Two-component waterborne wear-resisting and low-ice-adhesion anti-icing coating and coating layer, and preparation methods and applications thereof

An anti-icing, two-component technology, applied in coatings, epoxy resin coatings, chemical instruments and methods, etc., can solve the problems of volatilization, large pollution, loss, etc., and achieve simple preparation and construction processes and simple preparation processes , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

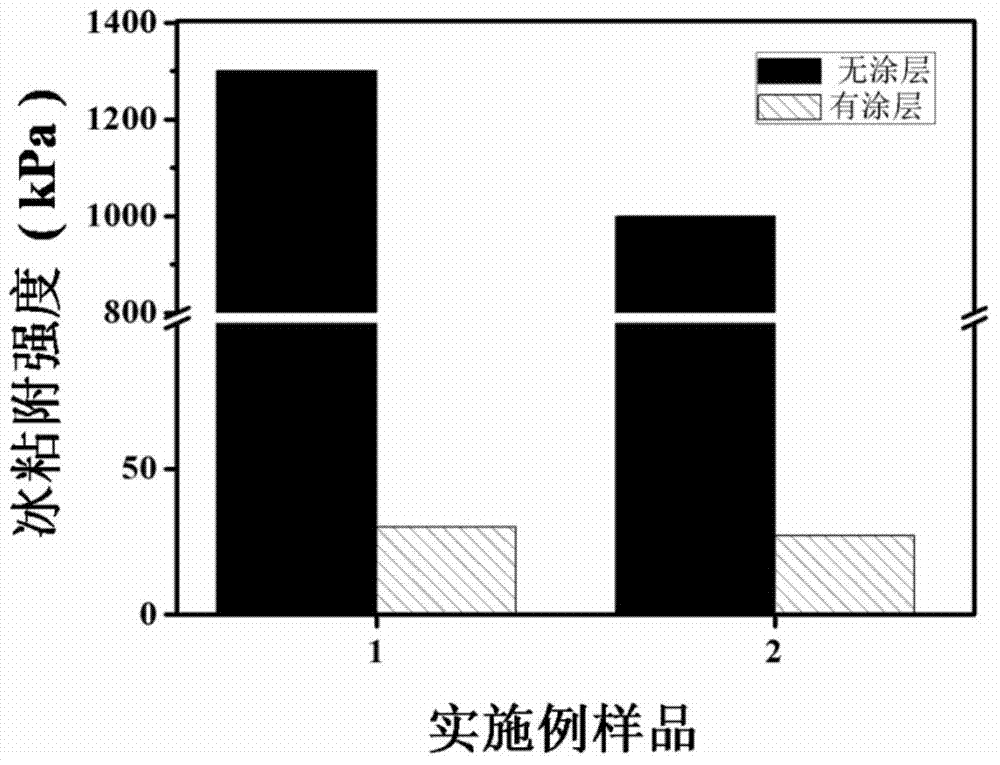

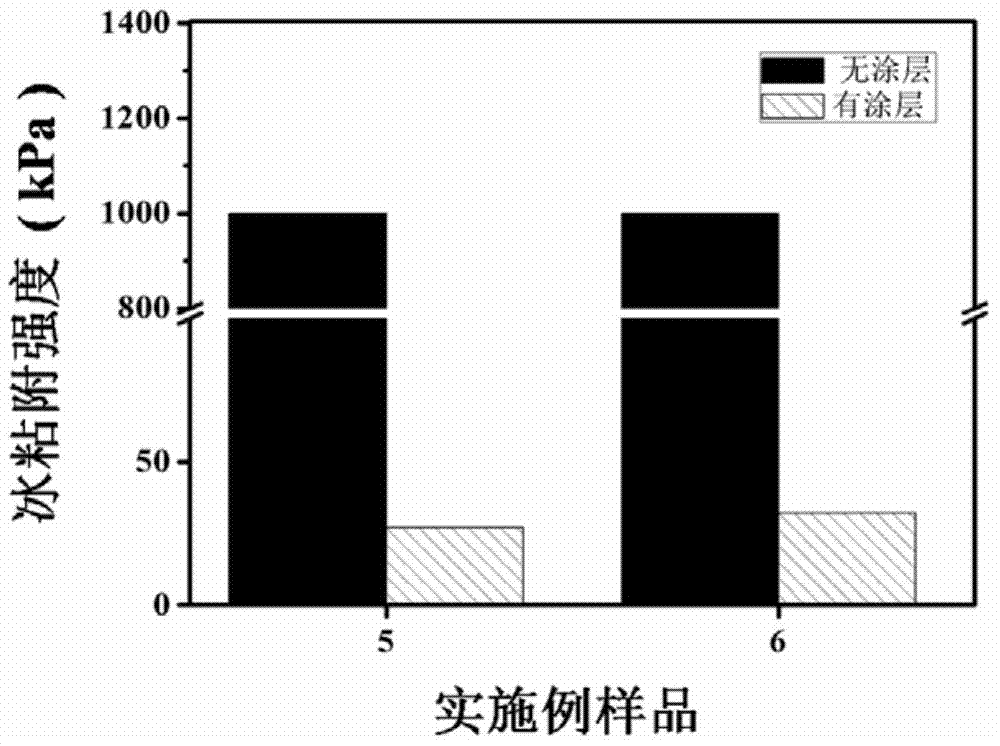

Examples

Embodiment 1

[0062] (1) Polycaprylyl adipate after vacuum dehydration (M n =2000) 90g, 76g of toluene diisocyanate (TDI), add it to a three-necked flask, mix well, heat up to 85°C for 1.5h, then add 10g DMPA, react at 85°C for 1h, and finally add 23g of diethylene glycol Alcohol, add a few drops of catalyst, acetone, react at 60°C for 4-5h, cool to 25°C, neutralize the prepolymer with triethylamine and add 500g of water for high-speed emulsification to obtain a white emulsion.

[0063] (2) The montmorillonite, which accounts for 15% of the total mass of component A, is mixed and stirred evenly with the polyurethane emulsion which accounts for 85% of the total mass of component A, to obtain the A component of the anti-icing coating.

[0064] (3) Adding a curing agent that accounts for 10% of the mass of the core-shell polymer emulsion to component A, and stir evenly to obtain the anti-icing coating.

[0065] (4) The anti-icing paint prepared in step (3) is directly coated on the ceramic surface an...

Embodiment 2

[0068] (1) Add 15g of polyvinyl alcohol (PVA) and NaHCO to a four-necked flask equipped with a condenser thermometer, dropping funnel and stirrer 3 2g, emulsifier TX-106g, H 2 O560g, adjust the temperature to 70°C and stir well. Then add (NH 4 ) 2 S 2 O 8 1.8g of aqueous solution, add 150g of monomer acrylic acid, 30g of styrene, 30g of methacrylic acid, and 12g of acrylamide in the funnel and mix uniformly. After 3 hours of dripping, continue to stir at 80℃ for 1 hour, and then cool to room temperature to obtain acrylate. Lotion.

[0069] (2) The activated alumina accounting for 20% of the total mass of component A is mixed and stirred evenly with the acrylic emulsion accounting for 80% of the total mass of component A to obtain the A component of the anti-icing coating.

[0070] (3) Add a curing agent that accounts for 10% of the mass of the acrylic emulsion to the A component, and stir evenly to obtain the anti-icing coating.

[0071] (4) The anti-icing paint prepared in step (3)...

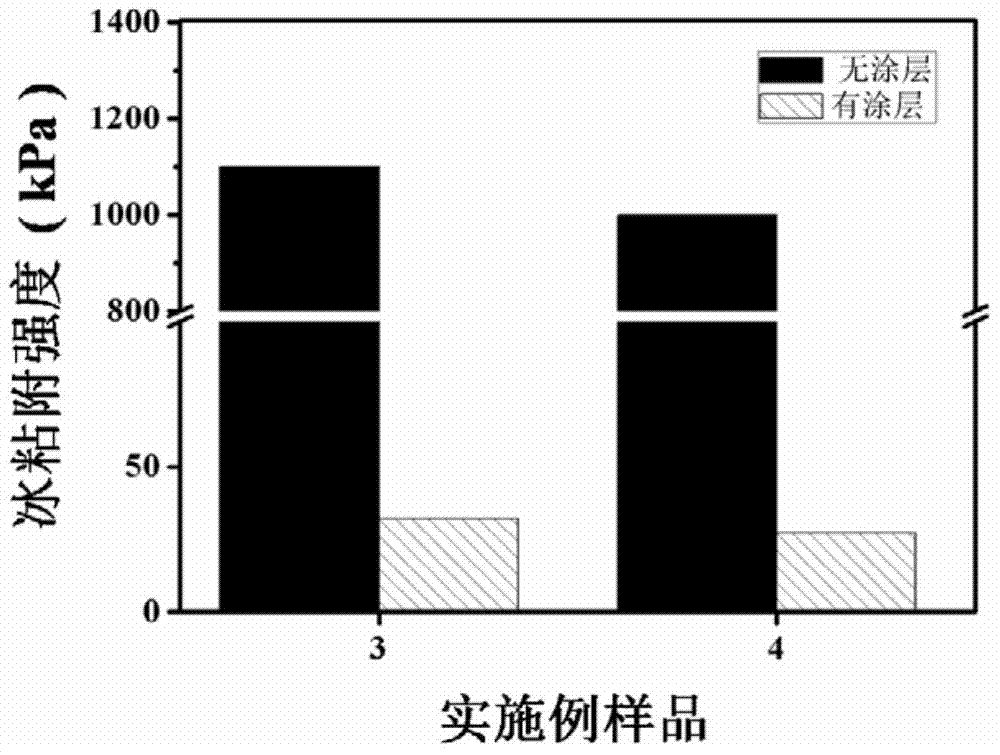

Embodiment 3

[0074] (1) Take 50g epoxy resin E-44 into a three-necked flask, add a mixed solvent of 4g ethanol and 8g ethylene glycol monobutyl ether, pass nitrogen protection, heat up to 80℃, stir at constant temperature to completely dissolve the resin, add the right Aminobenzoic acid, continue to react for 13.5 hours under the protection of nitrogen at 80℃. As the reaction progresses, the color of the reaction system changes and the viscosity increases. After the reaction is completed, the solvent is removed and the sample is mixed with ethanol and water (1:5 volume Than) mixed solvent washing to remove unreacted p-aminobenzoic acid, and then vacuum drying for 48h. Dissolve the modified epoxy resin with DMF (1:1 volume ratio), add ethanolamine to neutralize, and add water dropwise under stirring to make an epoxy resin emulsion.

[0075] (2) Mix 3% of the total mass of the A component of silica with 97% of the total mass of the A component of the epoxy resin emulsion and stir evenly to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ice adhesion strength | aaaaa | aaaaa |

| Ice adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com