Closed multifunctional reducing wrapper

A multifunctional and closed technology, applied in the field of rolling aid equipment, can solve the problems that the rolling aid cannot realize the 360° closure of the tape wrap angle, the appearance quality of the coil is difficult to guarantee, and the tension adjustment of the rolling aid belt is difficult, etc., to achieve the goal of the equipment The safety evaluation index is high, the effect of realizing automatic flow operation and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

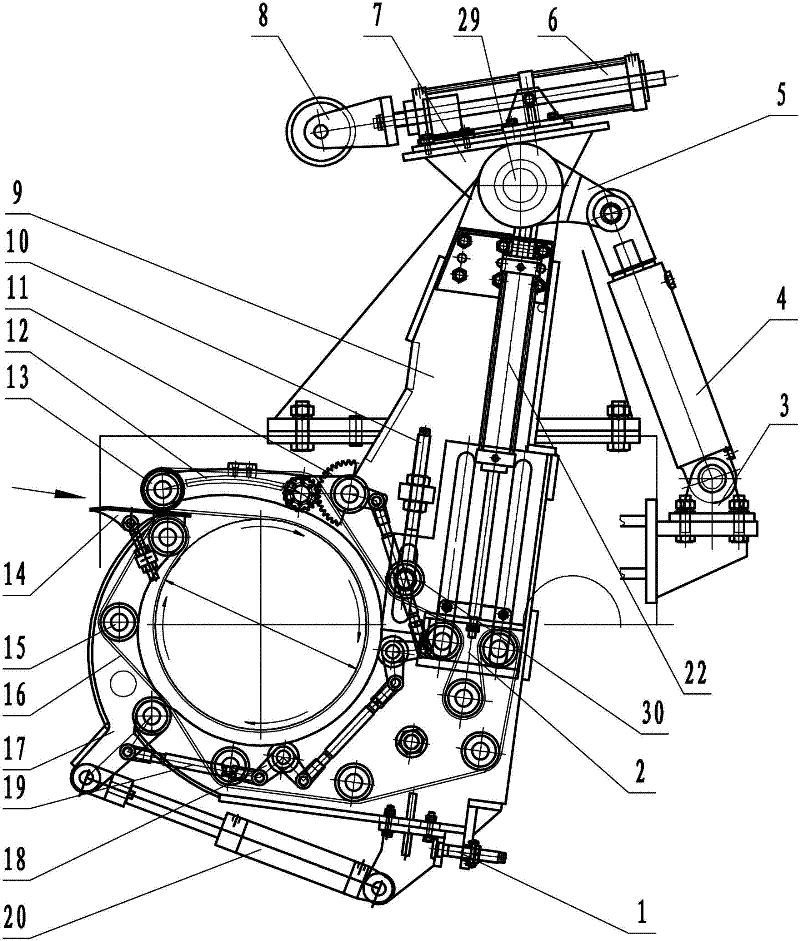

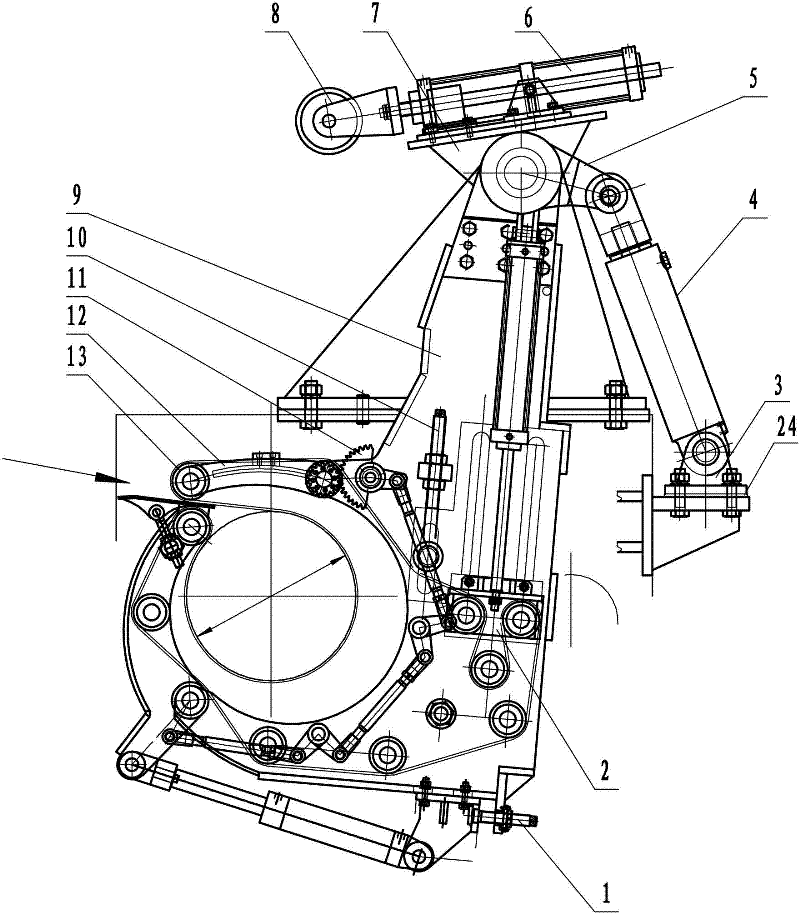

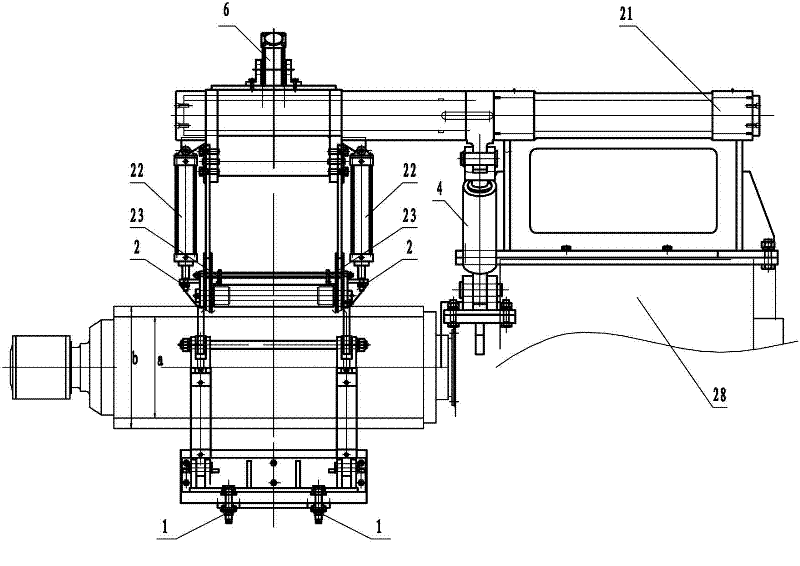

[0031] Such as figure 1 — Figure 4 Among them, a closed multifunctional variable-diameter winding aid includes a support seat 21. The support seat 21 is installed on the top of the chassis 28, does not occupy the surface area of the workshop, is beneficial to the process layout, realizes automatic flow operation, greatly improves labor productivity, and saves factory space.

[0032] The big crotch 9 is connected with the supporting seat 21 through the rotating shaft 29, the big crotch 9 is provided with an upper pressing arm 12 and a lower pressing arm 17, the lower pressing arm 17 is connected with the pressing cylinder 20, and the lower pressing arm 17 is also passed through the amplification mechanism 11 It is connected with the upper pressing arm 12; viewed from the projection of the horizontal plane, the rotating shaft 29 is located in the middle of the working station and the standby station. The roll-assisting device returns from the working station to the standby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com