Anti-icing method of carbon crystal and wind power generator anti-icing system employing method

A carbon crystal and anti-icing technology, which is applied in the direction of wind turbine components, wind engines, wind engine control, etc., can solve the problems of reducing blade structural force, low reliability, energy waste, etc., and achieves strong thermal aging resistance, High electrothermal conversion efficiency and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A specific implementation of a carbon crystal anti-icing method and a wind power generator anti-icing system using the method will be described in detail below in conjunction with the accompanying drawings.

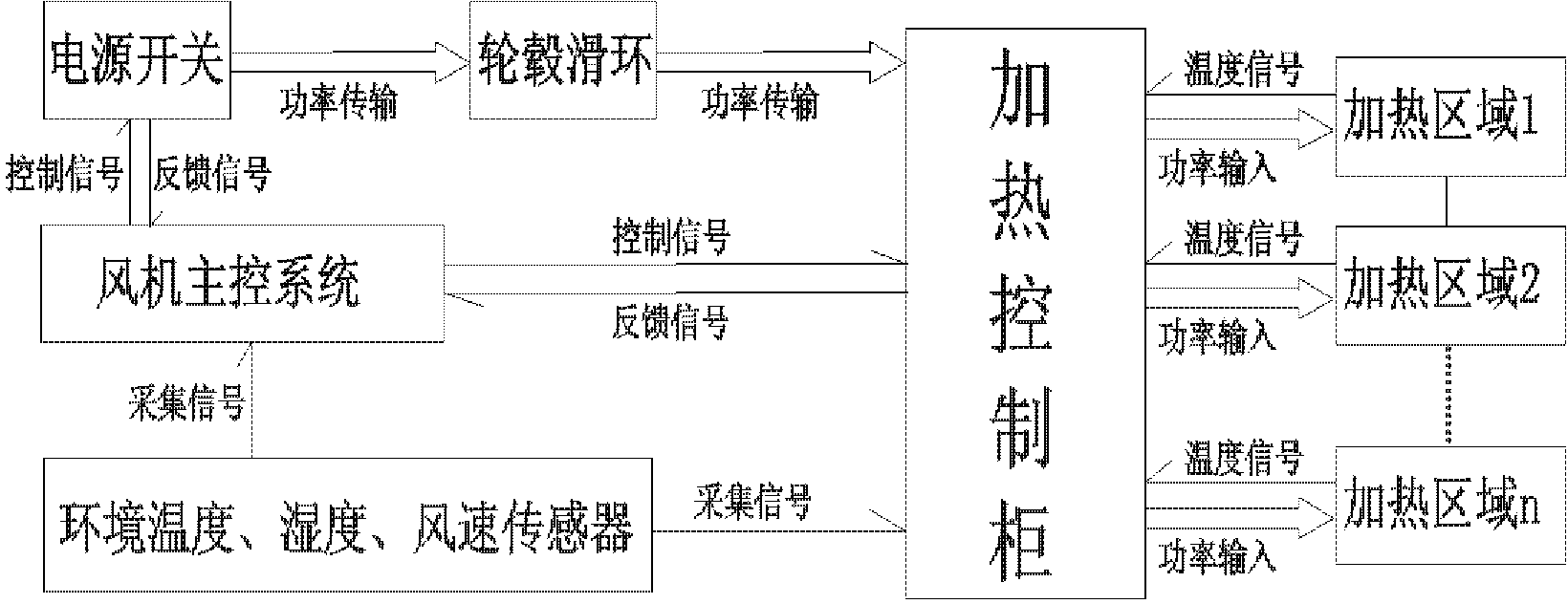

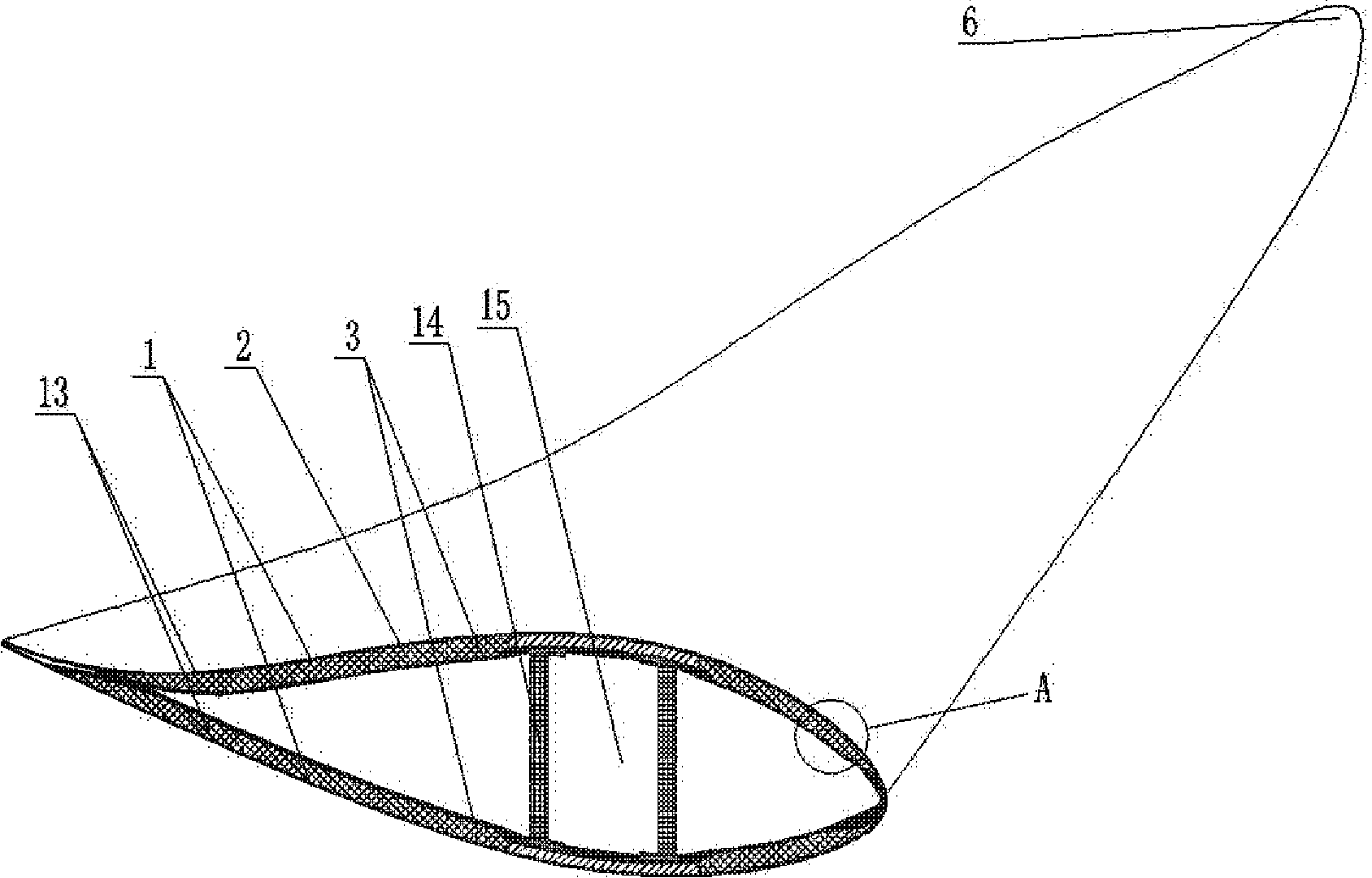

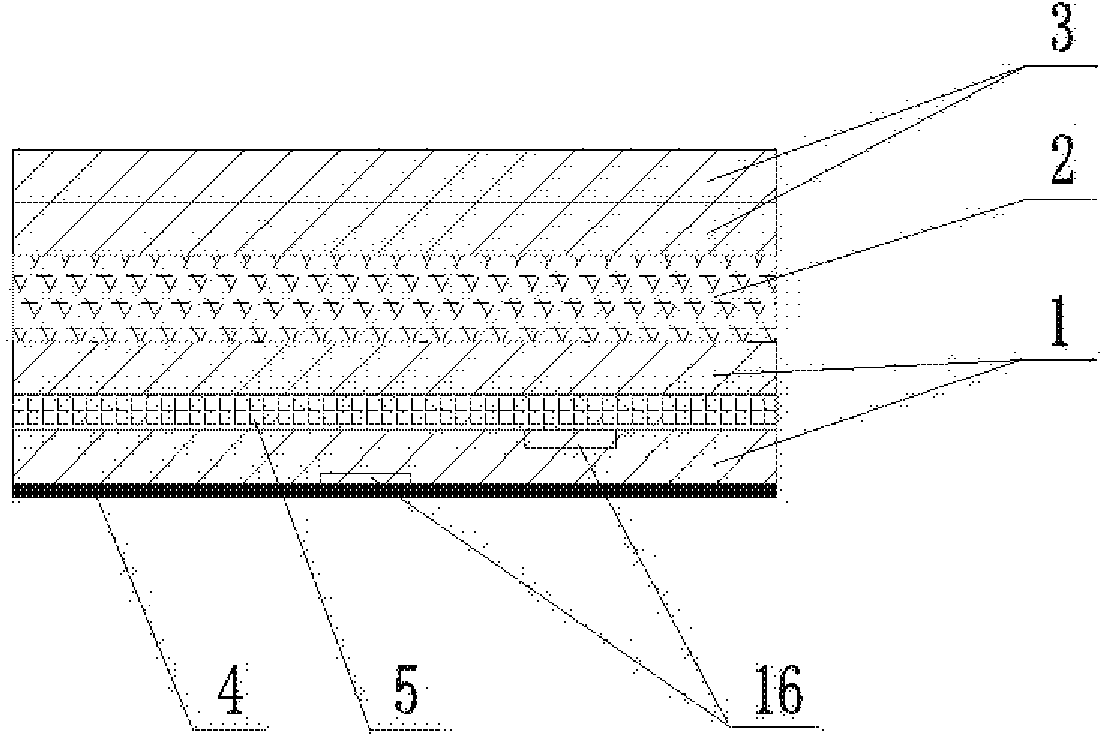

[0026] like Figures 1 to 7As shown, a carbon crystal anti-icing method is to print nano-scale conductive carbon crystal 13 on the carrier surface 12, and make a thinner one with two copper strips or surface silver-plated electrodes through solidification and hot pressing process. The carbon crystal electric heating plate of 10 adopts the carbon crystal electric heating plate to be set as a layer of the blade composition layer as the heating layer 5. During the manufacturing process of the fan blade, carbon crystal electric heating plates of different powers are set according to the different linear speeds of the different radius positions of the fan blade during operation. Crystal electric heating plate, the heating layer 5 is set as the surface layer or subsurfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com