Wind turbine blade ice prevention and removal mechanism

A wind turbine blade and control technology, applied in wind turbines, machines/engines, engines, etc., can solve the problems of waste heat loss, increased manufacturing cost, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

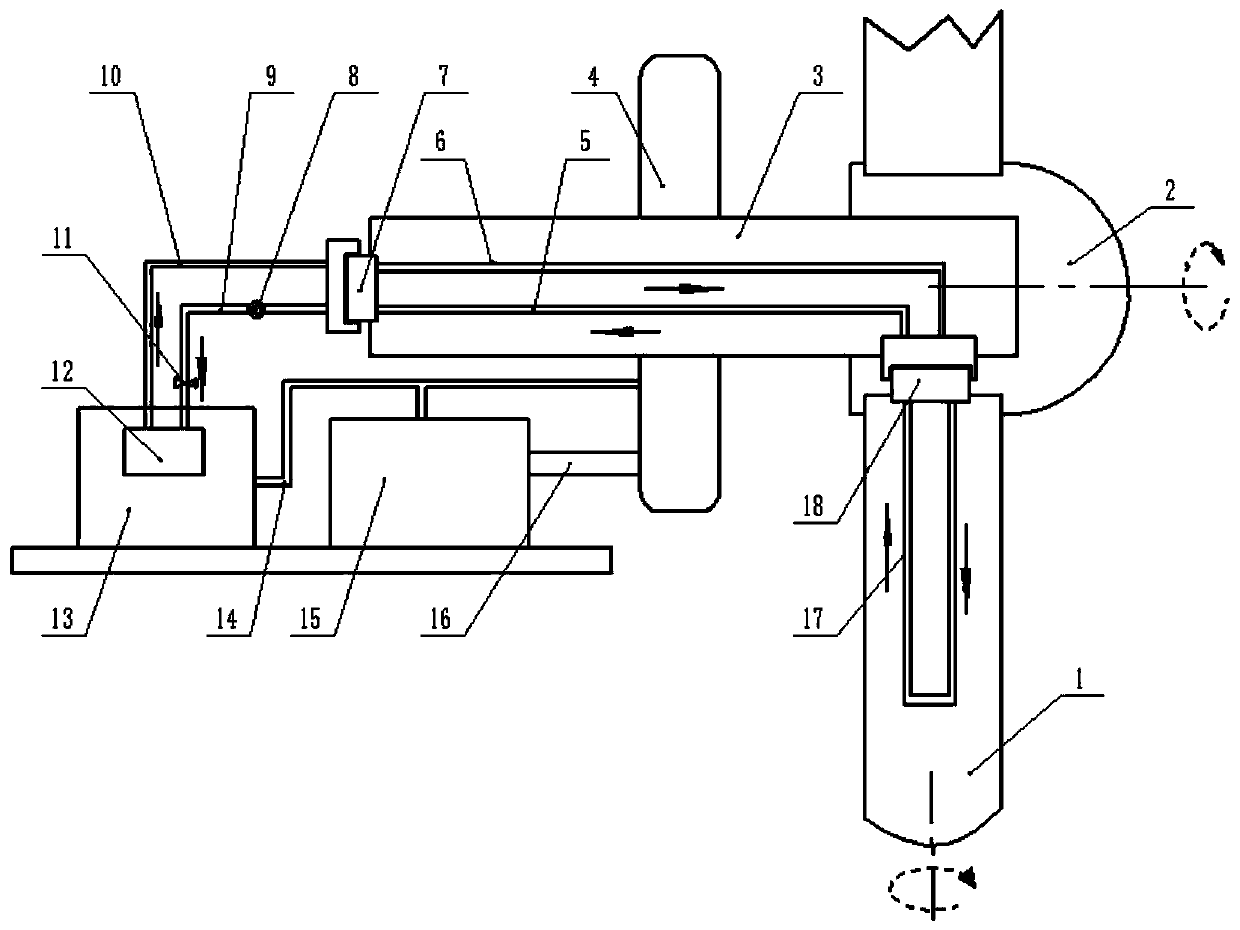

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] A wind turbine blade anti-icing mechanism, the main shaft 3 is rotatably fitted on the gear transmission box 4, and is connected with the gear transmission box 4, the hub 2 is fixed on the front end of the main shaft 3, and the gear transmission box 4 passes through the transmission shaft 16 Connected with the generator 15, the blade 1 is rotatably fitted on the hub 2 through the rotary joint B18, and the condenser 17 is installed in the blade 1, and the inlet end and the outlet end of the condenser 17 are respectively connected with the rotary joint The rotary end of B18 is fixedly connected; the rotary joint A7 is installed on the rear end of the main shaft 3, the steam delivery pipe B6 and the liquid return pipe A5 are arranged in the shaft cavity of the main shaft 3, and the steam inlet and outlet ends of the steam delivery pipe B6 Connect w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com