Electric lifting rod

A lifting rod and electric technology, applied in the field of lifting rods, can solve the problems of poor reliability and safety, limited lifting height, easy breakage of wire ropes, etc., and achieve reliable work, short lifting time and good anti-icing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

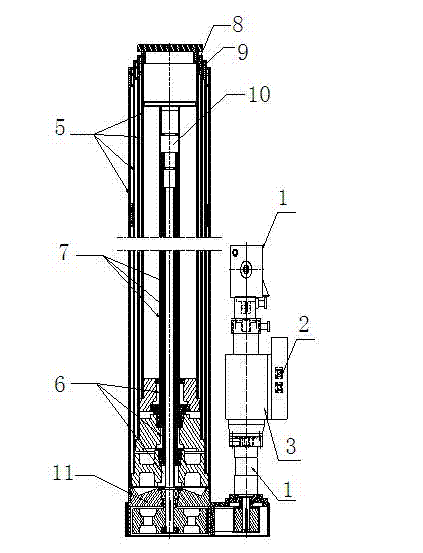

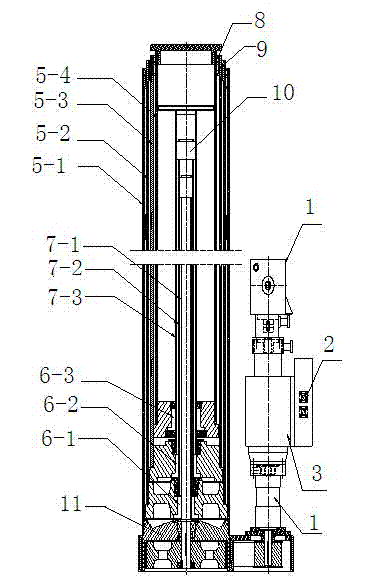

[0017] Example 1: Such as figure 1 A kind of electric elevating rod shown, comprises driving device and lifting device, and driving device comprises driving motor 3, speed reducer 4 and hand box 1, and lifting device comprises base 11, casing 5, transmission structure, casing 5 and transmission The structures are all connected to the base 11; the transmission structure includes a screw rod 7 and a screw nut 6, and the lifting device is a joint transmission structure through n sleeves, n-1 screw rods and n-1 screw nuts; the screw rod 7 It is fixedly connected with the screw nut 6, the screw nut 6 is fixedly connected with the base 11, the base 11 is fixedly connected with the bushing 5, different screw rods are connected through the transmission of the key 10, and different bushings are slidingly connected through the self-lubricating bearing 8. The unique self-lubricating bearing can reduce frictional resistance.

Embodiment 2

[0018] Example 2: Such as figure 1 As shown, the sleeve pipe of the present invention is a square tube with good guiding performance, good bending resistance and twist resistance performance of the rod body; Dustproof and other sealing functions; the upper end of the casing is provided with a limit block, which acts as a mechanical safety limit; the screw and the screw nut are rolling helical pairs of ball screws, which have high transmission efficiency, but are not self-locking. Brake motor 3 It has a safety locking function; the rise and fall of the lifting rod is realized by controlling the positive and negative rotation of the motor, and the upper and lower limit of the lifting rod is realized by an analog stroke device.

Embodiment 3

[0019] Example 3: As a further improvement of the present invention, the driving motor is a power-off brake motor 3, and the control switch adopted by the driving device is an analog travel limit switch. It can ensure the safe and self-locking work of lifting at any height, and ensure the safety of the limit position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com