Self-repairing anti-icing aluminum stranded wire with composite holes and preparation method of self-repairing anti-icing aluminum stranded wire

An aluminum stranded wire, self-repairing technology, applied in the direction of cable/conductor manufacturing, conductors, non-insulated conductors, etc., can solve problems such as anti-icing failure, structural damage, and limited application prospects, so as to improve poor self-repairability and improve self-repair The effect of ability and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

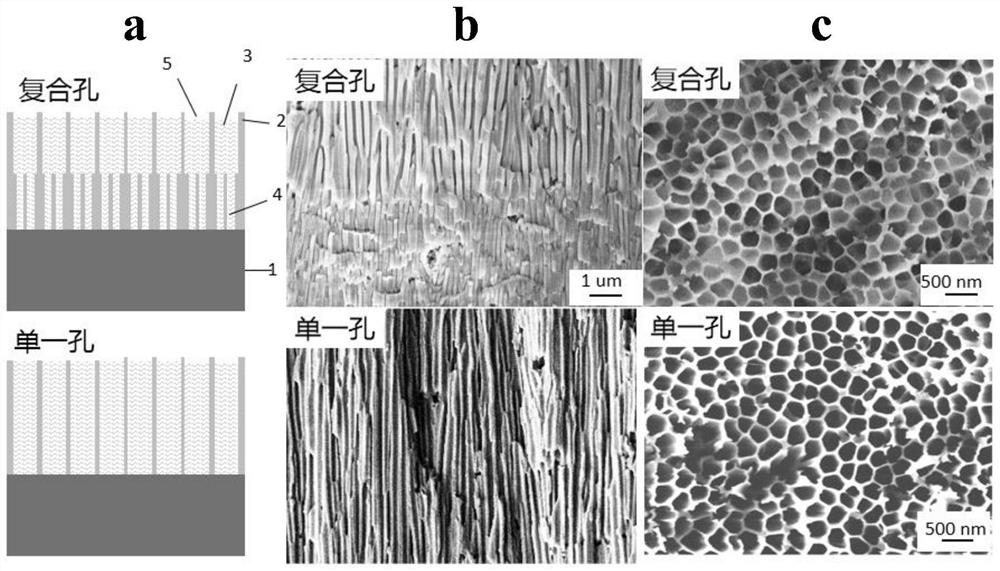

[0038] A self-repairing anti-icing aluminum stranded wire with composite holes, which is prepared by anodizing twice, specifically includes the following steps:

[0039] (1) The first anodic oxidation: wash the aluminum substrate (aluminum alloy core aluminum strand ) as the anode is placed in the phosphoric acid electrolyte (the concentration of phosphoric acid is 0.3mol / L, the solvent is water), the ring electrode made of 304 stainless steel plate is the cathode, and the applied current density is 0.15A / cm 2 DC current, and then perform the first anodic oxidation at 25°C for 15 minutes to form outer layer pores with a pore diameter of 250nm and a pore depth of 26um on the surface of the aluminum substrate;

[0040](2) Second anodic oxidation: place the product in step (1) as an anode in oxalic acid electrolyte (the concentration of oxalic acid is 0.15mol / L, and the solvent is water), lead plate, aluminum plate, graphite plate or 304 stainless steel The ring electrode made o...

Embodiment 2

[0043] A self-repairing anti-icing aluminum stranded wire with composite holes, which is prepared by anodizing twice, specifically includes the following steps:

[0044] (1) The first anodic oxidation: put the cleaned aluminum alloy strand as the anode in phosphoric acid In the electrolyte (the concentration of phosphoric acid is 0.3mol / L, the solvent is water), the ring electrode made of lead plate is the cathode, and the applied current density is 0.2A / cm 2 DC current, and then perform the first anodic oxidation at a temperature of 10°C for 10 minutes to form outer layer pores with a pore depth of 20um and a pore diameter of 220nm on the surface of the aluminum substrate;

[0045] (2) second anodic oxidation: the product in step (1) is placed as the anode in the oxalic acid electrolyte (the concentration of oxalic acid is 0.1mol / L, and the solvent is water), and the ring electrode made of the lead plate is the negative electrode, The applied current density is 0.1A / cm 2 Af...

Embodiment 3

[0048] A self-repairing anti-icing aluminum stranded wire with composite holes, which is prepared by anodizing twice, specifically includes the following steps:

[0049] (1) The first anodic oxidation: wash the aluminum substrate (steel-cored aluminum strand) (firstly wash the aluminum substrate in clean water, and then place it in a 1mol / L sodium hydroxide solution for 2 minutes) As the anode, it is placed in a phosphoric acid electrolyte (the concentration of phosphoric acid is 0.15mol / L, and the solvent is water), and the ring electrode made of aluminum plate is the cathode, and the applied current density is 0.1A / cm 2 DC current, and then carry out the first anodic oxidation at 50°C for 25 minutes to form outer layer pores with a pore diameter of 180nm and a pore depth of 35um on the surface of the aluminum substrate;

[0050] (2) The second anodic oxidation: the product in step (1) is placed as the anode in the oxalic acid electrolyte (the concentration of oxalic acid is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com