Addition fluorinated silicone rubber nano antifreezing adhesive paint and preparation method thereof

A fluorosilicone rubber, anti-freezing and sticking technology, applied in the coating and other directions, can solve the problems of high curing temperature of the coating and poor anti-icing effect, and achieve the effect of improving the bonding strength and good anti-icing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Its preparation method steps are:

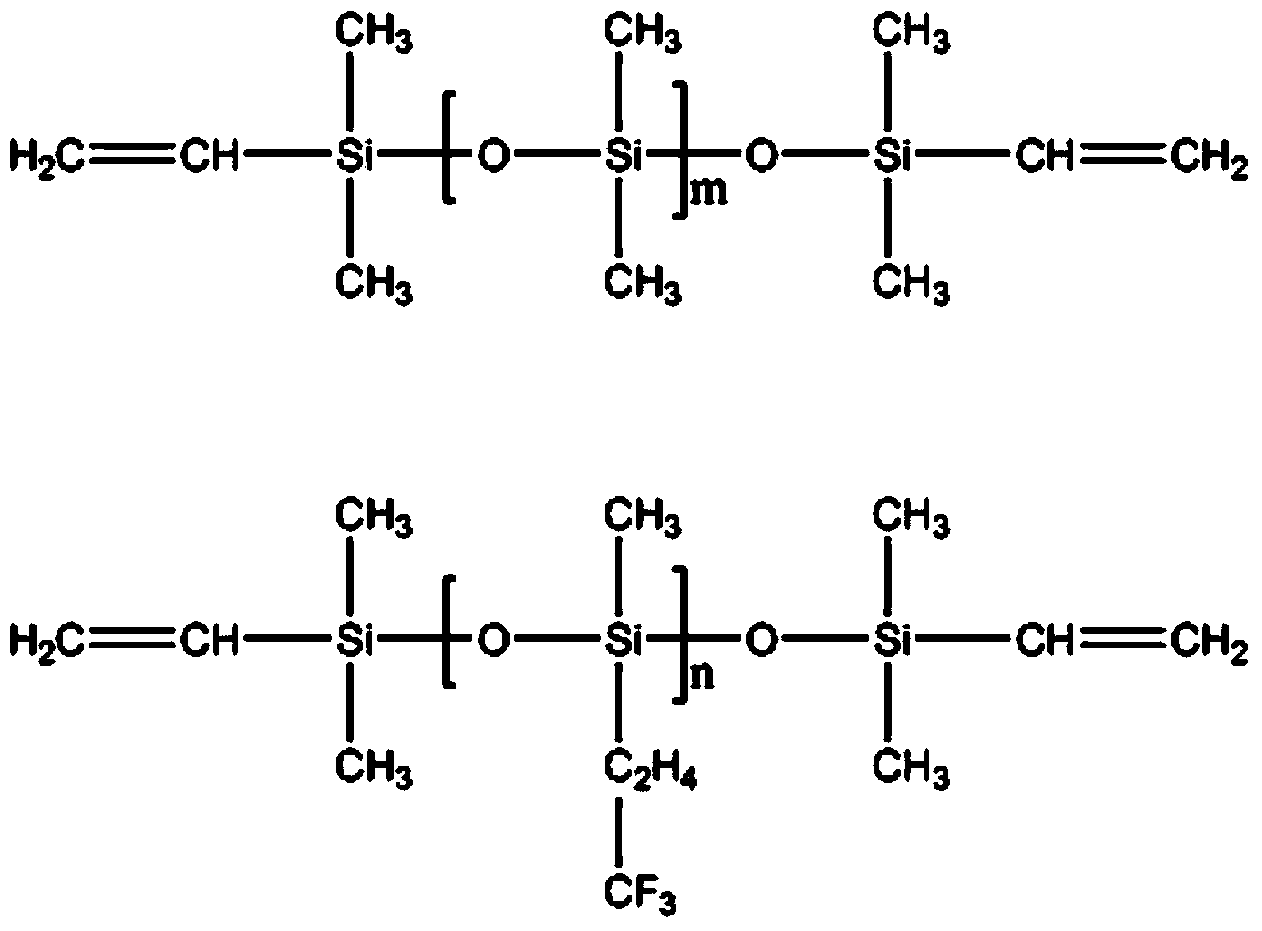

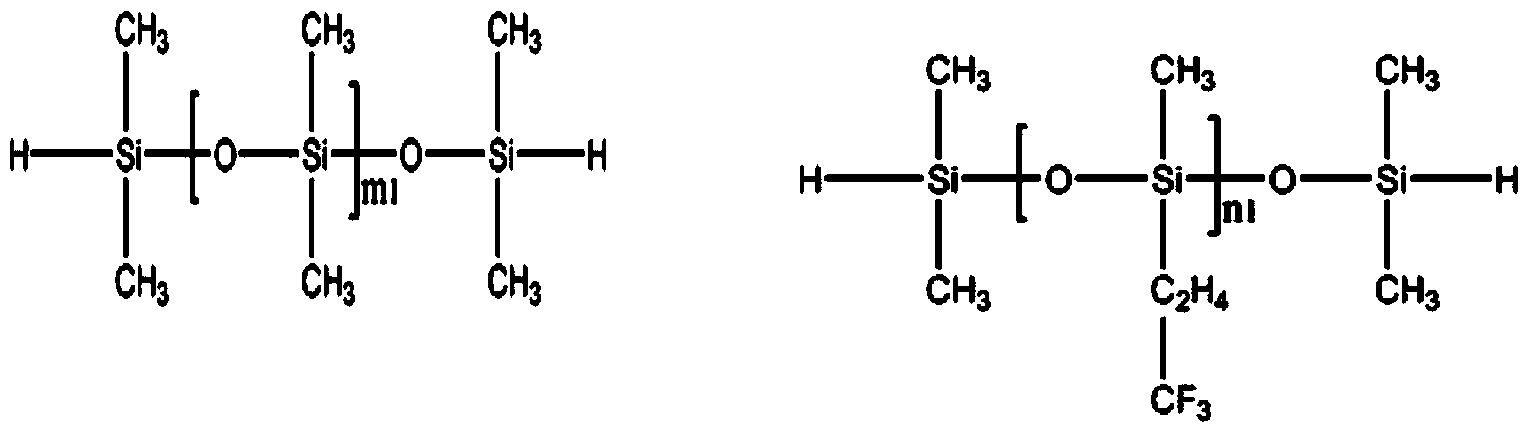

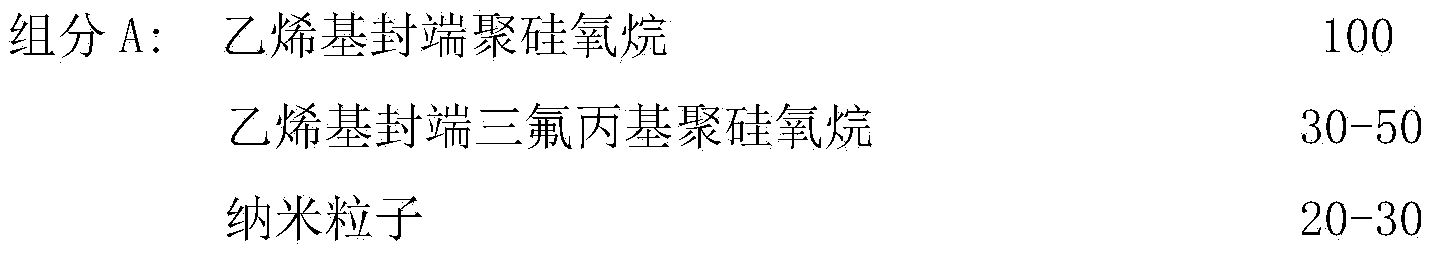

[0034] The first step: 100 mass parts of vinyl-terminated polysiloxane and 30-50 mass parts of vinyl-terminated trifluoropropyl polysiloxane, 20-30 mass parts of nanoparticles and 20-30 mass parts Parts of solvent are mixed uniformly to obtain component A, and then ball milled; 9-12 parts by mass of terminal hydrogen-containing silicone oil, 9-10 parts by mass of terminal hydrogen-containing fluorosilicone oil, 20-30 parts by mass of solvent and 0.0074-0.012 parts by mass of The Karstedt catalyst, 0.05-1 mass part of defoamer, and 1-2 mass parts of dispersant are mixed uniformly to obtain component B.

[0035] Step 2: After mixing components A and B evenly, apply it evenly on the surface of the workpiece coated with silane primer, and then cure at room temperature.

[0036] Vinyl-terminated polysiloxane and hydrogen-terminated silicone oil are the main components of the coating of the present invention, and are the main materials con...

Embodiment 1

[0044] First, 100 parts by mass of vinyl-terminated polysiloxane and 30 parts by mass of vinyl-terminated trifluoropropyl polysiloxane, 20 parts by mass of nanoparticles and 20 parts by mass of solvent are uniformly mixed to obtain component A , then ball milling; with 9 mass parts of terminal hydrogen-containing silicone oil, 9 mass parts of terminal hydrogen-containing fluorosilicone oil, 20 mass parts of solvent and 0.0074 mass parts of Karstedt catalyst, 0.05 mass parts of defoamer BYK-052, 1 mass part Parts of dispersant AMJ Dispers H-942 were mixed uniformly to obtain component B. Finally, after mixing components A and B evenly, apply it evenly on the surface of the workpiece coated with silane primer, and then cure at room temperature for 5 hours to obtain a two-component addition type fluorosilicone coating.

Embodiment 2

[0046]First, mix 100 parts by mass of vinyl-terminated polysiloxane and 35 parts by mass of vinyl-terminated trifluoropropyl polysiloxane, 25 parts by mass of nanoparticles and 25 parts by mass of solvent to obtain component A , then ball milling; with 10 mass parts of terminal hydrogen-containing silicone oil, 9 mass parts of terminal hydrogen-containing fluorosilicone oil, 25 mass parts of solvent and 0.009 mass parts of Karstedt catalyst, 0.05 mass parts of defoamer BYK-052, 1 mass part Parts of dispersant AMJ Dispers H-942. Finally, after mixing components A and B evenly, apply it evenly on the surface of the workpiece coated with silane primer, and then cure at room temperature for 5 hours to obtain a two-component addition type fluorosilicone coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com