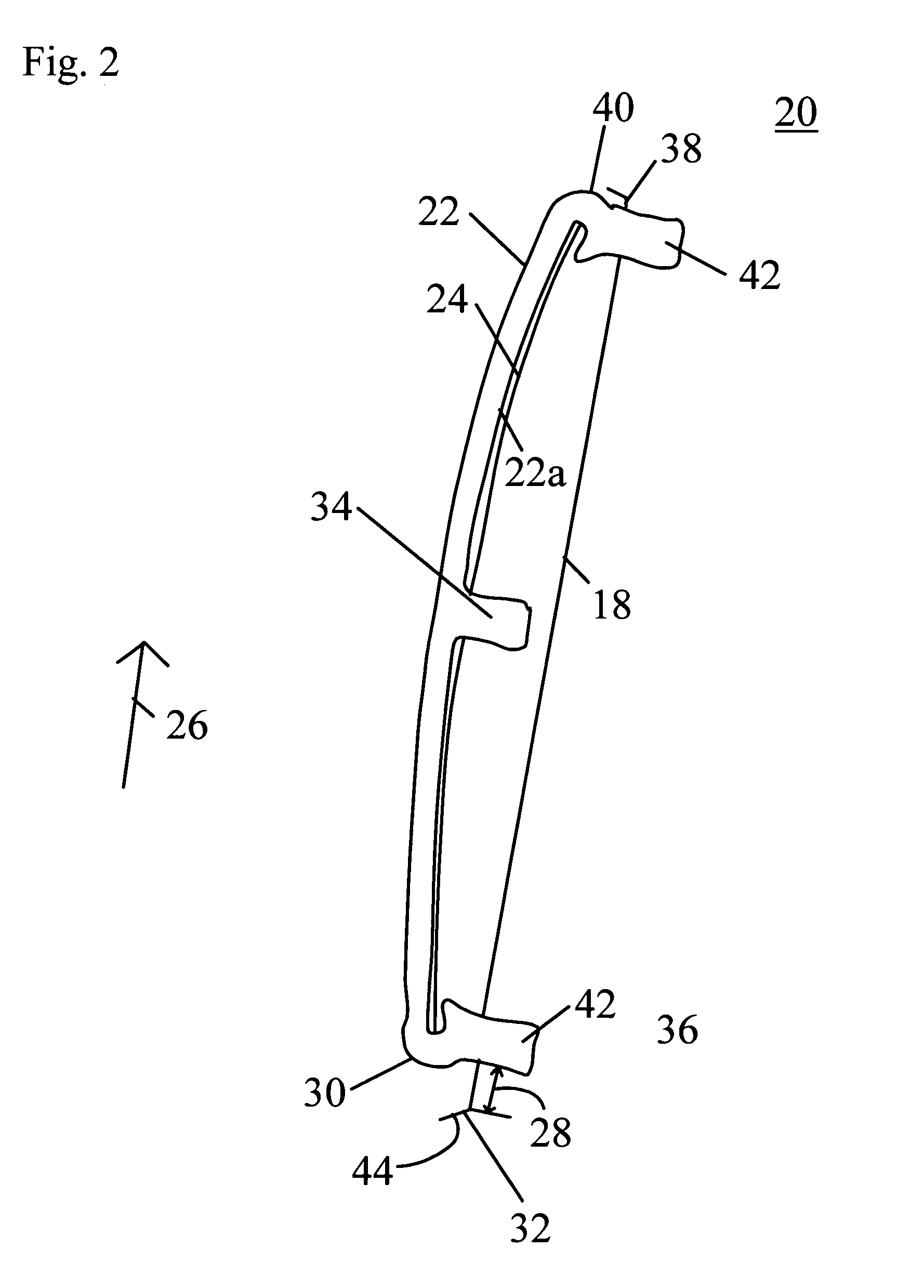

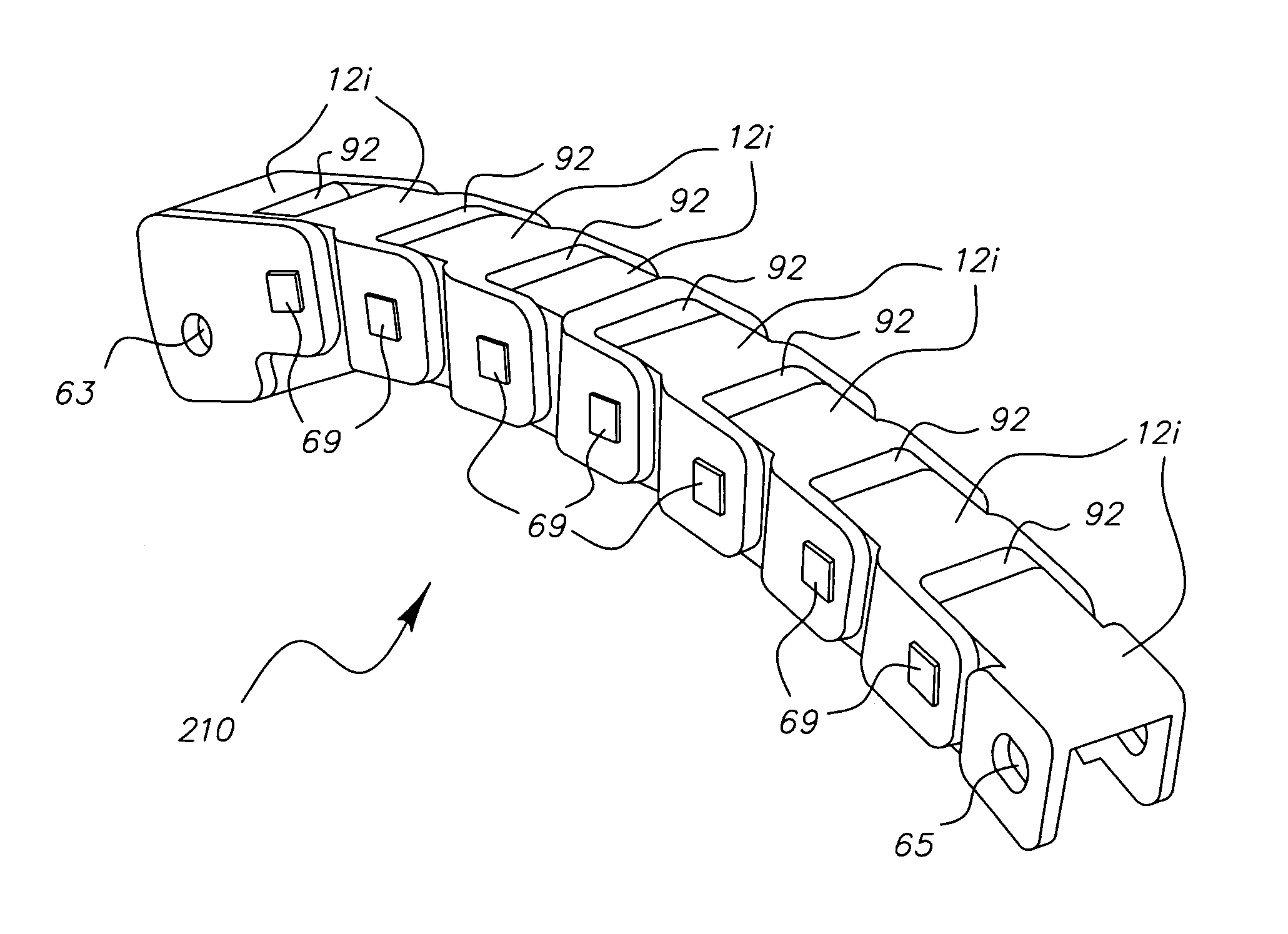

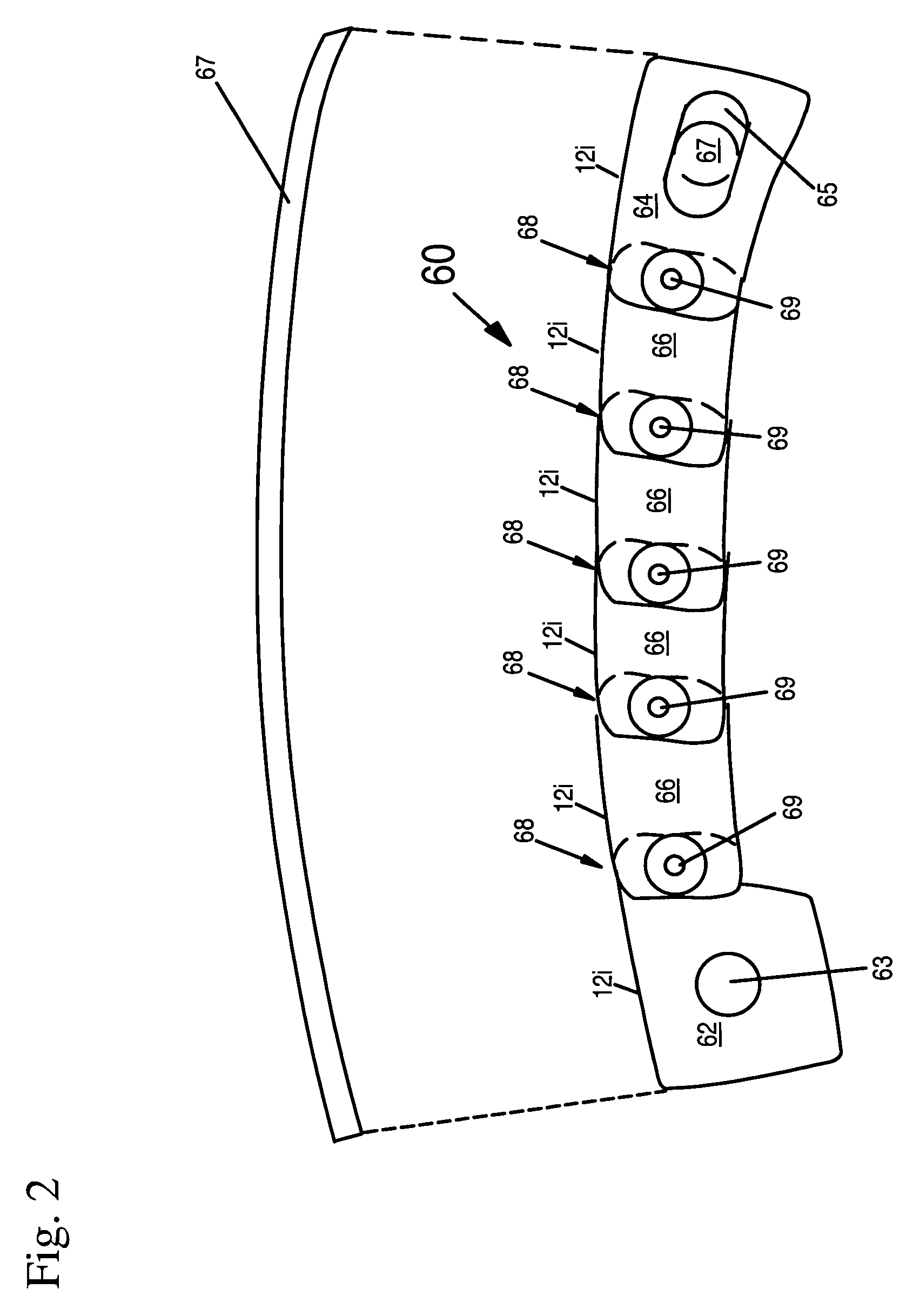

Compliant chain guide with blade spring

ActiveUS20050090345A1Improved drive behaviorLow cost designGearingMachines/enginesEngineeringMechanical engineering

Owner:BORGWARNER INC

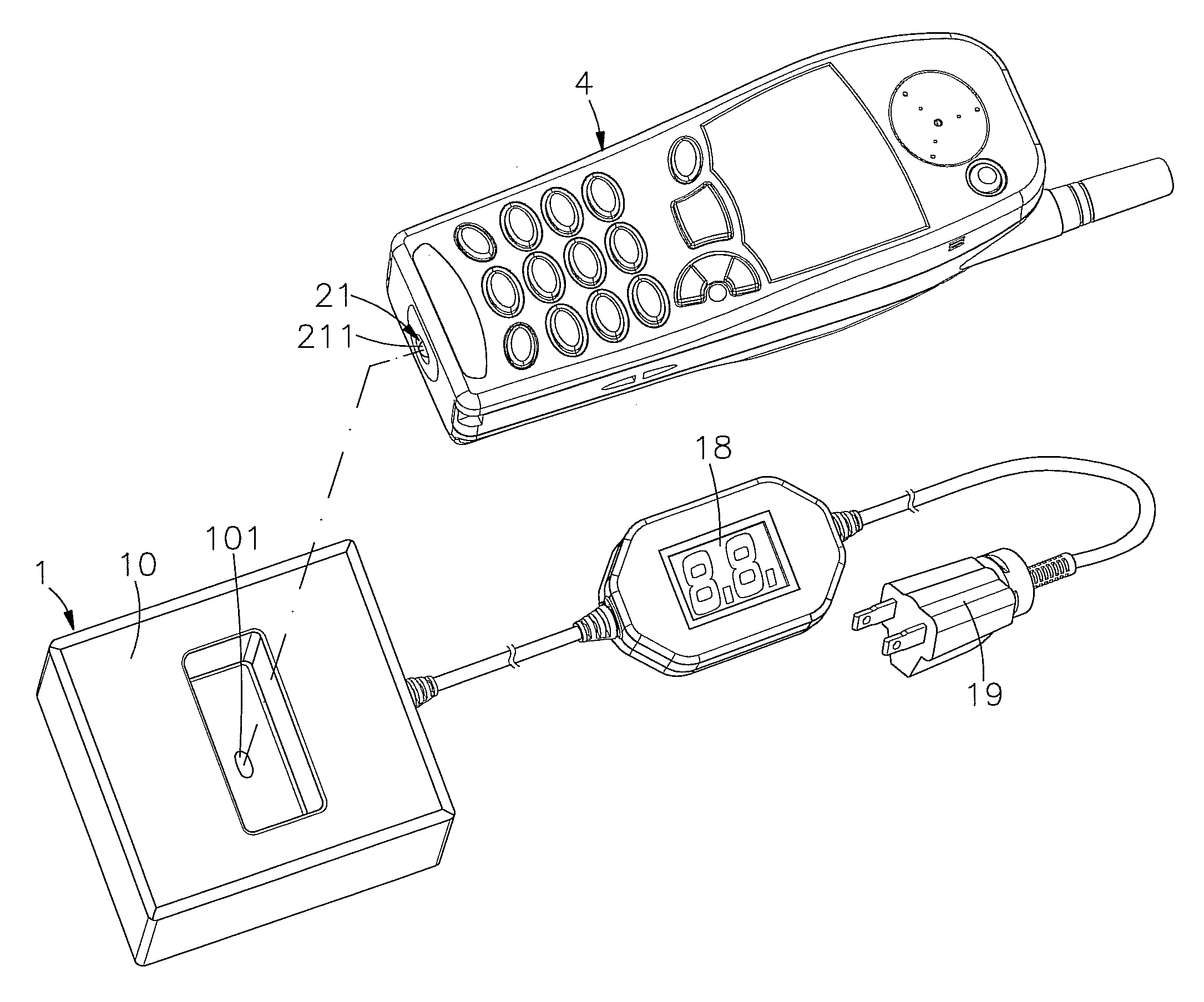

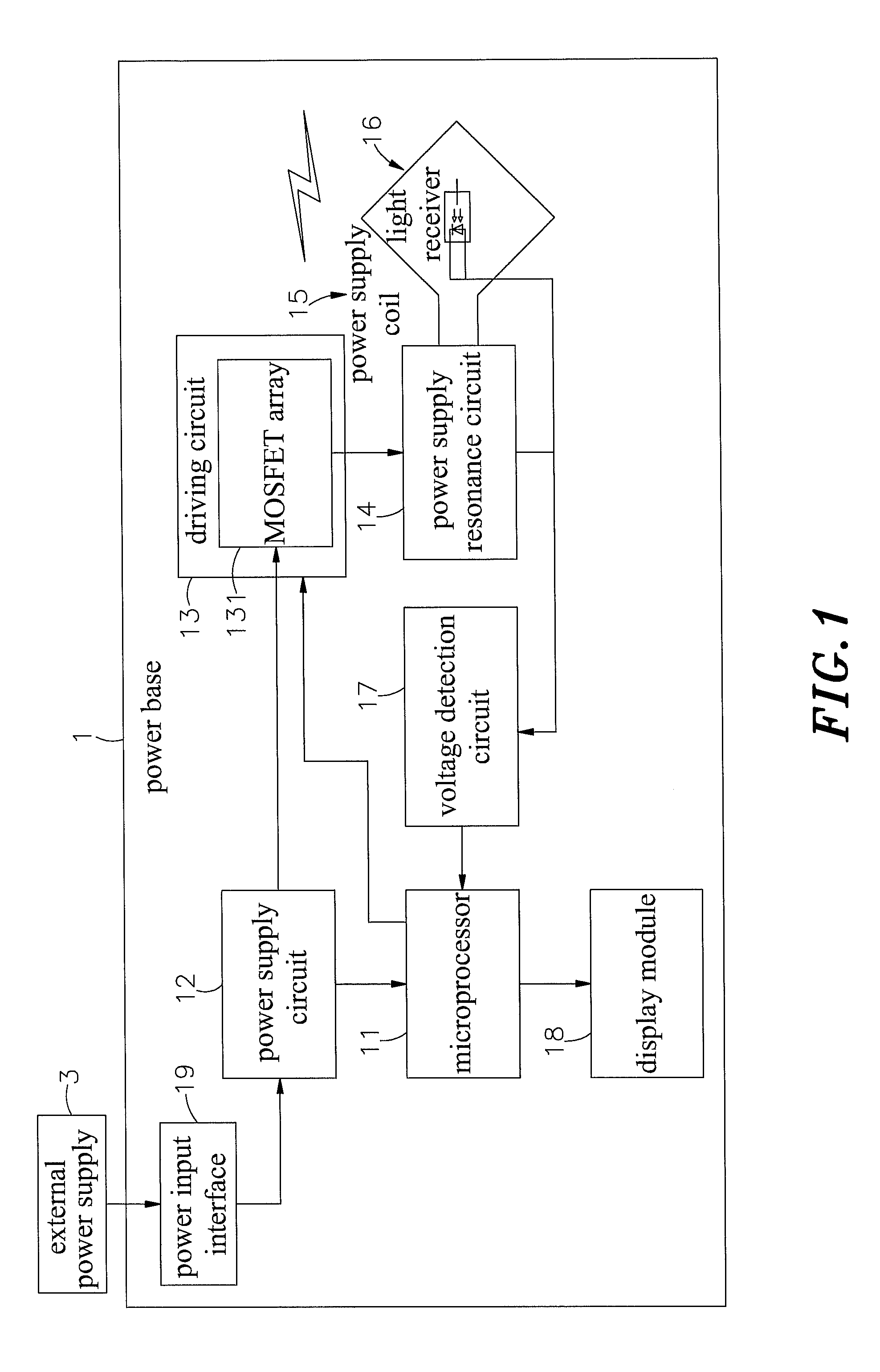

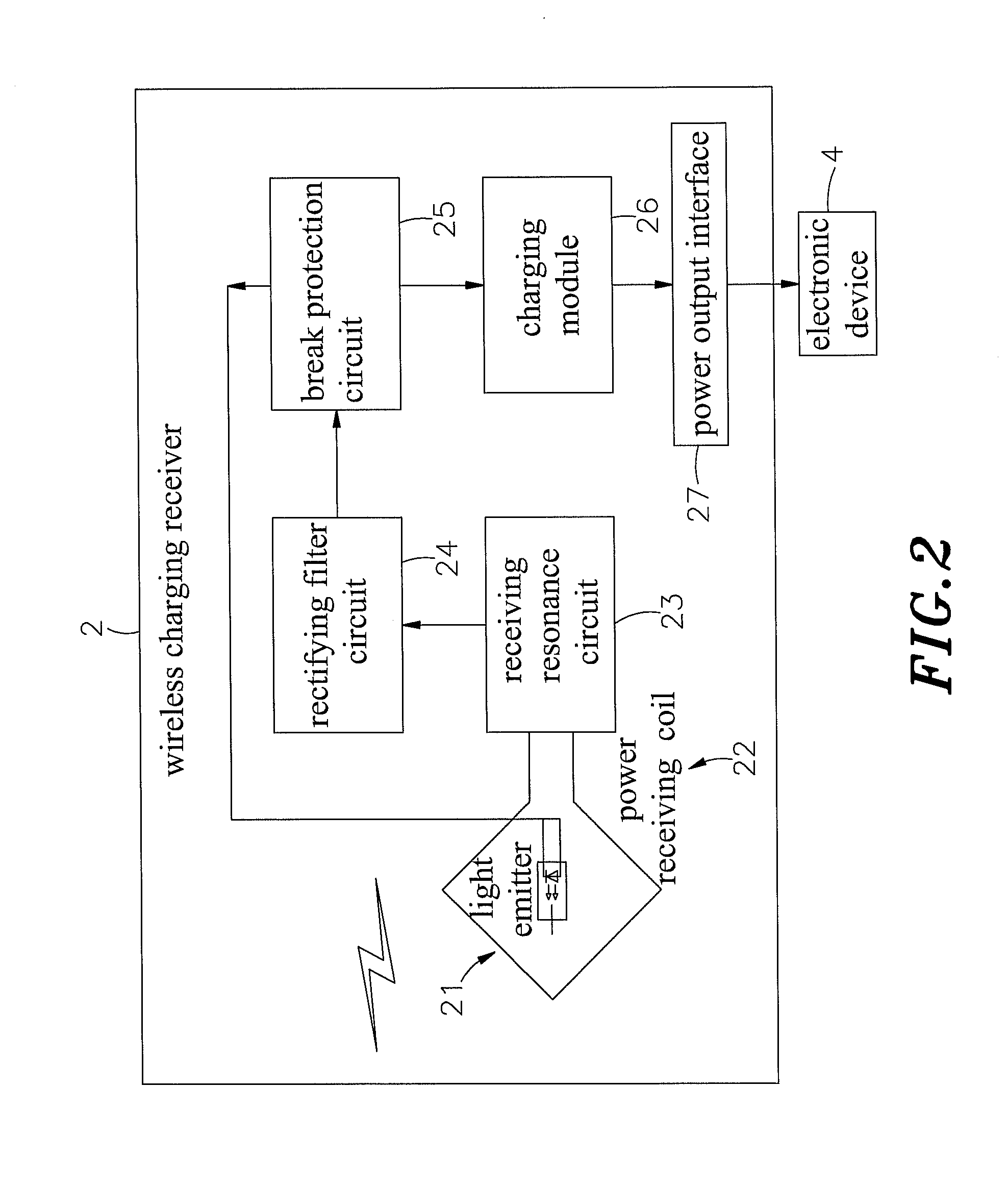

Method for identification of a light inductive charger

ActiveUS8729852B2Reduce usageSimplify overall circuit layoutCircuit monitoring/indicationTransformersLight signalInductive charging

The present invention relates to a method for identification of a light inductive charger, in which a power base includes a light receiving hole to expose a light receiver, and a light emitting component is established in a light emitter of a wireless charging receiver to emit lights towards the light receiving hole. The power base transmits electromagnetic wave energy to the receiving terminal for a short period of time when finding it covered by an object, in a dark place or covered by the wireless charging receiver after having received lights from the light receiver and transmitted the signals to the microprocessor via a voltage detection circuit. The charging module of the wireless charging receiver, if not fully charged, feeds back light signals for the same time period to indicate that charging is required. Then charging energy of electromagnetic waves will be emitted to start charging.

Owner:FU TONG TECH

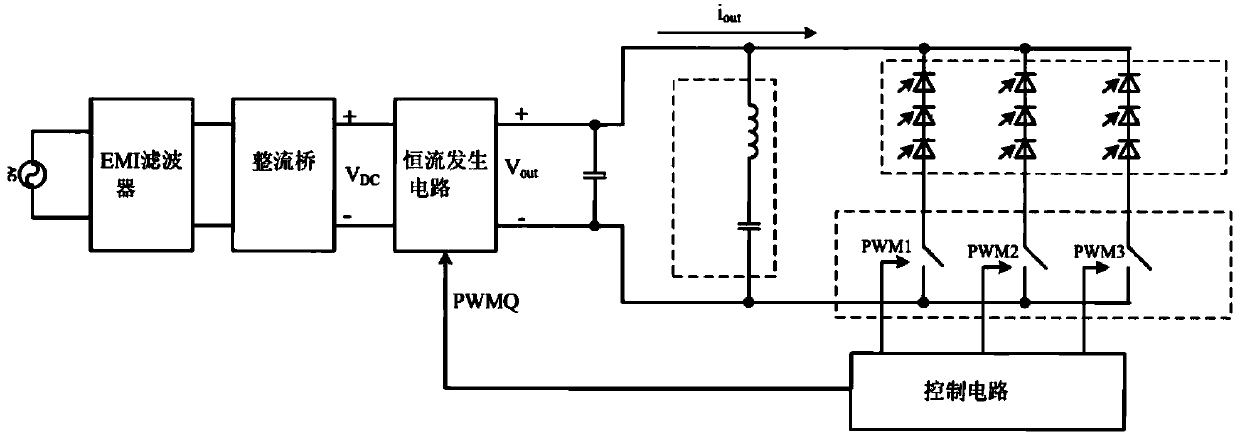

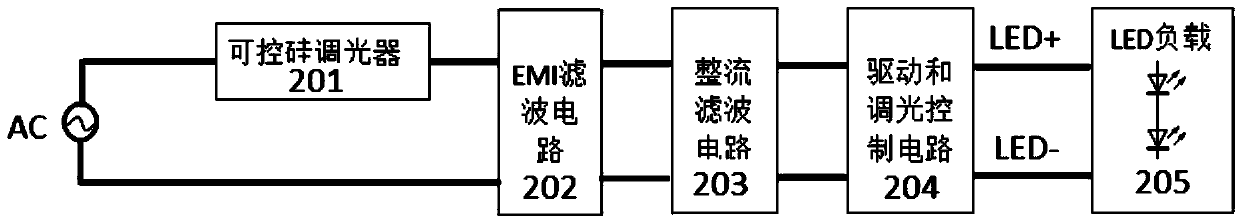

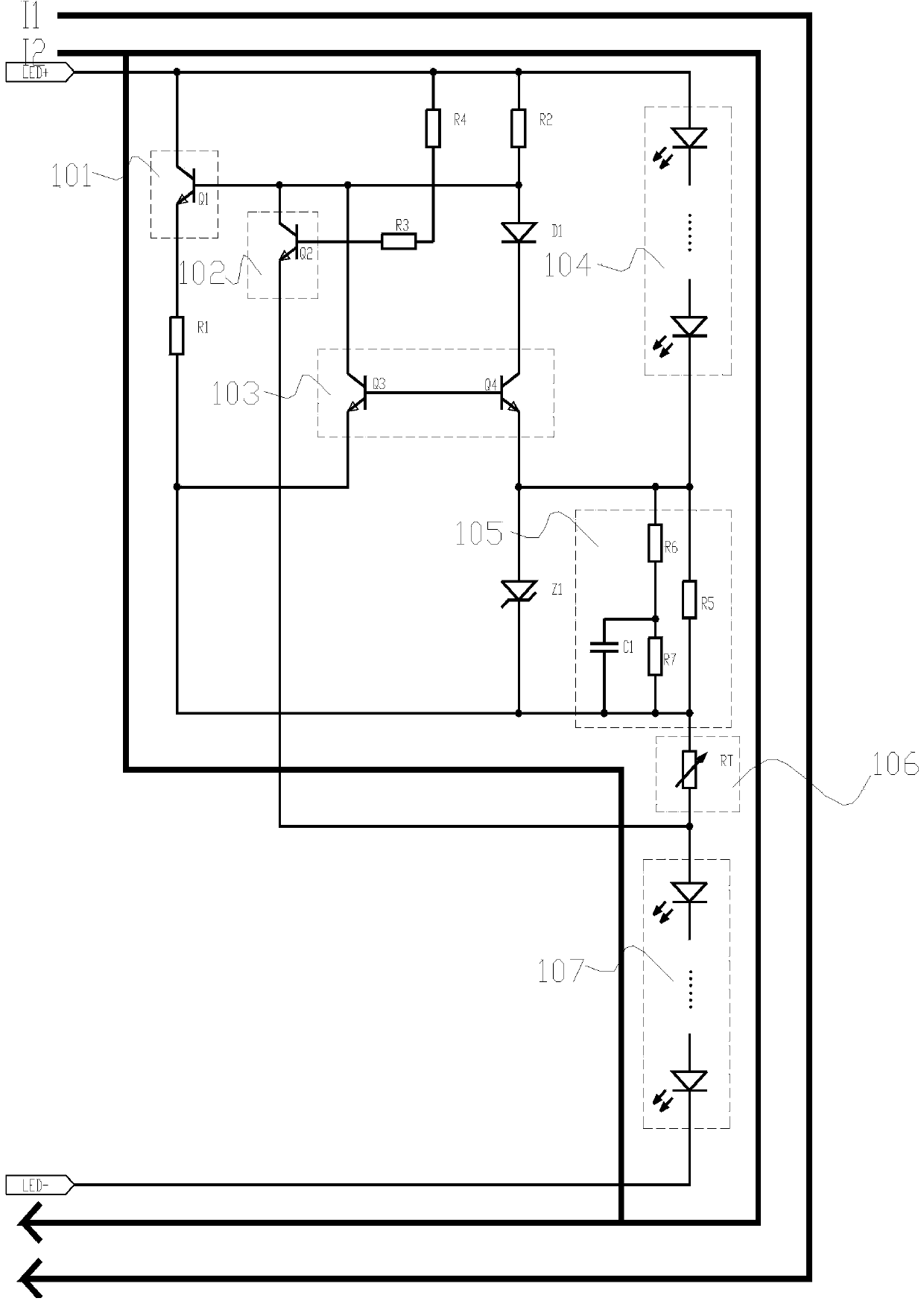

LED illumination control circuit for silicon controlled light modulator to achieve light and color synchronous adjustment and method thereof

ActiveCN103997835AMeet the needs of useSimple designElectric light circuit arrangementComputer moduleEngineering

The invention discloses an LED illumination control circuit for a silicon controlled light modulator to achieve light and color synchronous adjustment and a method thereof. The control circuit comprises a bypass amplifying circuit, a bypass switching circuit, a self-adaptive detection circuit, LED modules, a color temperature adjusting depth control point circuit and a color temperature adjusting start point control circuit. The bypass amplifying circuit, the bypass switching circuit, the self-adaptive detection circuit, the color temperature adjusting depth control point circuit and the color temperature adjusting start point control circuit are connected in sequence. The LED modules are respectively connected with the bypass amplifying circuit, the bypass switching circuit, the self-adaptive detection circuit and the color temperature adjusting depth control point circuit. According to the method, the different current magnitudes of the first LED module and the second LED module are synchronously controlled, color mixture happens to the LED modules with different color temperatures, and the luminance rate is changed. Light and color modulation detection and control circuits are additionally arranged at the two ends of an LED load, the color temperature can be changed synchronously while light modulation is conducted on the silicon controlled light modulator, and therefore the synchronous light and color adjusting function can be achieved.

Owner:HENGDIAN GRP TOSPO LIGHTING

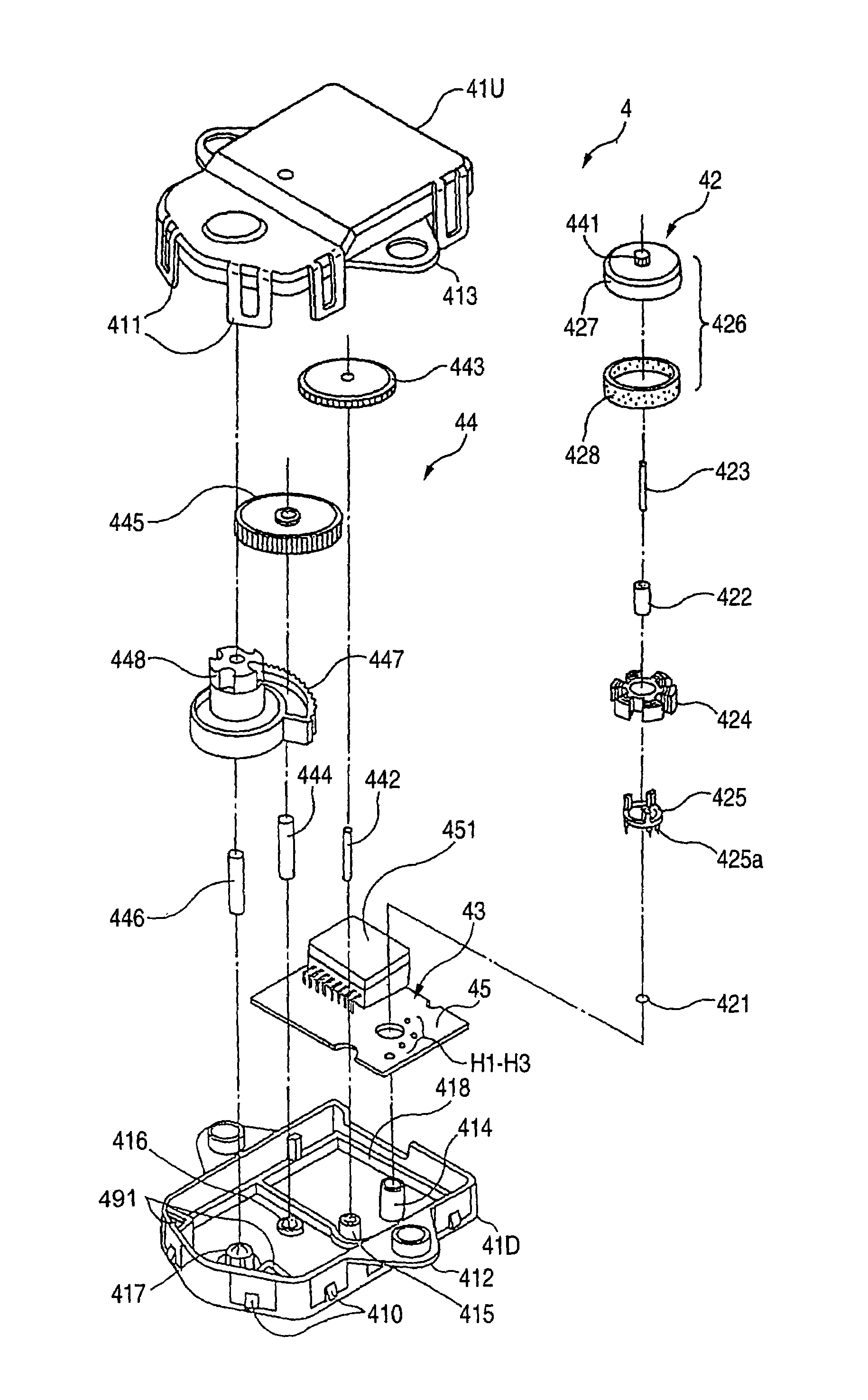

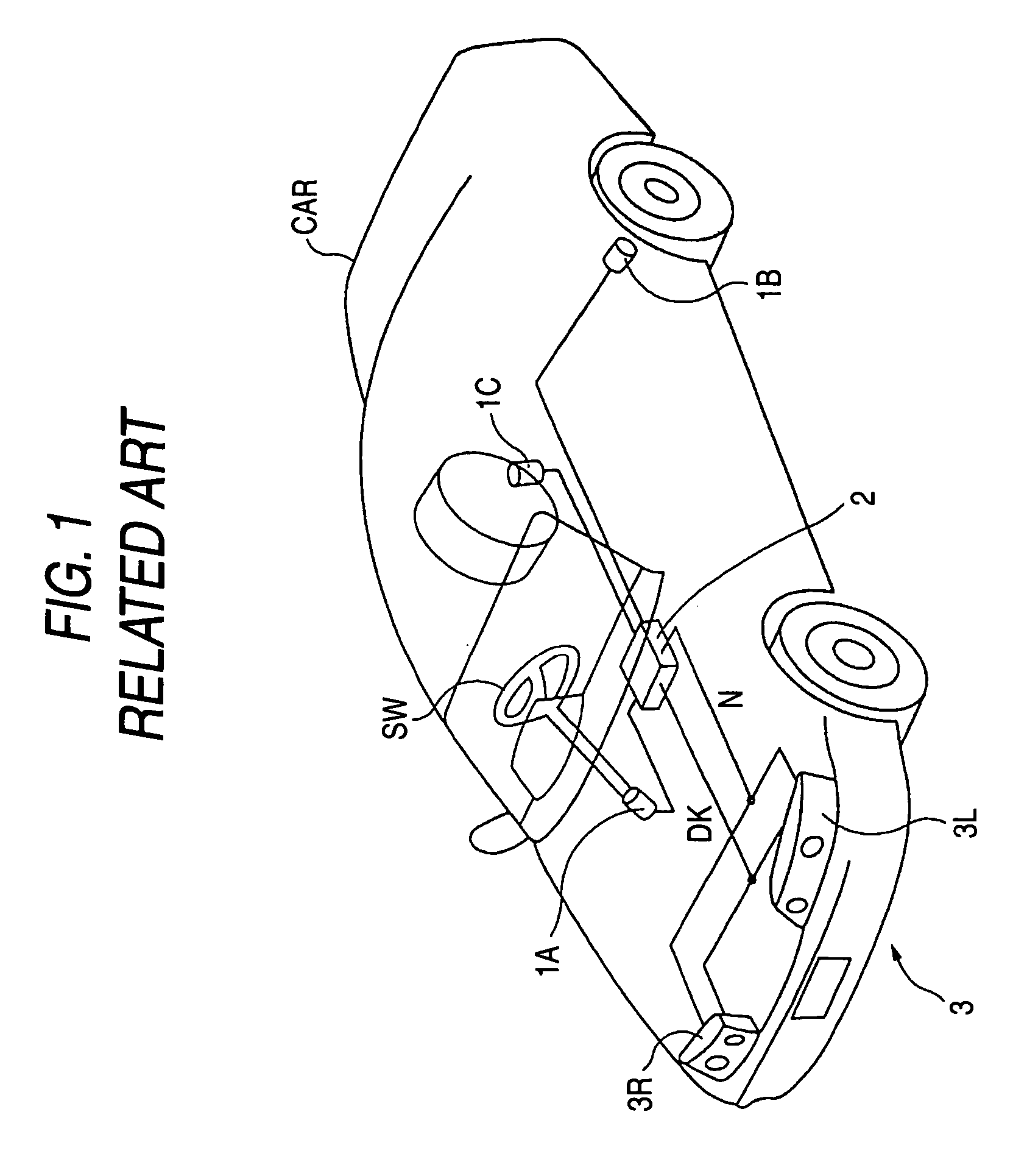

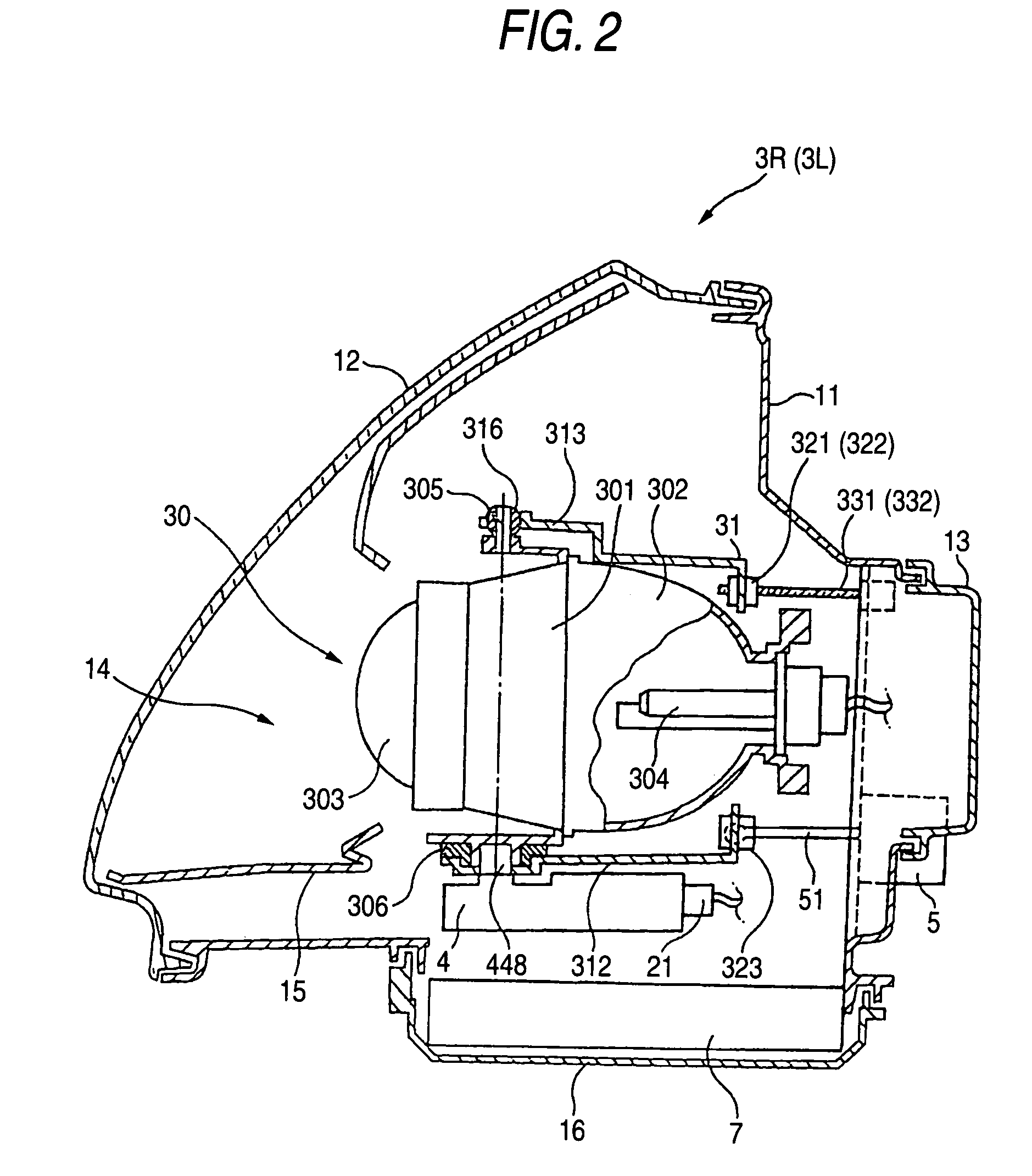

Vehicle headlamp unit

InactiveUS7121706B2Easy to installReduce in quantityVehicle headlampsLighting support devicesPrinted circuit boardHeadlamp

In an actuator of a vehicle headlamp unit for deflecting a direction or a range of illumination, a step-like rib for supporting a printed circuit board is formed at an inner side of a peripheral edge portion of a resin molded casing, and an opposed rib is formed at an outer side of this peripheral edge portion by a generally channel-shaped groove. A gear in a gear mechanism of the actuator is made of a resin having self-lubricating properties. The actuator includes a brushless motor, a yoke molded of a resin having a cylindrical container-shape. A gear is formed integrally on a central portion of an outer end surface of the yoke. A fixing means for fixing the stator coil of the brushless motor to a housing or the board has a positioning structure for positioning the stator coil.

Owner:KOITO MFG CO LTD

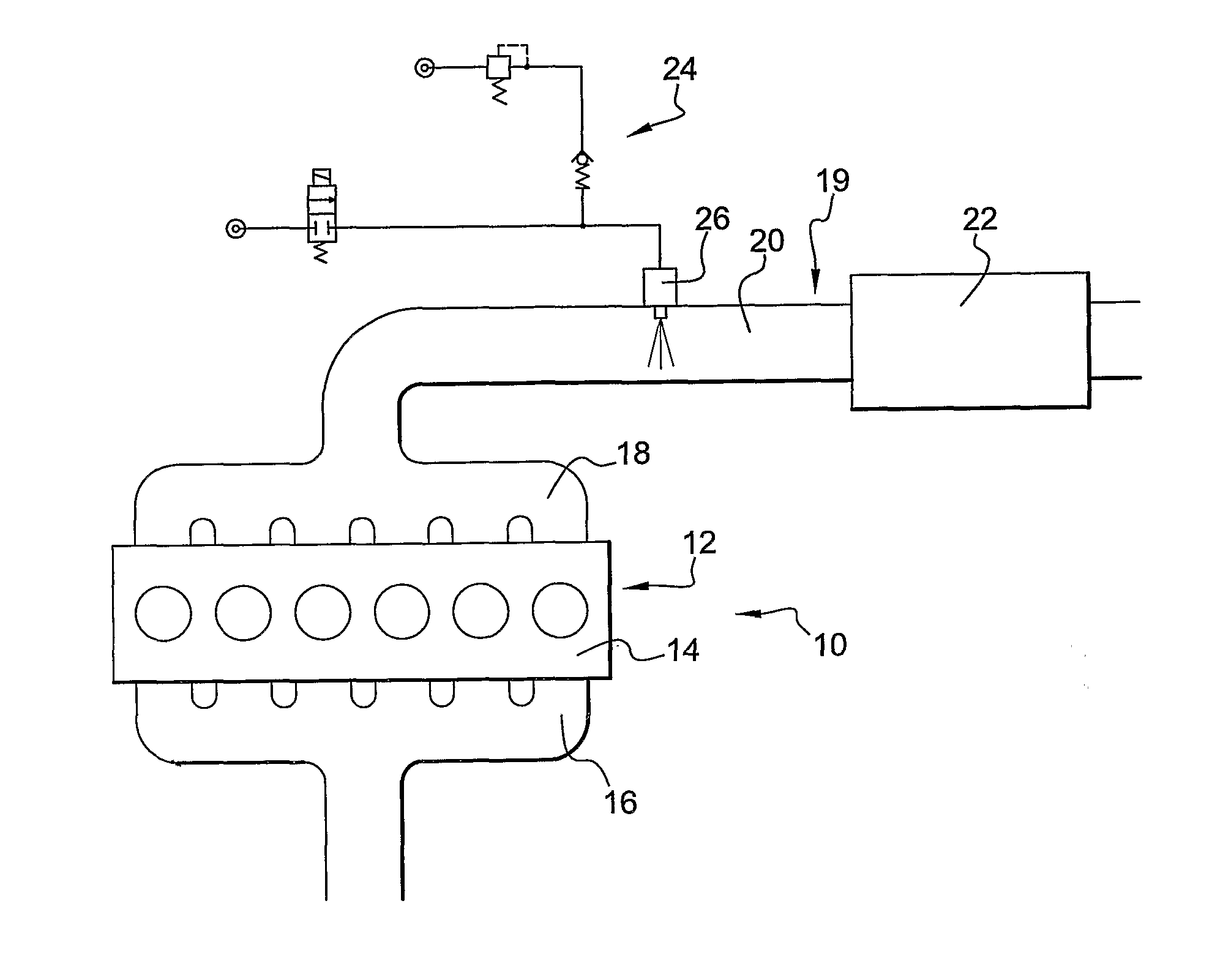

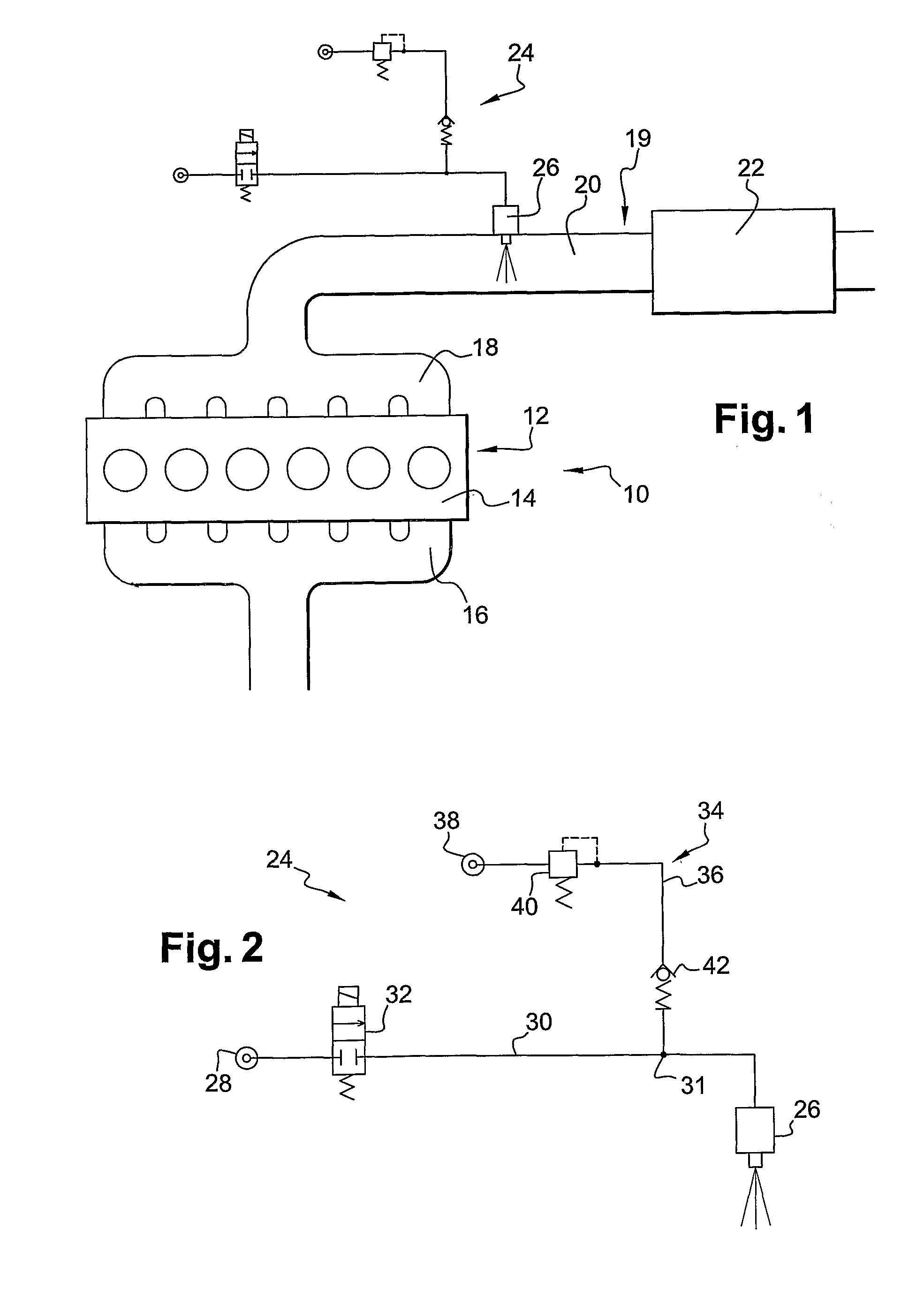

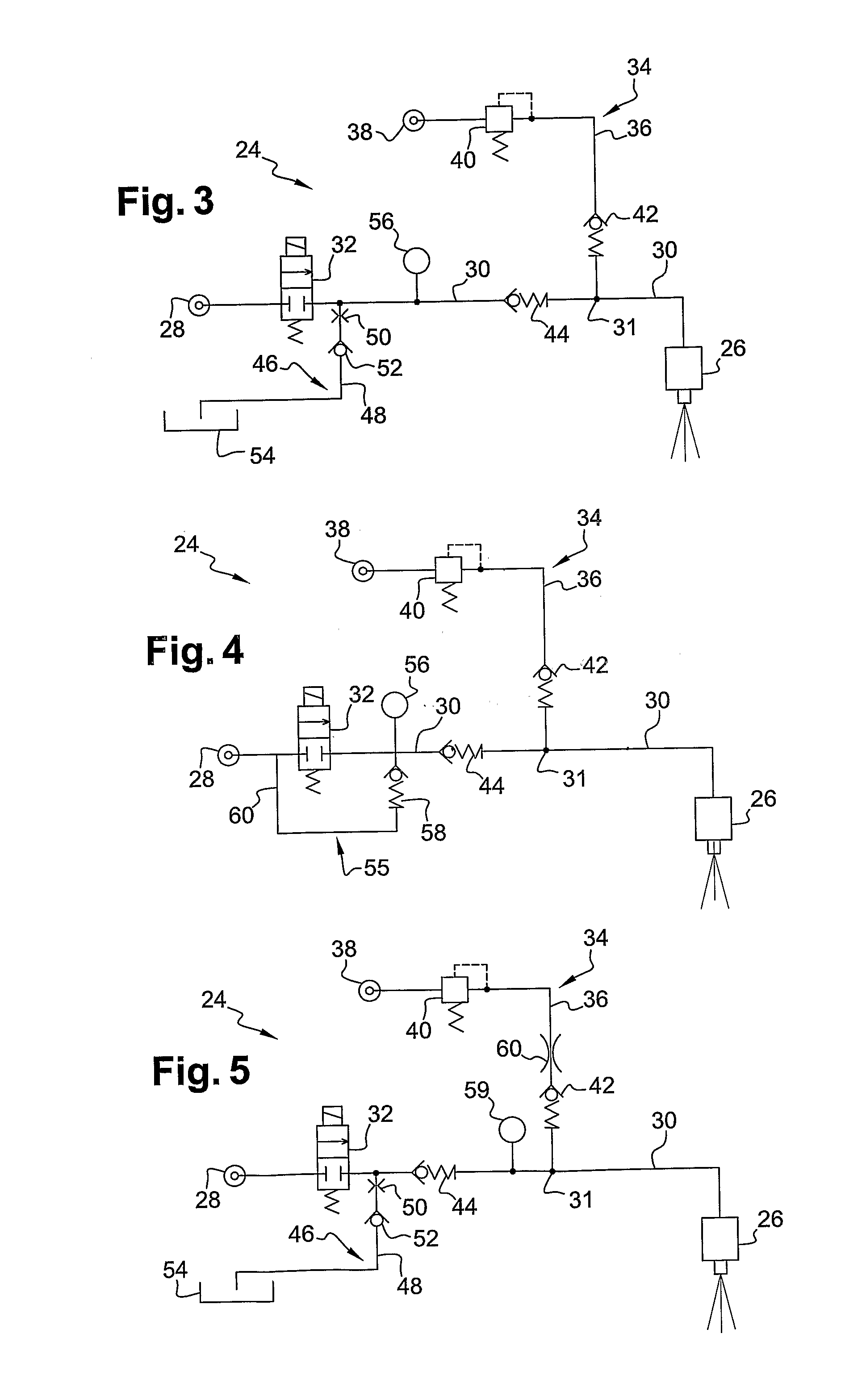

Apparatus and method for injection of a fluid for an exhaust gases treatment device

ActiveUS20110016854A1Cheap and effectiveLess cumbersomeDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringInternal combustion engine

An apparatus is provided for injection of a fluid for an exhaust gases treatment device of an internal combustion engine arrangement. The apparatus includes a fluid injector fed from a source of fluid under pressure through a fluid conduit, a feed valve in the fluid conduit between the source of fluid the said injector, a purge system including a gas conduit connecting a source of pressurized gas to the fluid conduit, a pressure limiter within the gas conduit, and a check valve downstream of the pressure limiter. The pressure limited by the pressure limiter is lower than the pressure of fluid delivered by the source of fluid.

Owner:VOLVO LASTVAGNAR AB

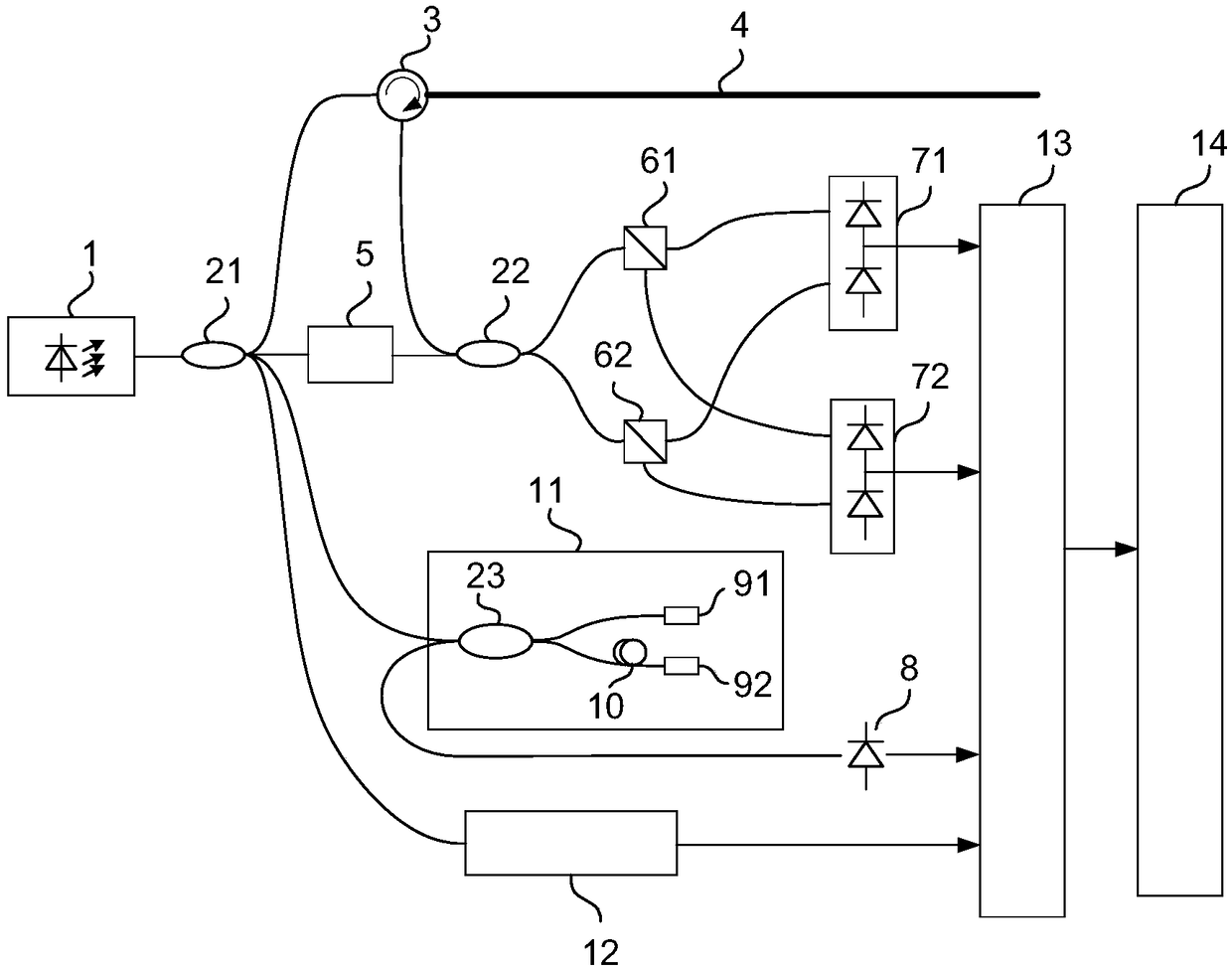

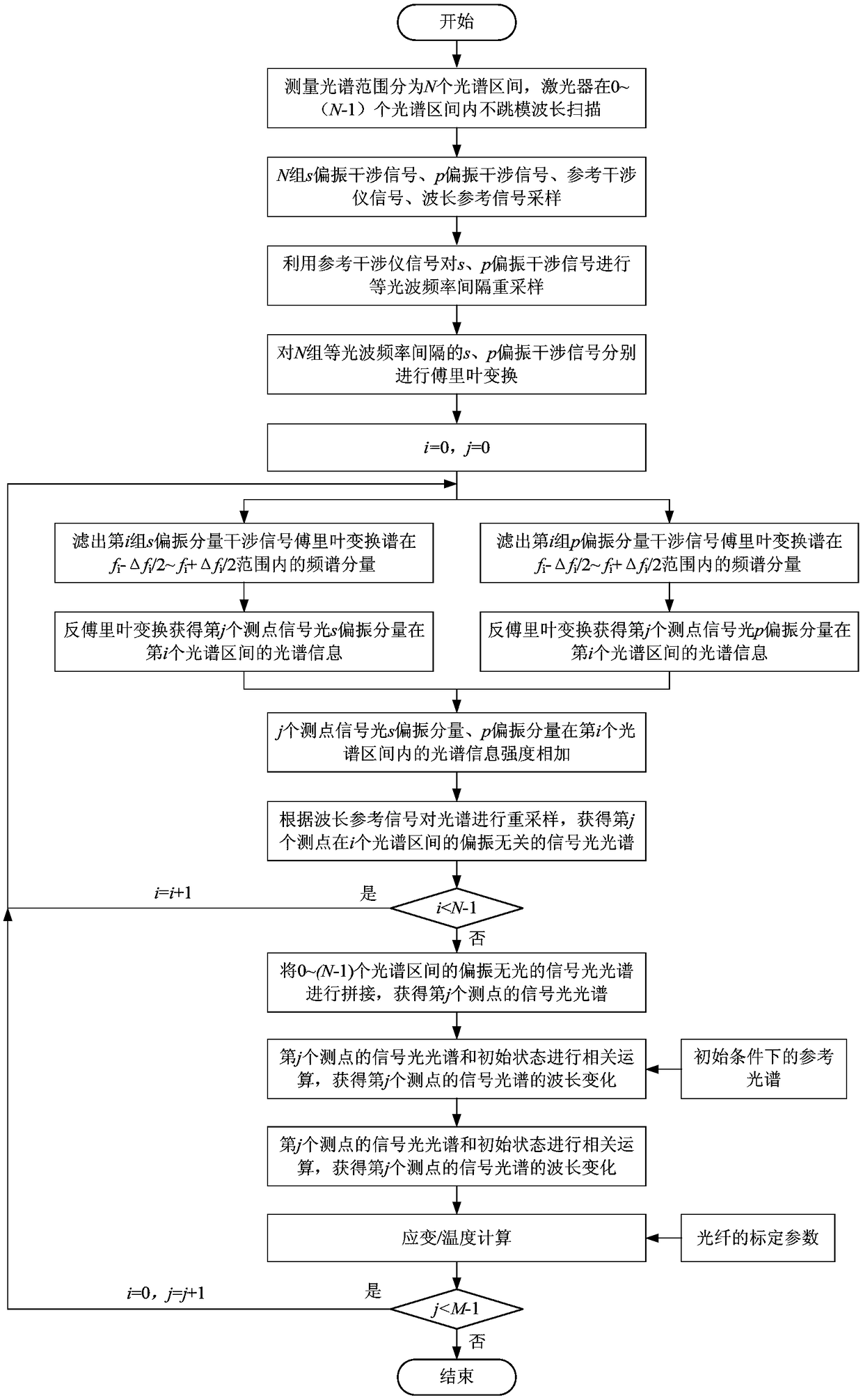

Spectrum splicing optical frequency domain reflection-type distributed fiber sensor and signal demodulation method

ActiveCN109186644AReduced requirement for non-mode-hopping spectral rangeLow cost designConverting sensor output opticallyPhotovoltaic detectorsMiniaturization

The present invention discloses a spectrum splicing optical frequency domain reflection-type distributed fiber sensor and a signal demodulation method. The spectrum splicing optical frequency domain reflection-type distributed fiber sensor comprises a narrow linewidth scanning laser, a first optical fiber coupler, an optical circulator, a sensing optical fiber, a polarization control unit, a second optical fiber coupler, a first polarization beam splitter, a second polarization beam splitter, a first balance photoelectric detector, a second balance photoelectric detector, a third optical fibercoupler, a first Faraday rotation reflector, a second Faraday rotation reflector, a reference fiber optic interferometer, a photoelectric detector and a signal collection processing unit. Through spectrum splicing, it is avoided that a laser with a broadband spectrum range and without mode jump is employed to reduce the cost; the laser package and control are simplified to facilitate miniaturization design; and the requirements for the environment temperature and the vibration condition are reduced to facilitate project promotion application.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

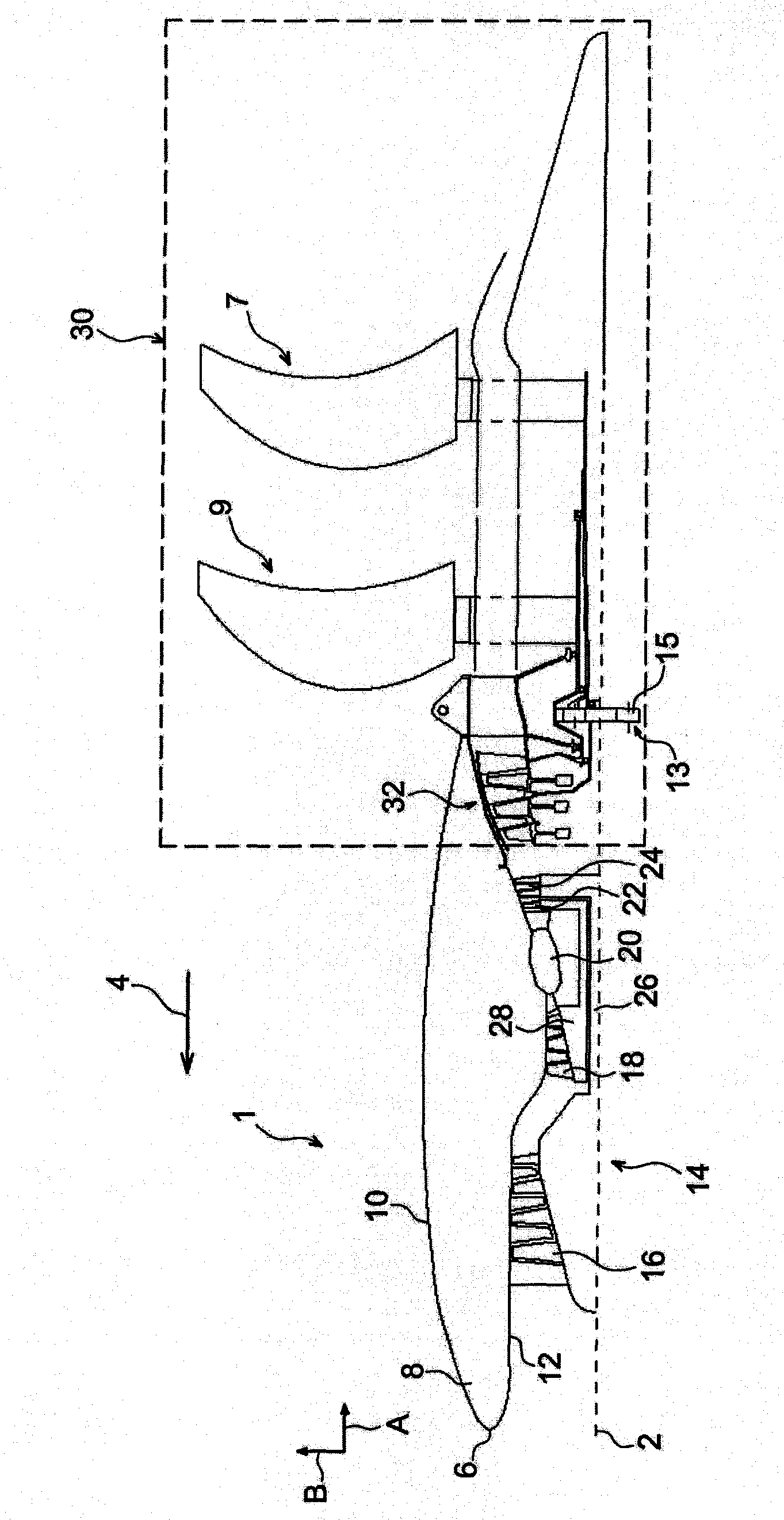

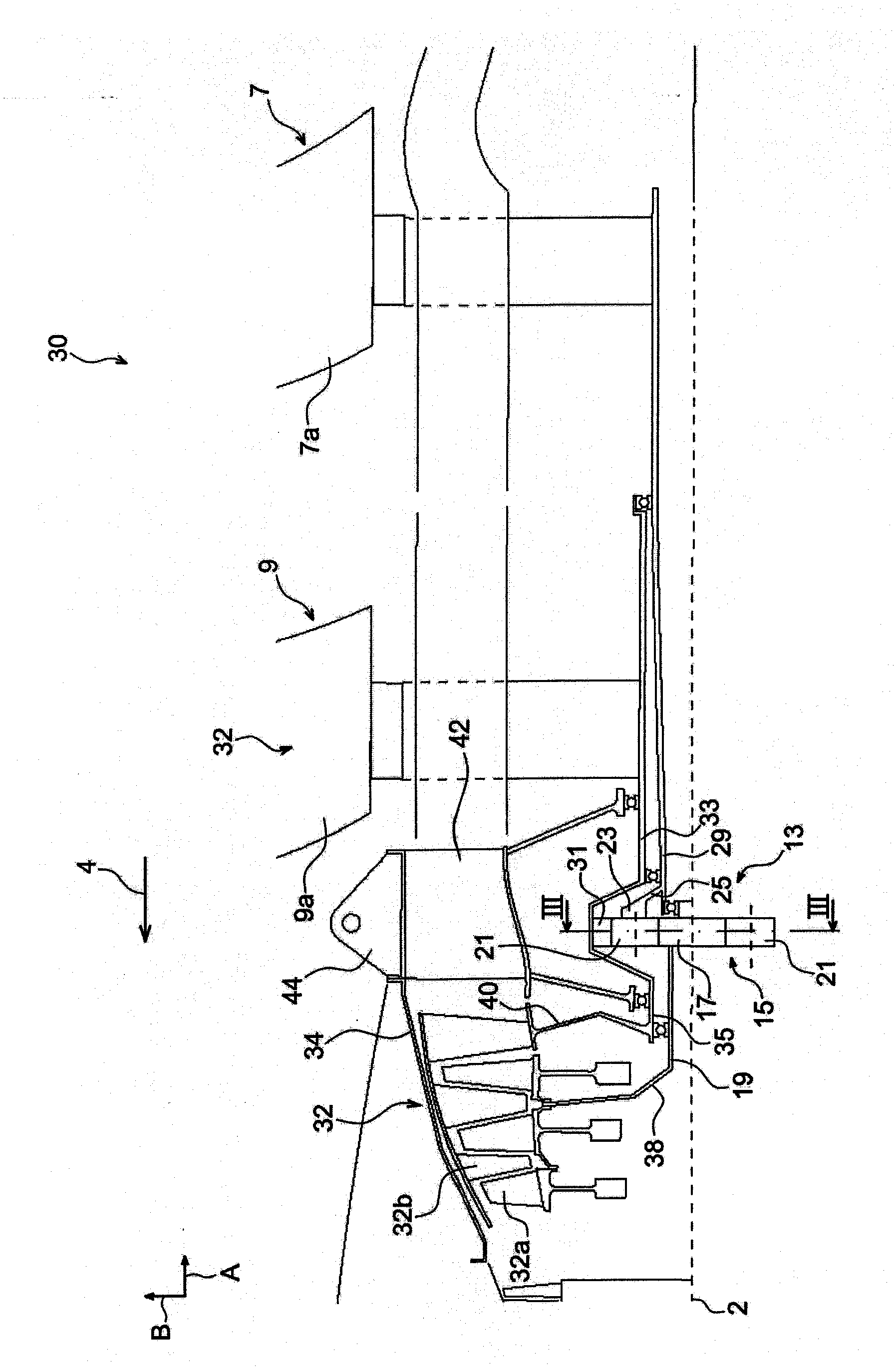

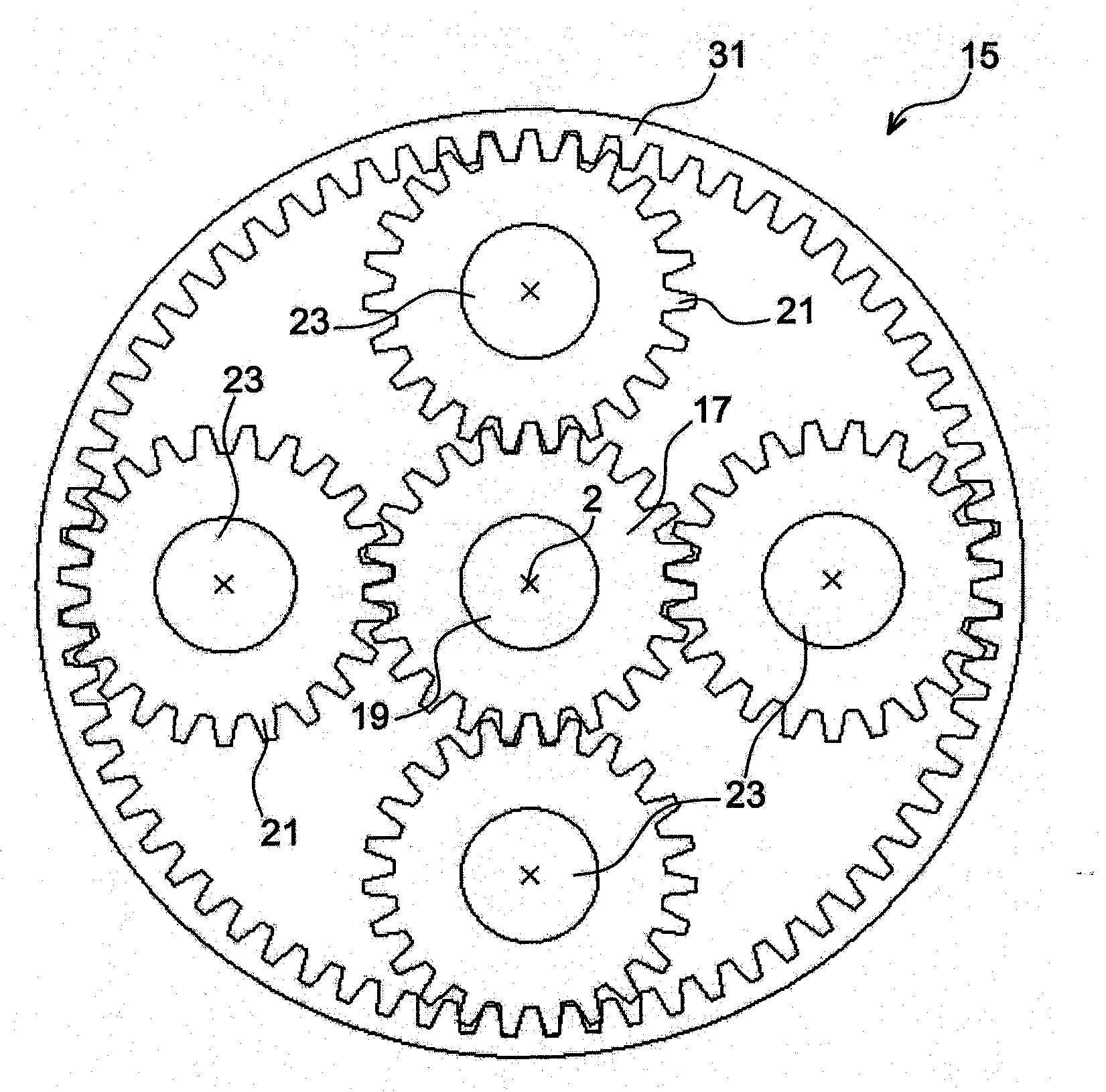

System including counter-rotating propellers driven by an epicyclic train ensuring a balanced couple distribution between the two propellers

ActiveCN102257260AShow counter-rotation characteristicsPrevent harmful phenomenon of residual rotationPropellersEngine fuctionsGear wheelPropeller

The present invention relates to a system of counter-rotating propellers (30) for an aircraft turbine engine, including: a free power turbine (32) including a first rotor (32a); first and second propellers (7, 9); and a mechanical transmission device (13) including an epicyclic train (15) with a planetary gear (17) driven by the rotor (32a), at least one satellite (21), a satellite carrier (25) driving the first propeller (7) and a gear (31) driving said second propeller (7). According to the invention, the free turbine (32) also includes a second rotor (32b) counter-rotating relative to the first rotor (32a) and rotating the gear (31).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

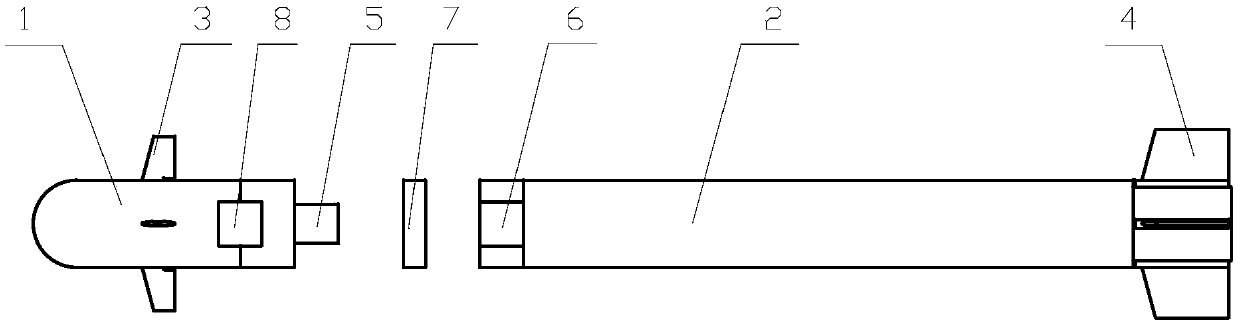

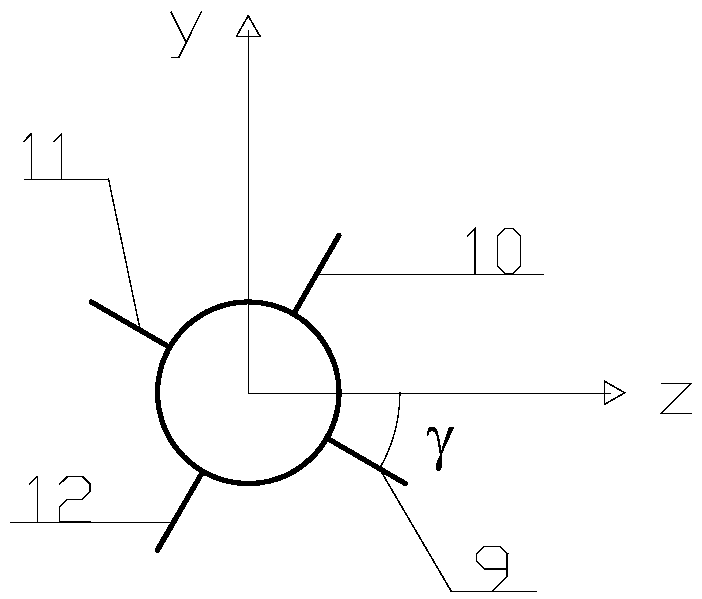

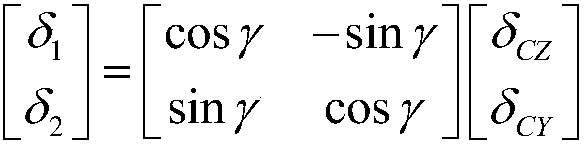

Canard configuration missile general structure with roll and despun stabilizing function

ActiveCN109596011ASimple designSolve the control puzzleSelf-propelled projectilesSystems designAngular velocity

The present invention provides a canard configuration missile general structure with a roll and despun stabilizing function, comprising a front section (1) and a rear section (2); and the front section (1) and the rear section (2) are connected by a roll and despun stabilizing device. The canard configuration missile general structure divides a missile into the front section and the rear section,a canard system is mounted at the front section, the rear section rotates around the longitudinal axis by an inclined tail under the aerodynamic action, and the front section realizes the roll stabilizing by the roll and despun stabilizing control, which solves the roll channel control problem caused by the canard wash of the canard configuration missile. At that same time, for the canard system,only pitch motion control and yaw motion control are needed and can be realized only by two sets of motor servo systems, so that the design of the canard system is greatly simplified, and the requirement for the structure space and the development cost are reduced. A guidance assembly is installed in the front section of the despun stabilized missile body, so that the disadvantageous influence oflarge roll angular velocity on the system stable imaging is avoided.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

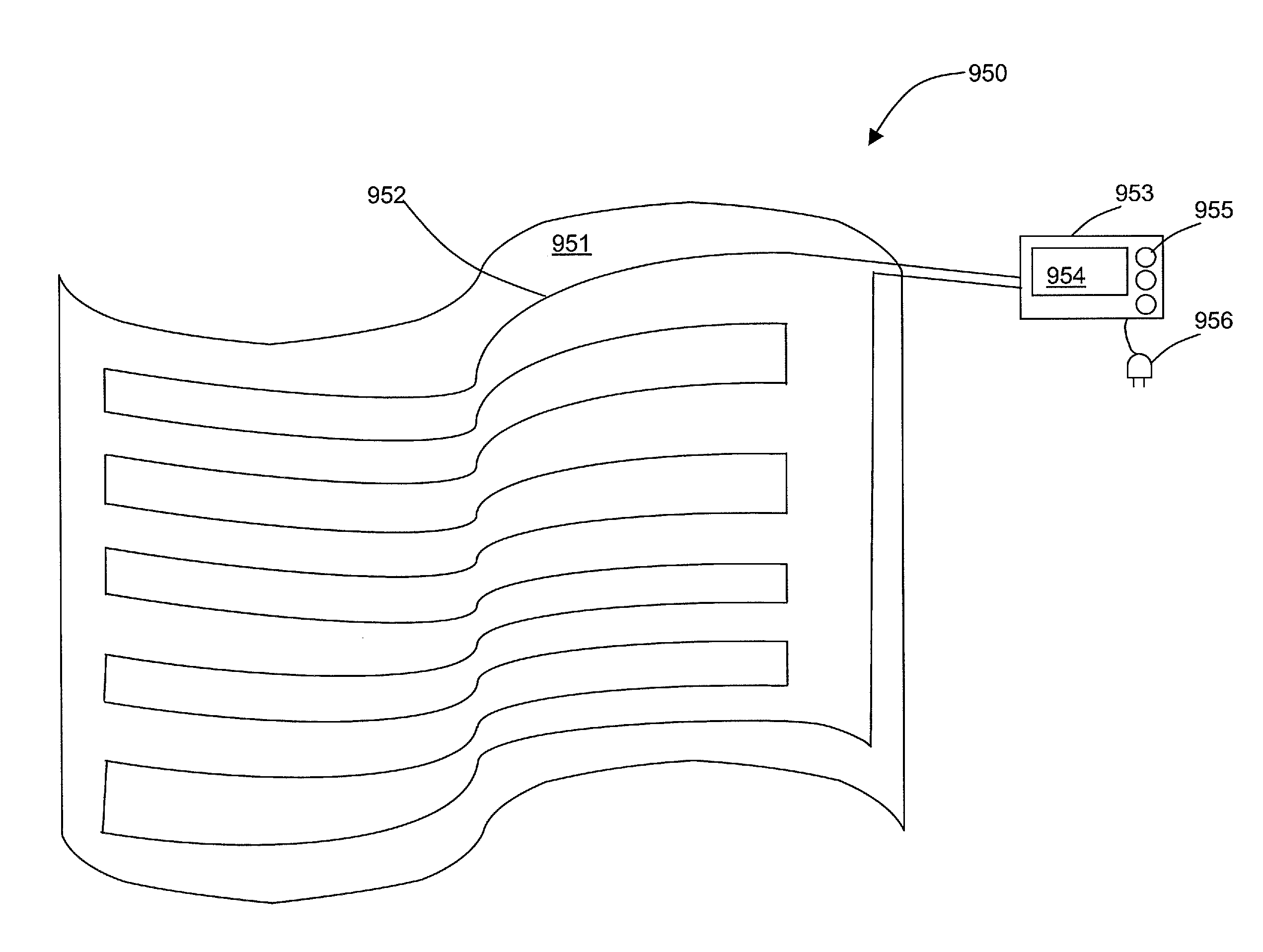

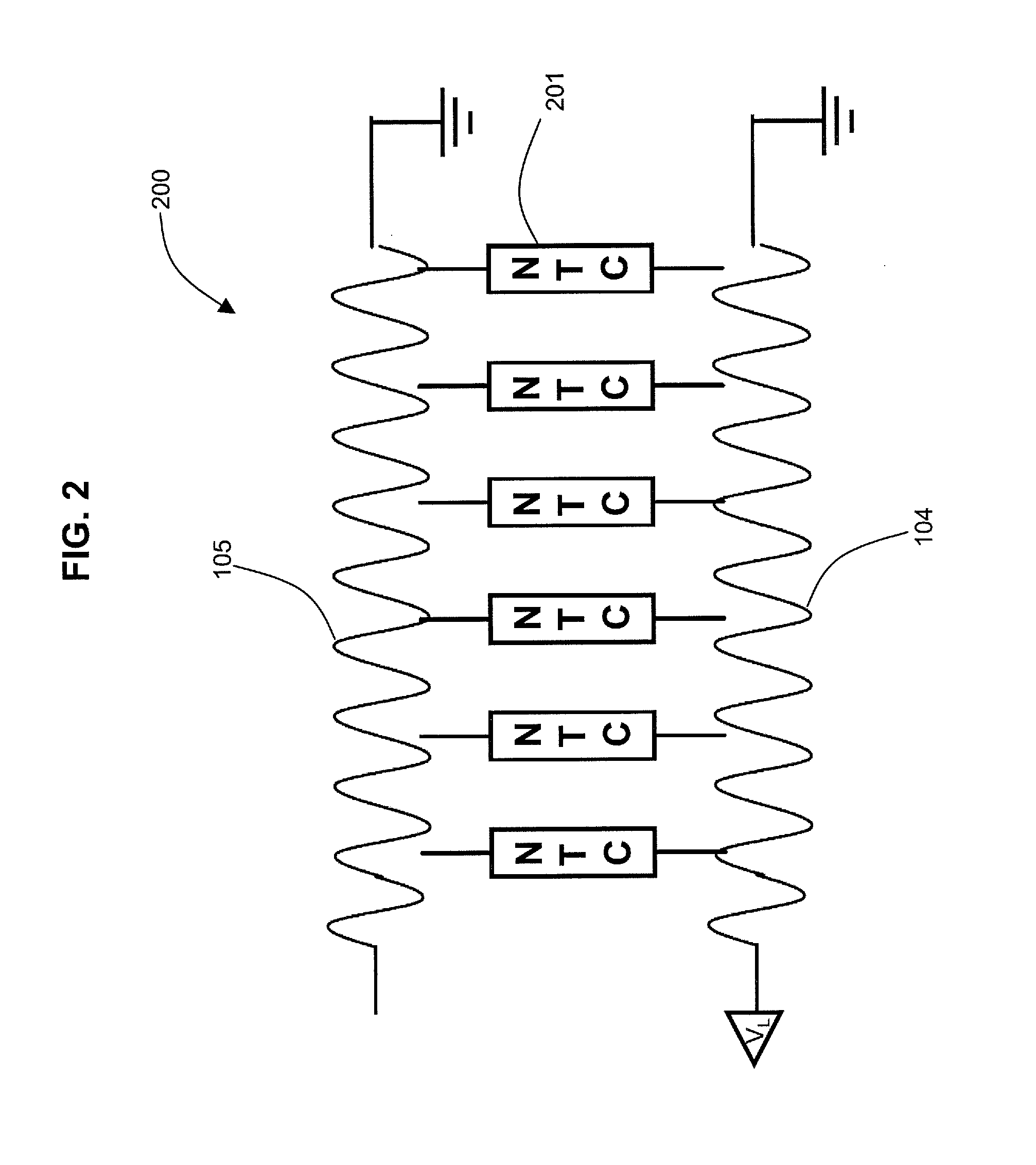

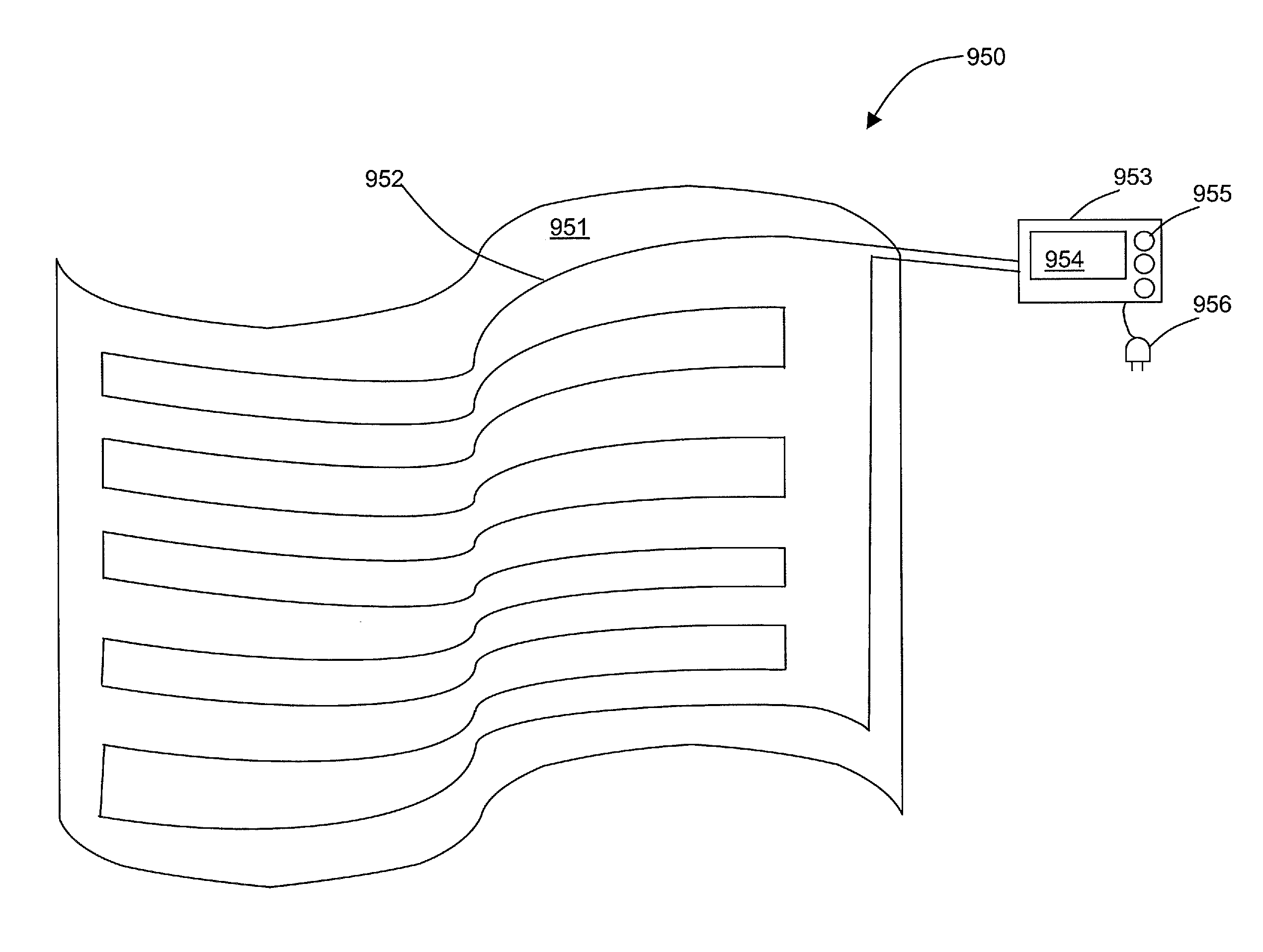

Ntc/ptc heating pad

InactiveUS20110259872A1Control of heat generationPositive control of the temperature of the heating padSedimentation separationHeating element shapesElectrical resistance and conductanceElectrical conductor

A controllable heating pad, having a heating conductor embedded in the heating pad, a sensing conductor embedded in the heating pad, a resistive material providing a distributed electrical path between the heating conductor and the sensing conductor, a first current sensor to sense a current in the heating conductor and a second current sensor to sense a current in the sensing conductor. A method of controlling a temperature of a heating pad, including the steps of: warming the heating pad to at least a first predetermined temperature by use of an adjustable on / off signal to the controllable switch, measuring currents through an NTC material or a combination of a PTC material and an NTC material; and maintaining a temperature of the heating pad to within a predetermined temperature range by use of the adjustable on / off signal to the controllable switch.

Owner:HELEN OF TROY LIMITED

Compliant chain guide with blade spring

ActiveUS7063635B2Improved drive behaviorLow cost designGearingMachines/enginesEngineeringMechanical engineering

Owner:BORGWARNER INC

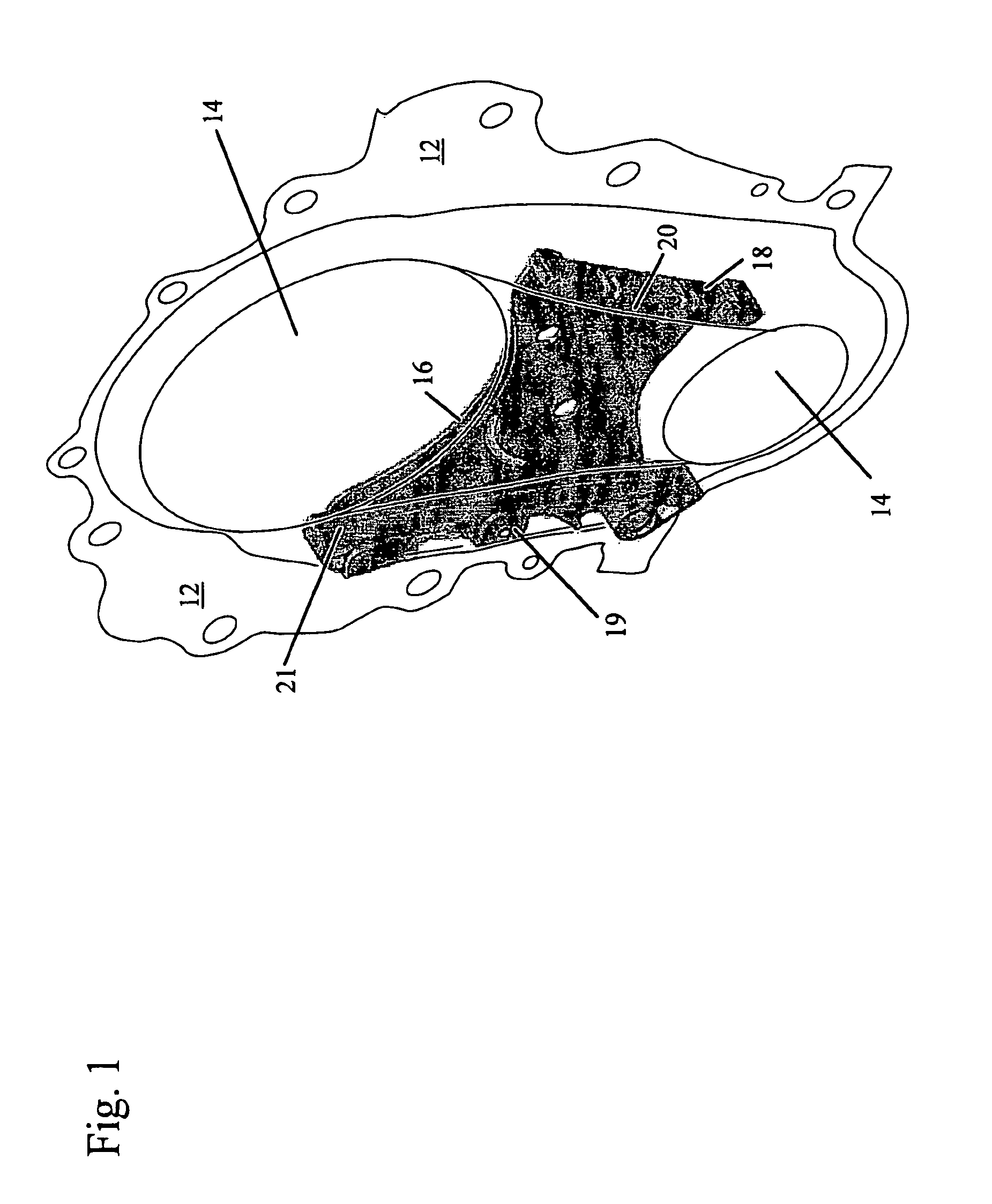

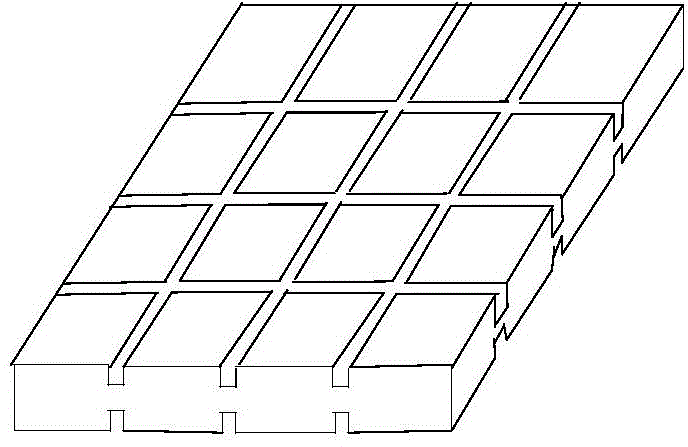

Micro/nano-satellite multi-star adaption portion deploy device and application

ActiveCN104816842ALow cost designLow-cost multi-star adaptationCosmonautic component separationNano satelliteEngineering

The invention discloses a micro / nano-satellite multi-star adaption portion deploy device which comprises a deploy instrument and a platform interface. The platform interface is used for achieving physical and electric connection between the deploy instrument and the satellite platform. The deploy instrument comprises a support assembly and an ejection assembly. The support assembly comprises partition plates (1) and lateral plates (2). A slot (11) is formed in each partition plate (1), and the lateral plates (2) are clamped in the slots (11). The plurality of partition plates arranged in parallel and the plurality of lateral plates of different specifications are utilized to form a plurality of layers of cases with different sizes to contain micro / nano satellites of different specifications. The ejection assembly (3) is used for ejecting the micro / nano satellites. The deploying instrument can contain the micro / nano satellites of various specifications and launch the satellites, and is good in generality and low in cost.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

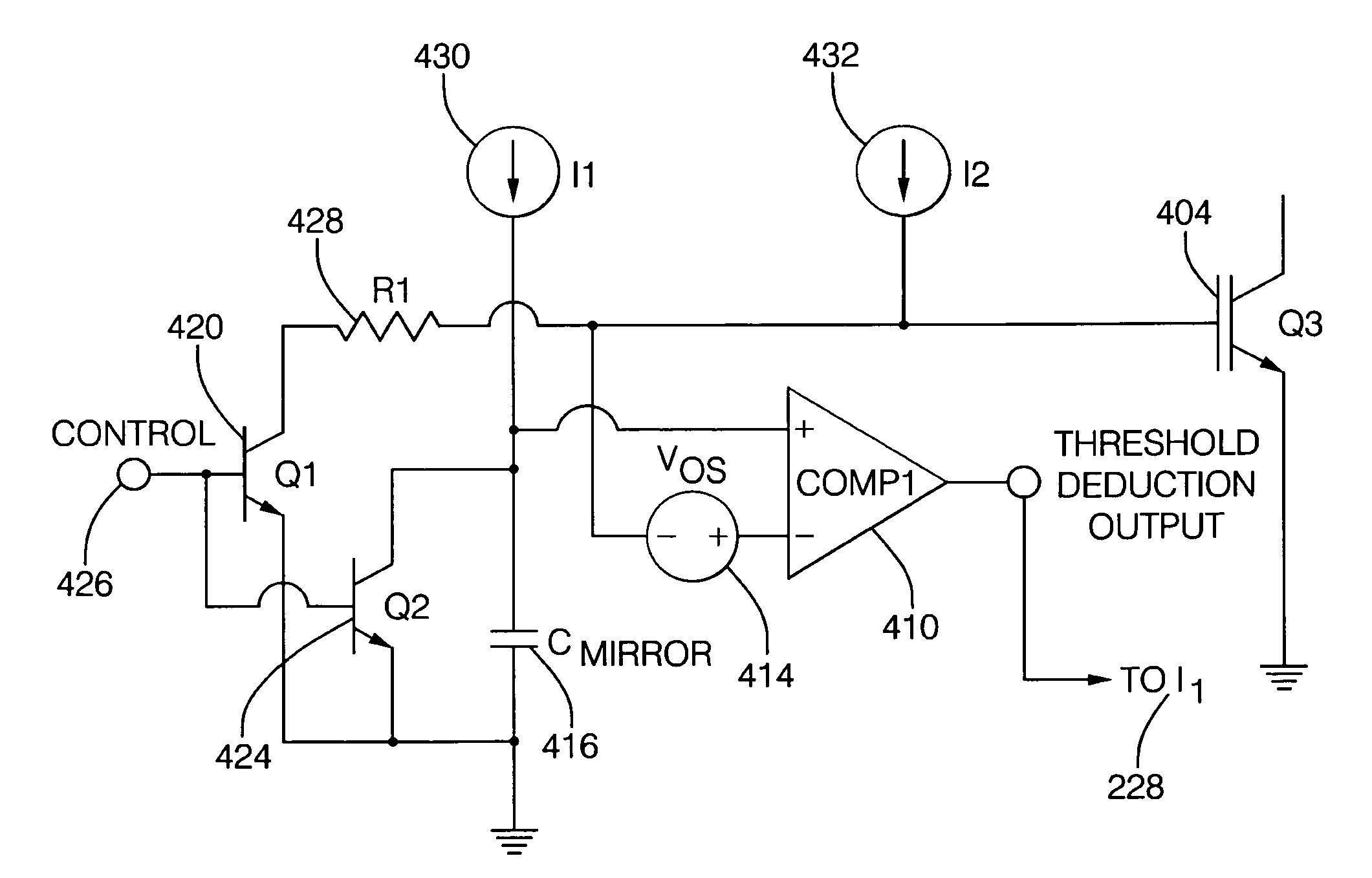

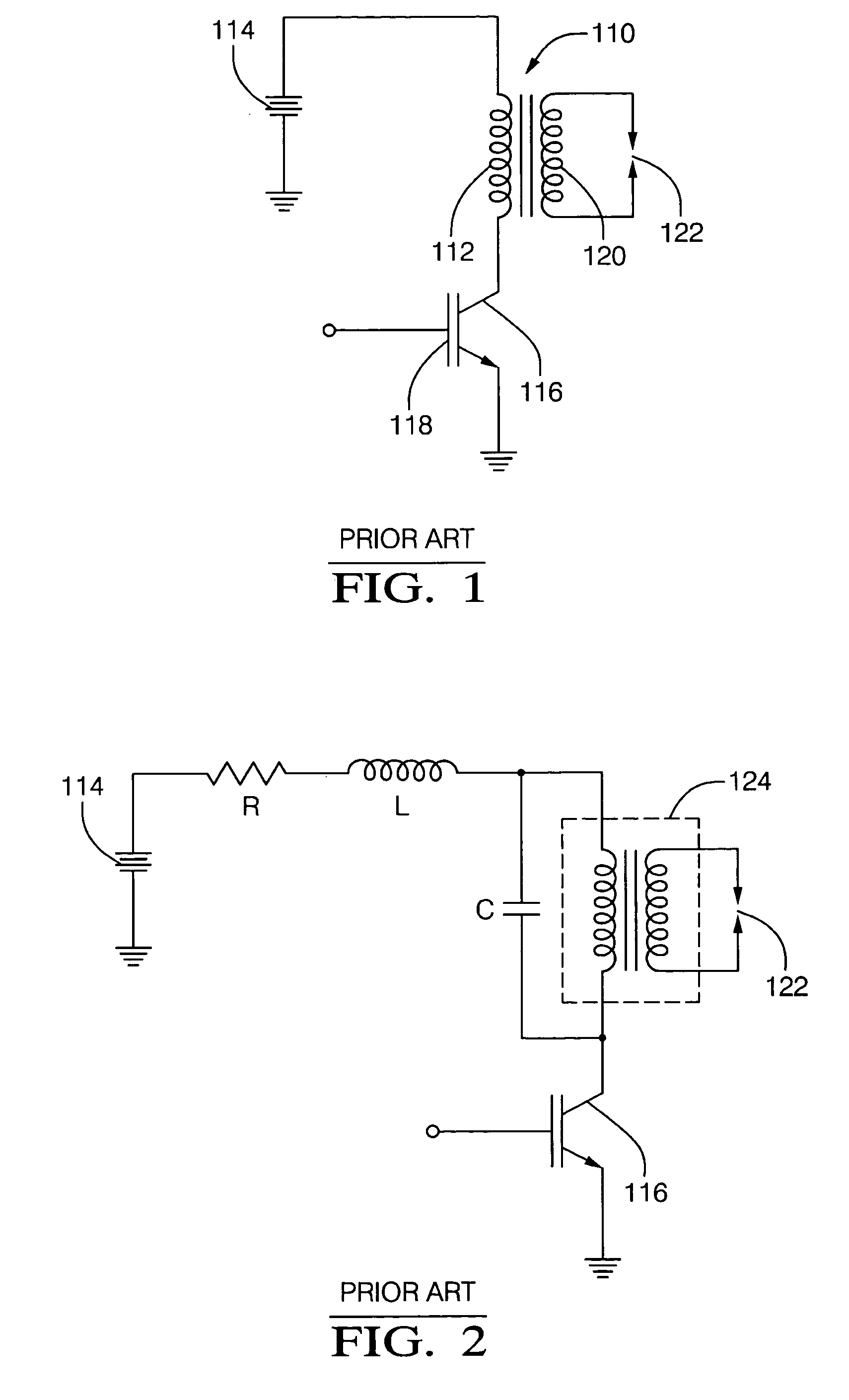

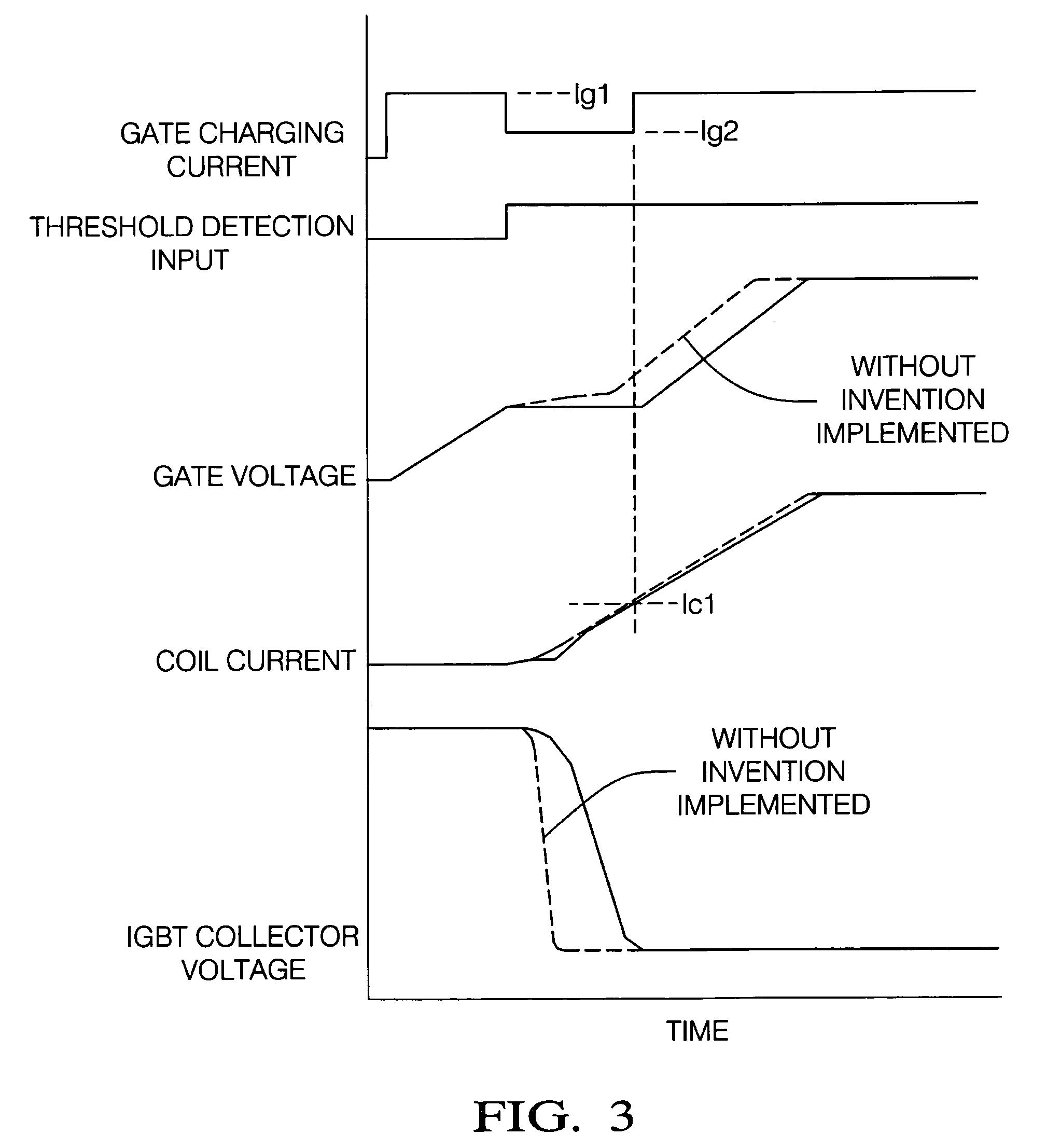

Switching control system to reduce coil output voltage when commencing coil charging

ActiveUS7675346B2Eliminate errorsMinimize dwell timing error and current conduction overlapElectronic switchingElectric pulse generatorIgnition coilCapacitor voltage

A switching control system and method is provided that optimizes switching efficiencies for power switching applications including automotive ignition systems, solenoid drivers, motor drivers and power regulation systems. In an ignition system, a coil current switching magnitude is controlled at the start of ignition coil charging, thereby avoiding an untimely spark event. When the transistor threshold voltage is reached, the collapse rate of the ignition system transistor collector voltage is reduced by reducing the gate charging current. The reduced collector voltage slew rate results in a reduced primary and secondary coil output voltage. After the collector voltage collapses, a continued rapid charge is provided to place the transistor in a hard saturation bias condition. In an aspect, the present invention dynamically determines the threshold voltage of a power transistor. A mirror capacitor substantially matches a transistor gate voltage and a signal is generated when the mirror capacitor voltage proportionally exceeds the transistor gate voltage as a consequence of the transistor reaching a threshold voltage.

Owner:DELPHI TECH IP LTD

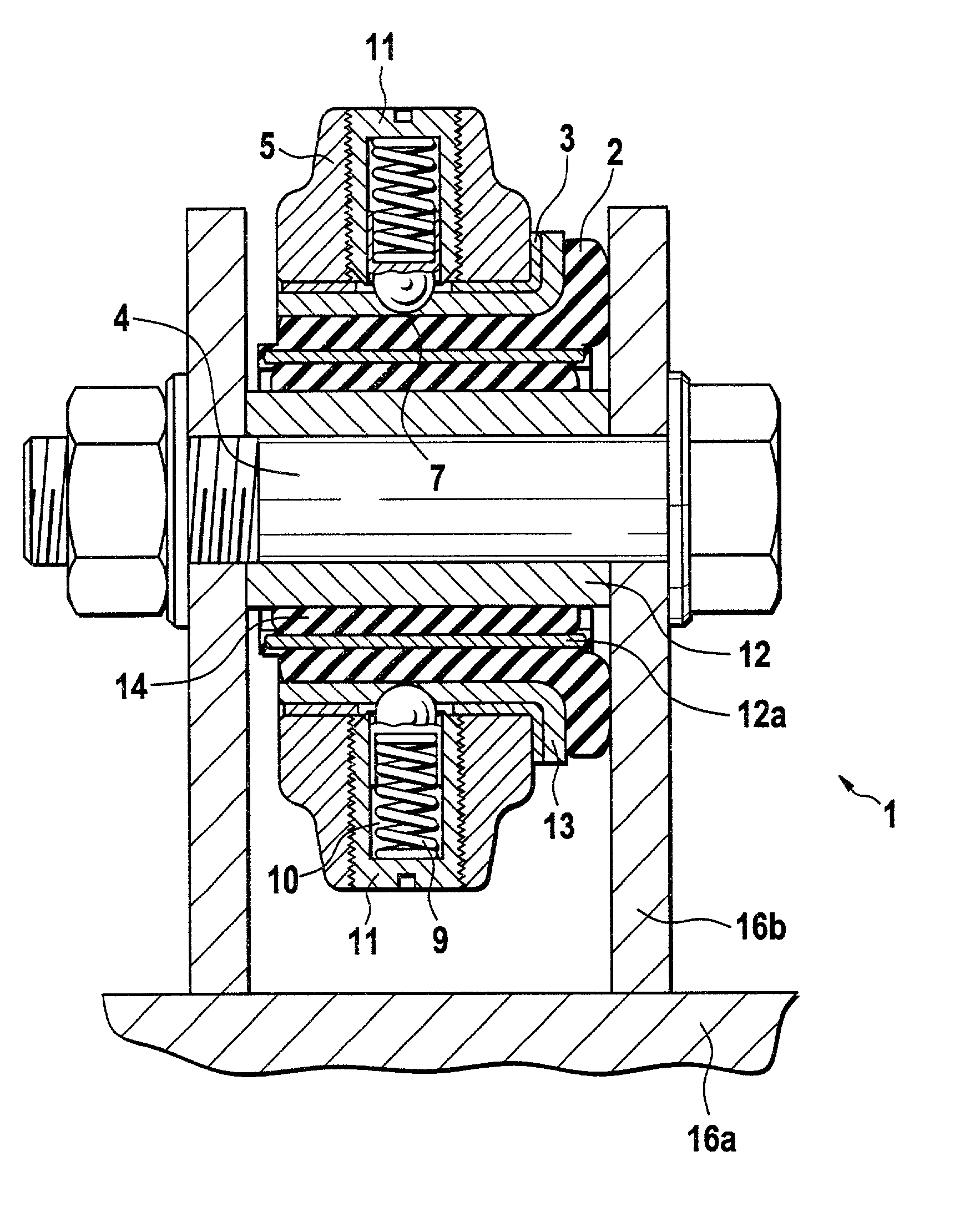

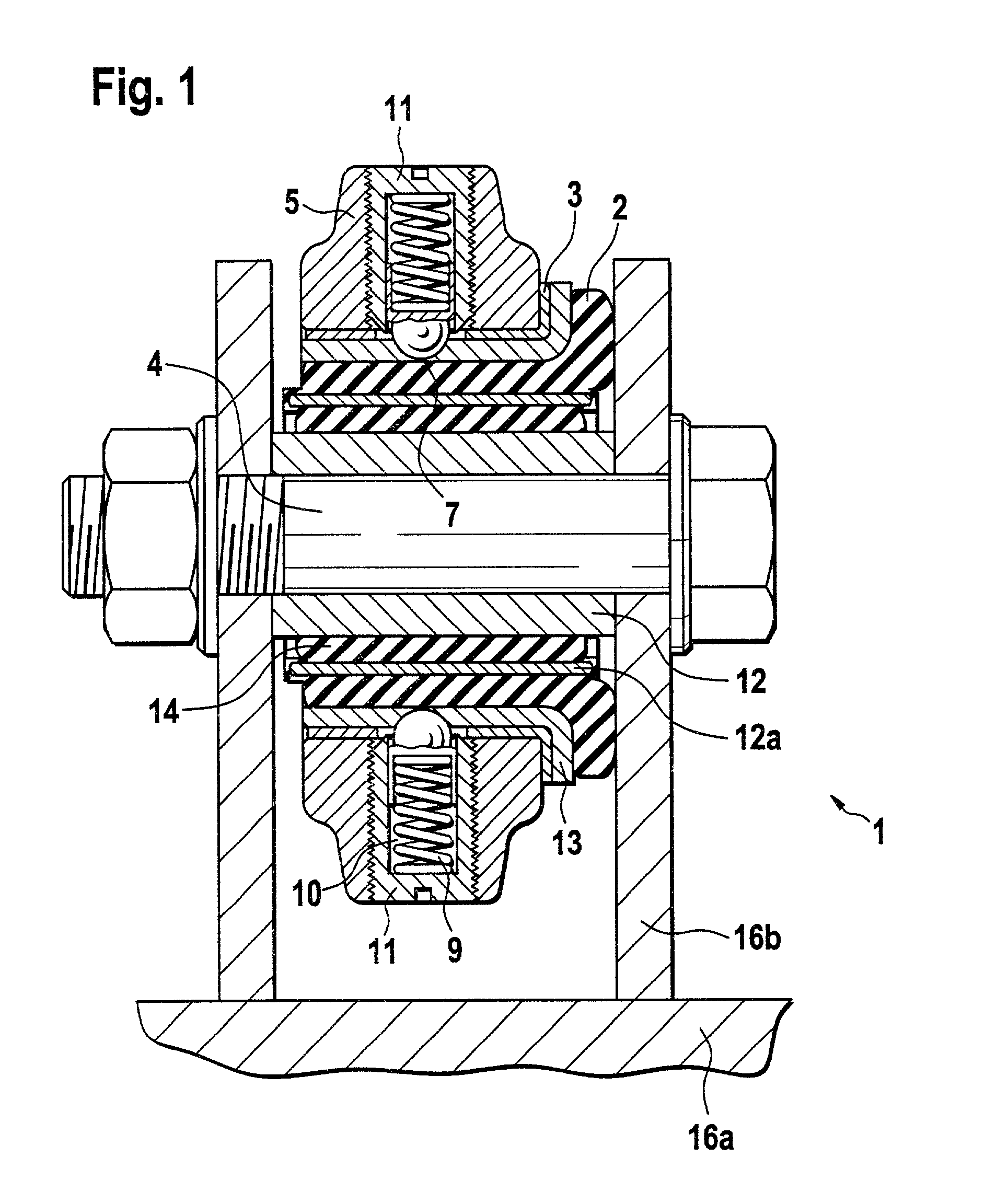

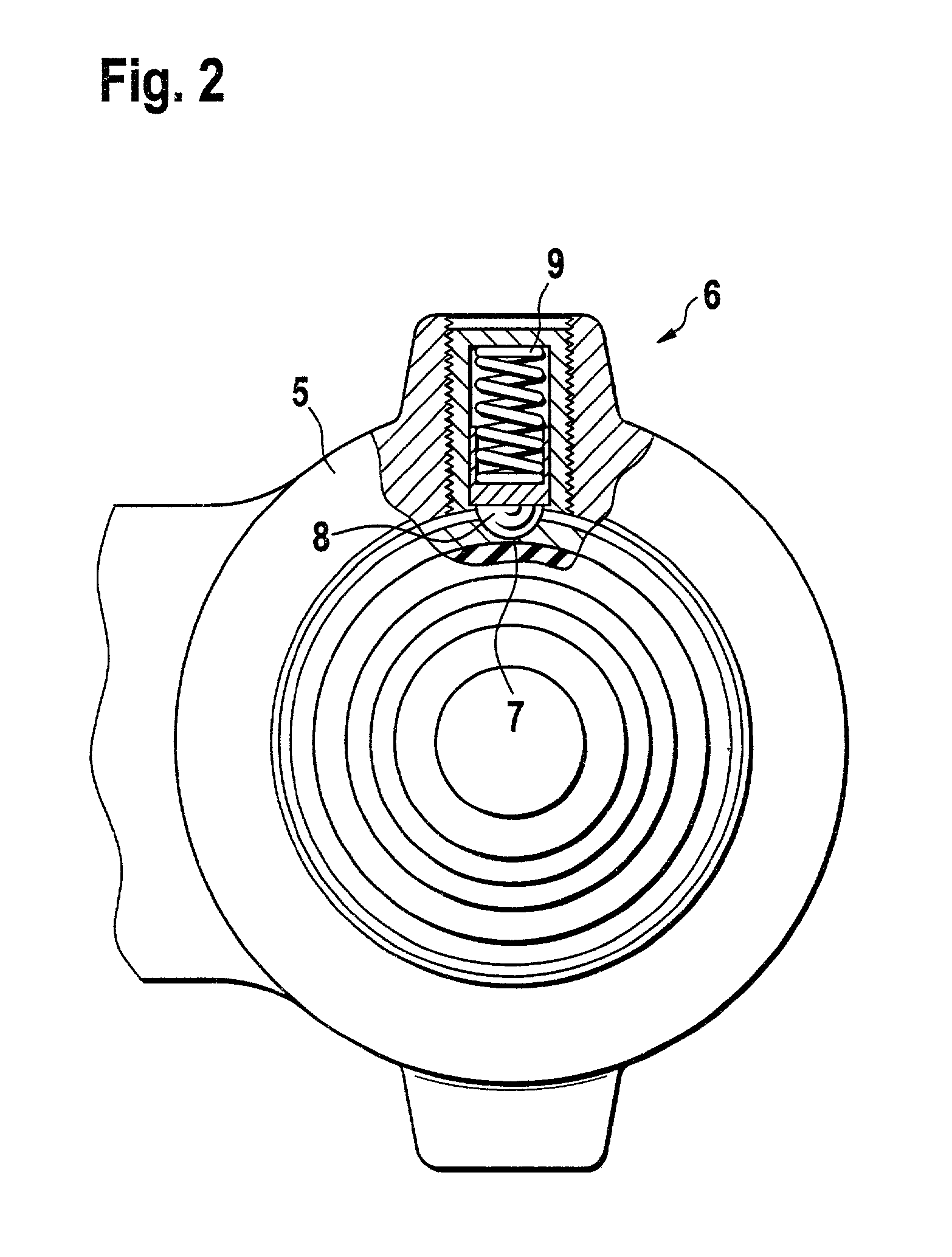

Forward bearing arrangement for the tilting cab of a truck

InactiveUS20020028031A1Maintain good propertiesLow costSpringsSprings/dampers design characteristicsVehicle frameTorsional load

The cab is supported at the front by elastic bearings mounted on bearing axles in alignment with each other and supported by at least two brackets attached to the vehicle frame. The elastic bearings are mounted in bearing shells attached to the floor of the cab. Each elastic bearing includes a rubber bearing with a plain bearing coaxial to it. An arresting device between the plain bearing and the elastic bearing presents relative rotation until a threshold torsional load is exceeded.

Owner:MANNESMANN BOGE

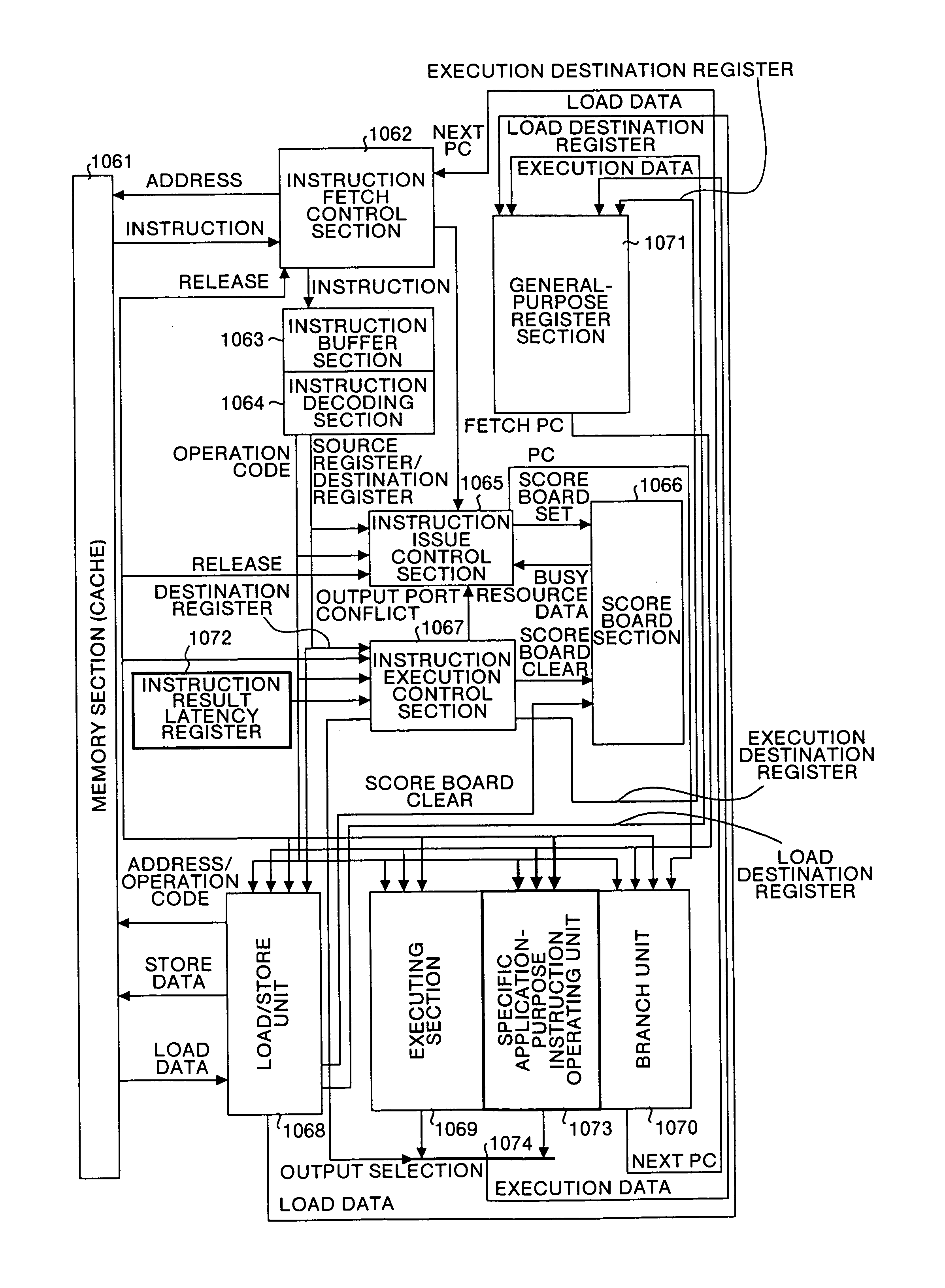

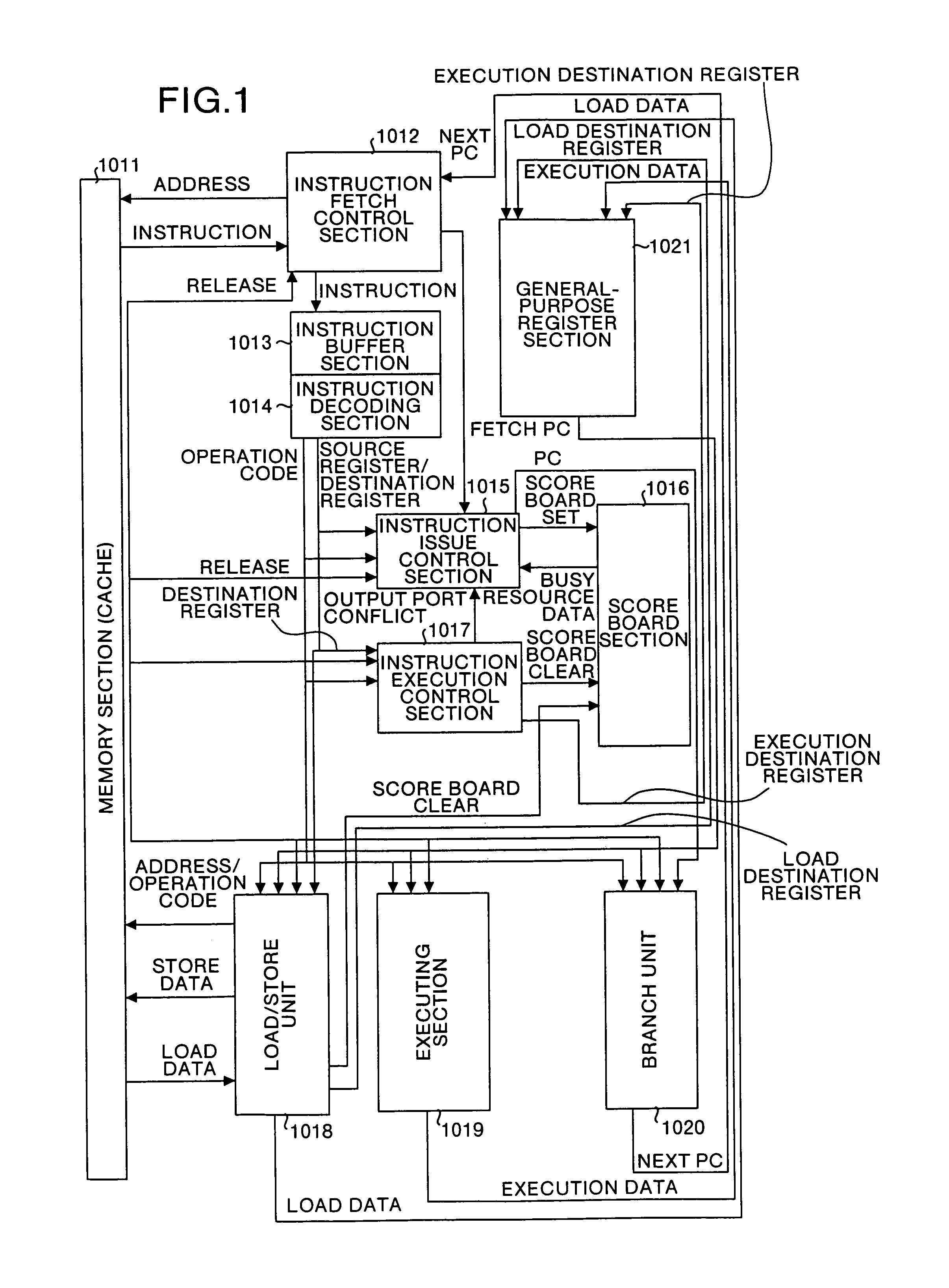

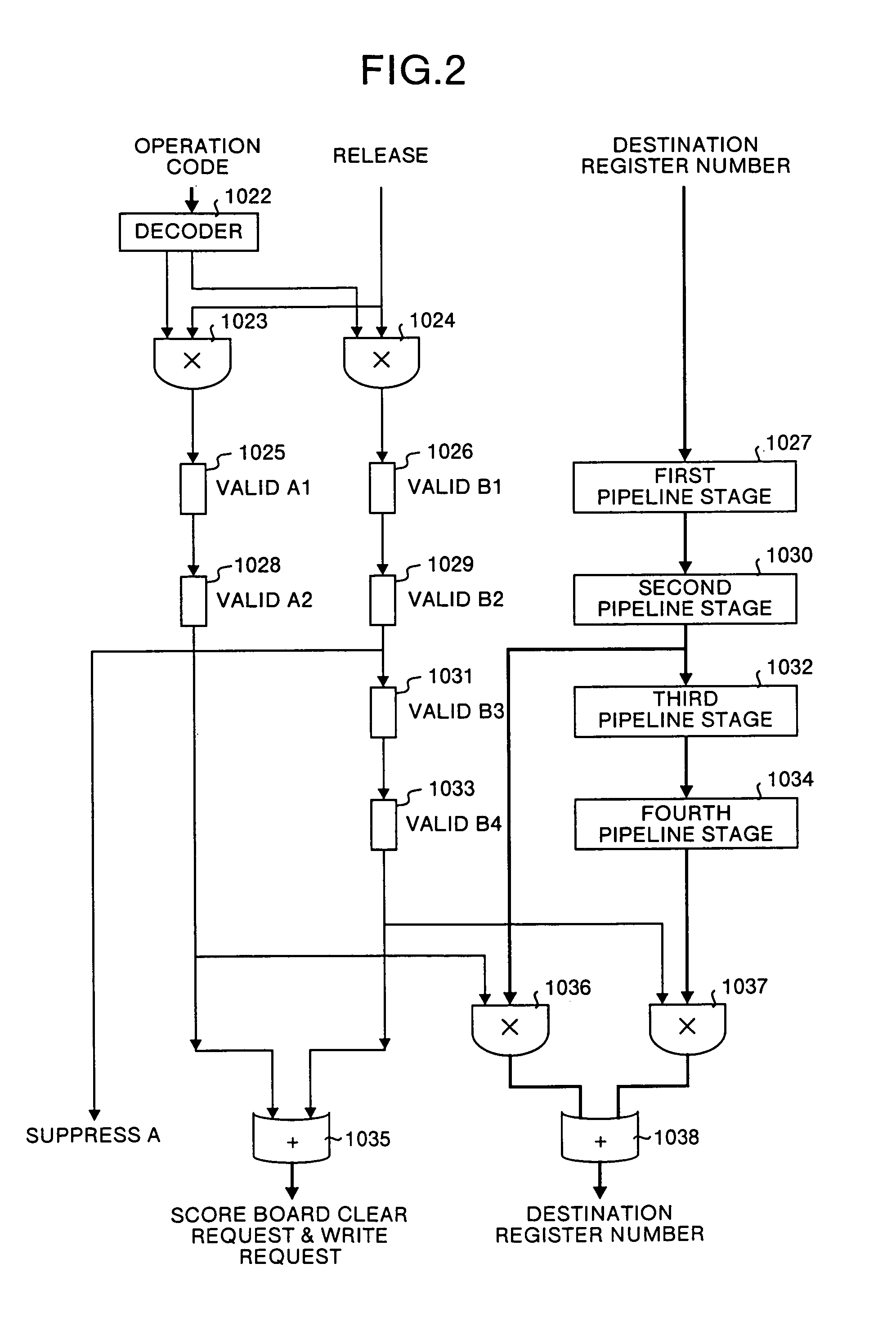

Information processing unit, and exception processing method for specific application-purpose operation instruction

InactiveUS7376820B2Easy to changeIncrease the number ofInterprogram communicationDigital computer detailsInformation processingMain processing unit

In the control section, an operation instruction not prescribing a functional specification, and a unit for processing the specific application-purpose operation instruction is provided within the processor core. The structure of this unit can be changed based on a flexible pipeline structure, and is separately designed for each application field. A register that prescribes a latency from when an instruction of the above unit is issued till when a result can be utilized is also provided in the processor core so as to prevent contention of an output port. Another register that prescribes a latency relating to a constraint of an interval of issuing an instruction of the above unit is also provided in the processor core so as to prevent contention of a resource with the preceding instructions.

Owner:FUJITSU LTD

Compliant chain guide with multiple joints

Owner:BORGWARNER INC

NTC/PTC heating pad

InactiveUS8383992B2Positive control of the temperature of the heating padControl of heat generationSedimentation separationHeating element shapesElectrical resistance and conductanceElectrical conductor

A controllable heating pad, having a heating conductor embedded in the heating pad, a sensing conductor embedded in the heating pad, a resistive material providing a distributed electrical path between the heating conductor and the sensing conductor, a first current sensor to sense a current in the heating conductor and a second current sensor to sense a current in the sensing conductor. A method of controlling a temperature of a heating pad, including the steps of: warming the heating pad to at least a first predetermined temperature by use of an adjustable on / off signal to the controllable switch, measuring currents through an NTC material or a combination of a PTC material and an NTC material; and maintaining a temperature of the heating pad to within a predetermined temperature range by use of the adjustable on / off signal to the controllable switch.

Owner:HELEN OF TROY LIMITED

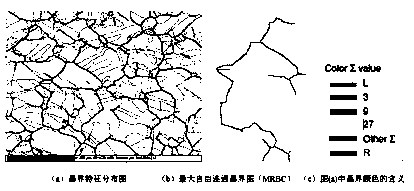

Preparation method of yttrium-based heavy-rare-earth copper-nickel alloy

The invention relates to the field of copper-nickel (CuNi) alloy corrosion resistance improvement using rare-earth modification and grain boundary engineering, in particular to a preparation method ofyttrium-based heavy-rare-earth copper-nickel alloy. The yttrium-based heavy-rare-earth copper-nickel alloy comprises, by mass percentage, 9-12% of Ni, 1.0-2.0% of Fe, 0.5-1.5% of Mn, less than 0.01%of S, less than 0.01% of P, less than 0.01% of C, 50-300ppm of Y, less than 0.1% of other impurities and the balance copper. The alloy is prepared by smelting the raw materials into casting blanks under vacuum gas protection and subjecting the casting blanks to forging, hot rolling, primary cold rolling, intermediate annealing, secondary cold rolling and finished-product annealing. The high-corrosion-resistant CuNi alloy structurally comprises an alpha-Cu matrix and yttrium-based rare-earth compound inclusion, the grain size (not considering twin crystals) of the matrix is 40-60 micrometers, the low-energy coincidence site lattice grain boundary proportion of the matrix is larger than 75%, and the ratio of maximum free grain boundary length to free grain boundary total length is smaller than 0.3. The CuNi alloy is low in preparation cost, applicable to board and band products, excellent in corrosion resistance and especially applicable to service environments high in seawater corrosionresistance requirements, and the preparation method of the CuNi alloy is simple in process and easy to operate.

Owner:JIANGXI UNIV OF SCI & TECH

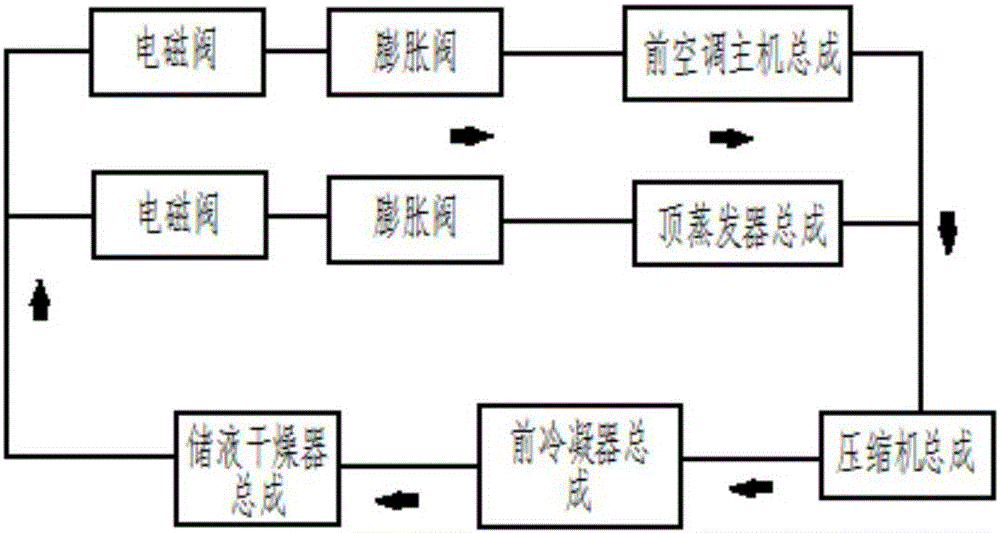

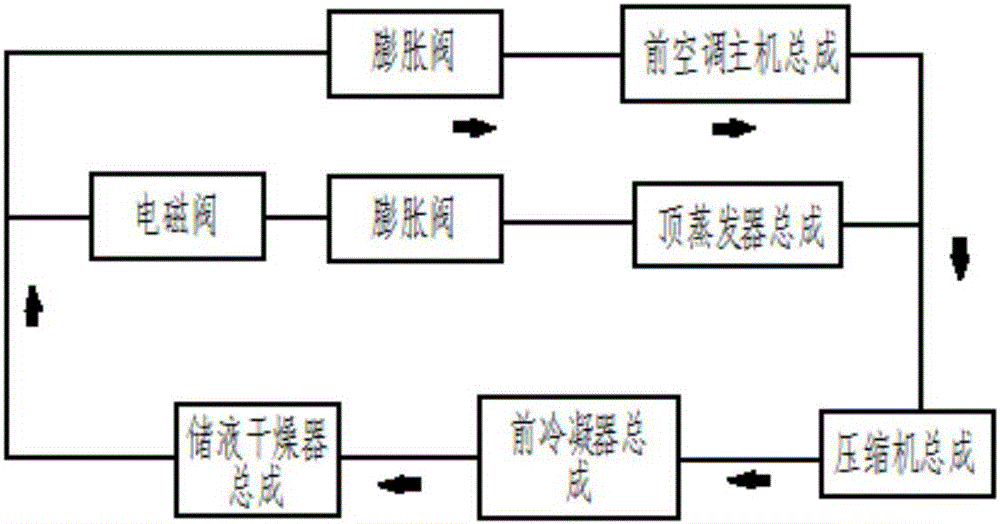

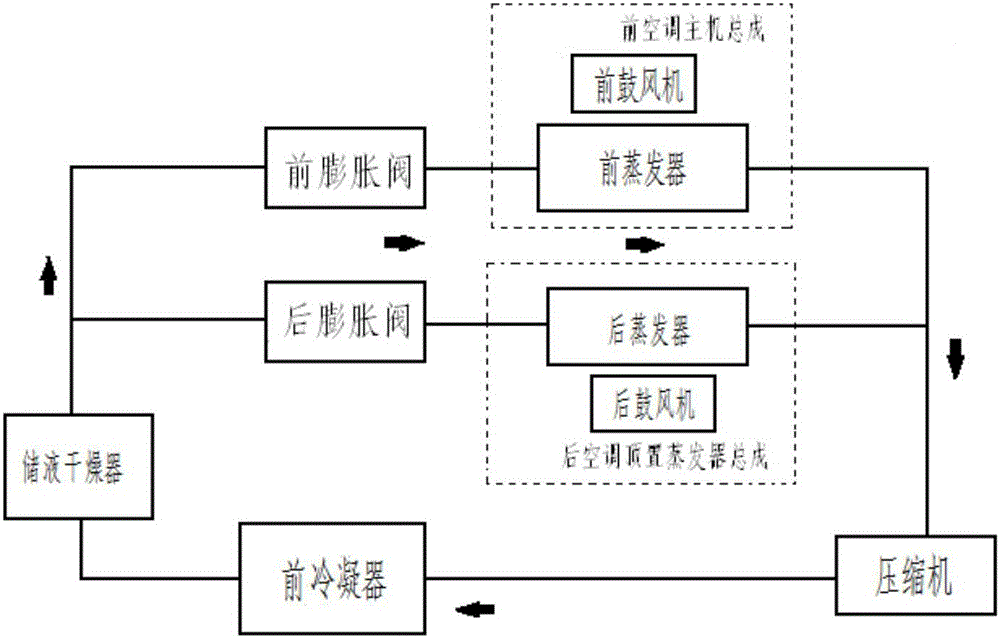

Automobile double-air-conditioner control system and method

ActiveCN106004327ALow cost designAir-treating devicesVehicle heating/cooling devicesControl systemRefrigerant

The invention relates to the technical field of automobile air conditioners, in particular to an automobile double-air-conditioner control system and method. The automobile double-air-conditioner control system comprises a compressor, a front air conditioner host assembly, a rear air conditioner top evaporator assembly, a front condenser, a receiver-drier, a front expansion valve and a rear expansion valve. A refrigerating agent is discharged into the front condenser from the compressor, is condensed through the front condenser, then flows to the receiver-drier, is filtered and dried through the receiver-drier and then branches into a first refrigerating agent entering the front expansion valve and a second refrigerating agent entering the rear expansion valve. The first refrigerating agent is throttled and depressurized through the front expansion valve, then enters the front air conditioner host assembly and finally returns back to the compressor. The second refrigerating agent is throttled and depressurized through the rear expansion valve, then enters the rear air conditioner top evaporator assembly and finally returns back to the compressor. By the adoption of the system and method, low-cost design of an air conditioner system is achieved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

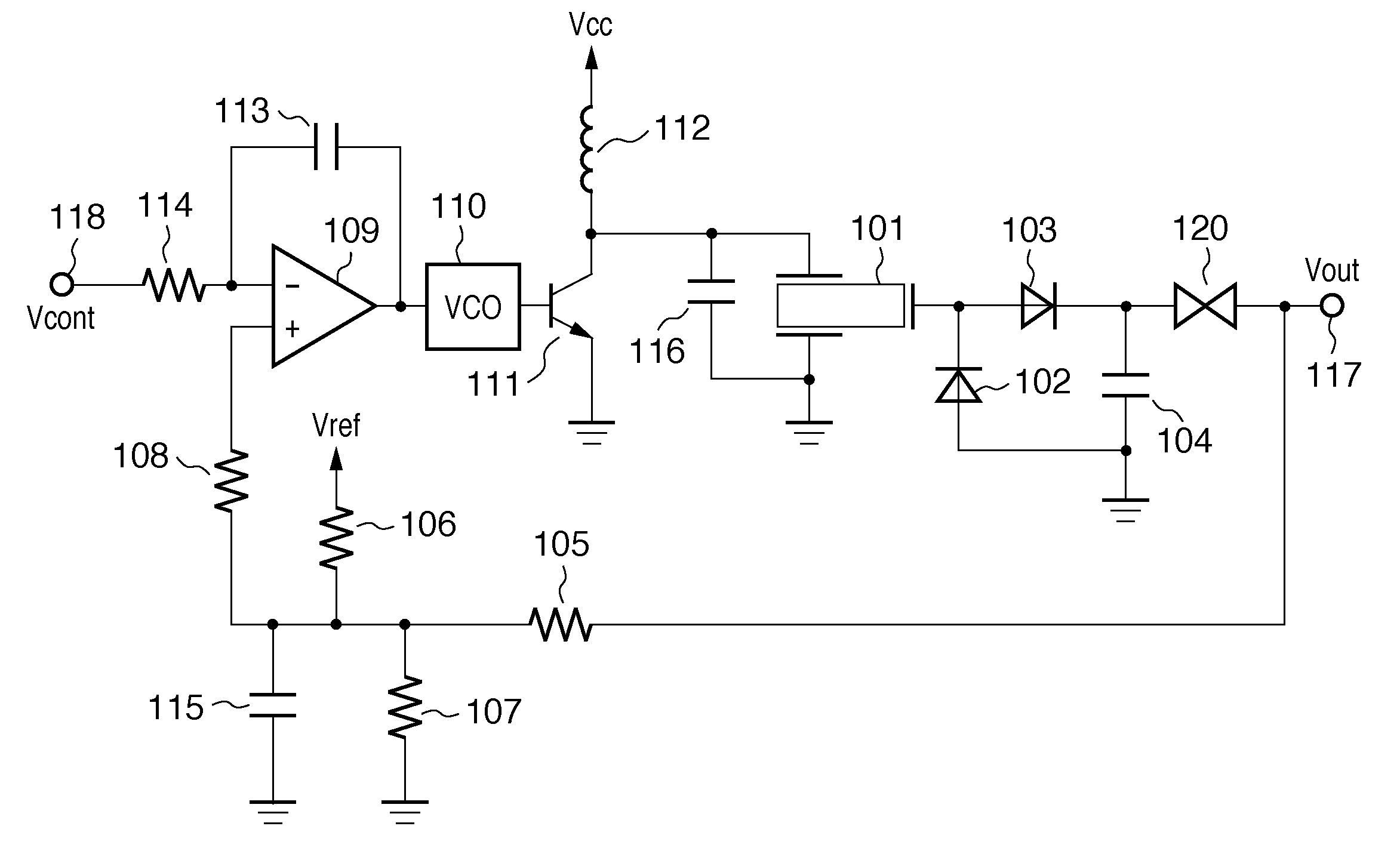

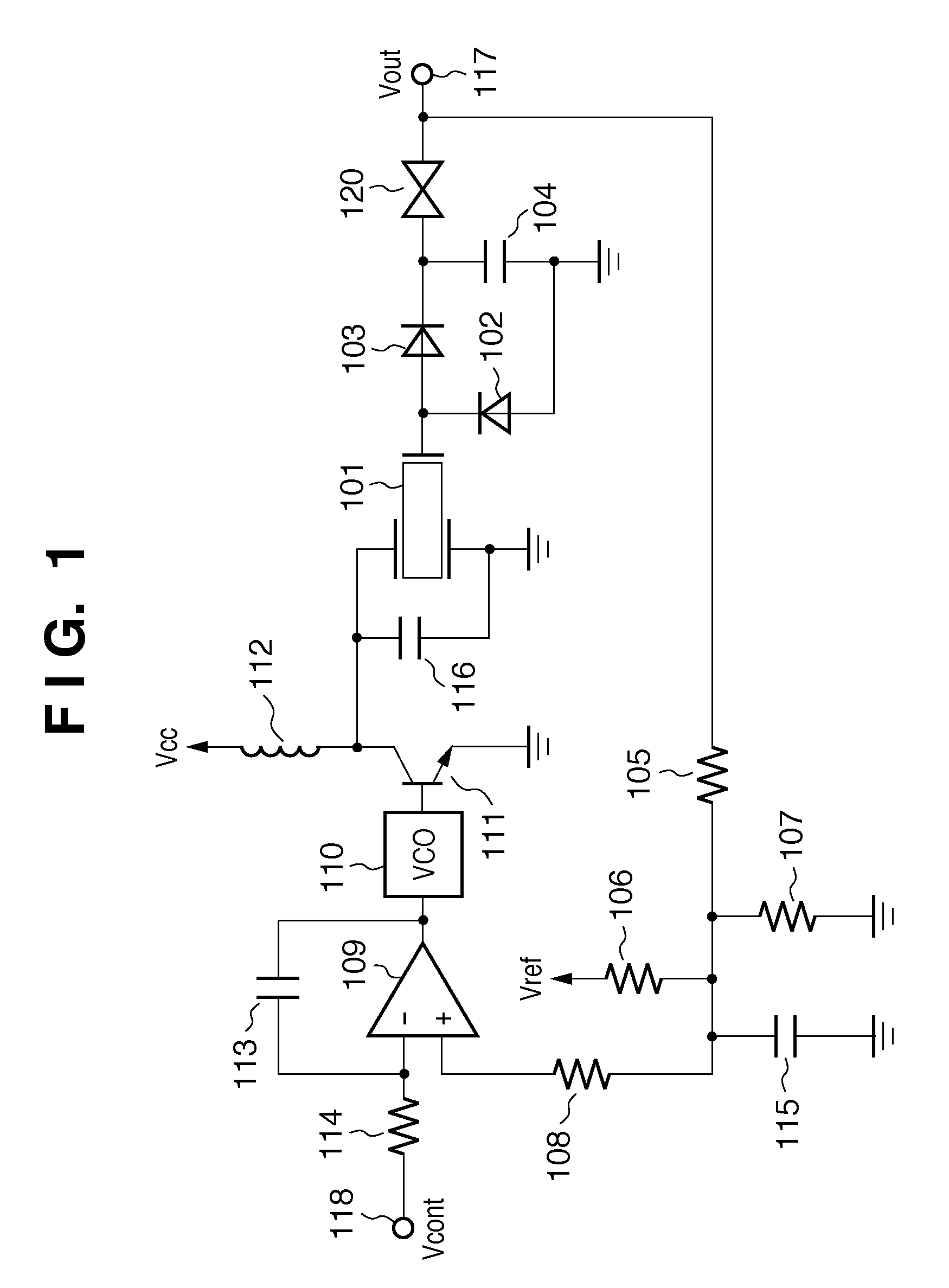

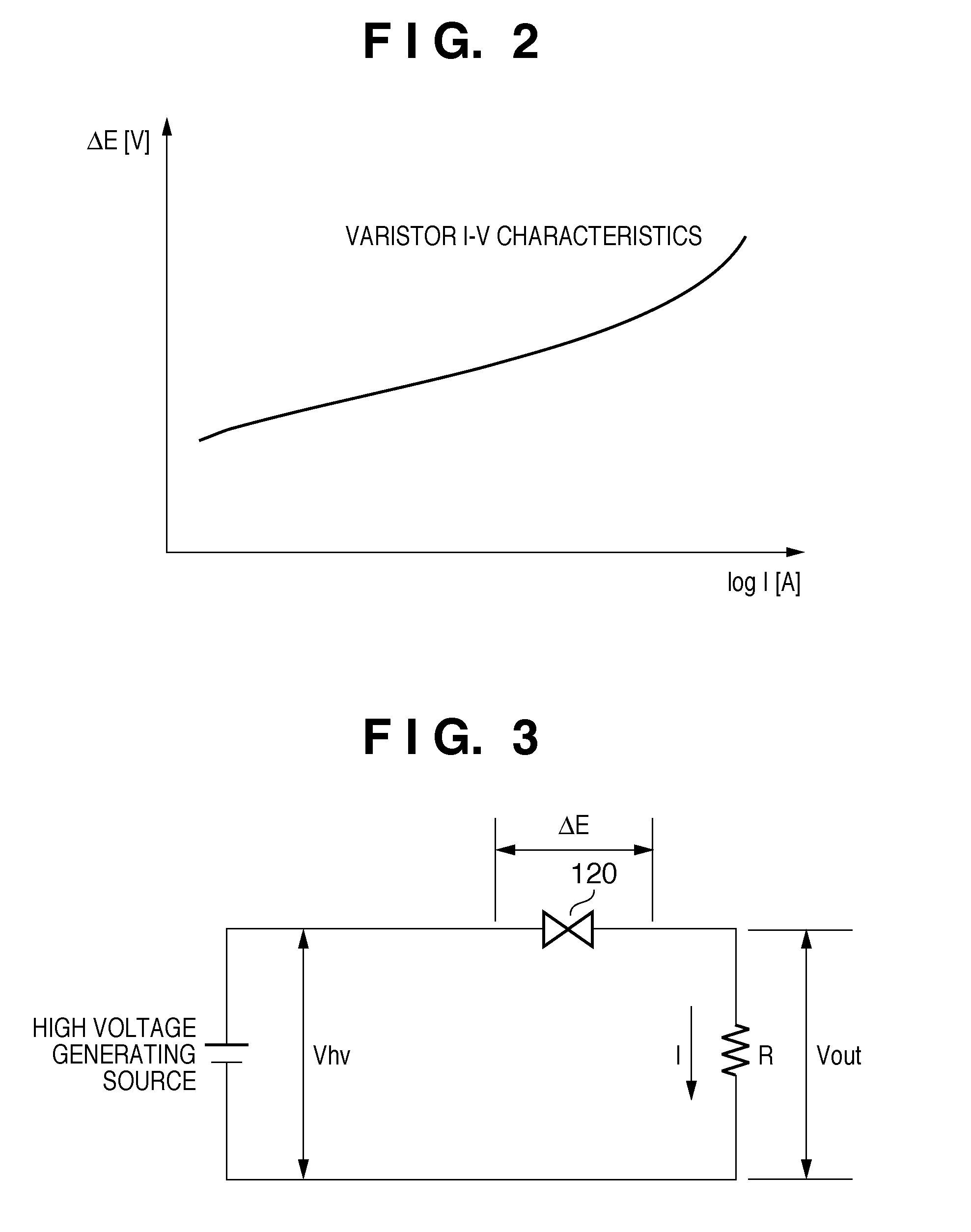

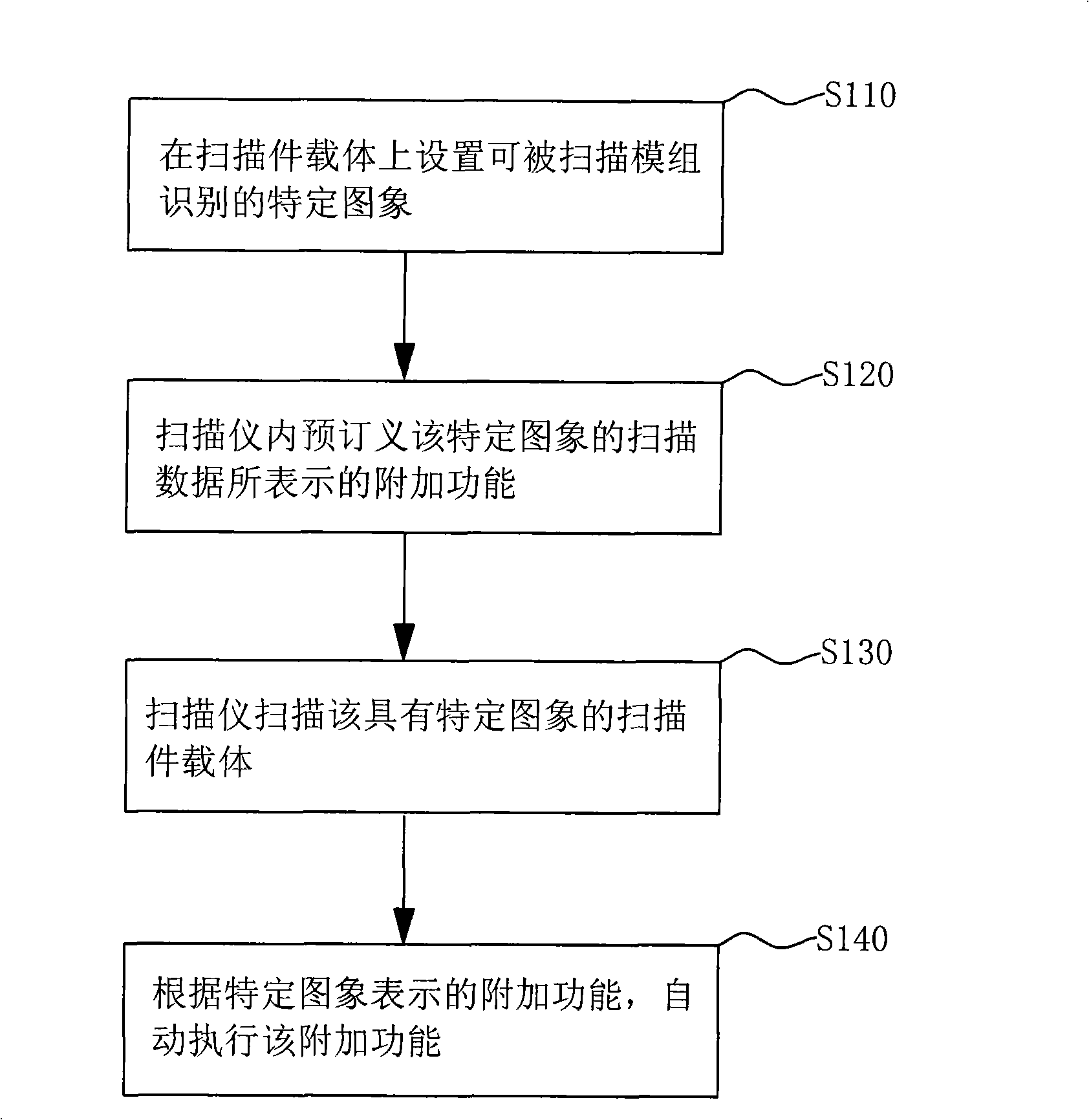

High-voltage power supply apparatus and image forming apparatus employing same

InactiveUS20080297129A1Reduce voltageLow cost designElectric variable regulationVoltage rangeFrequency oscillation

The voltage at a spurious frequency is decreased while maintaining as much as possible the voltage at a resonance frequency of a piezoelectric transformer, thus controlling a wide voltage range with a comparatively low cost configuration. A high-voltage power supply apparatus includes a piezoelectric transformer that outputs a highest voltage at a predetermined resonance frequency, and a generating unit that generates a signal that oscillates at a drive frequency that drives the piezoelectric transformer, throughout a frequency range that includes the resonance frequency. Furthermore, the high-voltage power supply apparatus includes an output terminal connected to the piezoelectric transformer, and a constant-voltage element inserted in a path that couples the piezoelectric transformer and the output terminal.

Owner:CANON KK

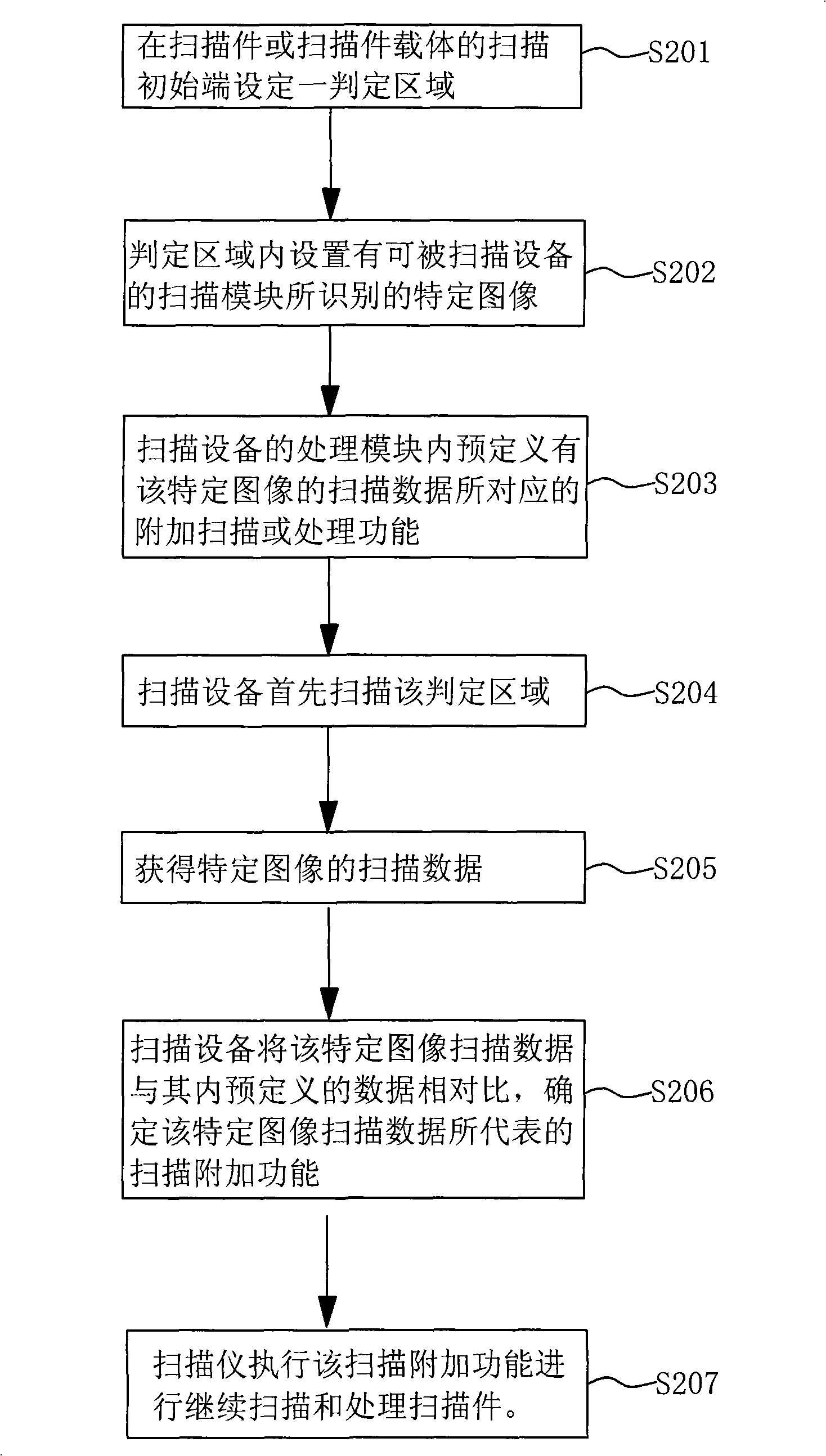

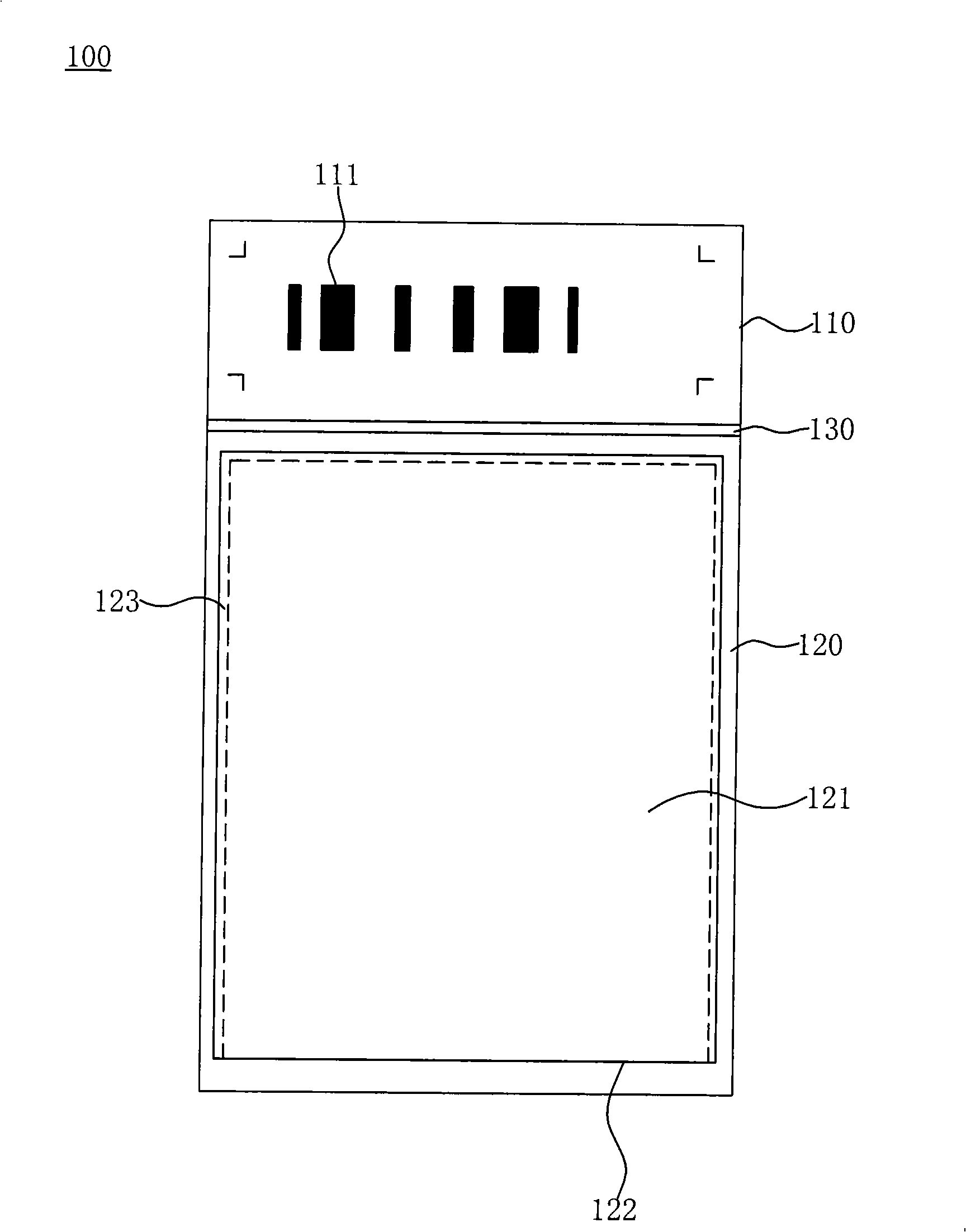

Scanning method for automatically performing scanning extended function and its auxiliary device

InactiveCN101345806ALow cost designVersatileSensing record carriersPictoral communicationBusiness cardImaging processing

Disclosed is a scanning method capable of automatically performing the scanning additional function and auxiliary device thereof. The method includes: setting a specific image that can be identified by a scanning module group of the scanning device on a scanning piece or a scanning piece carrier, and predefining additional functions represented by the specific image in the processing module of the scanning device; when the scanning device scans the scanning piece or the scanning piece carrier of the specific image, the scanner can automatically perform the predefined affixation scanning or processing function according to the scanning data of the scanning operation. The invention realizes the a plurality of multifunction of the scanning operation and the low fabricating cost design of the scanner, which compromises that the scanner is in favor of small portable design and realizes a plurality of affixation scanning and image processing functions. The present invention can be applied in various portable scanners, specifically suitable for function extension of portable small scanners for scanning photographs and business cards, thereby realizing the display and connection of the scanner with direct display device or storage apparatus.

Owner:QISDA SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com