Method for preparing perfluor liquid injection type transparent flexible anti-icing thin film through electrostatic spinning

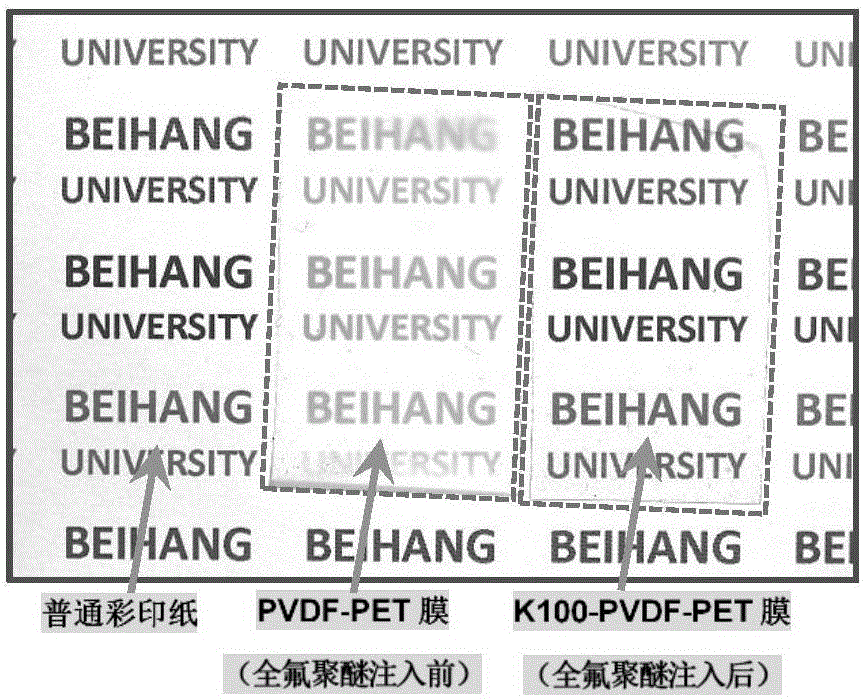

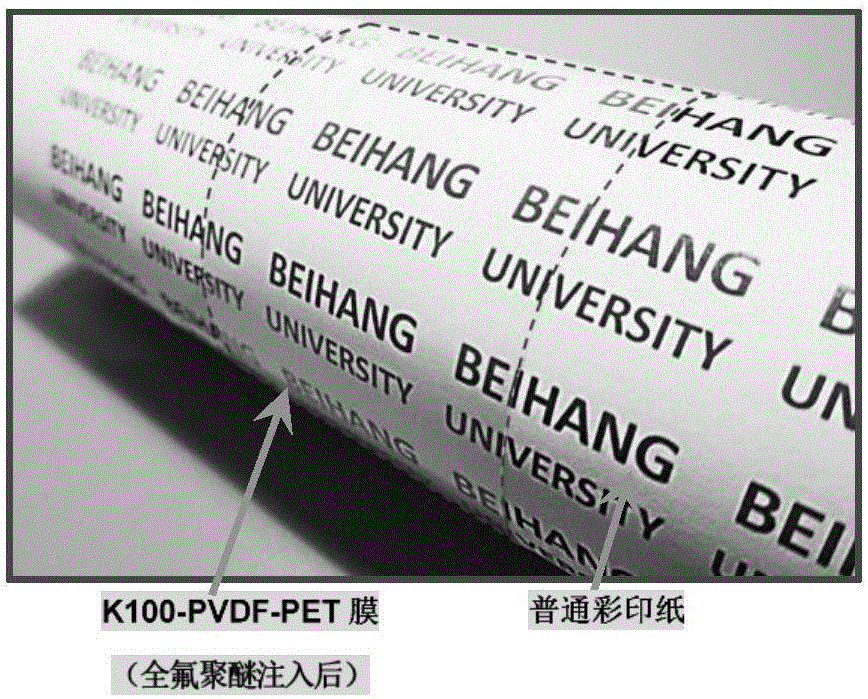

A technology of electrospinning and liquid injection, applied in filament/thread forming, textile and papermaking, non-woven fabrics, etc., can solve the problem of not being able to have high transparency and flexibility at the same time, and achieve good anti-icing effect and good anti-ice effect. Ice effect, high transparency and soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1: The preparation of K100-PVDF-PET transparent and flexible anti-icing film, the specific steps are:

[0061] Step 1: preparing electrospinning precursor solution;

[0062] Weigh 15g of PVDF powder, vacuum dry at 50°C for 24h, dissolve the dried PVDF powder in 85g of DMF, heat, and stir at 80°C for 8h to obtain the electrospinning precursor solution, let stand until the bubbles in the electrospinning precursor solution completely disappear .

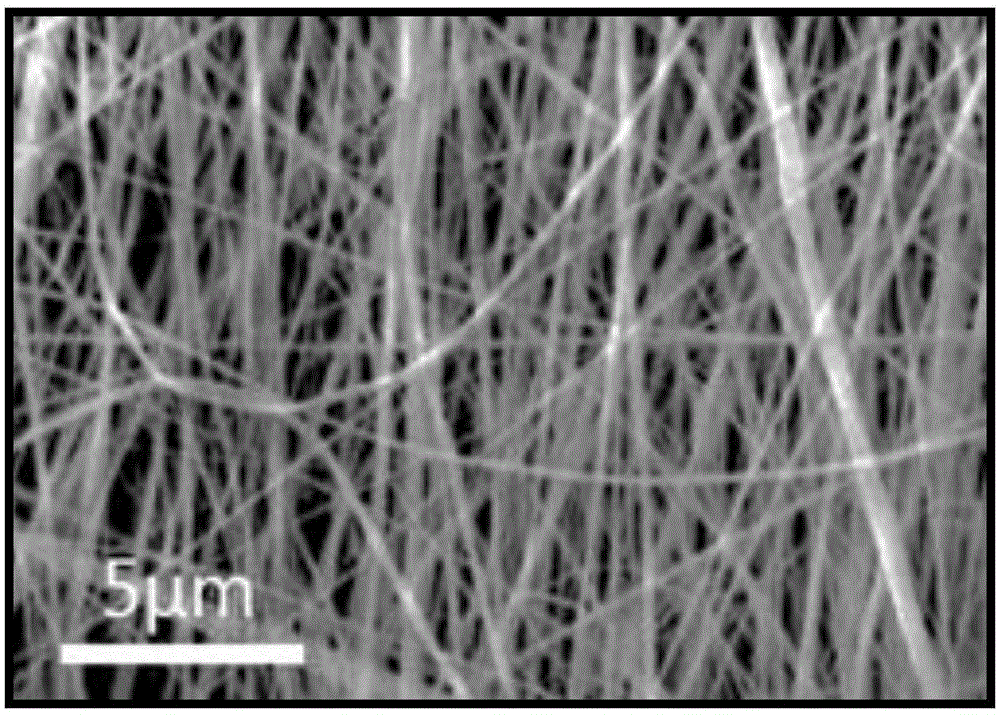

[0063] Step 2: Electrospinning to prepare an electrospun membrane;

[0064] Select aluminum foil as the receiving plate, put the electrospinning precursor in step 1 into a 20mL syringe, and place the syringe on a micro-syringe pump, and control the flow rate of the electrospinning precursor to 2.0mL / h. The inner diameter of the electrospinning needle is 0.2mm, the voltage applied by the electrospinning equipment to the electrospinning precursor solution is 25kV, the vertical distance from the spinneret to the receivin...

Embodiment 2

[0073] Example 2: The preparation of PO-PVDF-BOPP transparent and flexible anti-icing film, the specific steps are:

[0074] Step 1: preparing electrospinning precursor solution;

[0075] Weigh 15g of PVDF powder, vacuum dry at 50°C for 24h, dissolve the dried PVDF powder in 85g of DMF, heat, and stir at 80°C for 8h to obtain the electrospinning precursor solution, let stand until the bubbles in the electrospinning precursor solution completely disappear .

[0076] Step 2: Electrospinning to prepare an electrospun membrane;

[0077] Select aluminum foil as the receiving plate, put the electrospinning precursor in step 1 into a 20mL syringe, and place the syringe on a micro-syringe pump, and control the flow rate of the electrospinning precursor to 2.0mL / h. The inner diameter of the electrospinning needle is 0.2mm, the voltage applied by the electrospinning equipment to the electrospinning precursor solution is 25kV, the vertical distance from the spinneret to the receiving...

Embodiment 3

[0083] Example 3: The preparation of K100-PH-PET transparent and flexible anti-icing film, the specific steps are:

[0084] Step 1: Configure the electrospinning precursor;

[0085] Weigh 10g of PVDF-HFP copolymer, after vacuum drying at 50°C for 24h, dissolve the dried PVDF-HFP copolymer in 90g of dimethylacetamide and acetone mixture, and stir at 80°C for 8h to obtain the electrospinning precursor , stand still until the bubbles in the electrospinning precursor solution completely disappear.

[0086] Step 2: Electrospinning to prepare an electrospun membrane;

[0087] Select aluminum foil as the receiving plate, put the electrospinning precursor in step 1 into a 20mL syringe, and place the syringe on a micro-syringe pump, and control the flow rate of the electrospinning precursor to 1.0mL / h. The inner diameter of the electrospinning needle is 0.8 mm, the voltage applied by the electrospinning equipment to the electrospinning precursor solution is 20 kV, the vertical dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com