Non-Newtonian fuselage deicing and anti-icing fluid and preparation method thereof

A non-Newtonian, anti-icing fluid technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem that there is no deicing and anti-icing fluid viscosity and low temperature shear rheology, can not effectively reduce the ice on the surface of the object. Adhesion performance, only meeting the time requirements and other issues, to achieve the effects of excellent shear recovery ability, prolonged liquid freezing failure, and long anti-icing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

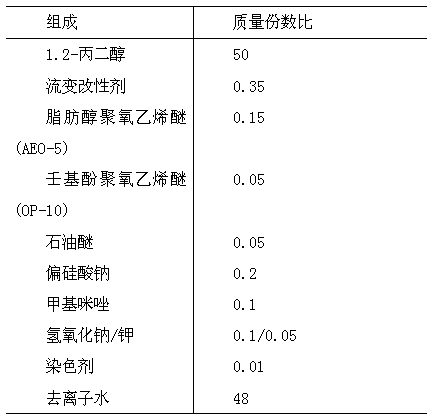

Embodiment 1

[0045] A non-Newtonian airframe deicing and anti-icing fluid is characterized in that it comprises the following components by mass and deionized water:

[0046] 40 ~ 50 parts of freezing point depressants;

[0047] 0.05 ~ 0.6 parts of rheology modifier;

[0048] 0.01 ~ 0.15 parts of anti-icing compound;

[0049] 0.01 ~ 1.5 parts of pH regulator;

[0050] 0.01 ~ 1.5 parts of corrosion inhibitor;

[0051] 0.01 ~ 0.25 parts of dyeing agent;

[0052] 40 ~ 50 parts of deionized water;

[0053] The rheology modifier is a modified carboxylic acid polymer in the form of loose powder, and the rheology modifier consists of 70 parts by mass. ~ 80 parts of at least one unsaturated carboxylic acid, and at least one double-branched structure monomer in the range of 0.5 to 12.5 parts by mass, are obtained by polymerizing in a mixed solvent;

[0054] The unsaturated carboxylic acid comprises acrylic acid, methacrylic acid, α-cyanoacrylic acid, crotonic acid, crotonic acid or ita...

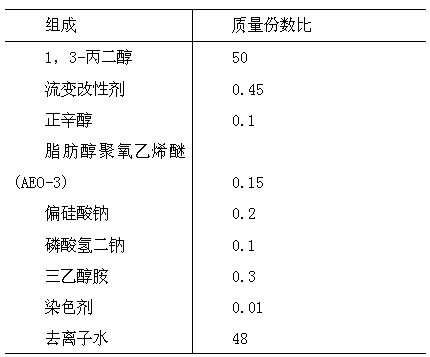

Embodiment 2

[0067] A non-Newtonian airframe deicing and anti-icing fluid is characterized in that it comprises the following components by mass and deionized water:

[0068] 50-60 parts of freezing point depressants;

[0069] 0.6-1.2 parts of rheology modifier;

[0070] 0.15-0.3 parts of anti-icing compound;

[0071] 1.5-3 parts of PH regulator;

[0072] 1.5-3 parts of corrosion inhibitor;

[0073] 0.25 to 0.5 parts of dyeing agent;

[0074] 50-60 parts of deionized water;

[0075] The rheology modifier is a hydrophobically modified carboxylic acid polymer in the form of loose powder, and the rheology modifier is composed of at least one unsaturated carboxylic acid in 80-90 parts by mass, and the range of parts by mass is It is obtained by polymerizing 12.5-25 parts of at least one double-branched monomer in a mixed solvent.

[0076] The unsaturated carboxylic acid is acrylic acid or methacrylic acid.

[0077] The mixed solvent is water and toluene, cyclohexane or ethyl acetate.

...

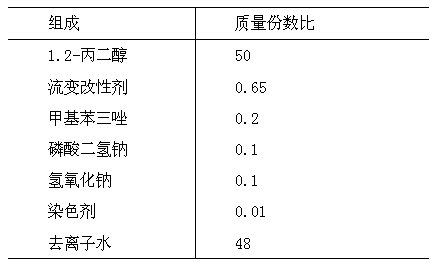

Embodiment 3

[0089] Examples of rheology modifiers:

[0090]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com