Preparation method of super-hydrophobic coating layer on aluminum surface

A super-hydrophobic coating, aluminum surface technology, applied in the device, coating, special surface and other directions of coating liquid on the surface, can solve the problem that the micro-nano composite structure cannot be etched on the surface of aluminum sheet, and the reaction conditions of chemical etching method are difficult. control, the surface superhydrophobicity effect is not obvious and other problems, to achieve the effect of excellent hydrophobicity, good practical value, excellent superhydrophobicity and hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] 1. Polish the aluminum sheet with sandpaper, ultrasonically clean it with acetone and ethanol for 10 minutes, and then wash it with distilled water to remove the oil on the surface of the aluminum sheet, and dry it in an oven at 100°C.

[0025] 2. Put the clean aluminum sheet into 3mol / L hydrochloric acid solution and etch it for 20min at room temperature, then take out the aluminum sheet and wash it with a large amount of distilled water to stop the reaction. Dry in an oven after ultrasonic cleaning.

[0026] 3. Immerse the aluminum sheet obtained in step 2 into nano-TiO with a particle size of 100nm and 1wt%. 2 in the ethanol solution for 2 min, and reacted in the muffle furnace at 300°C for 3 h after taking it out, and the nano-TiO 2 grafted onto the aluminum surface.

[0027] 4. The aluminum sheet in step 3 was dip-coated in 0.5wt% tridecafluorooctyltriethoxysilane ethanol solution for 1 hour, and cured at 150° C. for 3 hours after taking it out to obtain a super-...

example 2

[0030] 1. Polish the aluminum sheet with sandpaper, ultrasonically clean it with acetone and ethanol for 10 minutes, and then wash it with distilled water to remove the oil on the surface of the aluminum sheet, and dry it in an oven at 100°C.

[0031] 2. Put the clean aluminum sheet into 3mol / L hydrochloric acid solution and etch it for 20min at room temperature, then take out the aluminum sheet and wash it with a large amount of distilled water to stop the reaction. Dry in an oven after ultrasonic cleaning.

[0032] 3. Dip-coat the aluminum sheet in step 2 in 1wt% tridecafluorooctyltriethoxysilane ethanol solution for 1 hour, take it out and cure at 150°C for 3 hours to obtain a super-hydrophobic coating.

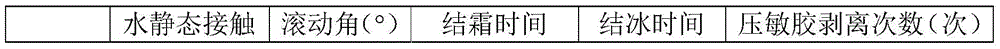

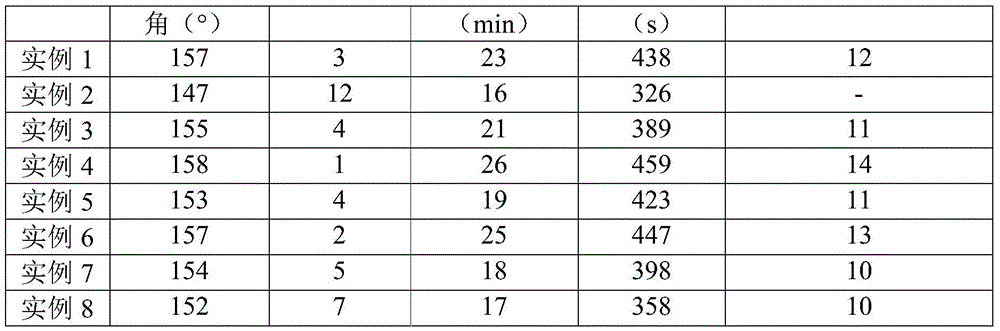

[0033] The static contact angle of water, the rolling angle test, the anti-frost and anti-icing test and the mechanical stability test were carried out on it, and the results are shown in Table 1.

example 3

[0035] 1. Polish the aluminum sheet with sandpaper, ultrasonically clean it with acetone and ethanol for 10 minutes, and then wash it with distilled water to remove the oil on the surface of the aluminum sheet, and dry it in an oven at 100°C.

[0036] 2. Put the clean aluminum sheet into 2mol / L sulfuric acid solution and etch it for 40min at room temperature, then take out the aluminum sheet and wash it with a large amount of distilled water to stop the reaction. Dry in an oven after ultrasonic cleaning.

[0037] 3. Immerse the aluminum sheet obtained in step 2 into nano-TiO with a particle size of 50nm and 1wt%. 2 in the ethanol solution for 2 min, and reacted in the muffle furnace at 300°C for 3 h after taking it out, and the nano-TiO 2 grafted onto the aluminum surface.

[0038] 4. Dip-coat the aluminum sheet in step 3 in a 3wt% ethanol solution of tridecafluorooctyltriethoxysilane for 2 hours, take it out and cure at 150° C. for 3 hours to obtain a super-hydrophobic coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com