System including counter-rotating propellers driven by an epicyclic train ensuring a balanced couple distribution between the two propellers

一种对转螺旋桨、行星齿轮的技术,应用在螺旋桨、发动机元件、发动机功能等方向,能够解决涡轮机副作用、减速比率螺旋桨系统总质量增加、不利于增加涡轮机声级等问题,达到减小比率减小、小尺寸的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

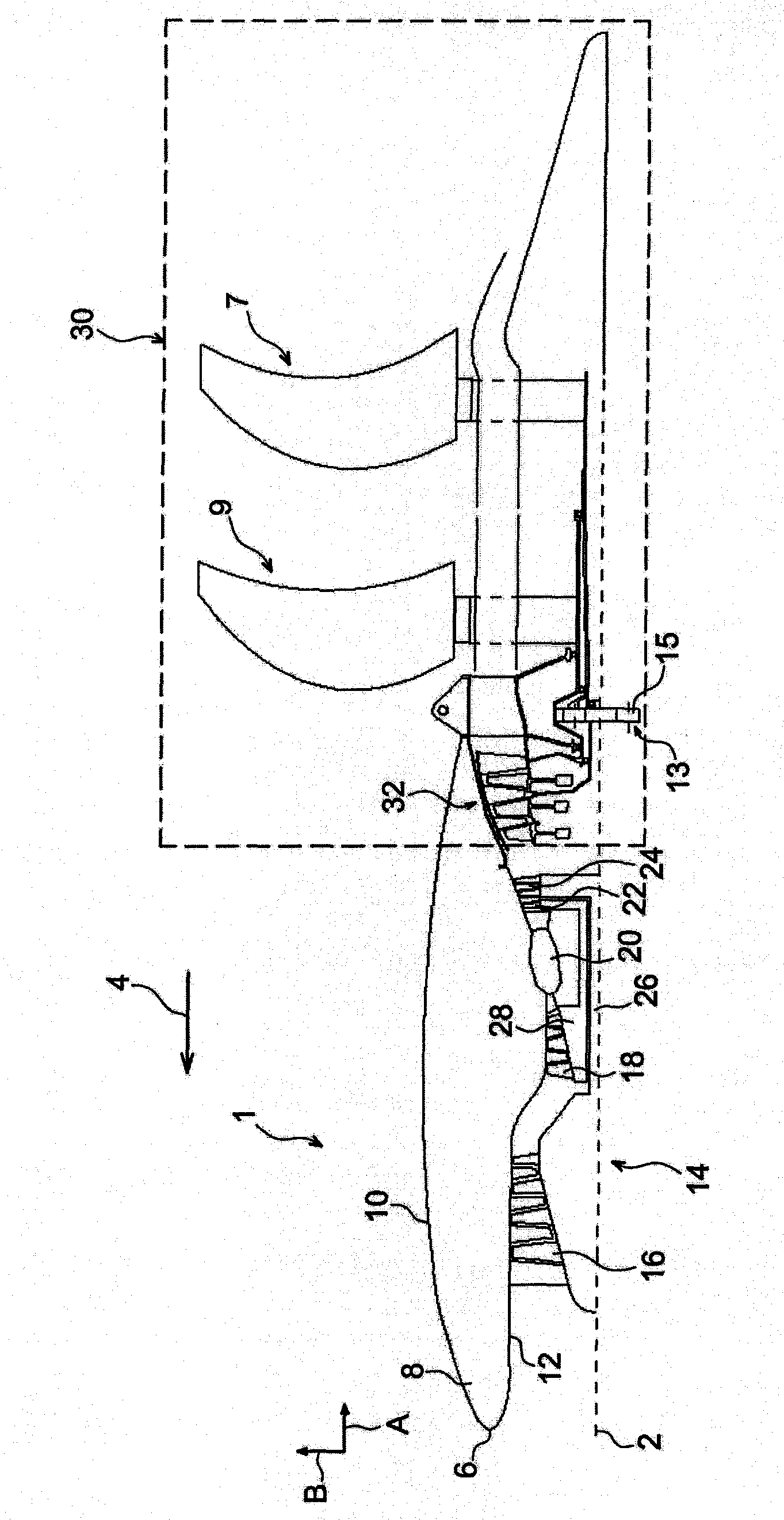

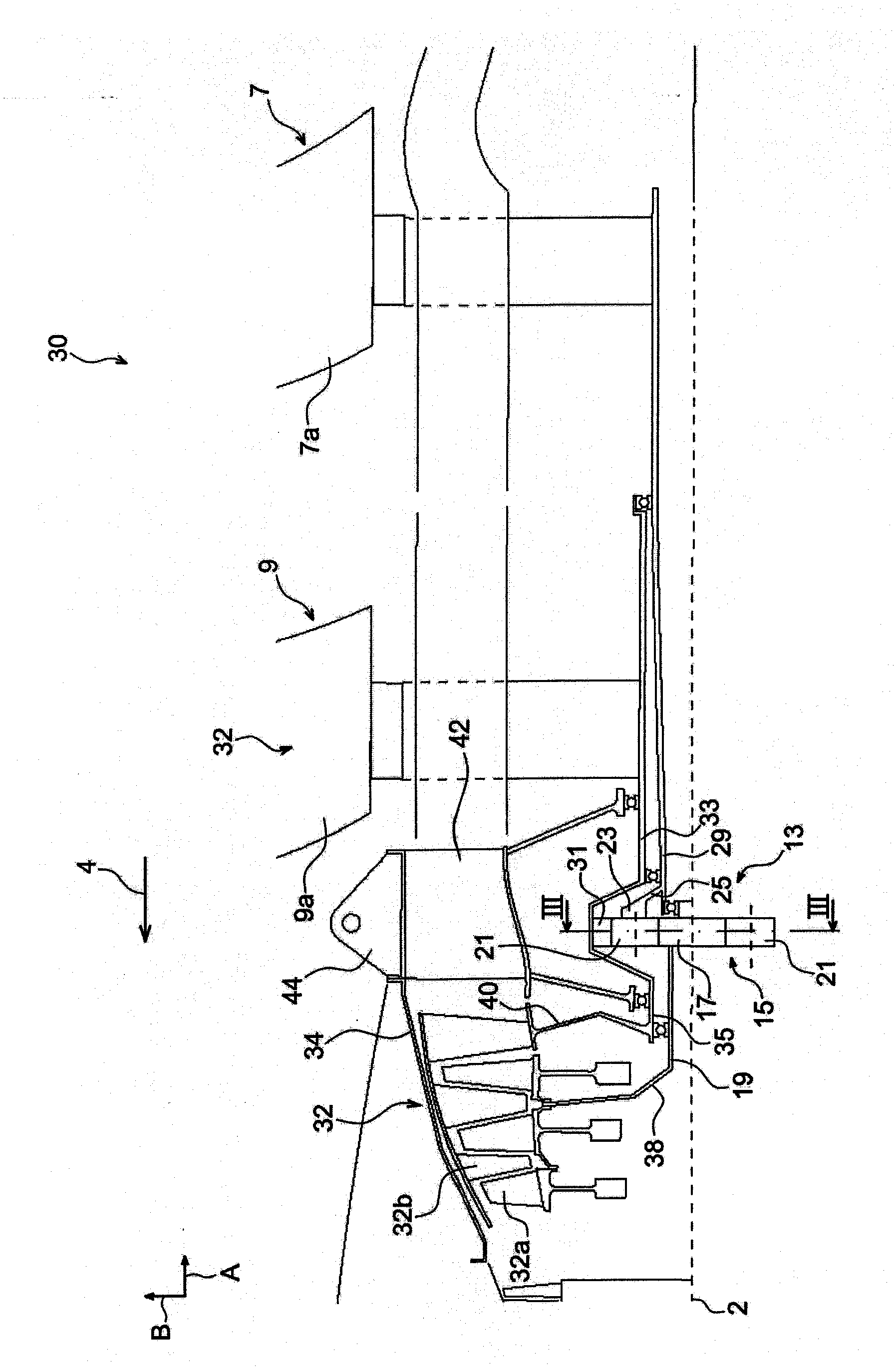

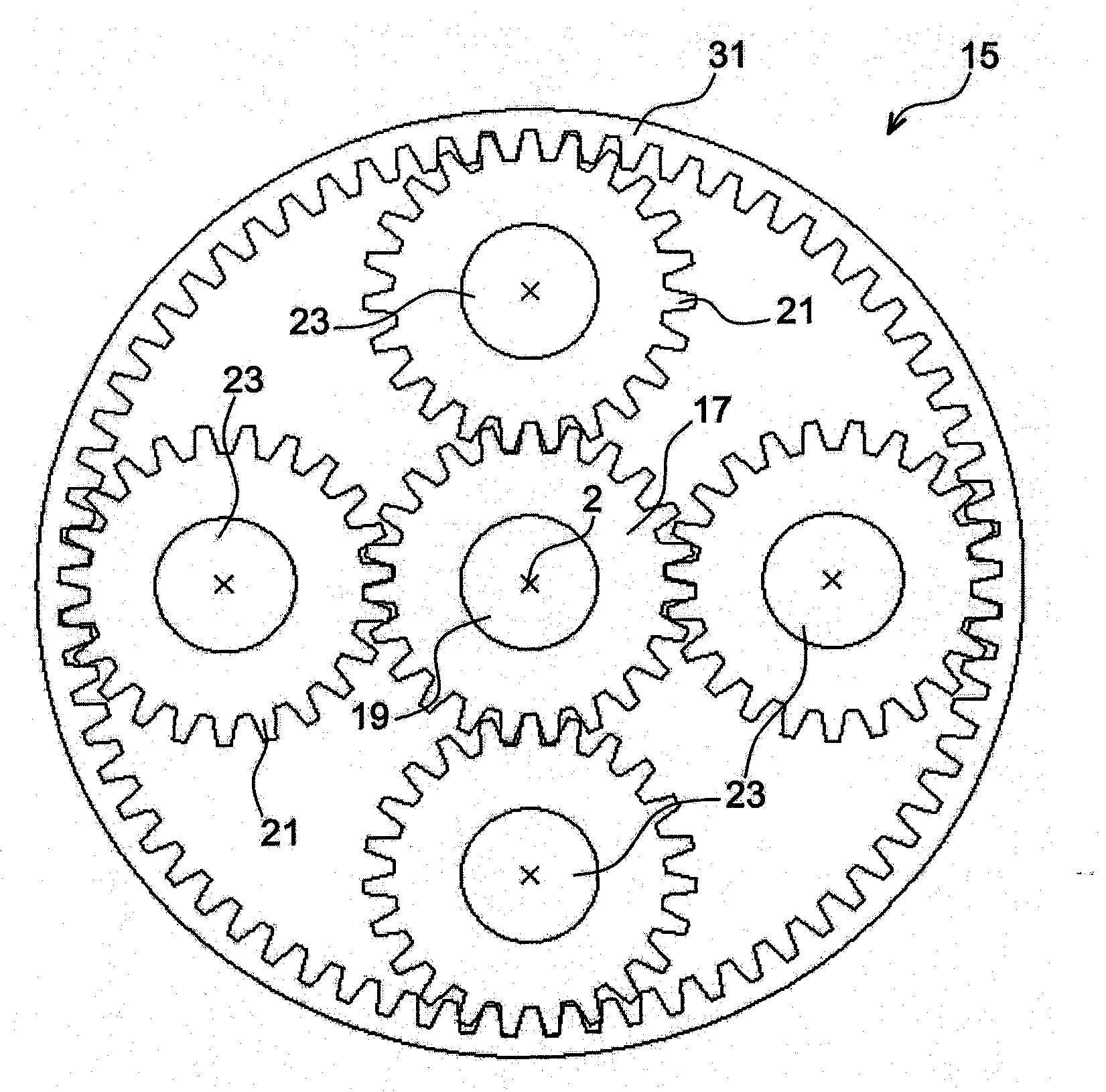

[0033] refer to figure 1 , an "open rotor" type turbine 1 according to a preferred embodiment of the present invention can be seen.

[0034] In the figures, direction A refers to the longitudinal or axial direction, parallel to the longitudinal axis 2 of the turbine. For this part, direction B refers to the radial direction of the turbine. Furthermore, the arrow 4 shows the direction of movement of the aircraft under the impetus of the turbine 1 , wherein this direction of movement is opposite to the general flow direction of the gas in the turbine. The terms "front end", "upstream", "rear end", "downstream" used in the rest of the description should be considered relative to said direction of movement 4 .

[0035] In the front part, the turbine has an air intake 6 which is connected to the rear end via a nacelle 8 . Here, the latter comprehensively includes an outer coating 10 and an inner coating 12 , the two latter being centered on the axis 2 and offset from each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com