Super-hydrophobic surface coating and preparation method thereof

A super-hydrophobic surface and coating technology, used in coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of inability to meet the requirements of large-area preparation, reduced protection ability, and reduced surface hydrophobic performance, and achieve excellent mechanical properties. Excellent performance and adhesion, excellent anti-icing ability, enhanced mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

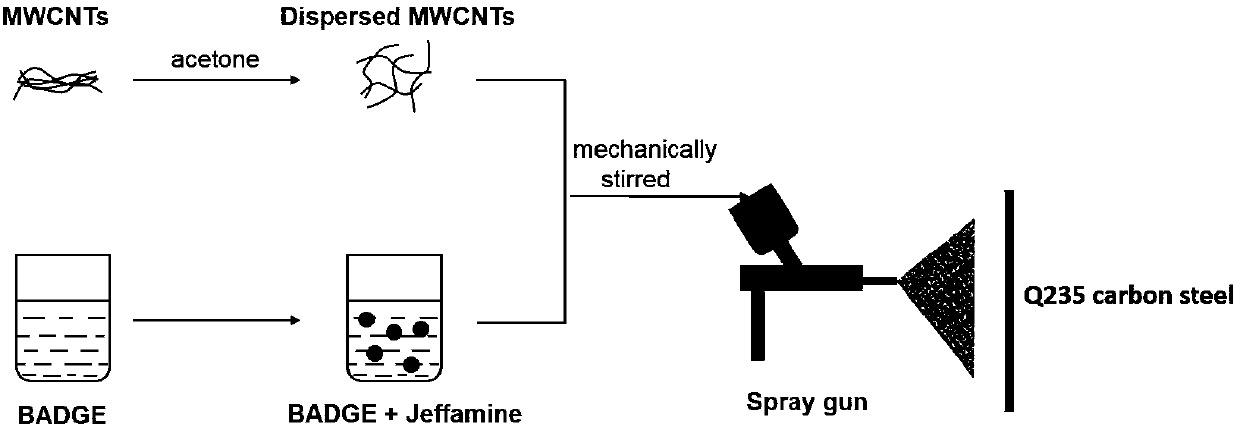

[0061] This embodiment provides a method for preparing a super-hydrophobic surface coating, including the steps of preparing a super-hydrophobic solution and spraying the super-hydrophobic solution.

[0062] Described preparation super-hydrophobic solution is specifically:

[0063] (1) Measure raw material epoxy resin, epoxy curing agent, epoxy solvent and carbon nanotube;

[0064] (2) After mixing the epoxy resin and the carbon nanotubes, add an epoxy solvent; then, carry out ultrasonic dispersion, during which the epoxy solvent is replenished at intervals of Δt until the epoxy resin and the carbon nanotubes are mixed evenly, to obtain a mixed solution;

[0065] Before replenishing the epoxy solvent, it is necessary to suspend the ultrasound. After replenishing the epoxy solvent, every 1-5 seconds of ultrasonic dispersion, pause for 1-5 seconds, so as to control the heat generated by the ultrasound, thereby reducing the volatilization of the solvent.

[0066] (3) Add the ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com